Anti-flotation Fe-refining and Si-reducing technology medicine

A reverse flotation and process technology, applied in flotation, solid separation, etc., can solve the problems of large consumption of reagents and insufficient flotation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0018] 1. Drug preparation

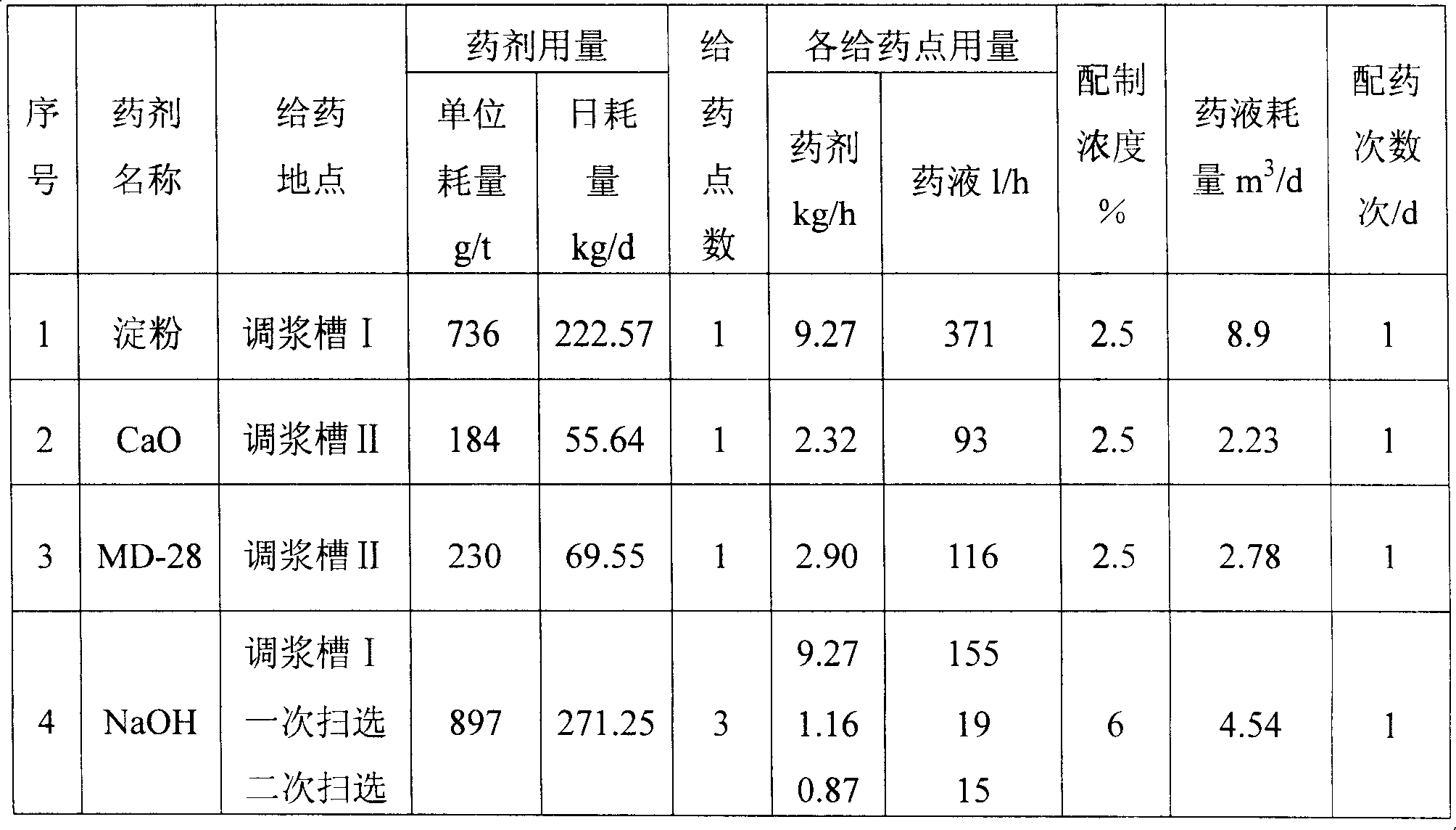

[0019] 1) Types and dosages of chemicals: See Table 1 for the chemicals used in reverse flotation operations and their types, concentrations, administration locations, unit consumption and total consumption, etc.

[0020] Table 1 The dosage and addition table of flotation reagent types

[0021]

[0022] 2) Preparation of medicine

[0023] a.NaOH: Add liquid alkali or solid alkali with a concentration of 40-50% into the stirring tank and add water to dilute to a solution with a concentration of 6%.

[0024] b. cornstarch: add a certain amount of cornstarch into a stirring tank equipped with an appropriate amount of water and NaOH (starch concentration is about 5%, and the amount of NaOH is about 2% of cornstarch) and stir, after stirring evenly (into Paste) was heated to 90-95°C with steam, then stirred for 1 hour, stopped heating, and then diluted with water to a concentration of 2.5%.

[0025] c. MD-28 collector: Take out the finished MD-28 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com