A smelting method for improving the fluidity of molten steel after refining and desulfurization of rebar

A smelting method and rebar technology, which is applied in the field of steel manufacturing, can solve problems such as poor fluidity of molten steel, and achieve the effect of ensuring normal pouring and improving fluidity of molten steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

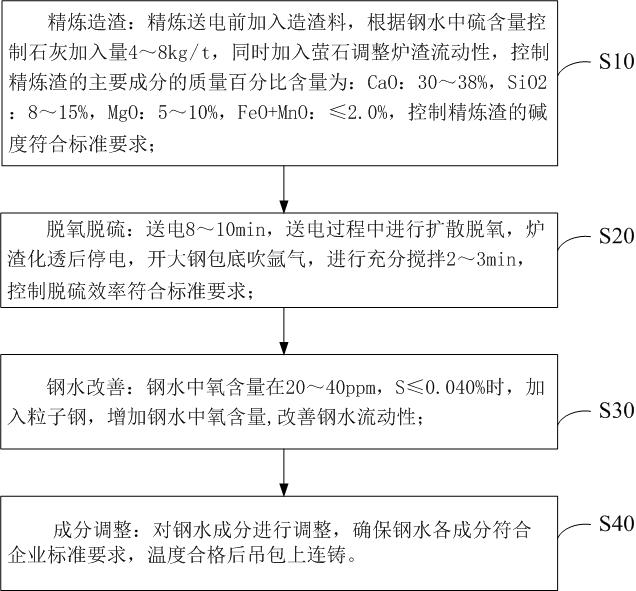

Method used

Image

Examples

Embodiment 1

[0046] converter smelting

[0047] ① Loading 41 tons of scrap steel, 119 tons of molten iron, and a total of 160 tons of molten iron. The composition of molten iron into the furnace is Si: 0.31%, S: 0.056%, and temperature T: 1326 °C; desulfurization process;

[0048] ② The top-bottom re-blowing mode is adopted, the amount of lime added: 5850kg, the tapping temperature: 1642℃, and the tapping amount is 149 tons.

[0049] (2) After furnace and argon station treatment

[0050] After the furnace alloying operation, the total bottom blowing time was 4min, and the sampling at the argon station was C: 0.204%, Si: 0.29%, Mn: 1.37%, P: 0.032%, S: 0.053%, V: 0.024%.

[0051] (3) LF refining

[0052] ①Add slag-forming material before refining and power transmission, add 690kg of lime, add 100kg of fluorite, and add 60kg of carbon powder during power transmission for diffusion and deoxidation;

[0053] ②Power on for 8 minutes, power off, blow argon at the bottom of the large ladle, s...

Embodiment 2

[0060] (1) Converter smelting

[0061] ① Loading 40 tons of scrap steel, 121 tons of molten iron, and a total of 161 tons of molten iron. The composition of molten iron into the furnace is Si: 0.28%, S: 0.067%, and temperature T: 1319 °C; desulfurization process;

[0062] ② The top-bottom re-blowing mode is adopted, the amount of lime added: 5950kg, the tapping temperature: 1645℃, and the tapping volume is 150 tons.

[0063] (2) After furnace and argon station treatment

[0064] After the furnace alloying operation, the total bottom blowing time is 5min, and the sampling at the argon station is C: 0.217%, Si: 0.29%, Mn: 1.39%, P: 0.035%, S: 0.062%, V: 0.023%.

[0065] (3) LF refining

[0066] ①Add slag-forming material before refining and power transmission, add 800kg of lime, add 150kg of fluorite, and add 60kg of calcium carbide during power transmission for diffusion and deoxidation;

[0067] ②Power on for 8 minutes, power off, blow argon at the bottom of the ladle, sti...

Embodiment 3

[0074] converter smelting

[0075] ① Loading 42 tons of scrap steel, 121 tons of molten iron, and a total of 163 tons of molten iron. The composition of molten iron into the furnace is Si: 0.42%, S: 0.036%, and the temperature is T: 1363 °C; the scrap contains iron castings, and the molten steel in the sampling furnace is S : 0.076%, it is determined that the refining and desulfurization process is adopted in the next step;

[0076] ② The top and bottom re-blowing mode is adopted, the amount of lime added: 5600kg, the tapping temperature: 1650 ℃, and the tapping amount is 150 tons.

[0077] (2) After furnace and argon station treatment

[0078] Alloying operation after the furnace, the total time of bottom blowing is 4min, and the sampling at the argon station is C: 0.211%, Si: 0.30%, Mn: 1.36%, P: 0.037%, S: 0.075%, V: 0.023%.

[0079] (3) LF refining

[0080] ①Add slag-forming material before refining and power transmission, add 1100kg of lime, add 200kg of fluorite, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com