Method for reclaiming coal gas of converter through guidance of mathematical model

A converter gas and mathematical model technology, which is applied in the field of metallurgical steelmaking, can solve the problems that it takes 4 hours to complete, and the accurate data of the calorific value of converter gas cannot be obtained, so as to achieve the effect of ensuring the smooth production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

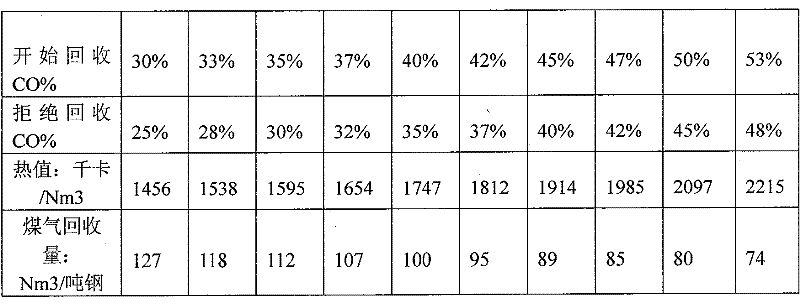

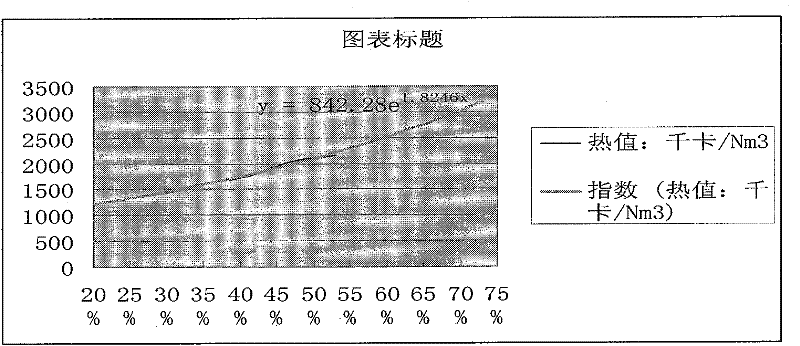

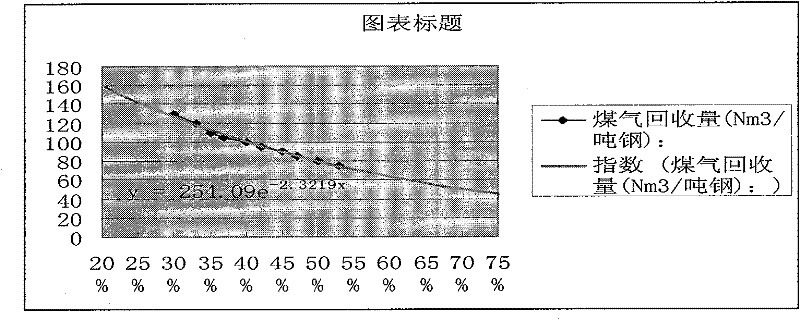

[0031] Example 1: Converter gas is supplied to power plant boiler users, and the CO content X is set to be 25% when the converter gas starts to recover, and the CO content X when the converter gas refuses to be recovered 1 is 20%, according to the formula Y 1 =842.28e 1.8246X and Y 2 =254.09e -2.3219X It is obtained that the calorific value of converter gas under this condition is 1329 kcal / Nm 3 , converter gas recovery is 142Nm 3 / t Steel.

Embodiment 2

[0032] Embodiment 2: The converter gas is supplied to the user of the hot rolling heating furnace, and the CO content X is set to be 75% when the converter gas starts to be recovered, and the CO content X1 is 70% when the converter gas refuses to be recovered, according to the formula Y 1 =842.28e 1.8246X and Y 2 =254.09e -2.3219X It is obtained that the calorific value of converter gas under this condition is 3309 kcal / Nm 3 , converter gas recovery is 44Nm 3 / t Steel.

Embodiment 3

[0033] Example 3: Converter gas is supplied to steelmaking bakery users, and the CO content X is set to 42% when the converter gas starts to be recovered, and the CO content X when the converter gas refuses to be recovered 1 is 37%, according to the formula Y 1 =842.28e 1.8246X and Y 2 =254.09e -2.3219X It is concluded that the calorific value of converter gas under this condition is 1812 kcal / Nm 3, converter gas recovery is 95Nm 3 / t Steel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com