Rolling ball type concrete pouring structure and method for overground large special-shaped stiff column

A concrete and yo-ball type technology, applied in the field of concrete pouring, can solve problems such as segregation, hollow concrete column, honeycomb, interception, and easy segregation of concrete, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

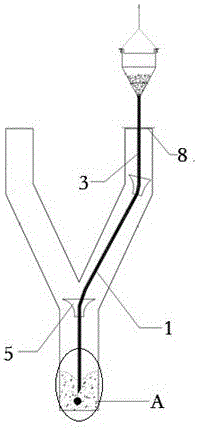

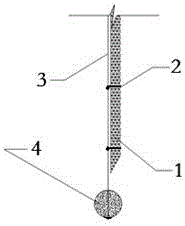

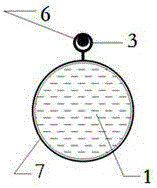

[0033] The concrete pouring structure of large-volume special-shaped stiff columnar yo-column tubes on the ground, the material of the prefabricated concrete yo-yo 4 is the same as that of the rigid column concrete, the diameter of the prefabricated concrete yo-yo 4 is 60mm, and the soft tube 1 is poured through the standard connection. The barge is processed in sections, each joint is in an inverted cone shape, and the length of each section is 2.4m. The diameter of the pouring soft conduit 1 is the same as that of the concrete prefabricated yo-ball 4. The pouring flexible conduit 1 passes through the conduit through the coil ferrule 2 and the steel wire. 3 are connected in series, the arrangement distance of the catheter through the coil hoop 2 is 1.2m, the catheter through the coil hoop 2 includes the through coil 6 and the catheter hoop 7, the through coil 6 is fixedly connected with the catheter hoop 7, and the through coil 6 is fixedly connected The steel wire 3 is fixedl...

Embodiment 2

[0035] The method for concrete pouring using the above-ground large-volume special-shaped rigid column yo-ball type conduit string concrete pouring structure described in Example 1 specifically includes the following steps:

[0036] Step 1: Pre-embed the string pipe 5 on the pouring hole of the stiffening plate at the inflection point of the special-shaped rigid column;

[0037] The second step: with the help of the self-weight of the concrete prefabricated yo-ball 4 , slide the pouring soft conduit along the inner wall of the column and the string tube 5 at the inflection point to the bottom of the special-shaped rigid column through the steel wire 3;

[0038] Step 3: Connect the top connecting port of the pouring flexible conduit 1 with the concrete hopper, and start pouring;

[0039] Step 4: During the pouring process, the flow rate of the concrete in the pipeline is 0.5m / s. According to this flow rate, the pulling delay time of the pouring flexible conduit 1 is controlled ...

Embodiment 3

[0041] The structure and connection relationship of each part of the above-ground large-volume special-shaped rigid column yo-ball type conduit series pipe concrete pouring structure described in this embodiment are the same as those in Embodiment 1, and the different technical parameters are:

[0042] 1, the diameter of concrete prefabricated yo-ball 4 is 70mm;

[0043] 2. The length of each section of pouring soft conduit 1 is 2.7m;

[0044] 3. The layout spacing of the catheter through the coil ferrule 2 is 1.6m;

[0045] 4. The diameter of the coil 6 is 1.18 times the diameter of the steel wire 3;

[0046] 5. The diameter of the conduit collar 7 is 1.1 times the diameter of the pouring flexible conduit 1;

[0047] 6. The specification of the steel wire 3 is 2.5mm;

[0048] 7. The string pipe 5 is 225mm in length;

[0049] 8. The diameter of the large mouth of the string pipe 5 is 2.2 times the diameter of the pouring flexible conduit 1, and the diameter of the small open...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com