One-time continuous pouring and forming construction method of stairs based on integral shaped formwork

A technology for shaping formwork and construction method, which is applied in the direction of formwork/formwork/work frame, stairs, construction, etc., which can solve the problems of inconvenience of people getting up and down, time-consuming, and large amount of engineering, so as to ensure accuracy and vibration quality. , the effect of reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

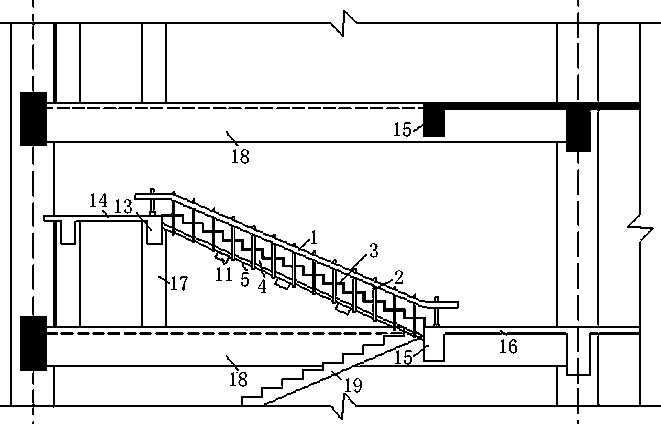

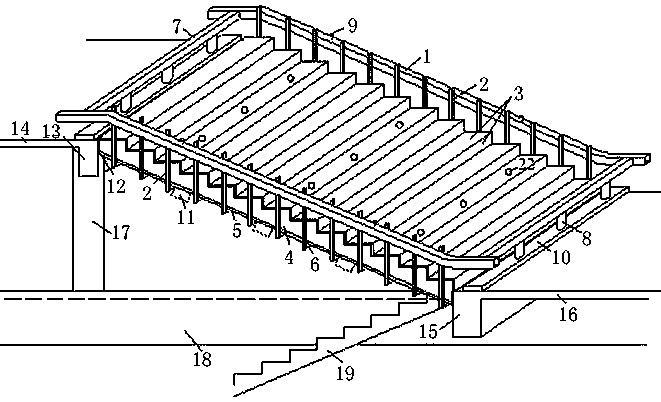

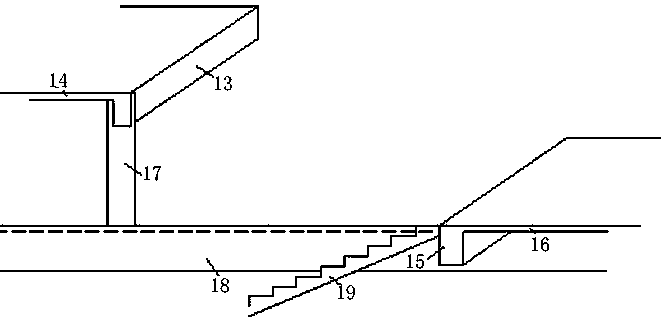

[0046] A stair section adopts a double-running structure with a span of 3.9m, a height of 1.95m, and a width of 1.5m. It is composed of 13 steps with a width of 300mm and a height of 150mm. The formwork supporting longitudinal beam 1 and the formwork crossbeam 7 are made of rectangular section steel with a section size of 150×100×8mm, and the two are connected by welding. The lower end of the template beam 7 is welded with an adjustable leg 8, which is made of a round steel pipe with a diameter of 100mm and a thickness of 8mm, and the lower end is provided with an adjustable length knob. The lower floor of the wooden spacer block 10 with damping is provided with a rubber pad with a thickness of 20mm, and the upper floor is a wooden block with a thickness of 100mm. The vertical connecting rod 2 and the bottom transverse stiffener 6 are made of a whole strip of rectangular section steel with a cross-sectional size of 50×50×6mm, which are welded to the side panel 4 and the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com