Technological method for reducing block masses containing carbon, iron, zinc, etc. into molten iron, zinc, etc. in blast furnace molten iron trough

A technology for tapping iron from molten iron ditch and blast furnace, which is applied to blast furnaces, blast furnace details, furnaces, etc., can solve problems such as environmental pollution, waste of resources, and large investment, and achieve the effects of reducing silicon content in molten iron, increasing production, and reducing fuel consumption costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

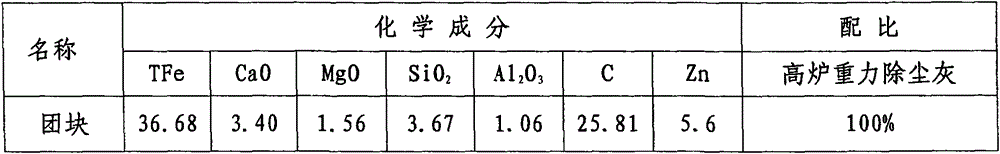

[0006] Example 1: At 820M 3 The carbon-containing iron and zinc oxide agglomerates made by adding carbon-containing blast furnace gravity dust to the iron-storage-type hot metal ditch of the No. 1 iron casting yard of blast furnace, with a lump size of about 20mm, go to the molten iron ditch and add 500 kg of agglomerates When the iron is tapped, the slag and iron stream spewing out from the iron mouth forms a large vortex at the falling point, and the temperature is about 1500 ℃. It reacts and melts quickly, producing a large amount of smoke, the reduced iron becomes molten iron, the molten slag and the molten slag in the molten iron ditch enter the slag flushing ditch to become water slag, and the elements such as zinc are reduced into smoke and inhaled into the dust hood in front of the furnace. It is collected and recycled in the bag filter in front of the furnace. The iron output is 120 tons.

[0007] Chunk ingredients:

[0008]

Embodiment 2

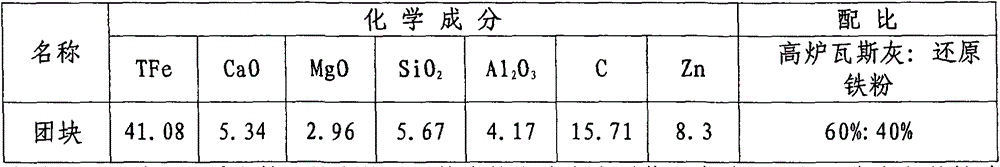

[0009] Example 2: At 820M 3 The carbon-containing iron and zinc oxide agglomerates are made of carbon-containing blast furnace gas ash and high-zinc-containing powder ash for reducing iron production in the iron-storage-type hot metal ditch of the No. 1 iron casting yard of blast furnace. , add 1 ton of agglomerates, add 50 kg of agglomerates to the iron ditch for tapping, and continuously add the remaining agglomerates into the molten iron ditch when tapping is opened. The strands form a large vortex at the falling point, the temperature is about 1500℃, the agglomerates react and melt rapidly in the molten iron ditch together with the churning high-temperature molten iron and slag, producing a large amount of smoke, the reduced iron becomes molten iron, and the molten iron becomes molten iron. The slag enters the slag flushing ditch together with the molten slag in the molten iron ditch to become water slag. After the reduction of zinc and other elements, the slag is sucked i...

Embodiment 3

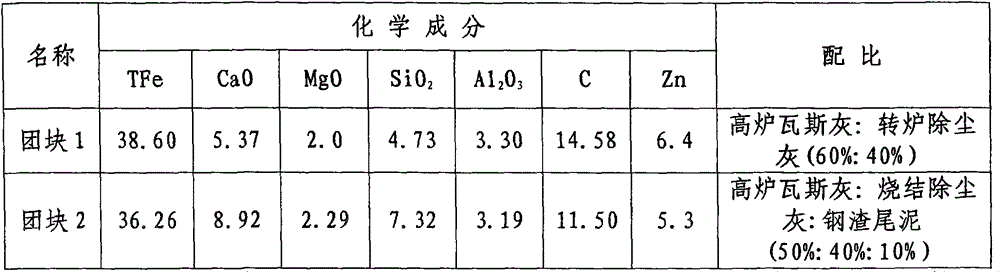

[0012] Example three: at 820M 3 Carbon-containing iron and zinc oxide agglomerates made of carbon-containing blast furnace gas ash and converter dust ash, blast furnace gas ash and sintering dust ash, and steel slag tailings were used in the iron-storing hot metal ditch of the No. 2 blast furnace. 1 and block 2, the block size is about 30mm. First, use the crane to lift the block 1 into the small hopper. When the iron mouth is opened, 2 tons of agglomerates are continuously added to the iron ditch through the valve and the feeding pipe. 1. The blanking pipe is facing the drop point of the molten iron in the tap hole. When the iron is tapped, the slag and iron streams spewing out from the tap hole form a large vortex at the point where the molten iron falls. The high-temperature molten iron and molten slag being churned in the large vortex react and melt rapidly, producing a large amount of smoke, the reduced iron becomes molten iron, and the molten slag enters the slag flushin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com