Preparation method of biomass derivative carbon material used for sodium-ion batteries

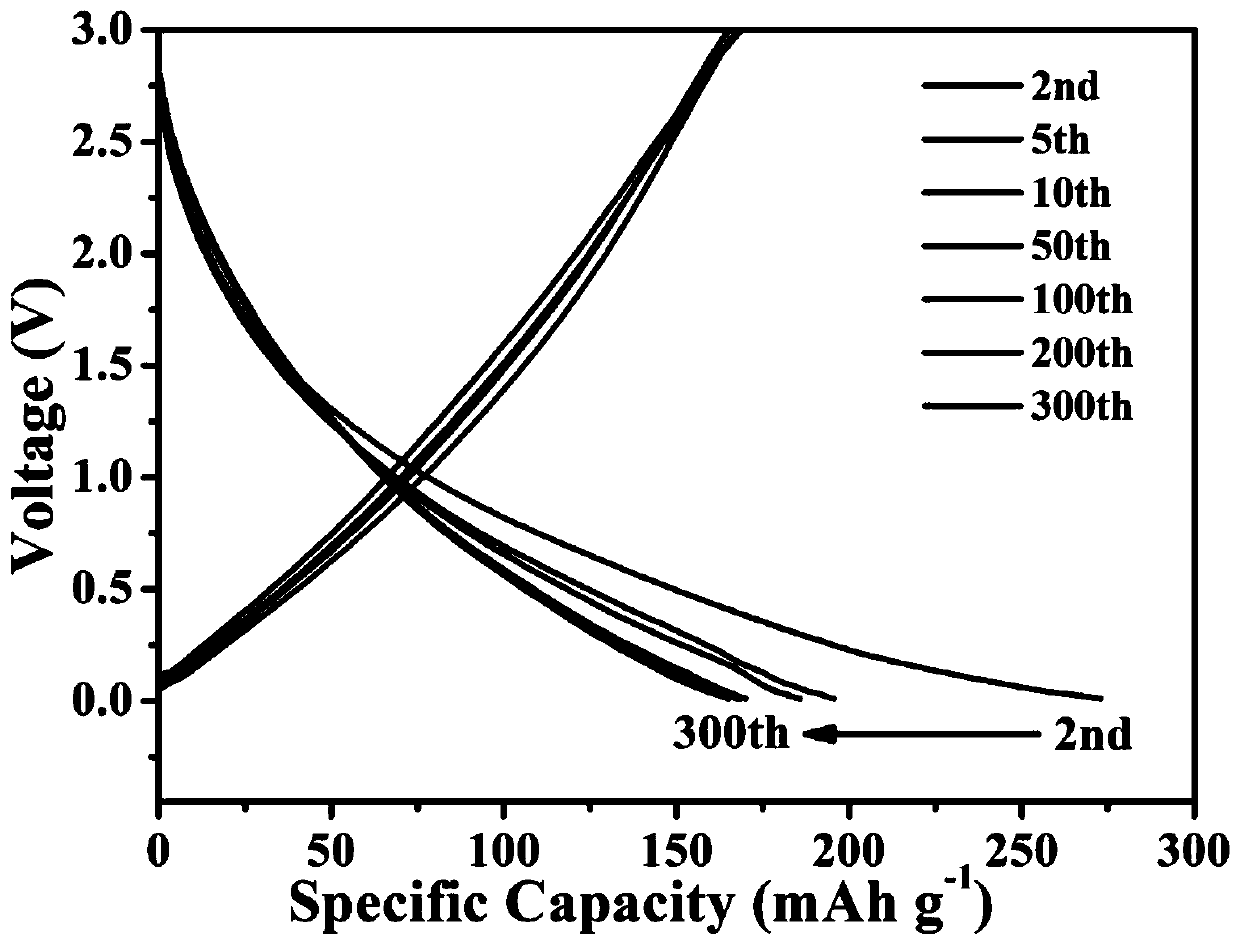

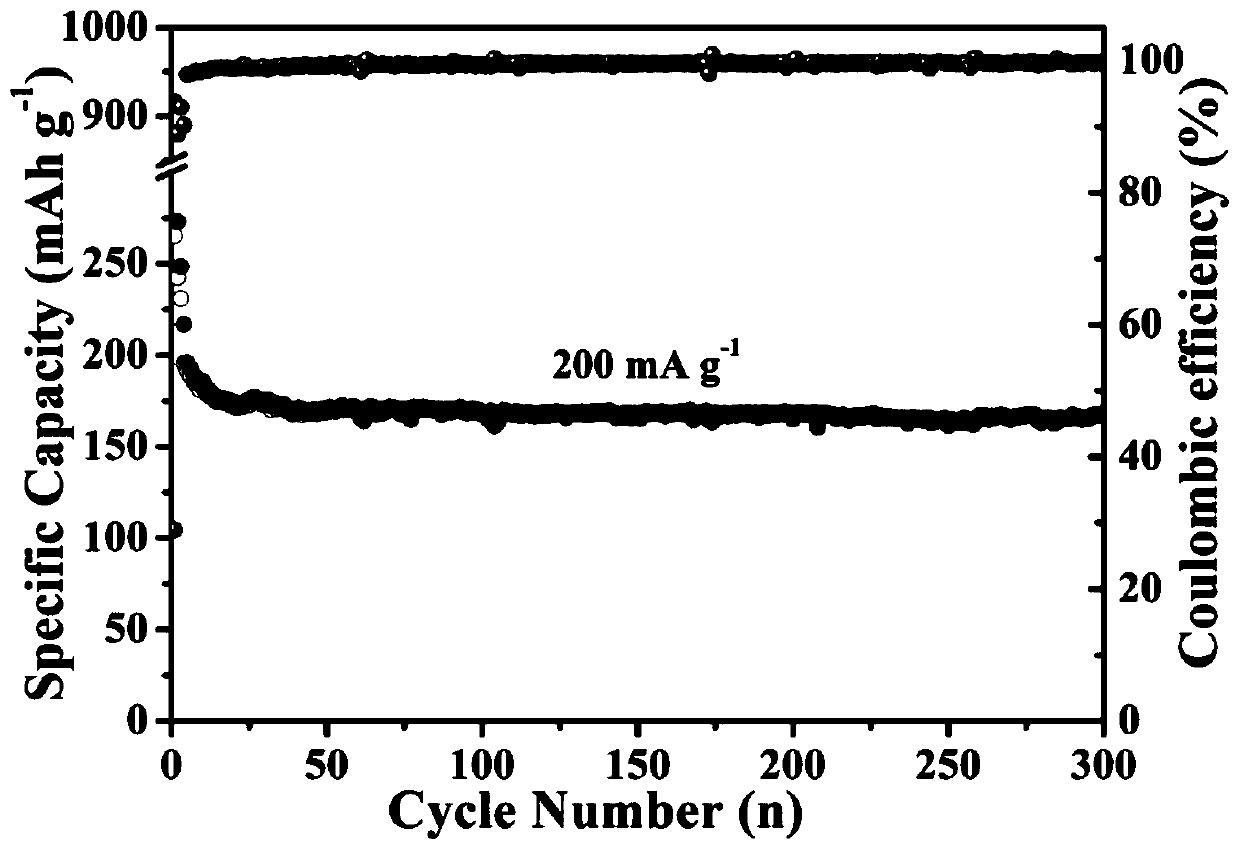

A sodium-ion battery and biomass technology, applied in battery electrodes, chemical instruments and methods, circuits, etc., can solve the problem of low specific capacity, achieve high capacity retention, facilitate infiltration, and expand the specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Weigh 10g of dried soybeans and place them in a grinder for 1h to make them into powder, then soak them in 50mL of 5% HCl solution for 1h to remove metal ions and other impurities, and then wash the powder materials with deionized water until neutral;

[0037] Add 50mL of 10mol·L to the obtained material -1 Soak in KOH solution and stir continuously, soak for 12 hours and then stand for 1 hour, pour off the supernatant, leave the precipitated part, collect the required materials by centrifugation, and dry in a drying oven at 100 °C for 12 hours;

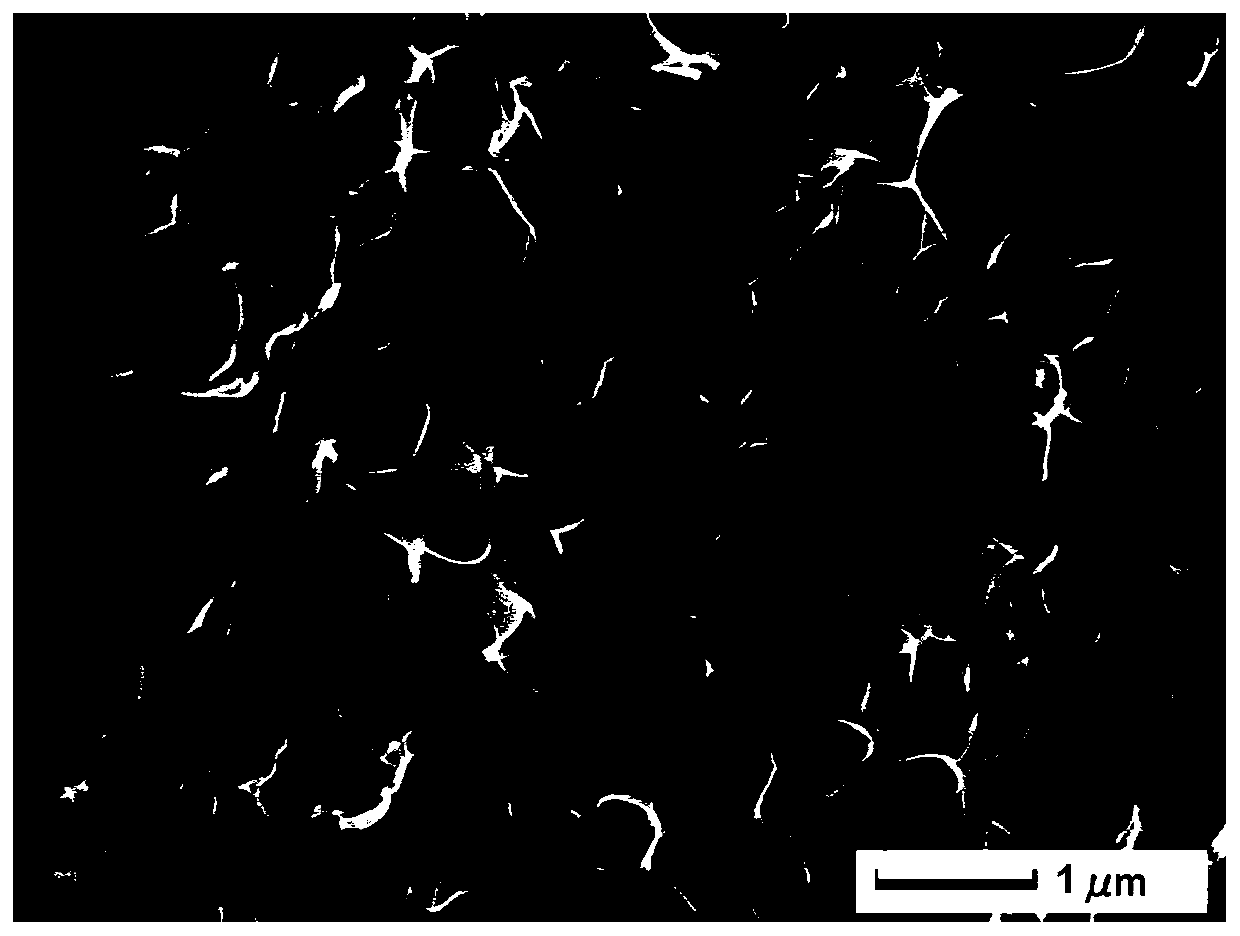

[0038] The obtained material was carbonized under a tube furnace with an argon atmosphere at a heating rate of 5 °C min -1 , the calcination temperature is 700°C, the calcination time is 2h, and after the calcination is completed, it is naturally cooled to room temperature;

[0039] The calcined material was washed with 5% HCl solution and deionized water until the solution became neutral. Finally, it is centrifuged and drie...

Embodiment 2

[0044] Weigh 10g of dry soybeans and place them in a grinder for 1h to make them into powder, then soak them in 50mL of 5% HCl solution for 1h to remove metal ions and other impurities, then wash the powder materials with deionized water until neutral; Add 50mL 10mol·L to the material -1 Soak in KOH solution and stir continuously, soak for 12h and then stand for 1h, pour off the supernatant, leave the precipitated part, collect the required material by centrifugation, dry in a drying oven at 100°C for 12h; place the obtained material in argon gas Carbonization was carried out in a tube furnace with a heating rate of 5 °C min -1 , the calcination temperature is 800° C., and the calcination time is 2 hours. After the calcination is completed, it is naturally cooled to room temperature; the calcined material is cleaned with 5% HCl solution and deionized water until the solution becomes neutral. Finally, it is centrifuged and dried in an oven to obtain a biomass-derived carbon ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com