Irregular II type large-span concrete vierendeel sandwich plate floor and making method thereof

A concrete, irregular technology, applied in the direction of floor slabs, building components, buildings, etc., can solve the problems of increasing project cost, fat beams and fat columns, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

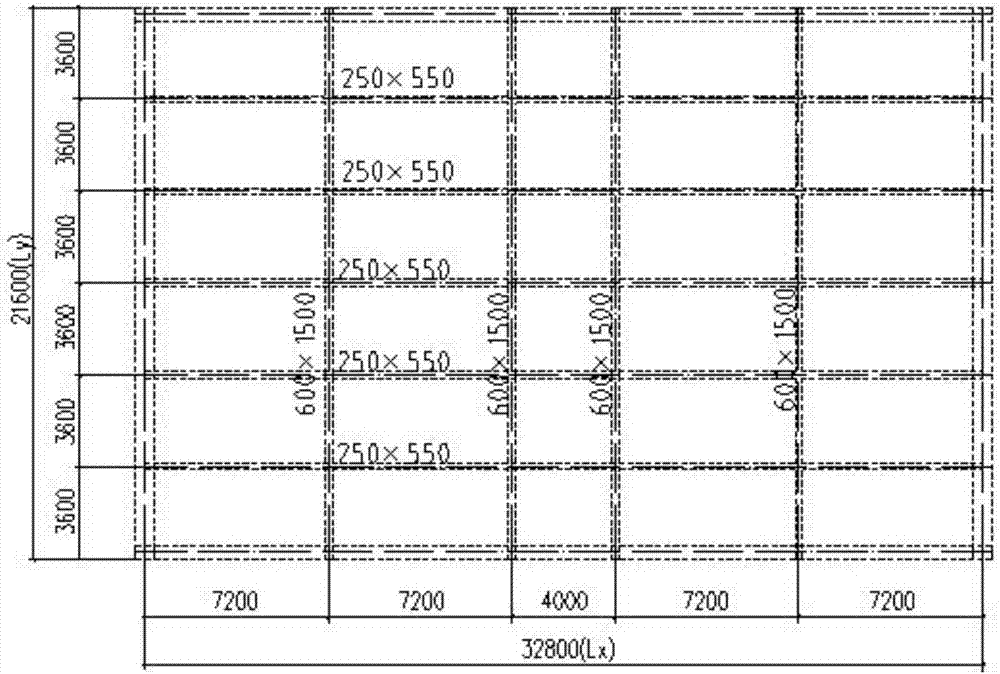

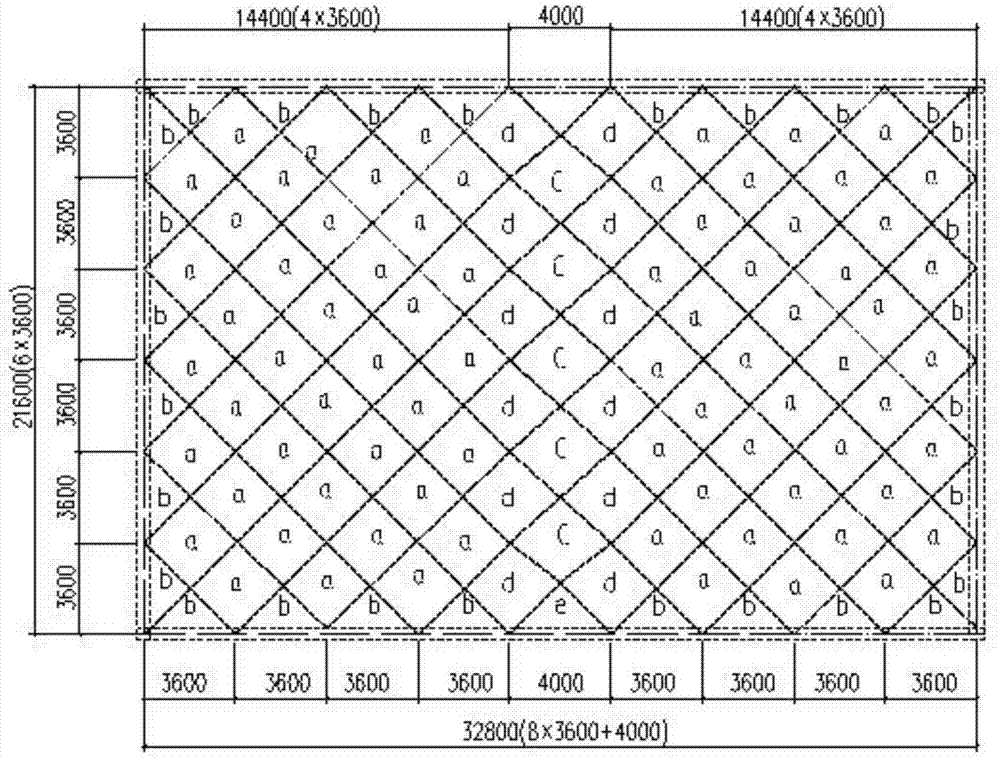

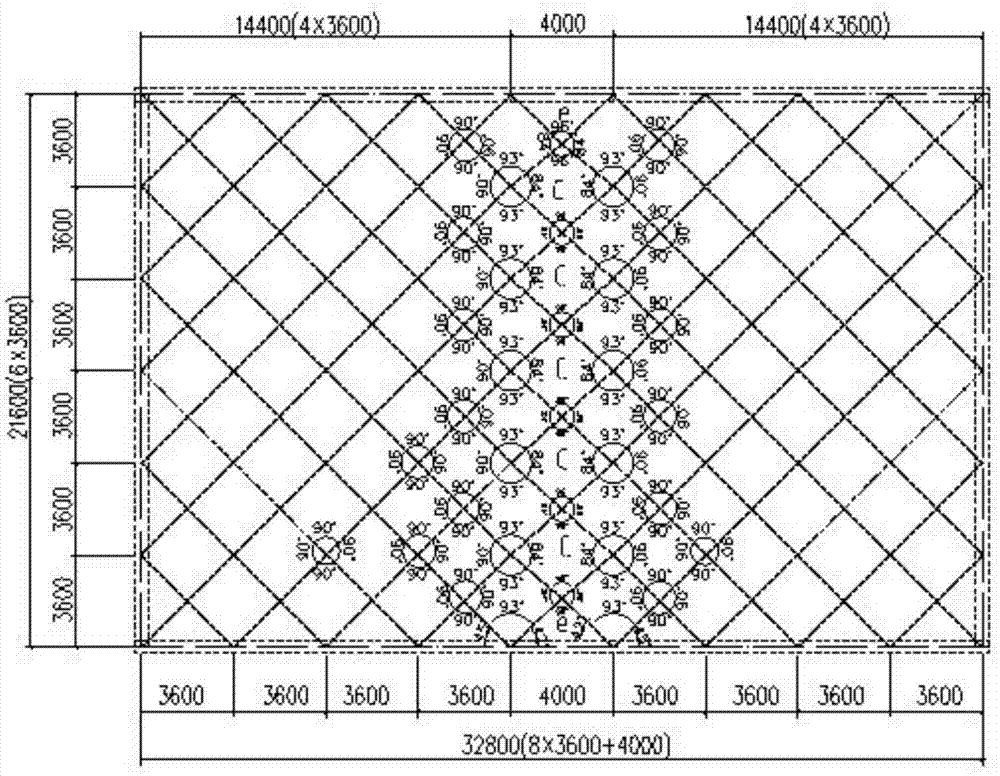

[0019] refer to Figure 1-6 , the present invention proposes an irregular type II large-span concrete hollow sandwich slab floor, including concrete hollow mesh division and hollow mesh node manufacturing methods. The ratio Lx / Ly of the long and short sides of the hollow concrete sandwich slab floor is greater than 1.5, forming a one-way force-bearing slab, the ratio of the distance between the supports of the long side Lx has no common denominator, and the position with a large distance between the supports is located in the middle of the long side. The fasting grid includes a square grid a, a right-angled isosceles triangle grid b, a parallelogram grid c, a trapezoidal grid d, and a non-right-angled isosceles triangle grid e;

[0020] Among them, the structural thickness δ of the long-span concrete hollow sandwich slab floor is (1 / 25-1 / 30)Ly, and the void ratio of the floor is u=80%-85%.

[0021] The upper and lower chords of the square grid and the right-angled isosceles t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com