Capacitor module

A capacitor and electrical connection technology, which is applied in the field of capacitor modules, can solve problems such as increased heat generation, and achieve the effect of improving adhesion and improving electrical insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the drawings. In addition, this invention is not limited by this embodiment.

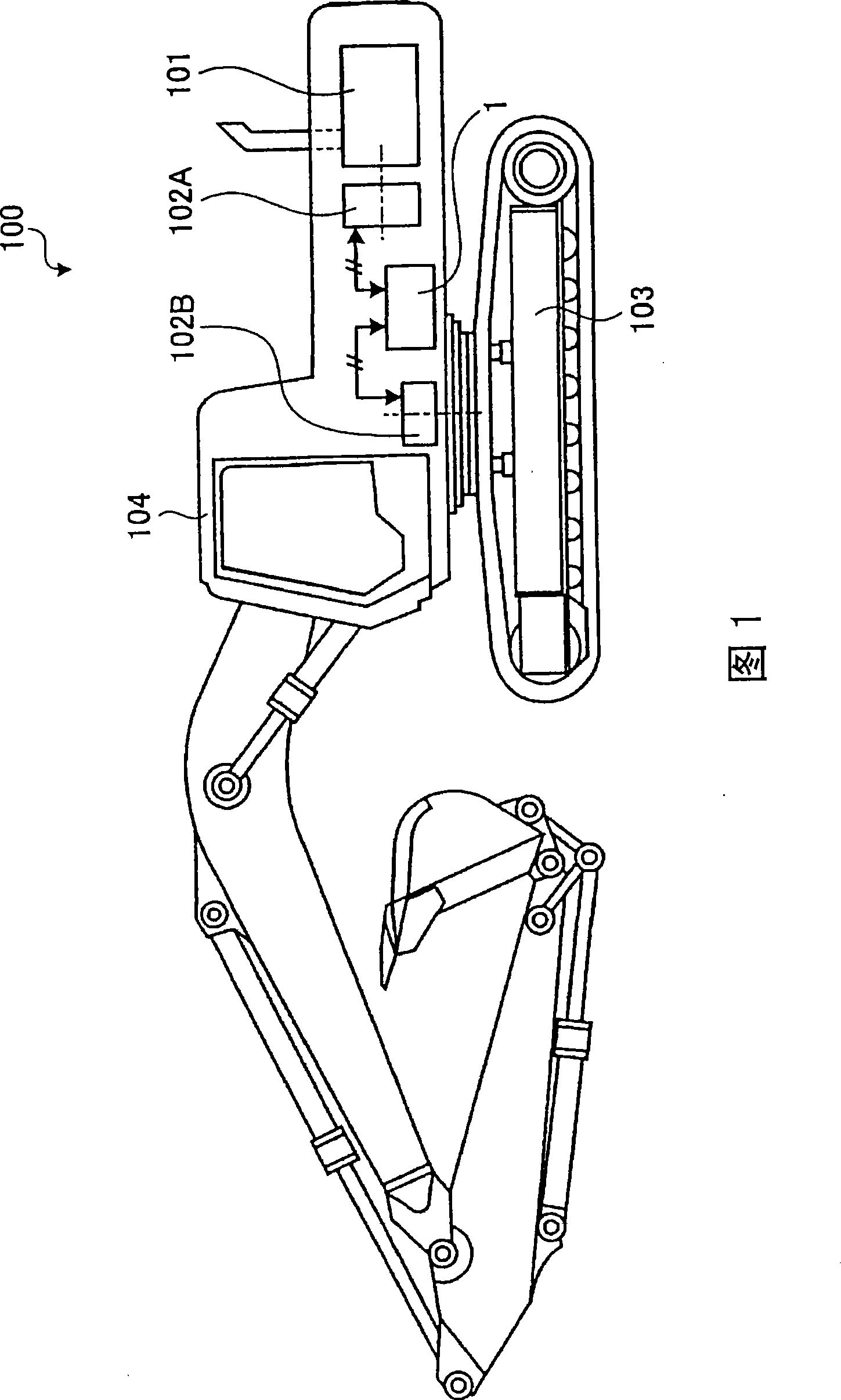

[0052] FIG. 1 is a schematic diagram showing an example of a construction machine to which the present invention is applied. Here, hydraulic excavator 100 is mentioned as an example as a construction machine. In this hydraulic excavator 100 , motors 102A and 102B are used in addition to the engine 101 as a drive system. Specifically, as shown in FIG. 1 , an assist motor 102A and a swing motor 102B are used. The auxiliary motor 102A is directly connected to the output shaft of the engine 101, and is used to assist the engine 101 in the case of immediately performing work when, for example, the rotation speed of the engine 101 is reduced due to an increase in fuel consumption, so as to improve responsiveness to an operator's operation. . The turning motor 102B is provided in the turning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com