Composition for blast furnace coal powder injection and preparation method thereof

A composition and pulverized coal technology, applied in blast furnaces, blast furnace details, furnaces, etc., can solve problems such as low comprehensive coke ratio, environmental pollution, and low coal pulverized combustion efficiency, and achieve environmental friendliness, increase iron production, and improve The effect of hot metal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-11

[0026] This example is used to illustrate the preparation of the composition for blast furnace injection of pulverized coal of the present invention

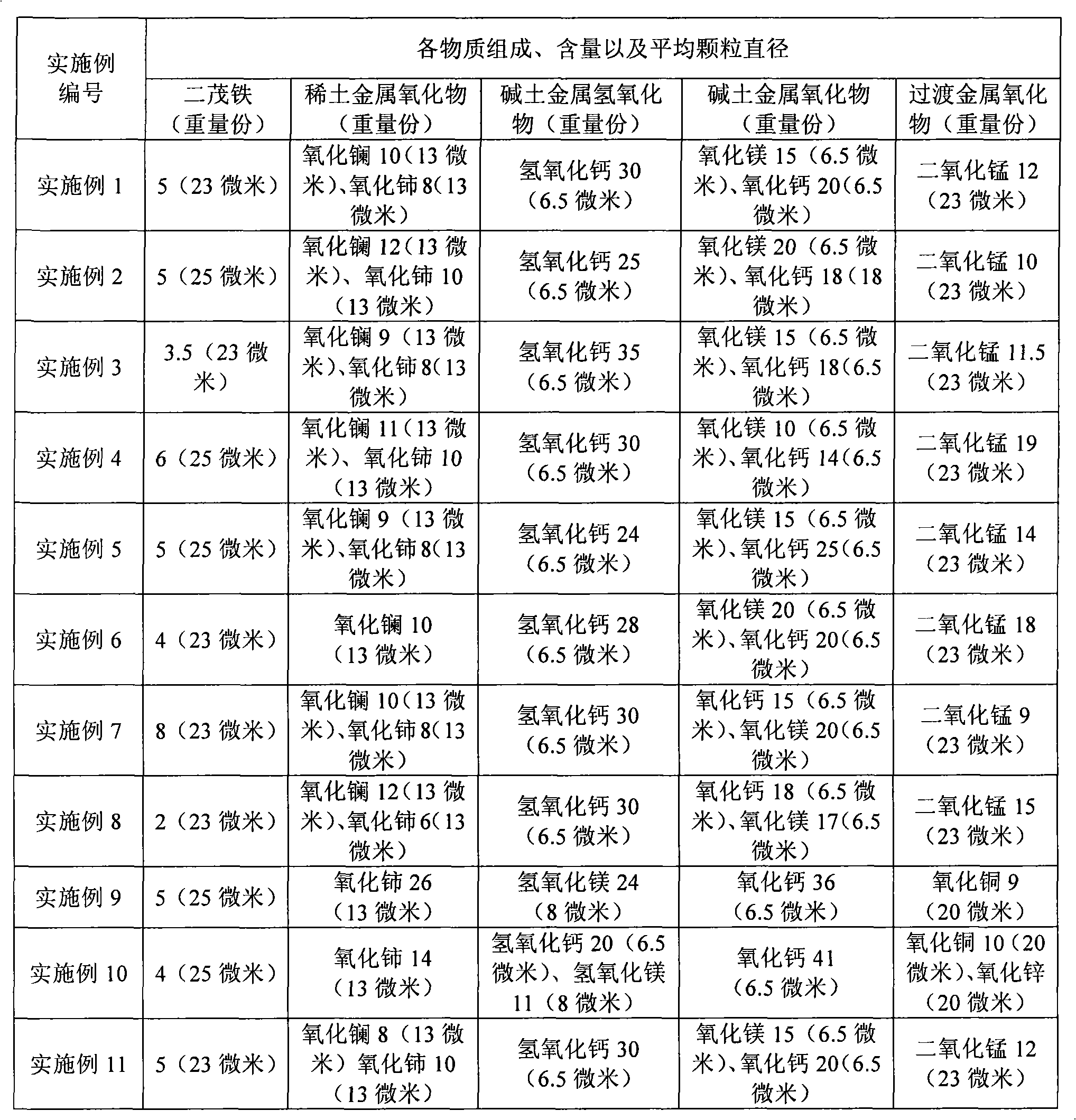

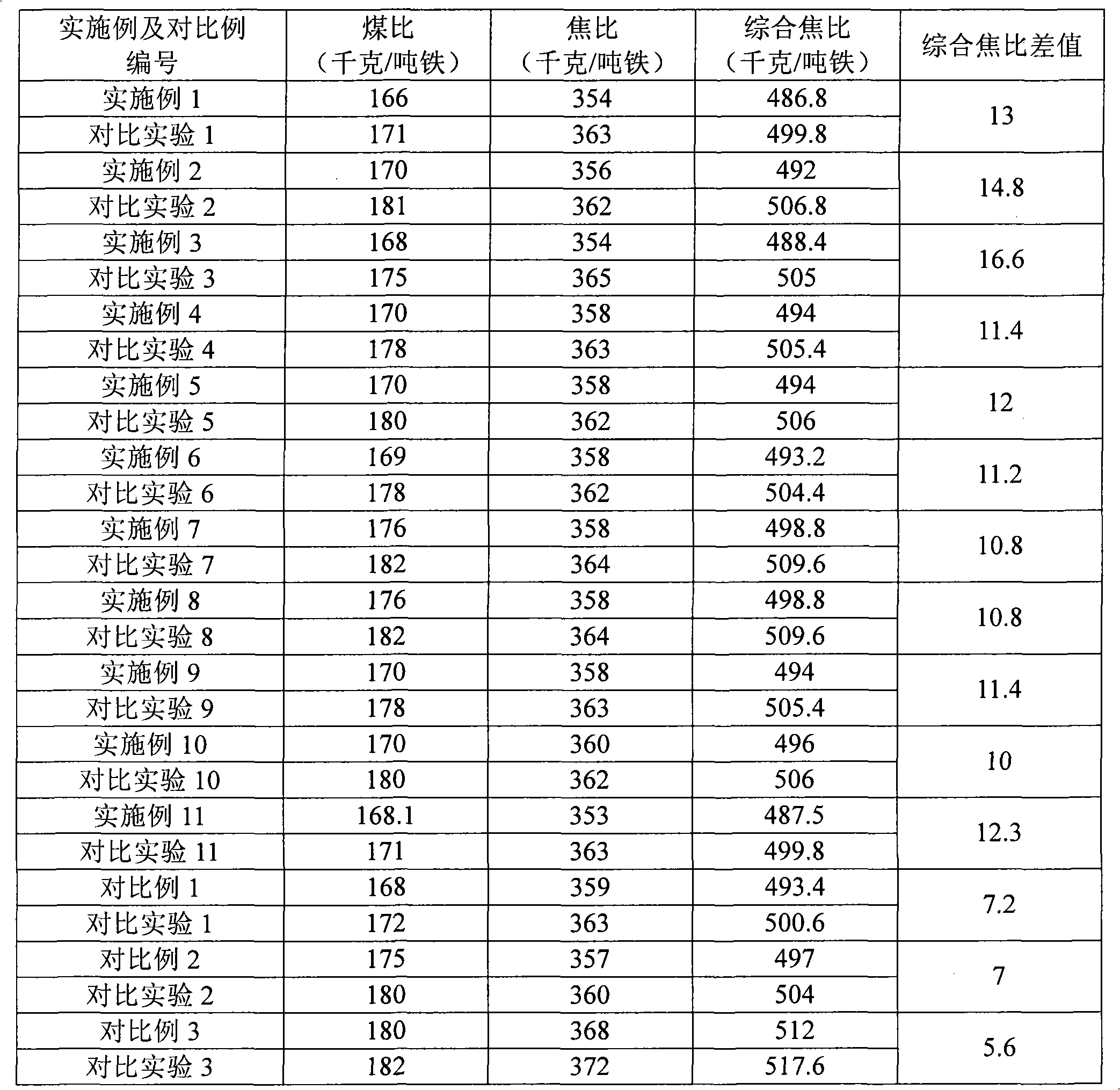

[0027] After the purchased ferrocene, rare earth metal oxides, alkaline earth metal hydroxides, alkaline earth metal oxides, and transition metal oxides other than rare earth metals are ground to the average particle diameter specified in the present invention, each group It is mixed according to the proportion to obtain the composition T1-T11 for preparing blast furnace injection coal powder provided by the present invention.

[0028] The grinding method is to mix the materials and the steel balls in a ratio of 2:1 by the volume ratio of the balls to perform ball milling, and the conditions of the ball milling are such that each substance reaches a certain average particle diameter. Table 1 shows the amount of each substance and the average particle diameter. The average particle diameter is measured with a laser particle size test...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com