Automatic oiling device for conveying chains of transverse moving rack

An automatic refueling and conveying chain technology, which is applied to transmission parts, escalators, transportation and packaging, etc., can solve the problems of large plate conveying chain, oil pollution on the lower surface of the steel plate, oil dripping and waste, etc., to improve friction conditions, Effect of reducing downtime and preventing fatigue fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

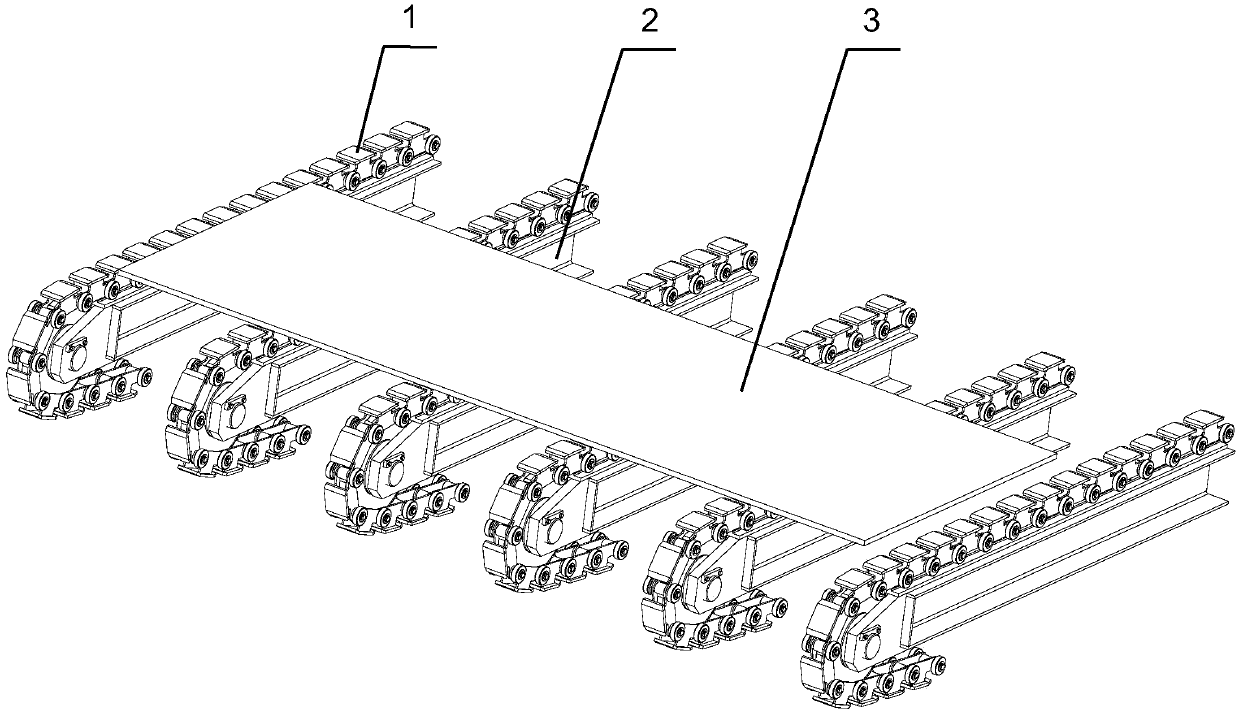

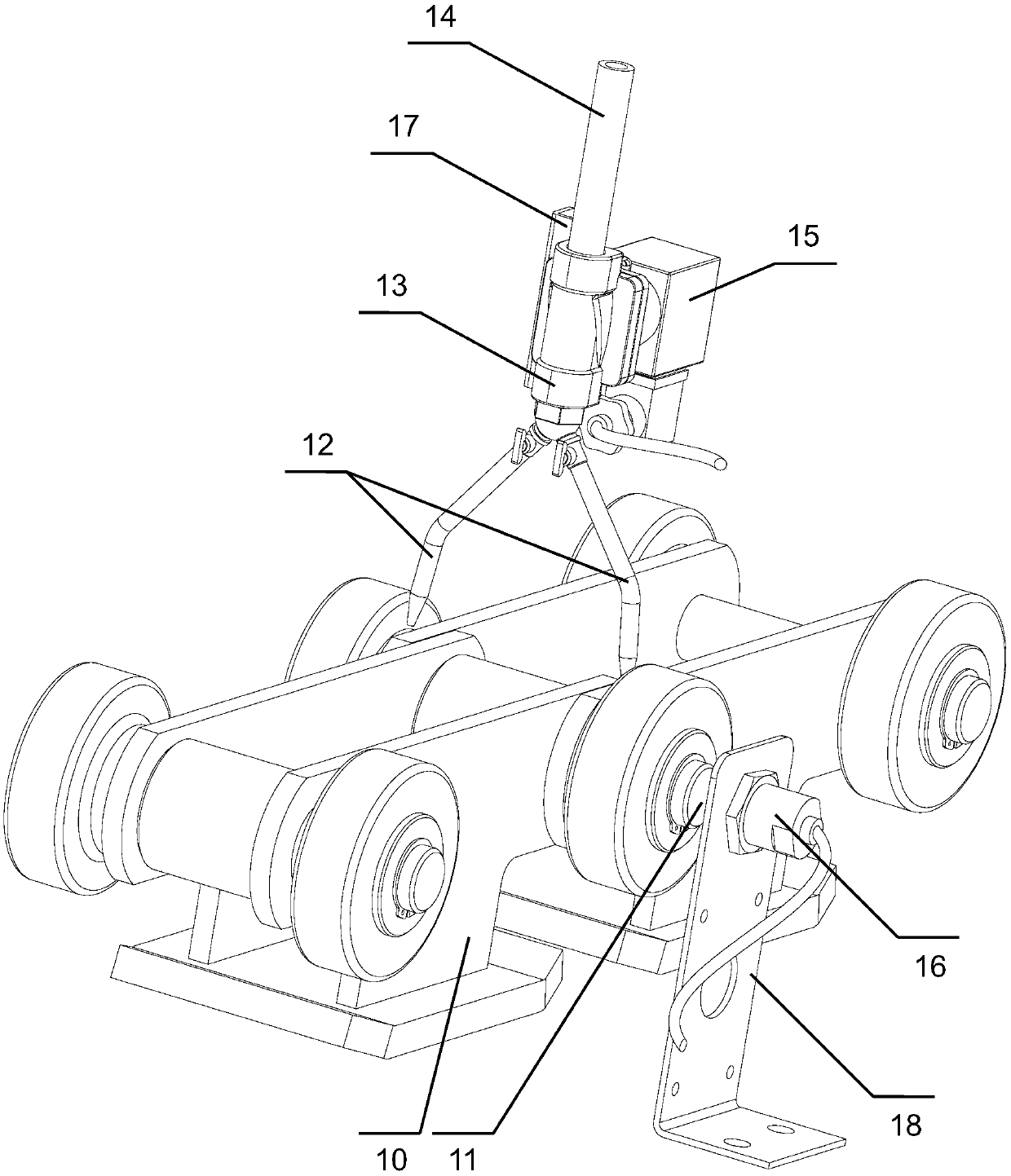

[0022] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

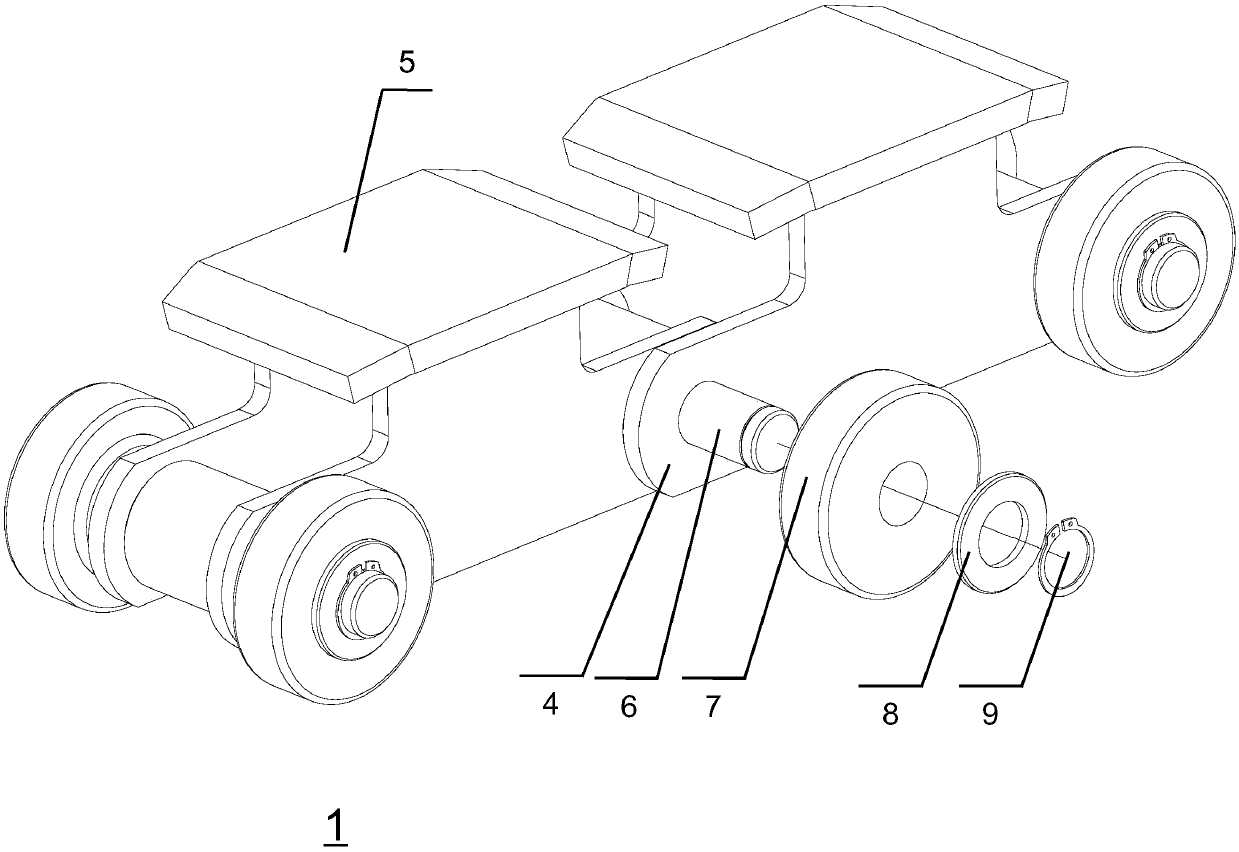

[0023] Please combine image 3 As shown, an automatic refueling device for a conveyor chain of a traversing platform provided by the present invention is provided on the tensioning sprocket fixing bracket of each conveyor chain, and the conveyor chain includes: a side chain plate 10, and is installed on The advantage of installing the roller shafts 11 on both sides of the side chain plate 10 at this position is that during the operation of the conveyor chain, the relative position of each chain is basically fixed, which is more suitable for the automatic oiling device of the present invention. . The automatic refueling device of the present invention comprises: several refueling mechanisms, and an electrical mechanism connected with the several refueling mechanisms, and the electric mechanism is used to control the several re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com