Automobile gutter channel assembly

A flow tank and assembly technology, which is applied in the direction of upper structure sub-assembly, vehicle parts, upper structure, etc., can solve the problems of failure to effectively ensure the rigidity of the whole vehicle and insufficient connectivity, so as to increase operational visibility and avoid Inadequate gluing, avoiding water accumulation and corrosion of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

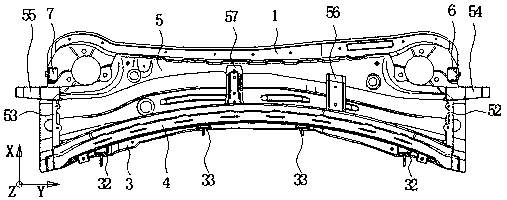

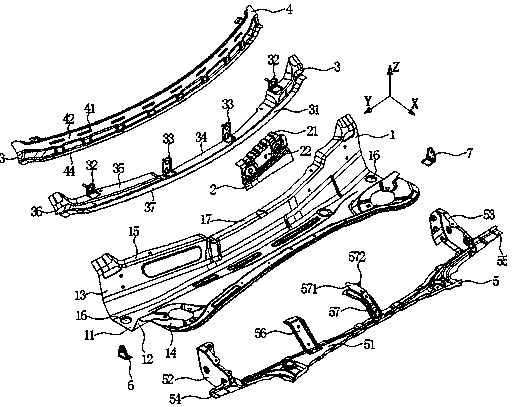

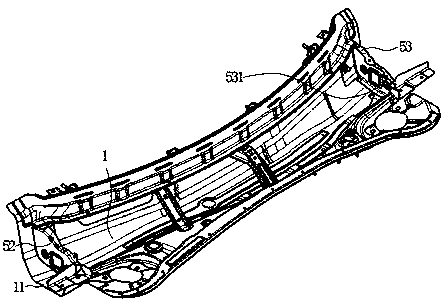

[0037] The XYZ three-axis coordinate system in the accompanying drawings shows the orientation relationship of the accompanying drawings. see figure 1 , figure 2 , the automobile water tank assembly, including the water tank 1, the water tank 1 includes a U-shaped first bending part 13, a bottom plate 11 and a second bending part 12 connected in sequence, and the upper end of the first bending part 13 is connected to There is a first flange portion 15 extending outward from the water tank 1, and the upper end of the second bent portion 12 is connected with a second flange portion 14 extending outward from the water tank 1. The first flange portion 15, the first The bending part 13, the bottom plate 11, the second bending part 12 and the second flange part 14 are integrally formed; the bottom plate 11 is in the shape o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com