Test engine and test method for combustion of double-base system propellant in different overload directions

A dual-base propellant and engine technology, which is applied in the direction of machines/engines, rocket engine devices, jet propulsion devices, etc., can solve the problems of affecting charge combustion, abnormal internal ballistic performance, and great influence on propellant burning speed, etc. , to achieve the effect of improving safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

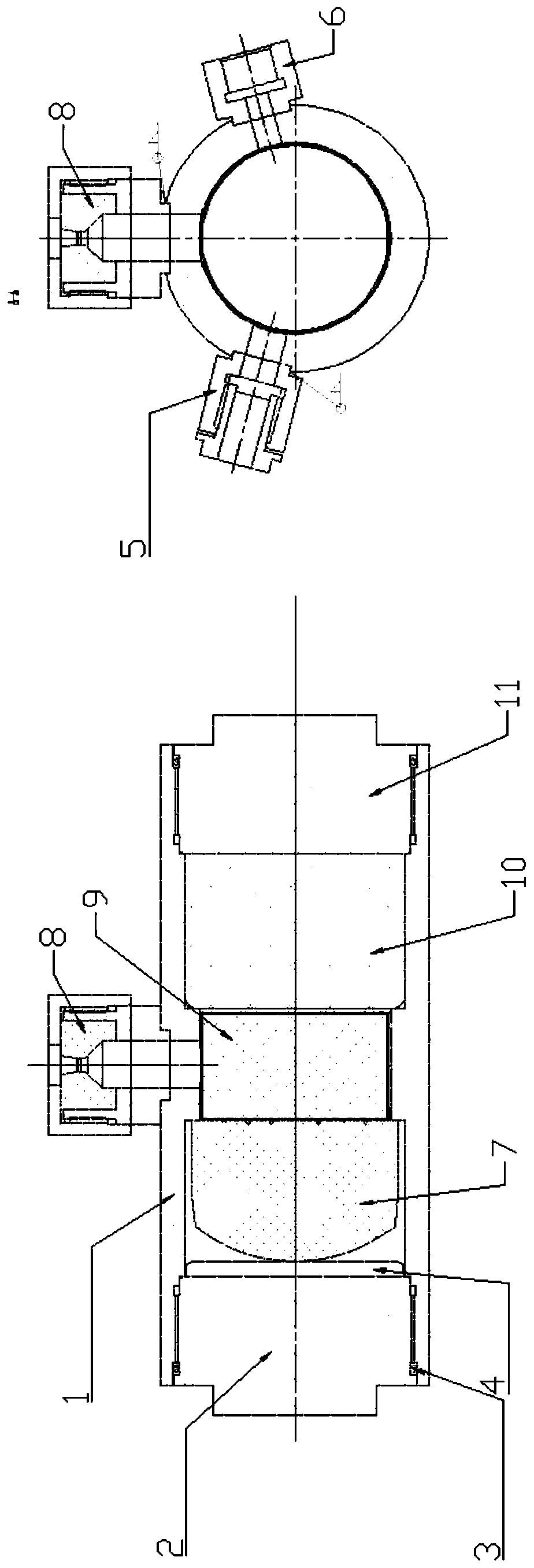

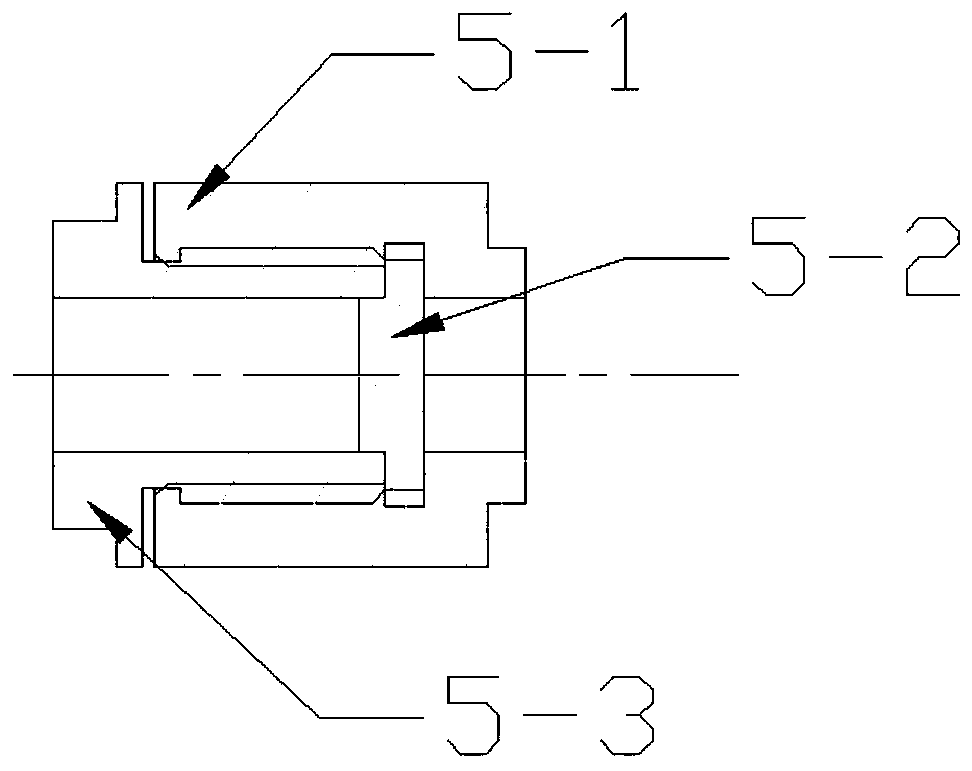

[0040] Investigation of overload test devices at home and abroad shows that: in order to study the influence of overload angle on its combustion characteristics and internal ballistic performance, by improving the device, the angle between the engine axis and the horizontal line of the test bench can basically be between 0° and 90° , without changing the overload direction, the present invention can realize the internal ballistic performance test of overload combustion at angles of 0° and 180° by designing a symmetrical structure and exchanging the installation direction without making major changes to the device.

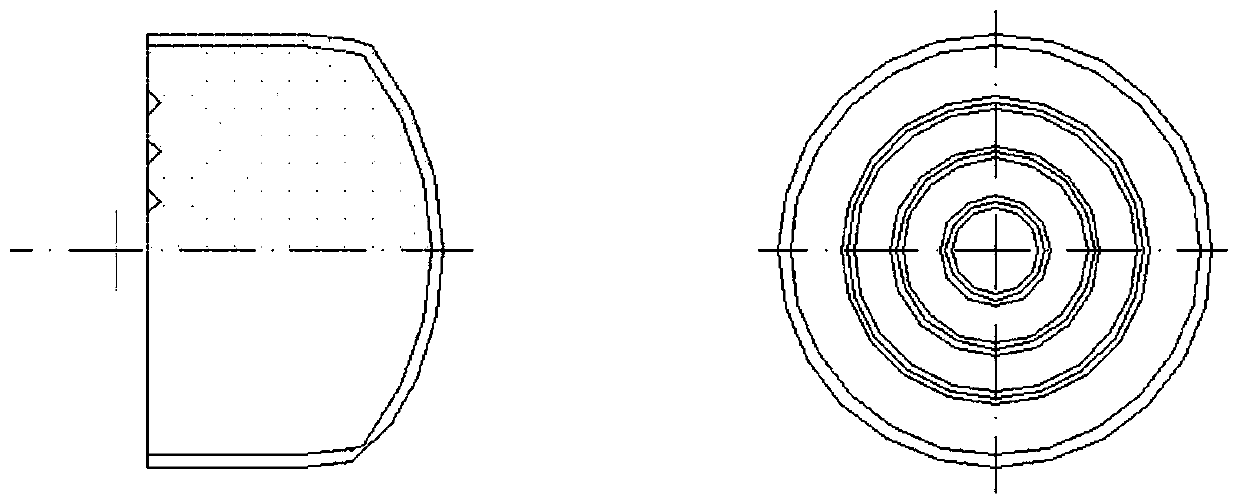

[0041] Such as figure 1As shown, the double-base propellant grain is prepared, the grain is shaped, turned, etc., and coated with EPDM coating technology, and the end-face combustion propellant grain is prepared, which passes the non-destructive testing techniques such as CT and DR. The charge has no defect or debonding, and the propellant charge meeting the requir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure endurance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com