Positioning mechanism of air sensor press-fitting equipment

An air sensor and positioning mechanism technology, which is applied to workpiece clamping devices, workbenches, manufacturing tools, etc., can solve the problems of small application range of positioning mechanism, low tooling efficiency, inconvenient adjustment and use for different groups of people, etc. Simple, easy to operate, and the effect of increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

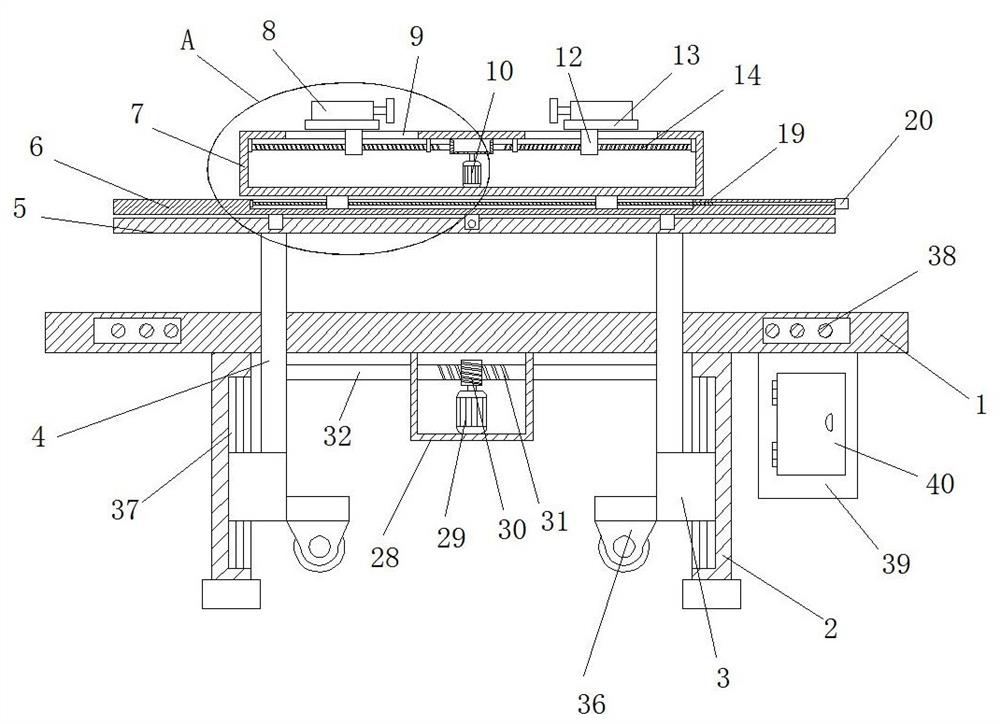

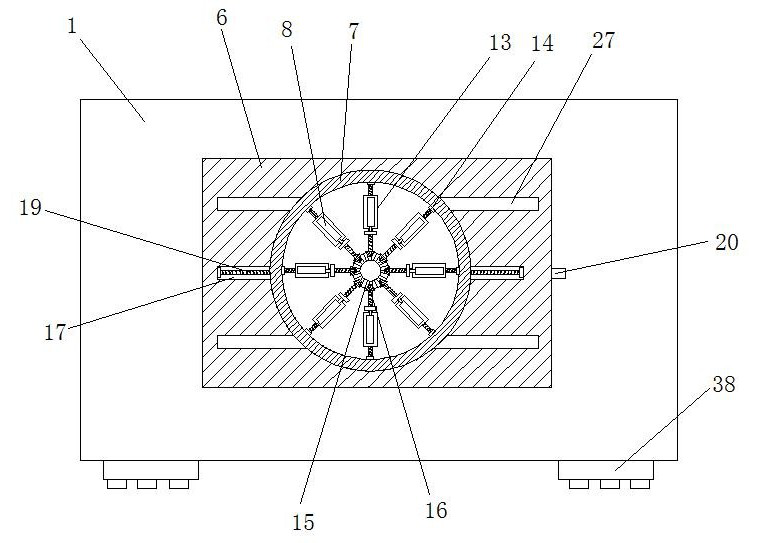

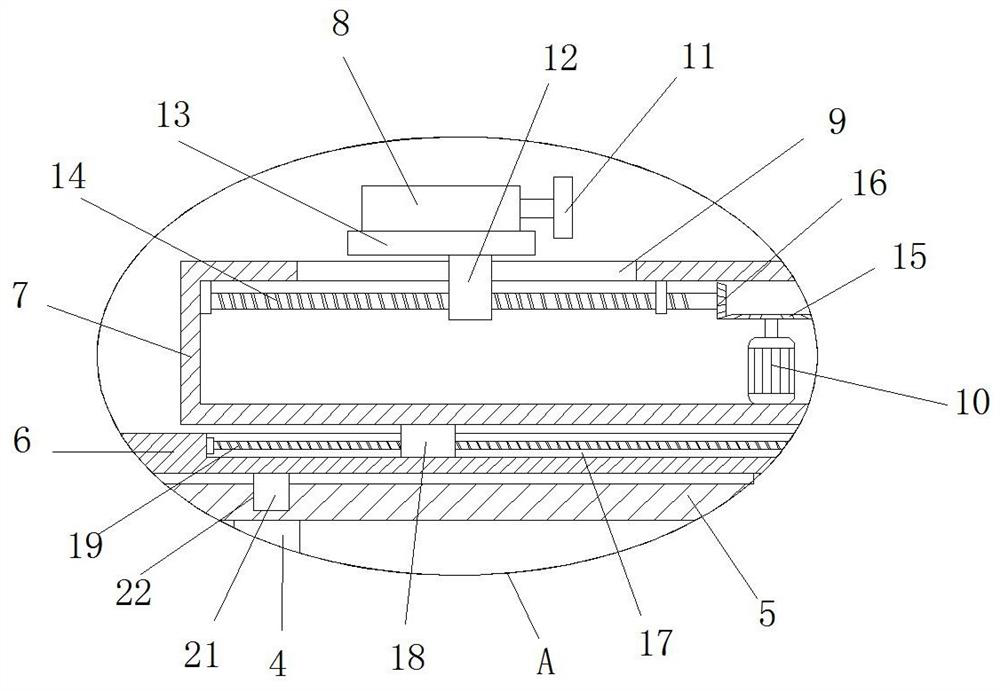

[0030] refer to Figure 1-5 , a positioning mechanism of an air sensor press-fitting equipment, including a work plate 1, four support legs 2 are fixedly installed at the bottom of the work plate 1, and slide blocks 3 are slidably installed on the four support legs 2, and the four slide blocks 3 A universal wheel 36 is fixedly connected on one side of the working plate 1, and two lifting plates 4 are vertically slidably installed on the top of the working plate 1. The bottom is provided with a lift drive mechanism, the two lift plates 4 are adapted to the lift drive mechanism, the tops of the two lift plates 4 are fixedly installed with a longitudinal support plate 5, and the top of the longitudinal support plate 5 is provided with a longitudinal drive mechanism. A lateral support plate 6 is installed on the drive mechanism, a lateral drive mechanism is arranged on the top of the lateral support plate 6, a positioning box 7 is installed on the lateral drive mechanism, and the ...

Embodiment 2

[0041] refer to Figure 1-5 , a positioning mechanism for air sensor press-fitting equipment, including a working board 1, four supporting legs 2 are fixedly installed on the bottom of the working board 1 by welding, sliding blocks 3 are installed on the four supporting legs 2, and four sliding One side of block 3 is fixedly connected with universal wheel 36 by screws, and the top of working plate 1 is vertically slid to install two lifting plates 4, and the two lifting plates 4 are respectively fixed to the tops of the corresponding two sliding blocks 3 by welding Installation, the bottom of the working board 1 is provided with a lifting drive mechanism, and the two lifting plates 4 are compatible with the lifting drive mechanism, and the tops of the two lifting plates 4 are fixedly installed with a longitudinal support plate 5 by welding, and the longitudinal support plate 5 The top is provided with a longitudinal driving mechanism, and a horizontal support plate 6 is instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com