Huge concrete filled steel tubular column core grouting pouring and tamping device and method

A technology of concrete-filled steel tube columns and steel tube columns, which is applied in construction, building construction, and processing of building materials, can solve problems such as height uncertainty, uneven vertical lifting, and unfixed horizontal positions of multiple conduits, and achieves guaranteed quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

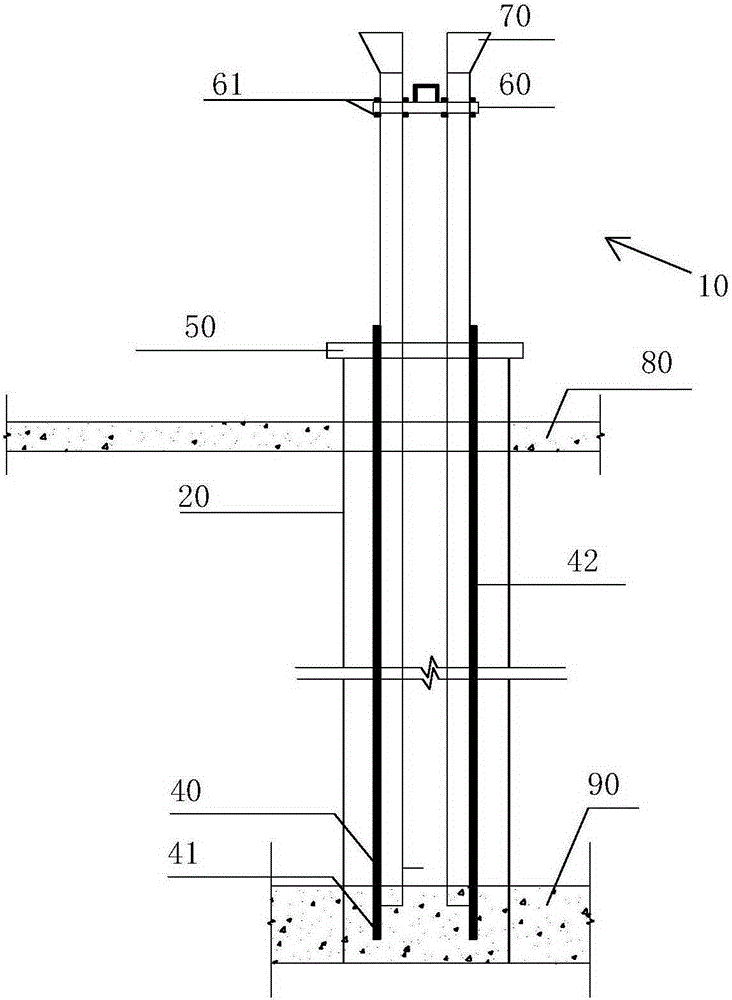

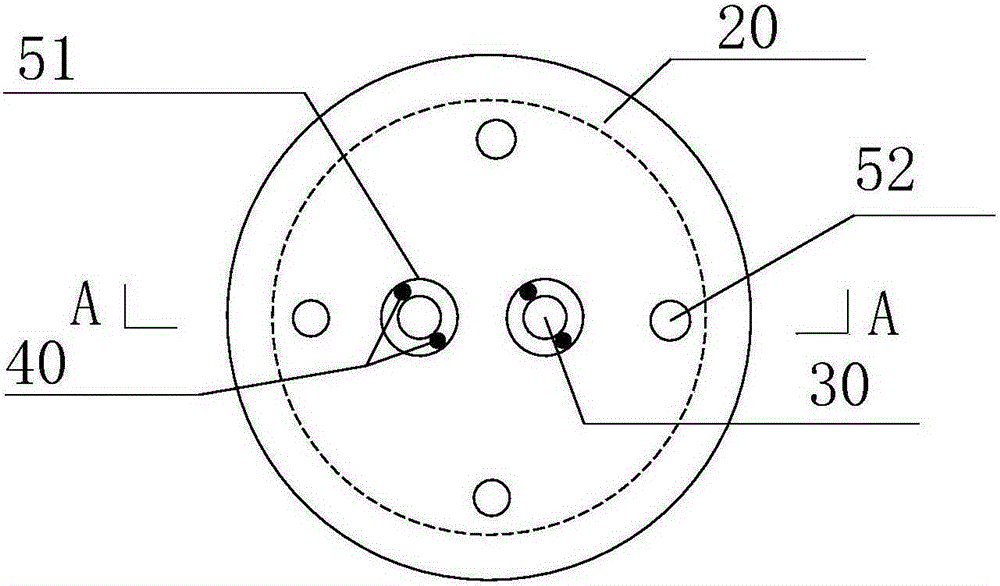

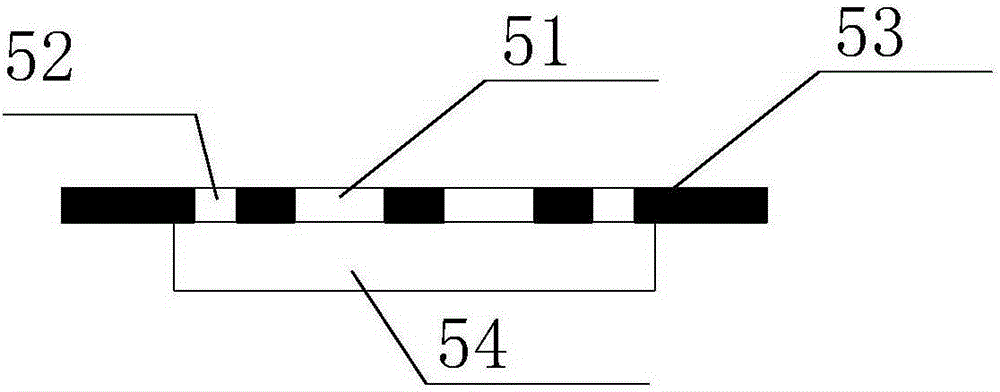

[0038] Such as Figure 1 to Figure 7 As shown, a giant steel pipe concrete column pouring and tamping device 10 is used for the pouring construction of the concrete conduit in the giant steel pipe column 20. The giant steel pipe column 20 is inserted with a number of pouring and tamping conduits 30, and the outer wall of the pouring and tamping conduit 30 is provided with vibration Rod catheter 40. The vibrating rod conduit 40 includes a vibrating machine hose 42 at the upper end and a vibrating rod 41 at the lower end, so that the aggregate is evenly distributed in the concrete member, thereby ensuring the pouring quality of the giant steel pipe concrete column. The pouring and tamping device 10 includes: a limiting plate 50 and a buckling fixture 60 . The lower end of the limiting disc 50 is embedded in the upper port of the giant steel pipe column 20 , and the limiting disc 50 is provided with a plurality of limiting holes 51 through which the pouring and ramming conduit 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com