Construction method for large cavity hollow floor slab

A hollow floor slab and construction method technology, which is applied to floors, building components, buildings, etc., can solve the problems of inconvenient form support, large cavity for large cavity hollow floor slabs, and easy vibration leakage during concrete construction, so as to ensure the vibration quality, Prevent floating and displacement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

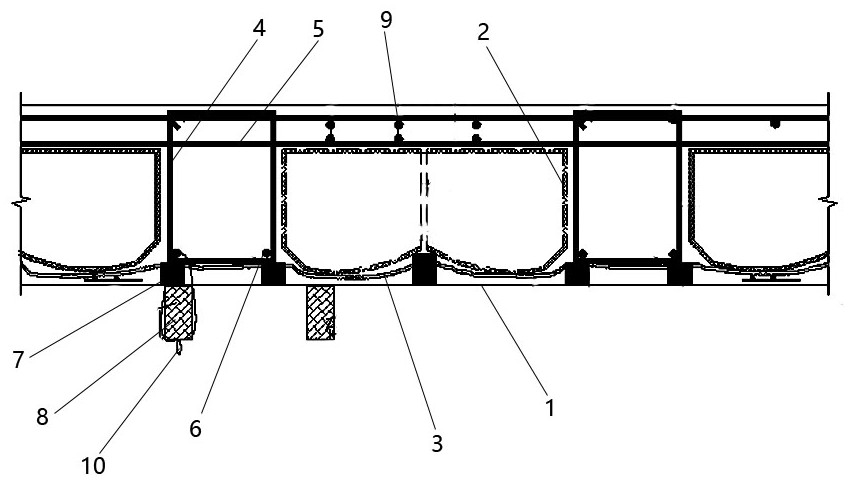

[0024] Such as figure 1 Shown, the present invention comprises the following steps:

[0025] a. Support the floor formwork 1, set the wires on the floor formwork 1, determine the position of the box formwork 2, the position of the water and electricity pipeline and the position of the hole.

[0026] b. Spread anti-crack steel wire mesh 3 on the floor formwork 1 .

[0027] c. Bind the box form side rib beam on the floor formwork 1. The side rib beam includes the rib beam stirrup 4, the rib beam upper steel bar 5 and the rib beam lower steel bar 6, and the rib beam upper steel bar 5 and the rib beam lower steel bar 6 are connected Inside the rib beam stirrup 4.

[0028] d. Lay embedded pipelines.

[0029] e. Place pads 7 between the side rib beams of the box form and the floor formwork 1, use iron wire 10 to pass through the floor formwork 1, and fix the side rib beams of the box form and the keel 8 of the floor formwork 1 together.

[0030] f. Install the box formwork 2 in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com