Novel prefabricated structure precast column unit and beam-column joint construction method

A prefabricated column and prefabricated technology, applied in the direction of columns, piers, pillars, etc., can solve the problems of complex on-site construction, difficult to guarantee, time-consuming and labor-intensive, etc., to achieve simple and convenient construction, ensure construction quality, and strong economic feasibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

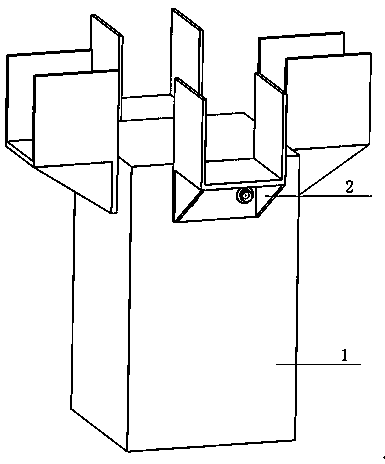

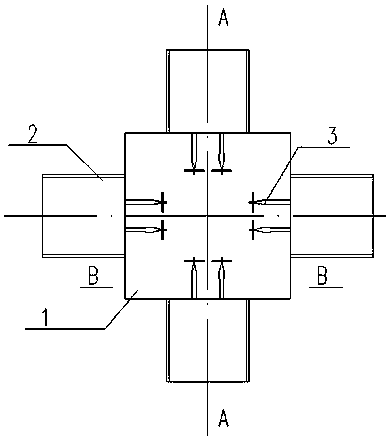

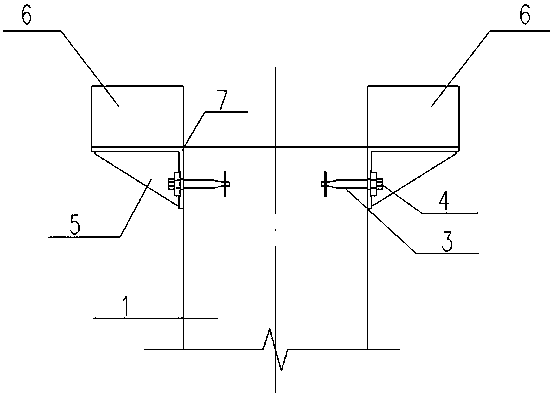

[0022] A novel assembled structural prefabricated column member according to the present invention comprises a prefabricated column (1), a support bracket (2), and a pre-embedded nut (3). The support bracket (2) is mainly composed of high-strength bolts (4), reinforcing steel plates (5), positioning steel plates (6), angle steels (7), and nuts (8). When producing the prefabricated column (1), the nuts (3) are pre-embedded according to the structural construction drawing in advance to fix the support bracket (2). According to the structural construction drawings, select a reasonable support bracket (2) according to the size of the composite beam (9), and use high-strength bolts (4) to connect the support bracket (2) with the prefabricated column (1). (2) Width D=dimension of composite beam (9)+50mm, the purpose is to facilitate the installation of composite beam (9), the construction is convenient and reliable, and the difficulty of construction is effectively reduced.

[0023...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com