Pressure testing machine for building quality detection

A pressure test and quality technology, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., can solve the effect of affecting the pressure test of building materials, reducing the accuracy of measurement, damage to building materials, etc. problem, to achieve the effect of improving the buffering effect, avoiding waste, and using it safely and conveniently

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

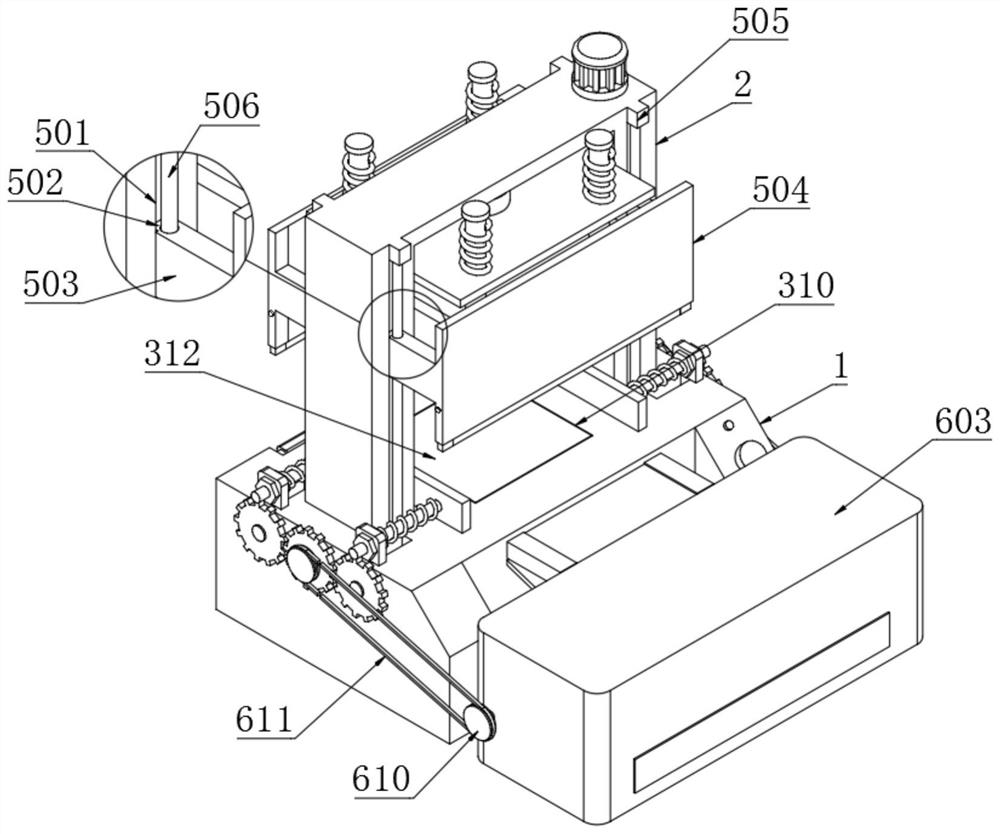

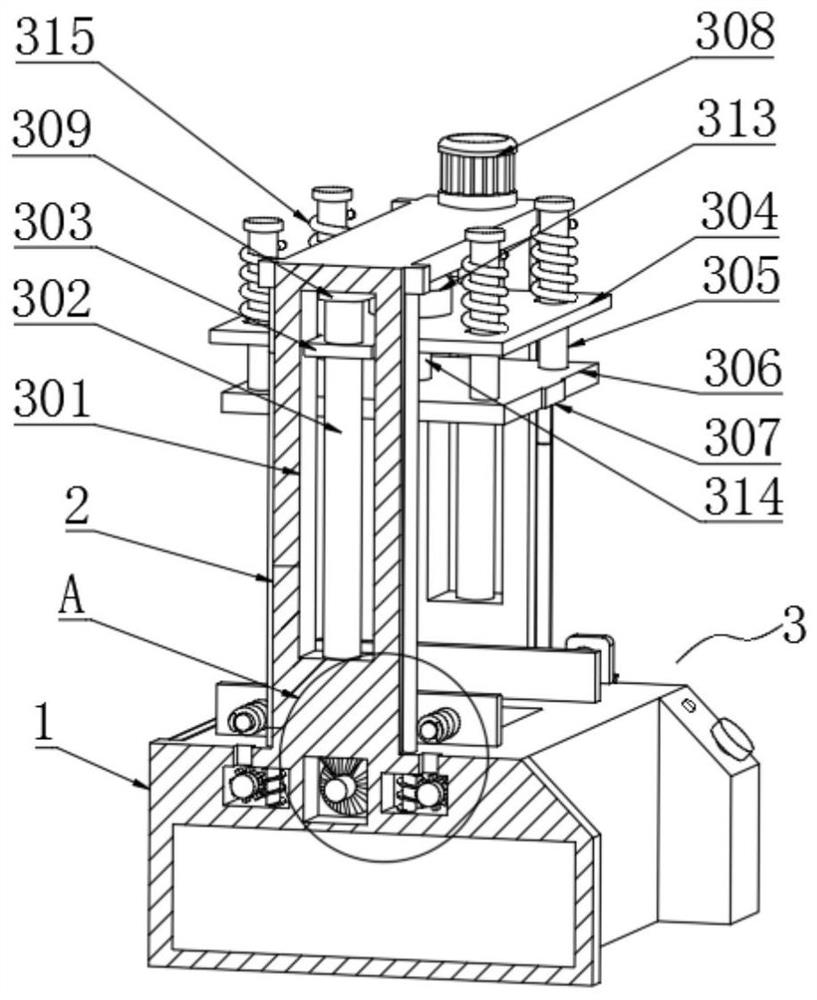

[0049] Example: such as Figure 1-8 As shown, the present invention provides a technical solution, a pressure testing machine for building quality inspection, including a base 1, a gantry 2 is symmetrically fixedly connected to the top of the base 1, and a pressure measuring and buffering mechanism 3 is movably connected inside the gantry 2;

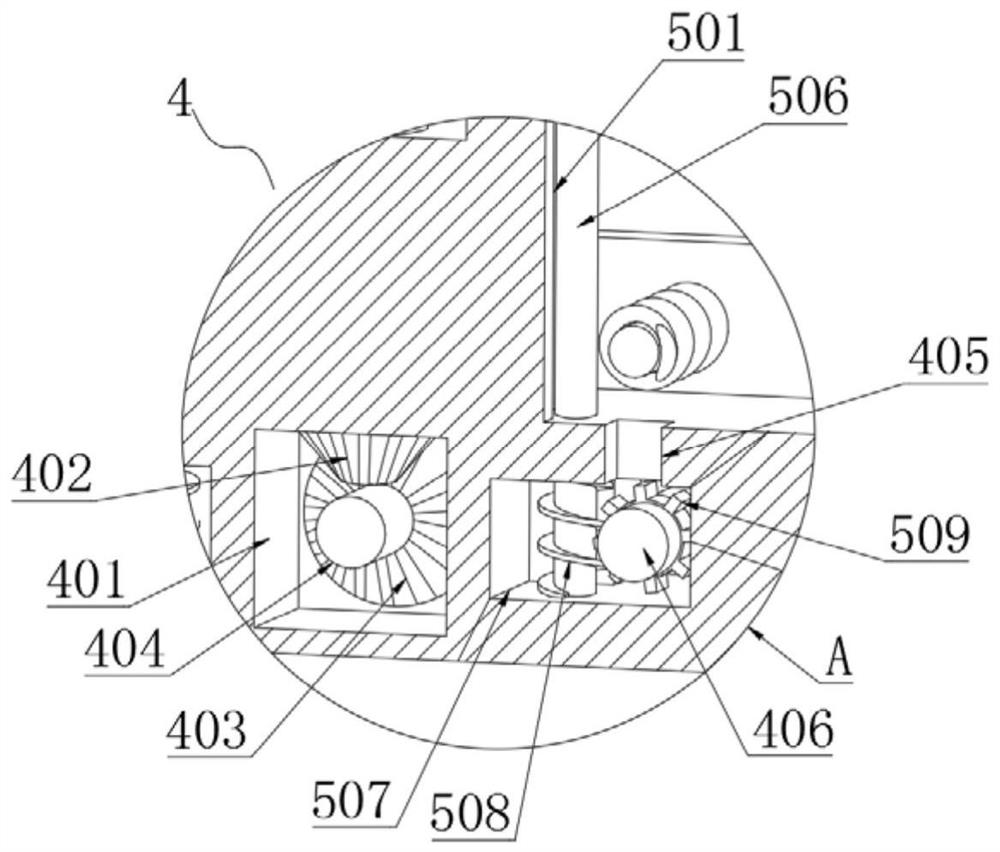

[0050] Power transmission and clamping and fixing mechanisms 4 are installed at positions corresponding to both sides of the gantry 2 inside the base 1;

[0051] One end of the base 1 is fixedly connected with a material recovery and crushing mechanism 6;

[0052] The pressure measurement and buffer mechanism 3 includes a groove 301, a screw rod 302, a lifting block 303, a movable plate 304, a buffer rod 305, a pressure plate 306, a pressure indicator 307, a driving motor 308, a first belt 309, a buffer groove 310, and a support spring 311, bearing plate 312, cylinder 313, piston rod 314 and buffer spring 315;

[0053] The inner wall o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com