Resource utilization method after iron content of steel pickling sludge after quickly increasing iron contentis quickly improved

A technology for steel pickling and iron content, which is applied in chemical instruments and methods, sludge treatment, and oxidation treatment of sludge, etc., can solve the problems of complicated operation and high cost of steel pickling sludge treatment, and achieves a simple and clean process. The effect of producing environmental protection circular economy, the effect of reducing the burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

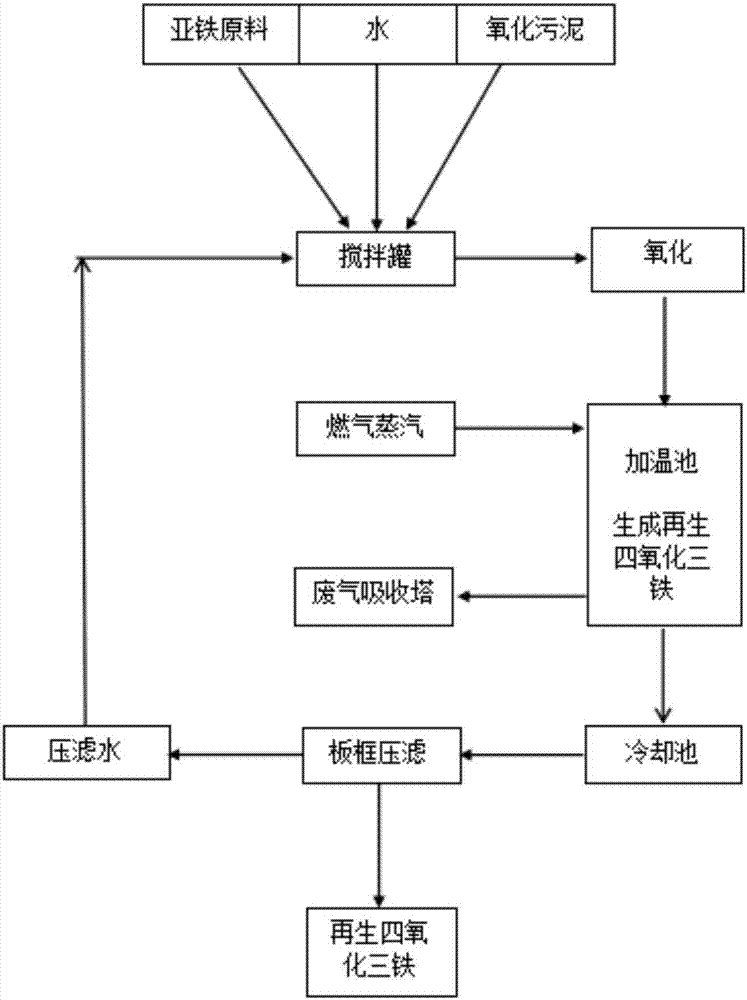

[0028] Such as figure 1 A resource utilization method after rapidly increasing the iron content of iron and steel pickling sludge is shown, comprising the following steps:

[0029] (1) Add the ferric hydroxide sludge and the ferrous salt solution produced after the pickling waste water and press filtration into the mixing tank, and mix and stir;

[0030] (2) Regulate the pH of the mixture in the stirring tank, and adjust the pH of the mixture to be 6;

[0031] (3) transfer the homogeneous mixture in the step (2) to the oxidation tank and feed air into the oxidation reaction;

[0032] (4) Transfer the oxidized mixture in step (3) to the heating pool for heating reaction to generate regenerated ferric oxide. The specific heating method is gas steam heating, and the heating temperature is 100 ° C. The color of the mixture to be observed is Stop heating when it is black;

[0033] (5) The waste gas produced in the step (4) is transported to the waste gas absorption tower for pro...

Embodiment 2

[0039] Such as figure 1 A resource utilization method after rapidly increasing the iron content of iron and steel pickling sludge is shown, comprising the following steps:

[0040] (1) Add the ferric hydroxide sludge and the ferrous salt solution produced after the pickling waste water and press filtration into the mixing tank, and mix and stir;

[0041] (2) Regulate the pH of the mixture in the stirring tank, and adjust the pH of the mixture to be 7;

[0042] (3) transfer the homogeneous mixture in the step (2) to the oxidation tank and feed air into the oxidation reaction;

[0043] (4) Transfer the oxidized mixture in step (3) to the heating pool for heating reaction to generate regenerated ferric oxide. The specific heating method is gas steam heating, and the heating temperature is 85 ° C. The color of the mixture to be observed is Stop heating when it is black;

[0044] (5) The waste gas produced in the step (4) is transported to the waste gas absorption tower for proc...

Embodiment 3

[0050] Such as figure 1 A resource utilization method after rapidly increasing the iron content of iron and steel pickling sludge is shown, comprising the following steps:

[0051] (1) Add the ferric hydroxide sludge and the ferrous salt solution produced after the pickling waste water and press filtration into the mixing tank, and mix and stir;

[0052] (2) Regulate the pH of the mixture in the stirring tank, and adjust the pH value of the mixture to be 8;

[0053] (3) transfer the homogeneous mixture in the step (2) to the oxidation tank and feed air into the oxidation reaction;

[0054] (4) Transfer the oxidized mixture in step (3) to the heating pool for heating reaction to generate regenerated ferric oxide. The specific heating method is gas steam heating, and the heating temperature is 75 ° C. The color of the mixture to be observed is Stop heating when it is black;

[0055] (5) The waste gas produced in the step (4) is transported to the waste gas absorption tower fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com