Control Method of Interlocking Protection of Pinch Roller

A technology of interlocking protection and control methods, which is applied in the direction of rolling mill control devices, roll safety equipment, manufacturing tools, etc., can solve problems such as pinch roll mismatch, equipment damage, etc., to ensure smooth production and eliminate collisions risk effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

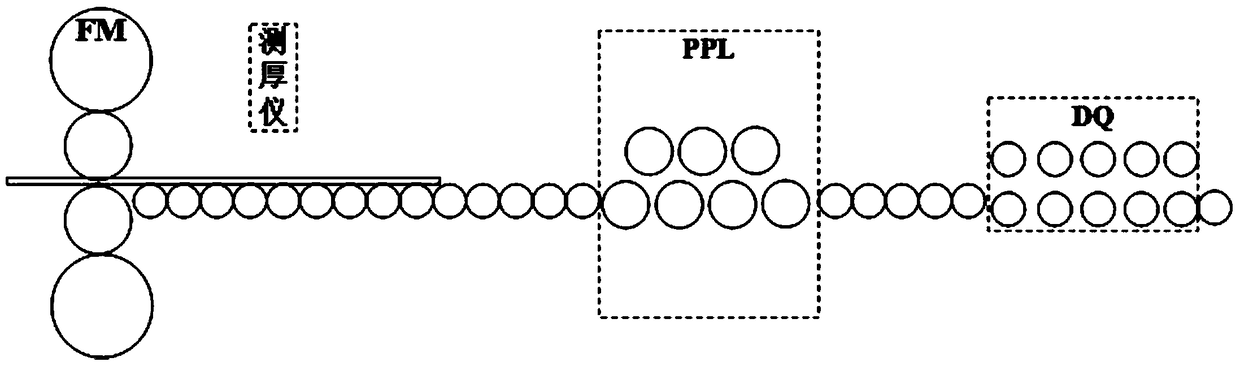

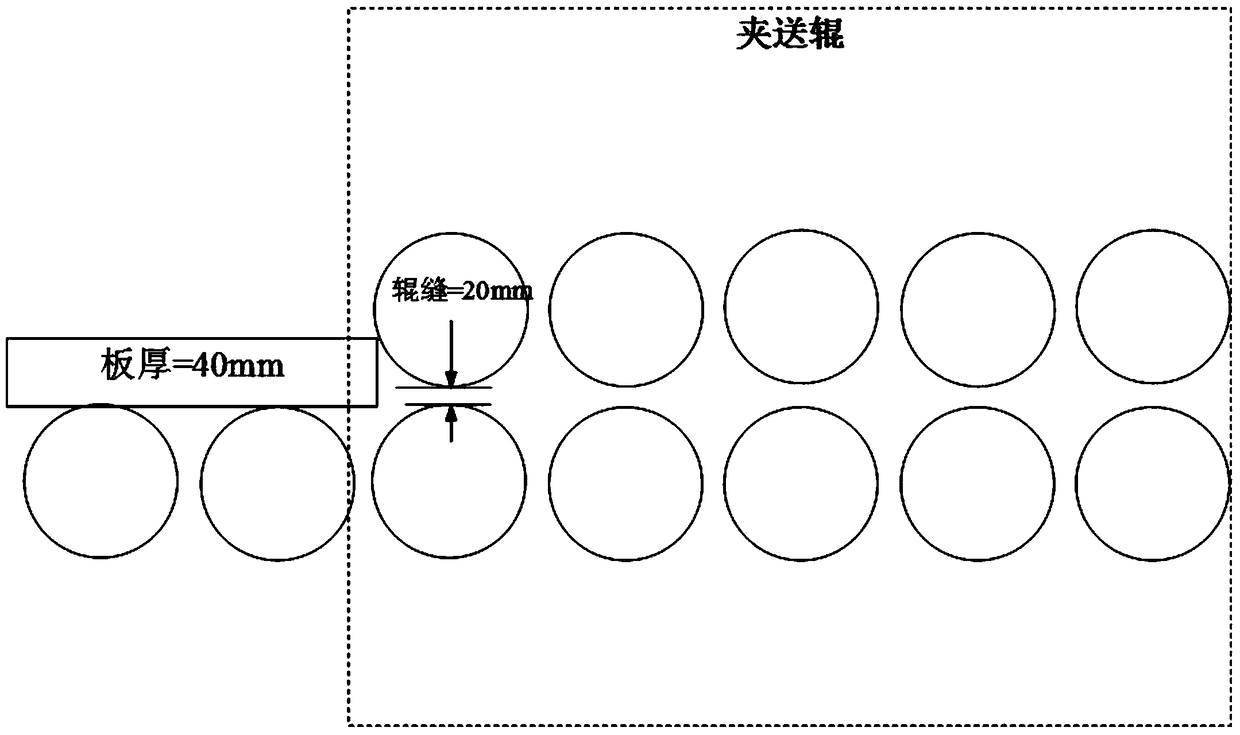

[0018] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0019] The invention discloses a control method for interlocking protection of pinch rollers. The main idea is to combine the existing automatic mode operation process and manual mode operation process to judge the occurrence of abnormal conditions in the respective modes and perform further control.

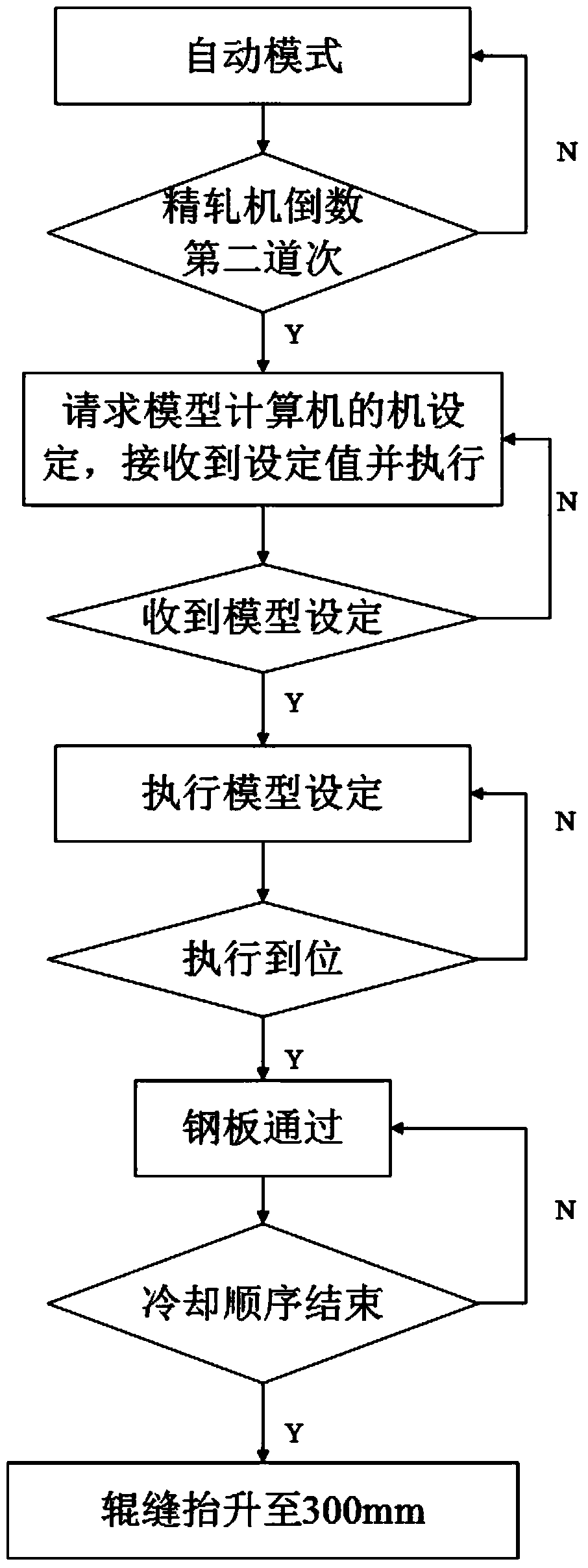

[0020] refer to Figure 5 , the present invention mainly comprises the following steps:

[0021] Step S1: Turn on the automatic mode.

[0022] Step S2: Judging whether the finishing mill has progressed to the penultimate pass, if yes, then go to step S3, if not, go back to step S1.

[0023] Step S3: Request the machine setting of the model computer, receive the steel plate information and the setting value of the upper computer, and execute the setting of the upper computer.

[0024] Step S4: Determine whether the model setti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com