Head ladder way and escalator thereof

An escalator and head technology, applied in the directions of escalator, transportation and packaging, can solve the problems of poor rigidity and stability, high installation cost, and easy deviation of the ladder, so as to improve rigidity and stability, simplify structure, reduce The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

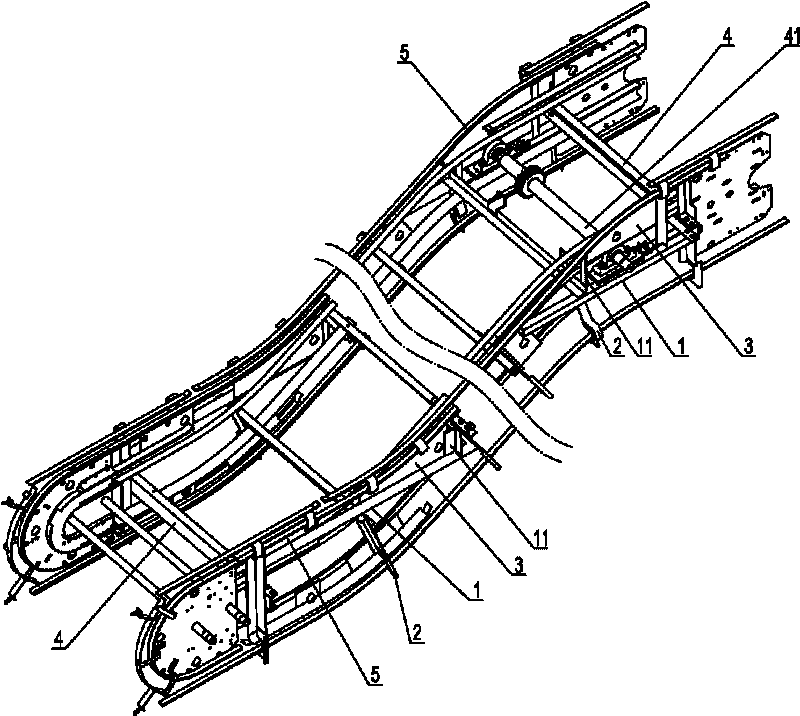

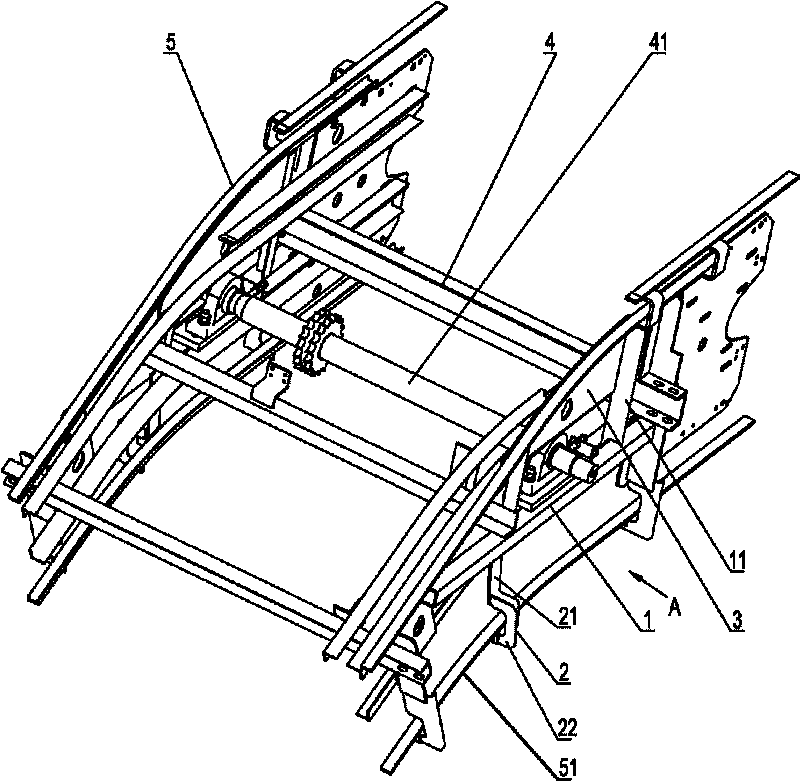

[0031] Example 1: In figure 1 In the shown embodiment, a head ladder of the present invention mainly improves the fixing method of the guide rail in the head ladder of the escalator in the prior art, and replaces the common one in the existing design with a vertical frame 1 The side panels and the vertical frame 1 are welded or bolted by a number of interlaced reinforcing rods 11 . In order to increase the connection points with the guide rail 5 so as to improve the accuracy and stability of the track of the guide rail working surface, the vertical frame 1 is fixedly connected with the connecting rod 2 and the support plate 3, and the guide rails 5 of the head ladder are fixedly welded on the support plate 3 On the connecting rod 2, the vertical frames 1 on the left and right sides are connected by three horizontal beams 4, so that the entire head ladder path is integrated into a large frame, so that it can be easily connected and installed with the truss, so that the head la...

Embodiment 2

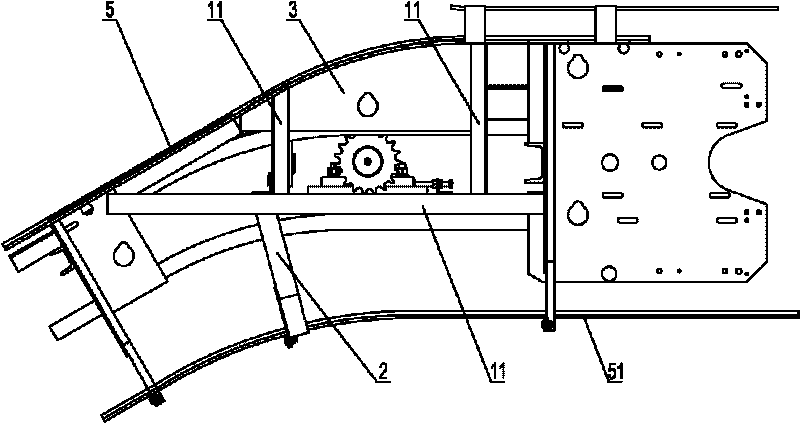

[0033] Embodiment 2: as Figure 10 A kind of escalator shown, comprises truss 73, upper head stairway 71 and lower head stairway 72 connected with truss 73, handrail drive part 41, described upper and lower head stairway 71,72 The structure is the same as the head ladder of the frame structure of Embodiment 1, so the head ladder has good rigidity and stability, and the cross guide rail 6 of the lower head ladder can realize a smooth transition. In particular, because in the entire ladder system of the escalator, the roller wheel pressure of the traction chain on the guide rail arc section of the step traction chain of the upper head ladder road 71 is the largest, the vertical frame 1 of the upper head ladder road An upright reinforcing rod 11 is arranged on both sides of the guide rail arc section of the step traction chain, and the lower end of the upright reinforcing rod 11 is connected with a horizontal reinforcing rod 11 (for details, refer to image 3 ), to effectively i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com