Manufacturing, pouring and forming method for reinforced concrete prefabricated wall

A reinforced concrete and forming method technology, which is applied in the field of reinforced concrete prefabricated wall production and pouring, can solve problems such as troublesome process, difficult form removal, poor stability, etc., and achieve the effects of improving efficiency, improving convenience, and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be embodied in various ways of claims defined and covered.

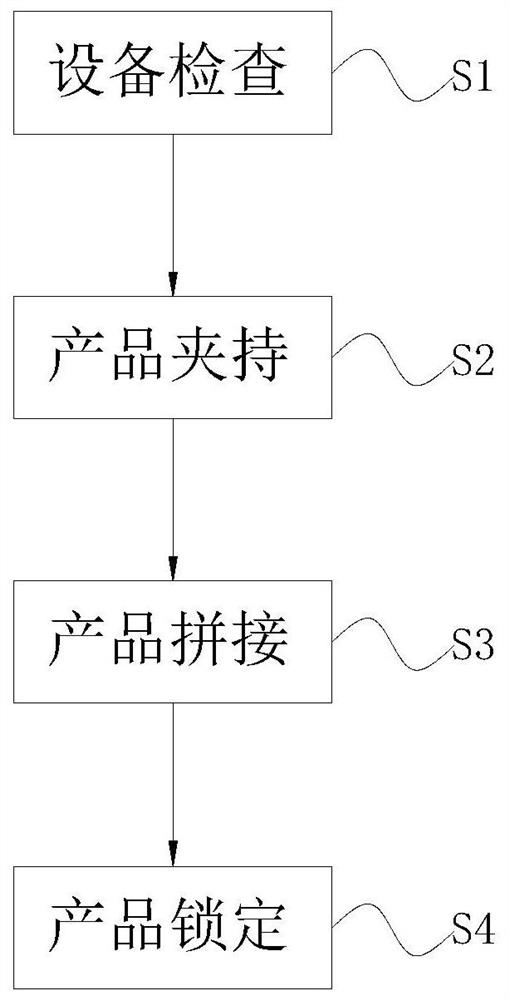

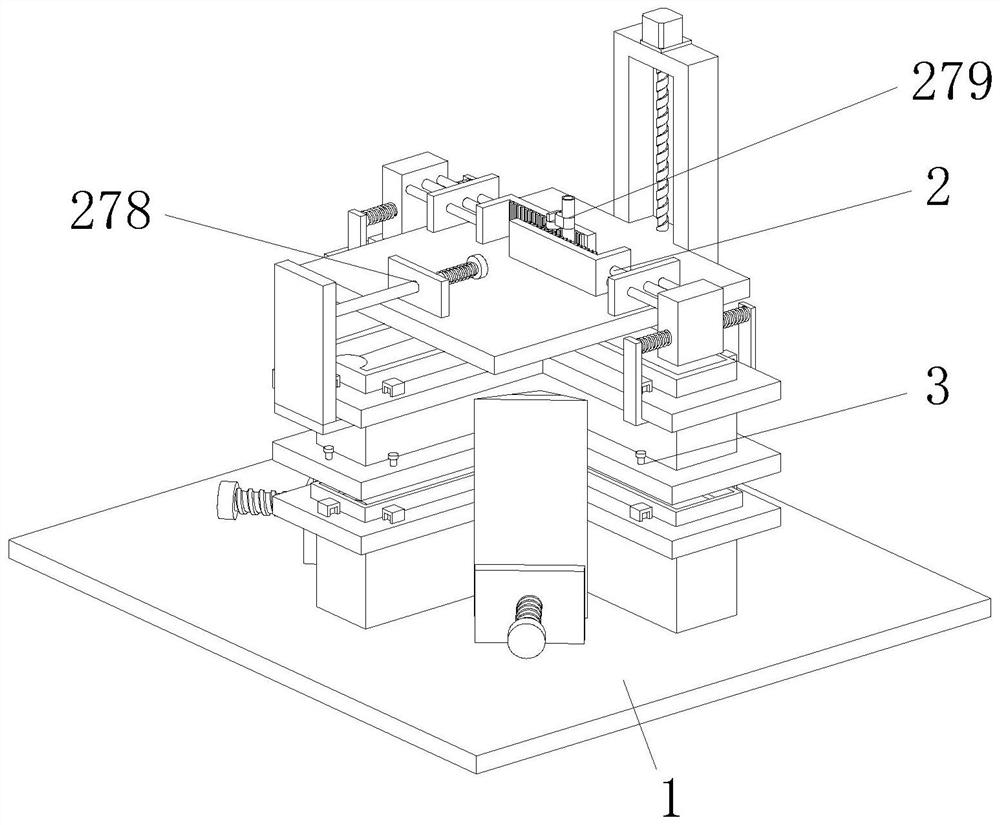

[0048] like Figures 1 to 14 As shown, a reinforced concrete prefabricated wall made a pouring forming method, the reinforced concrete prefabricated wall made a pouring forming method using a reinforced concrete prefabricated wall, which includes a bottom plate 1, a clamping device 2 and a pouring device. 3, the bottom plate 1 is fixedly mounted having a clamping device 2 on the bottom plate 1.

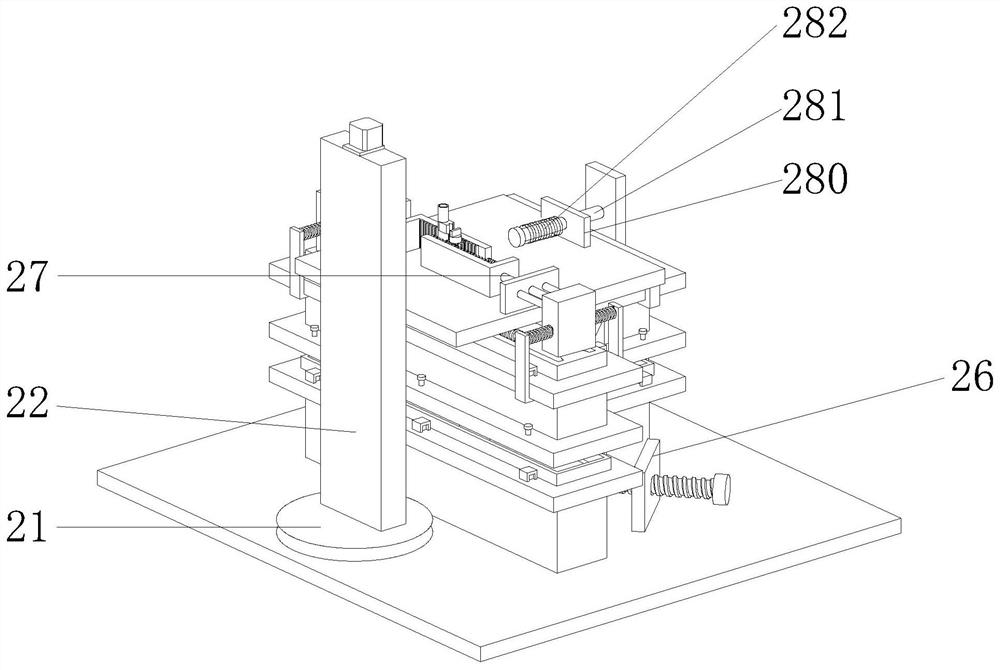

[0049] The clamping device 2 includes a disc 21, a vertical frame 22, a sliding screw rod 23, a screw motor 24, a horizontal panel 25, a restricted assembly 26 and a clamping mechanism 27, and the bottom plate 1 is rotated on the bottom plate 21, circle The vertical frame 22 is fixed to the disk 21, and the internal rotation of the vertical frame 22 is rotated, and the top en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com