Form erecting structure and method for concrete pouring of oblique arch surface structure

A concrete and structural formwork technology, which is applied to the preparation of building components on site, construction, building construction, etc., can solve the problems of construction quality defects, difficult to accurately grasp the size, etc., to ensure compactness, easy control and adjustment, The effect of high secondary utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

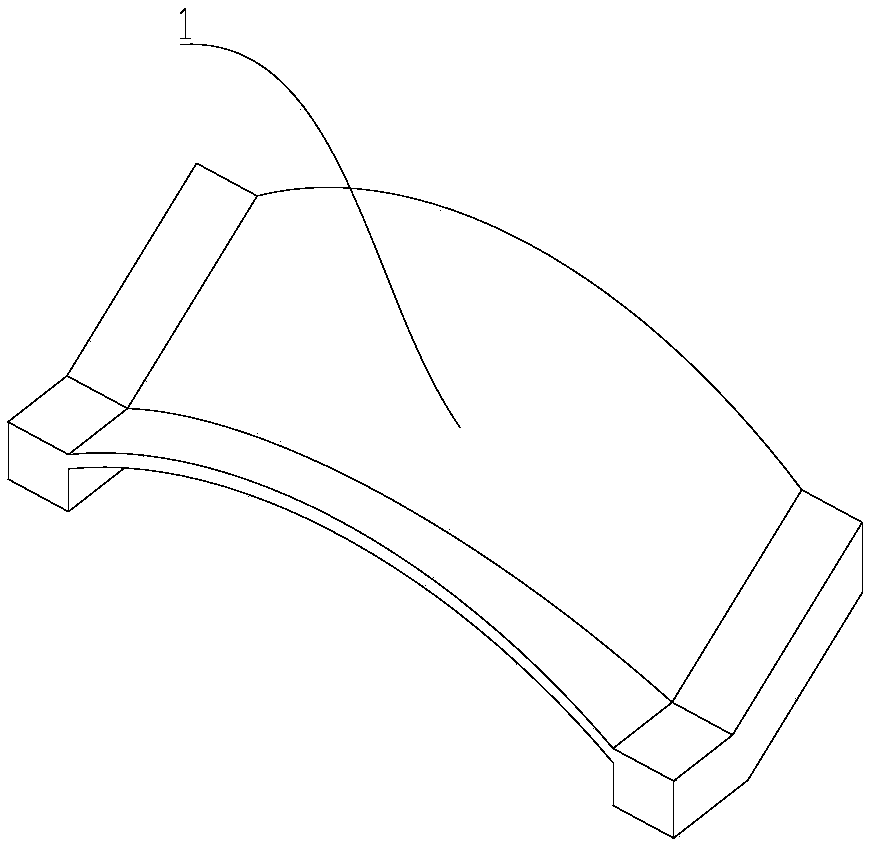

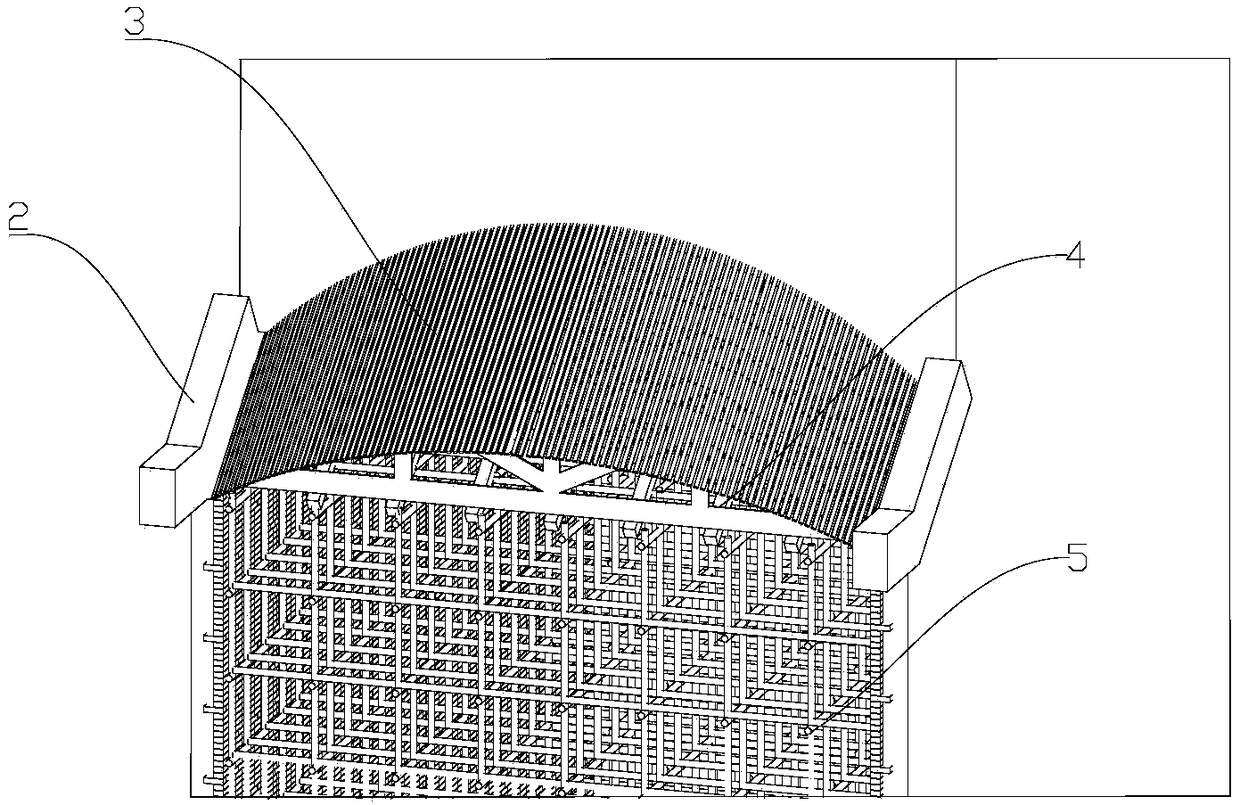

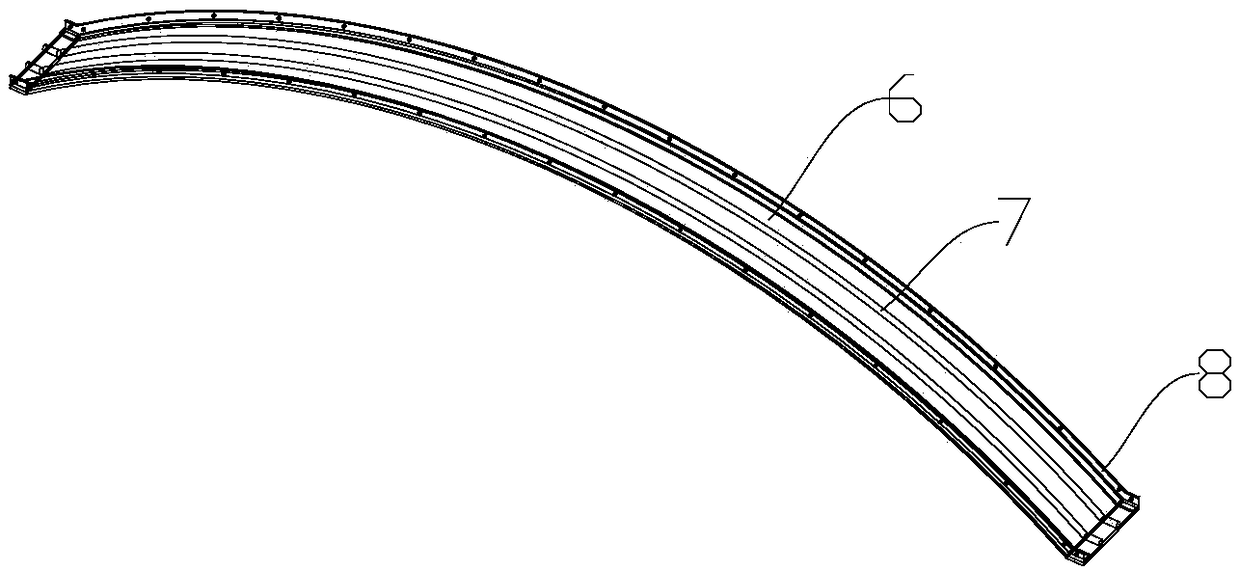

[0044] Such as Figure 1-Figure 5 , a formwork structure for pouring concrete with an oblique arch structure 1, comprising a support device, wooden arch tire strips 3 and an upper formwork structure;

[0045] The supporting device includes wooden arch tires 4 and full-wall brackets 5, wooden arch tires 4 are installed on the full-wall brackets 5, and wooden arch tire strips 3 are arranged on the wooden arch tires 4;

[0046] The upper mold structure adopts a segmented structure, and the upper mold structure includes at least two structural templates that can be joined together ( Figure 5 Including the first structural template 10.1, the second structural template 10.2, the third structural template 10.3 and the fourth structural template ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com