A method for increasing the carbon content of molten iron

A technology of molten iron and recarburizer, applied in the field of iron and steel metallurgy, can solve the problems of poor carburization effect and low carbon absorption rate, and achieve the effects of low cost, high carbon absorption rate and simple steps and methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

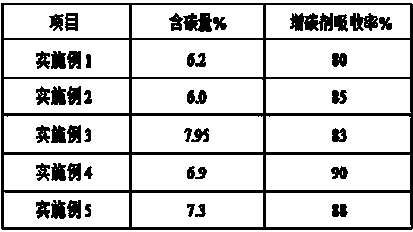

Examples

Embodiment 1

[0014] Add 85kg of recarburizer graphite powder with an effective carbon content of 90% and 1 ton of molten iron at a temperature of 1600°C into a 1.5-ton furnace, preheat the No. 1 molten iron ladle to 650°C in advance, and pour the graphite powder and molten iron into 1 In No. 2 molten iron ladle, part of the graphite powder is dissolved in the molten iron, and the excess graphite powder cannot be directly dissolved in the molten iron and floats on the surface of the molten iron; preheat the No. 2 molten iron ladle to 650°C in advance to remove the graphite powder It takes 10 seconds to pour molten iron from No. 1 ladle into No. 2 ladle. In the initial stage of pouring, an iron rod is needed to flow the graphite powder floating on the surface of the molten iron into the No. 2 ladle along with part of the molten iron. The carburizing agent is dissolved in molten iron to complete the carburizing process.

Embodiment 2

[0016] Add 320kg of recarburizer graphite powder with an effective carbon content of 92% and 4 tons of molten iron at a temperature of 1450°C into a 5-ton furnace, preheat the No. 1 molten iron ladle to 600°C in advance, and pour the graphite powder and molten iron into 1 In No. 2 molten iron ladle, part of the graphite powder is dissolved in the molten iron. The excess graphite powder cannot be directly dissolved in the molten iron and floats on the surface of the molten iron. Preheat the No. 2 molten iron ladle to 700°C in advance to remove the graphite powder floating on the surface of the molten iron. It takes 18 seconds to pour molten iron from No. 1 ladle into No. 2 ladle. In the initial stage of pouring, iron rods are used to first flow graphite powder floating on the surface of molten iron into No. 2 ladle along with part of the molten iron. Heat the No. 3 molten iron ladle to 660°C, pour the molten iron and the graphite powder floating on the surface of the molten iron...

Embodiment 3

[0018] Add 180kg of recarburizer graphite with an effective carbon content of 91% and 2 tons of molten iron at a temperature of 1500°C into a 3-ton furnace, preheat the No. 1 molten iron ladle to 680°C in advance, and pour graphite powder and molten iron into No. 1 In the molten iron ladle, part of the graphite is dissolved in the molten iron, and the excess graphite cannot be directly dissolved in the molten iron and floats on the surface of the molten iron. Preheat the No. 2 molten iron ladle to 670°C in advance, and use 13s for the graphite and molten iron floating on the surface of the molten iron Pour from No. 1 molten iron ladle to No. 2 molten iron ladle. In the initial stage of pouring, iron hooks should be used to first flow the graphite floating on the surface of the molten iron into the No. 2 molten iron ladle along with part of the molten iron, so that the recarburizer can be dissolved. In molten iron, the carburization process is completed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com