Anti-adhesive coating and monolithic stopper using anti-adhesive coating

A technology of anti-sticking coating and integral stopper, which is applied in the direction of coating, casting melt container, manufacturing tools, etc. It can solve the problems of anti-scouring, poor anti-erosion performance, high viscosity of glaze layer, large loss, etc., so that it is not easy to fall off Abrasion, not easy to fall off, high refractoriness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The anti-adhesive coating is prepared by crushing white corundum, clay and aluminum oxide through a 280-mesh or finer sieve, mixing uniformly according to the stated ratio, and then taking white dextrin and adding water according to the stated ratio and stirring evenly to obtain a sticky coating. Add agent, then pour in the mixed powder and stir evenly.

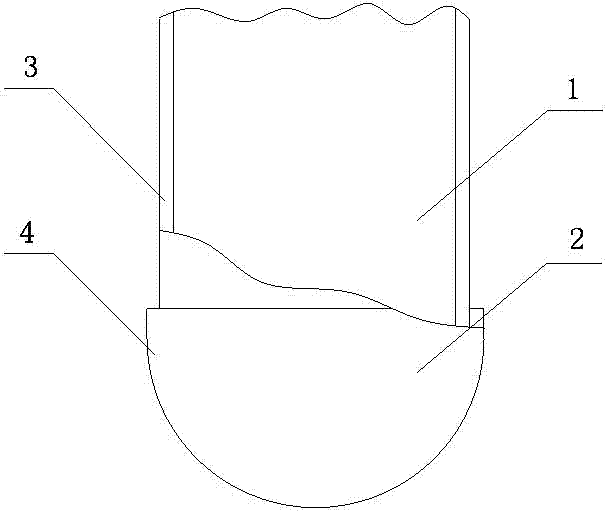

[0022] Such as figure 1 As shown, the integral stopper rod of the present invention includes a stopper rod body 1, a stopper rod head 2 and an anti-oxidation layer 3, the stopper rod body 1 and the stopper rod head 2 are integrally structured, and the outer surface of the stopper rod head 2 The anti-stick coating layer 4, the thickness of the anti-stick coating layer 4 should be 0.8-1.2mm. Its production is that the stopper body 1 and the stopper head 2 are manufactured integrally according to the conventional method, and a layer of anti-oxidation coating 3 is sprayed on the outer surface. Then the adhesive and solid...

Embodiment 1

[0024] The anti-stick coating of the present invention is mixed by high temperature resistant 200# white corundum, clay, aluminum oxide, and binder, and the proportioning by weight of described white corundum, clay, alumina, and binder can be: white corundum 70 10 parts of clay, 8 parts of alumina, and 1 part of binder. The binder is prepared by mixing water and white dextrin in a weight ratio of 40:60. The white corundum is preferably high temperature-resistant 200# white corundum, and the clay should be clay with high viscosity. The anti-adhesive coating is prepared by crushing white corundum, clay and aluminum oxide through a 280-mesh or finer sieve, mixing uniformly according to the stated ratio, and then taking white dextrin and adding water according to the stated ratio and stirring evenly to obtain a sticky coating. Add agent, then pour in the mixed powder and stir evenly.

[0025] The integral stopper made of the anti-sticking coating includes a stopper body 1, a sto...

Embodiment 2

[0027] In the anti-sticking coating of the present invention, the proportioning by weight of described white corundum, clay, aluminum oxide, binding agent is: white corundum 75 parts, clay 1 5 10 parts, 10 parts of aluminum oxide, 2 parts of binding agent; Said binding agent can press 4 5 : 55 The weight ratio is mixed and prepared; the thickness of the anti-adhesive coating layer 4 at the stopper tip 2 of the integral stopper can be 0.8-1.2mm, and the preparation method of the anti-adhesive coating and the integral stopper of the present embodiment is the same as that of Example 1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com