Integral engine turbine blade mounting and dismounting device and method

A turbine blade, the overall installation technology, applied in the direction of the workpiece clamping device, metal processing, metal processing equipment, etc., can solve the problems of high labor intensity of the operator, easy damage to the turbine disc and blade tenon, time-consuming and other problems, to ensure the installation Improve the quality of disassembly, improve the efficiency of installation and disassembly, and avoid damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

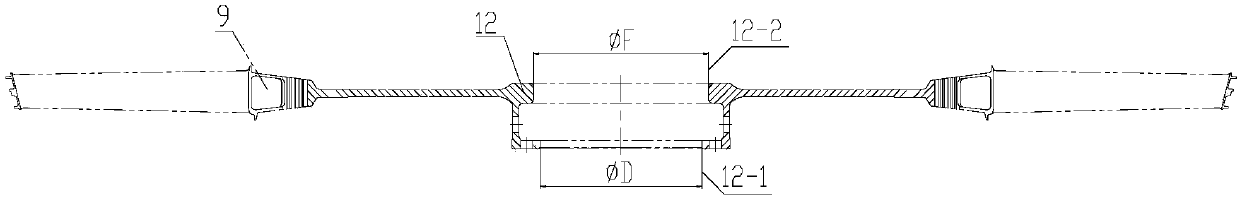

[0046] The engine turbine blade integral installation and removal device in this embodiment is used for installation and removal figure 1 The turbine blades and turbine discs of the engine are shown, and the number of turbine blades in the entire circle is 84.

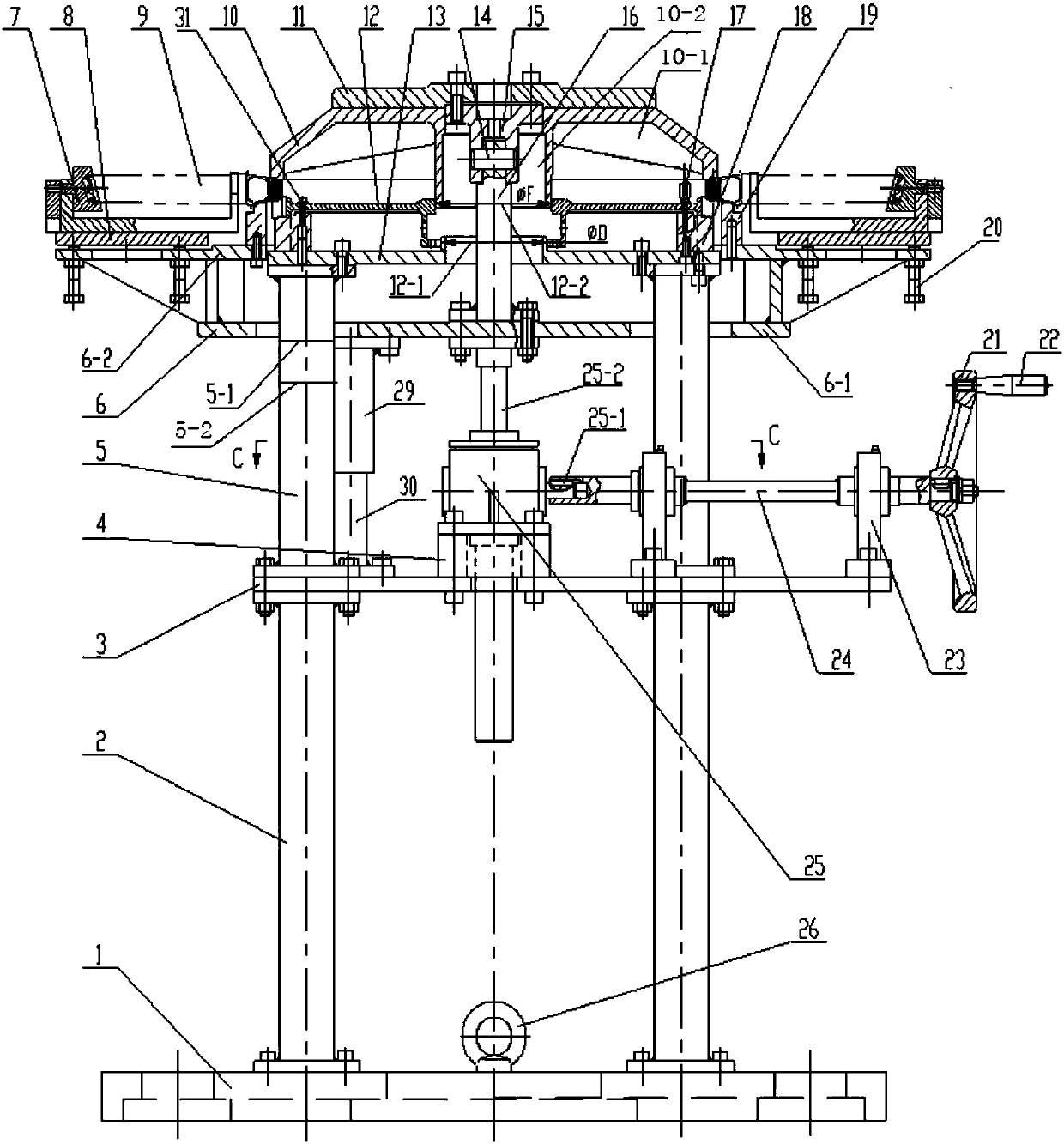

[0047] In this embodiment, the structure of the engine turbine blade overall installation and removal device is as follows: figure 2 As shown, it includes a base 1, a lower column 2, an upper column 5, an elevator 25, an elevator driving assembly, an elevator mounting plate 3, an elevator frame 6, an elevator frame guide rod 30, an elevator frame guide sleeve 29, a pull rod 16, a pull plate 11, Adapter 15 , positioning plate 13 , turbine disc support ring 18 , blade support ring 19 , assembly gland 10 and disassembly gland 27 .

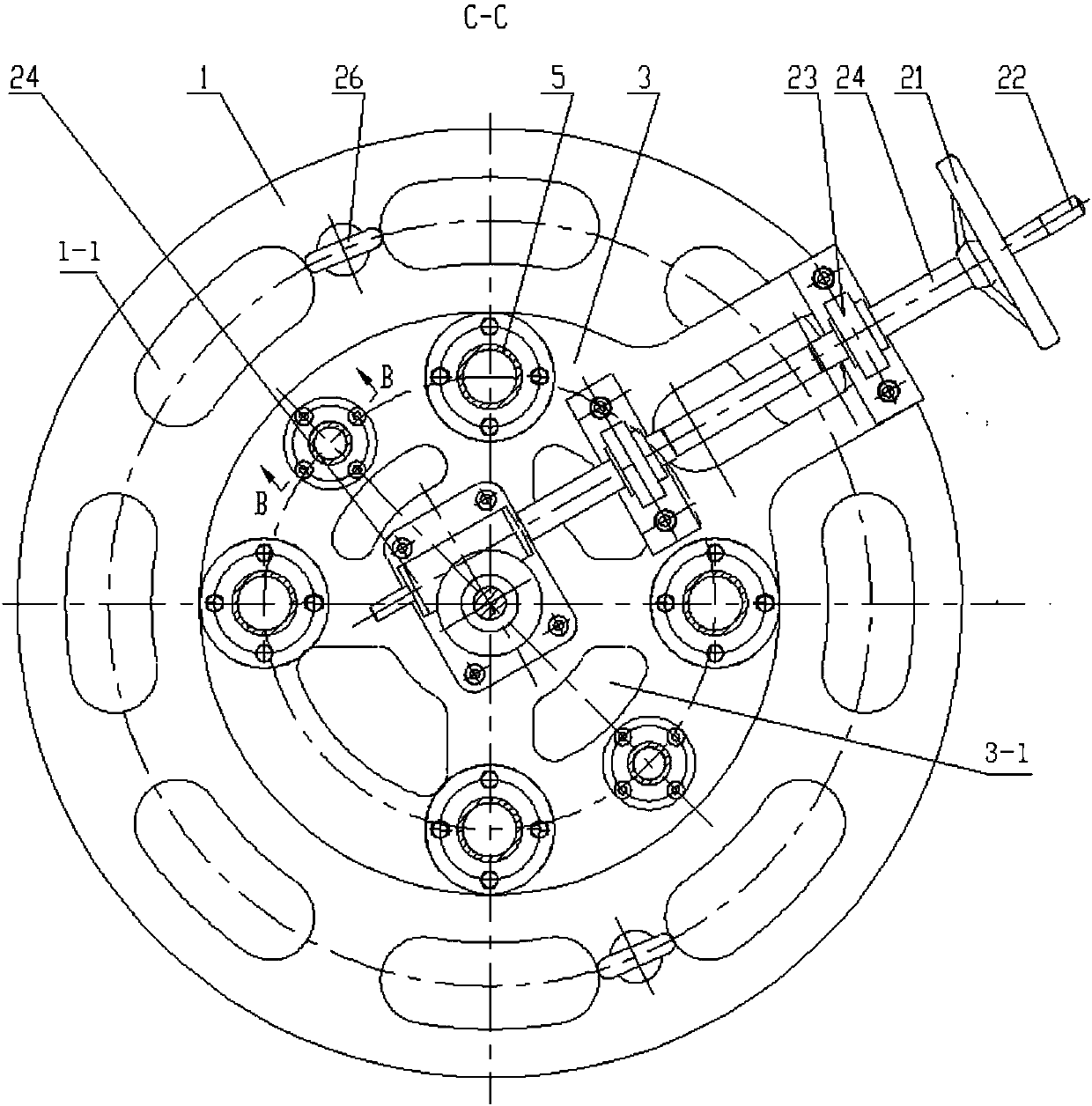

[0048] The base 1 is processed from a steel plate, such as figure 2 , image 3 As shown, the base is provided with a weight-reducing hole 1-1 and two suspension rings 26 are installed, th...

Embodiment 2

[0060] This embodiment uses the overall installation and removal device of the engine turbine blade described in Embodiment 1 and the clamp 7 for clamping the free end of the blade and the pair of backing plates 8 for placing the clamp. figure 1 The turbine blades of the engine shown are installed and removed. The fixture 7 is as Figure 17 As shown, it is composed of a support 7-1, a clamp 7-2 and a side plate 7-3. The clamp 7-2 is provided with a groove combined with the free end of the turbine blade and a combination of the support and the side plate. The stepped pin shaft is installed on the support and connected to the side plate through the stepped pin shaft. The backing plate 8 consists of Figure 15 , Figure 16 The shown four arc-shaped plates with a central angle of 90° are provided with lightening holes 8-1 on the arc-shaped plates. The materials of the clamp 7 and the backing plate 8 are medium carbon steel.

[0061] ⅰ Overall installation operation of turbine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com