One-time continuous pouring forming structure and construction method of integral aluminum formwork staircase

A construction method and technology of aluminum formwork, which are applied in the direction of stepped structure, formwork/formwork/work frame, stairs, etc., can solve the problems of inconvenience, large amount of work, and long time, so as to improve the overall construction efficiency and construction efficiency. Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below with reference to the accompanying drawings and examples. The following examples are explanations of the present invention and are not limited to the following examples.

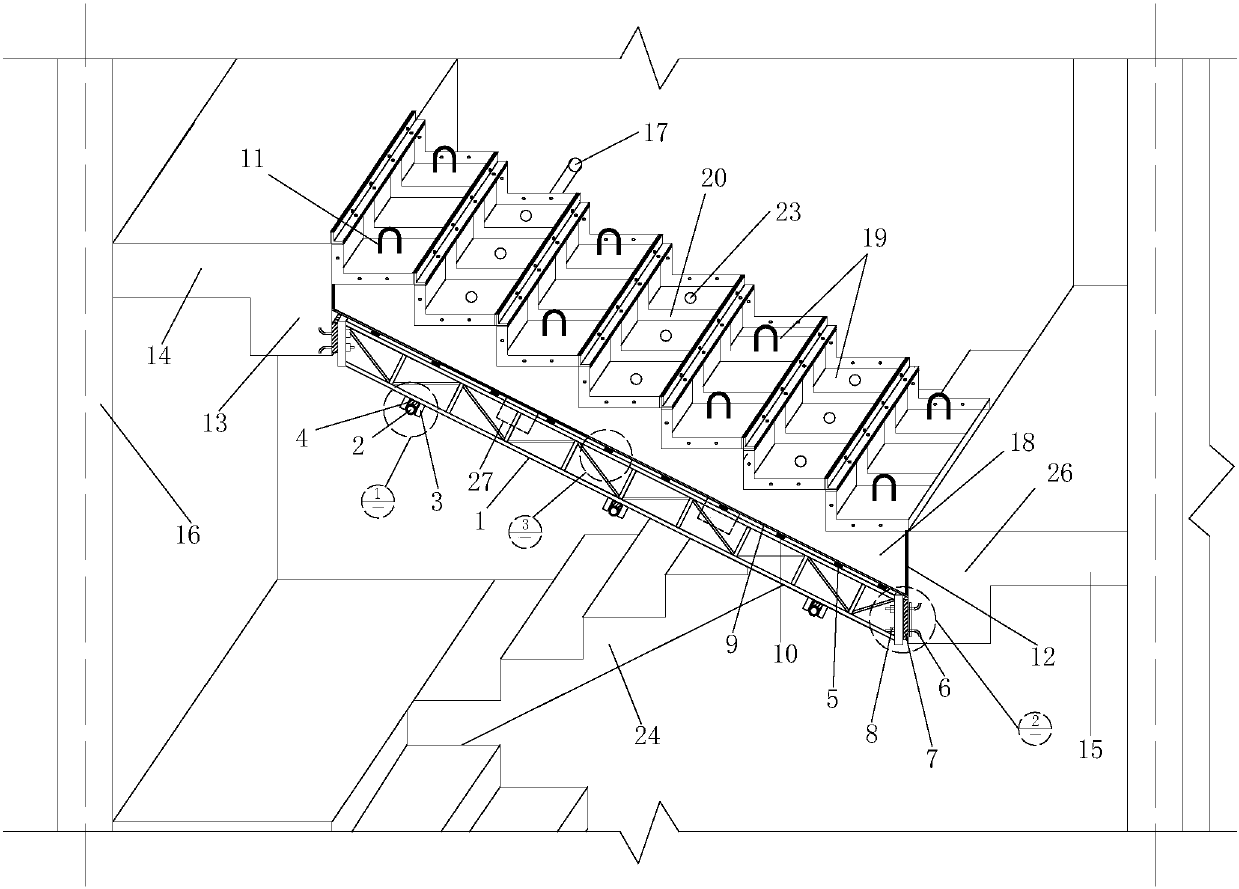

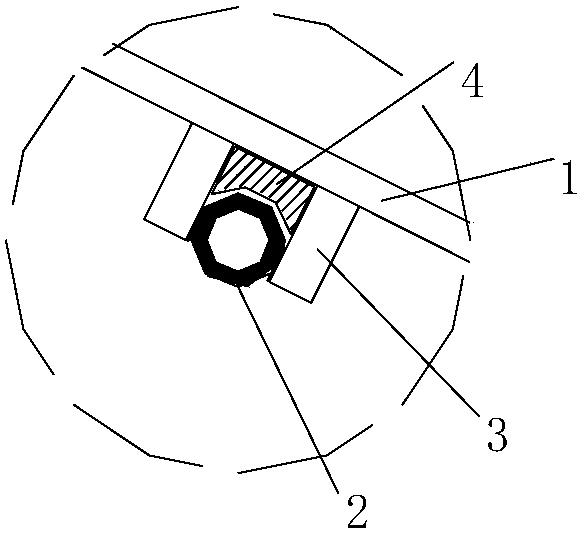

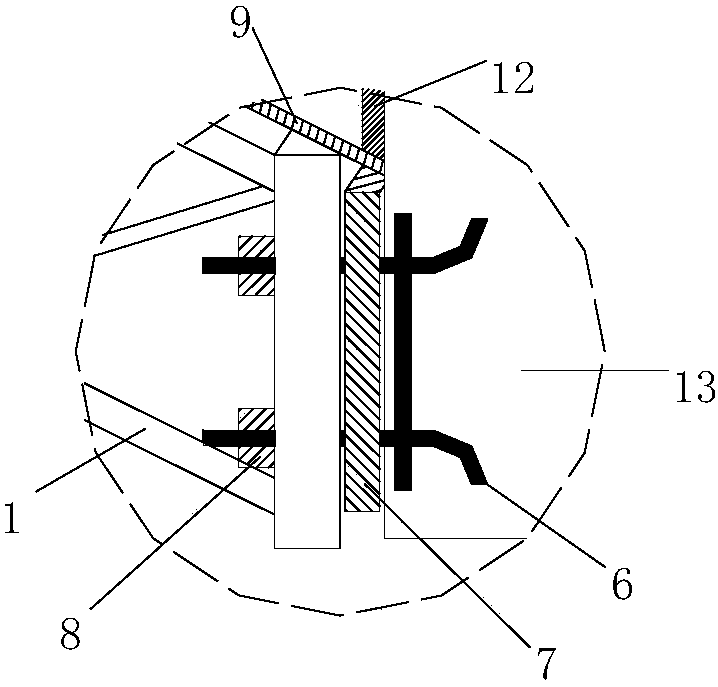

[0032] figure 1 It is a three-dimensional construction diagram of the integral aluminum formwork staircase formed by continuous pouring at one time. figure 2 It is a detailed drawing of the connection between the formwork support bracket and the steel pipe; image 3 It is the detailed diagram of the connection between the formwork support bracket and the embedded parts; Figure 4 It is the detailed drawing of the connection between the bottom plate and the formwork supporting bracket; Figure 5a~5f It is a construction flow chart of one-time continuous casting of integral aluminum formwork stairs.

[0033] A staircase is of elevator shaft shear wall structure, with a span of 3.9m, a height of 1.95m, and a width of 1.5m. It is composed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com