Sound insulation type flat ceiling keel buckle and mounting method thereof

An installation method and keel technology, applied in the field of building keels, can solve the problems of easy occurrence of gaps at joints, inconvenient splicing and installation, and difficulty in adjustment, etc., and achieve the effects of increasing strength, safe and convenient use, and increasing functions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

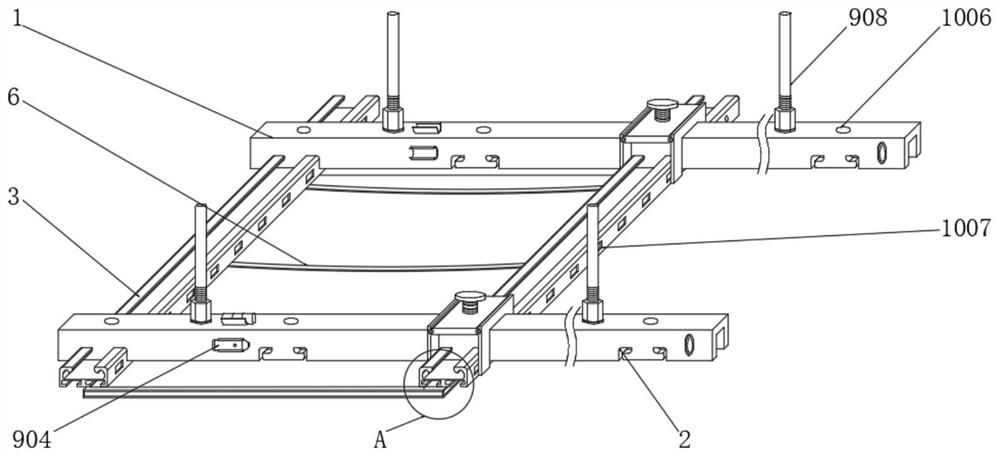

[0046] Example: such as Figure 1-8 As shown, the present invention provides a sound-proof flat-top keel buckle and its installation method technical scheme, including a main keel 1, the bottom of the main keel 1 is uniformly provided with a snap-in groove 2, and a secondary keel is movably installed inside the snap-in groove 2 3;

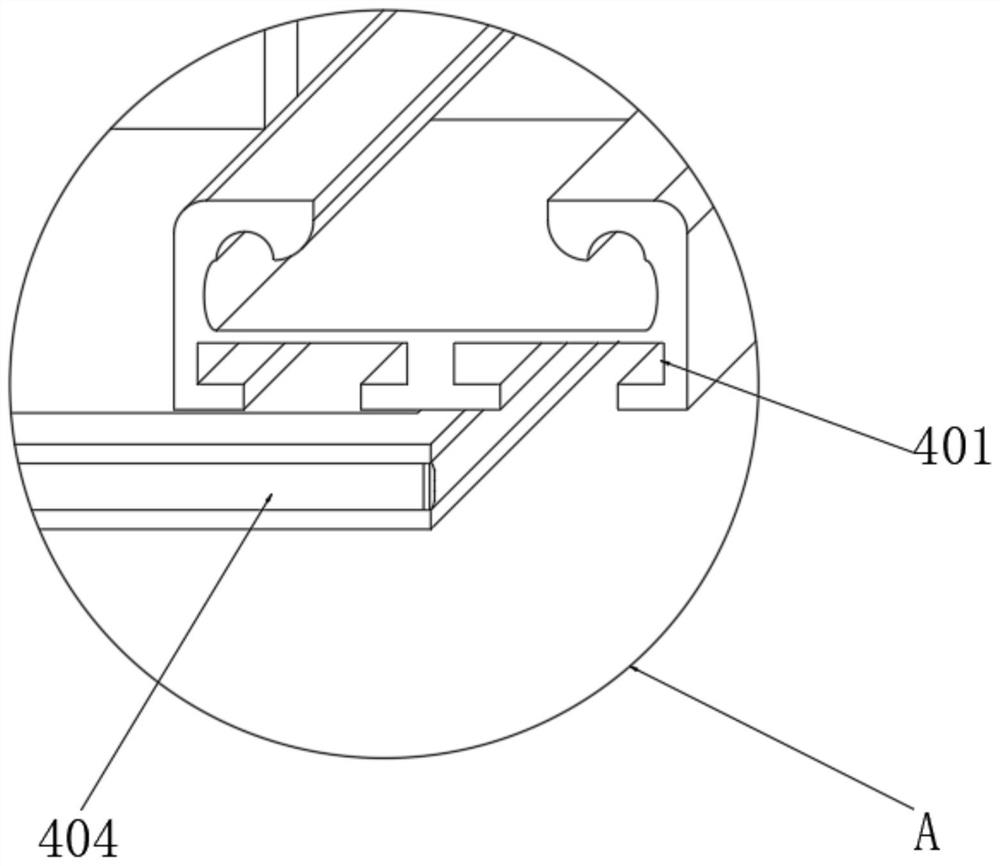

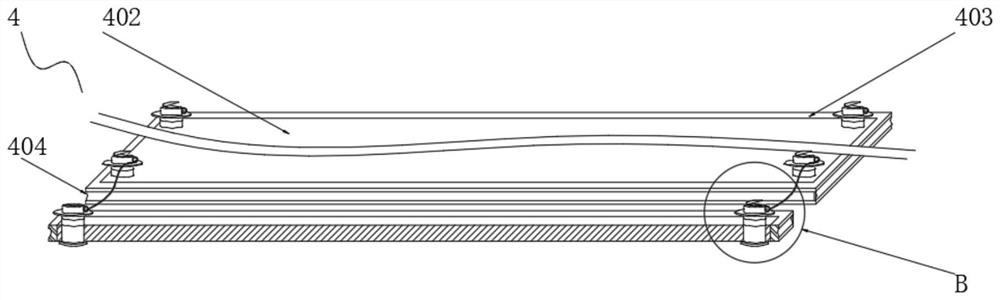

[0047] The bottom surface of the secondary keel 3 is provided with a partition assembly 4, which includes a chute 401, a decorative plate 402, a sealing strip 403, a sealing groove 404, a rotating column 405, a rotating piece 406, a limit piece 407, a bobbin 408, and a spring 409 , terminal ring 410 and thin steel wire 411;

[0048] Two chutes 401 are evenly opened on the bottom surface of the sub-keel 3, and the bottom surface of the sub-keel 3 is movably installed with a decorative plate 402, and the outer edge of the decorative plate 402 is bonded with a sealing strip 403, and the middle part of the side of the sealing strip 403 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com