Self-propelled track installation system for profiled frame glass curtain walls

A technology of glass curtain wall and installation system, which is applied in the processing of walls and building materials, scaffolding supported by building structures, etc., and can solve problems such as the inability to use external scaffolding and hanging baskets for construction, numerous civil construction projects, difficulties in transportation and installation, etc. , to achieve the effect of shortening the construction period, saving installation time and reducing transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

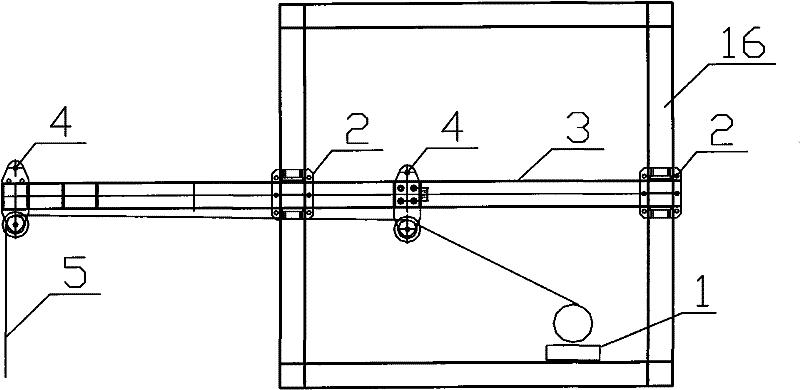

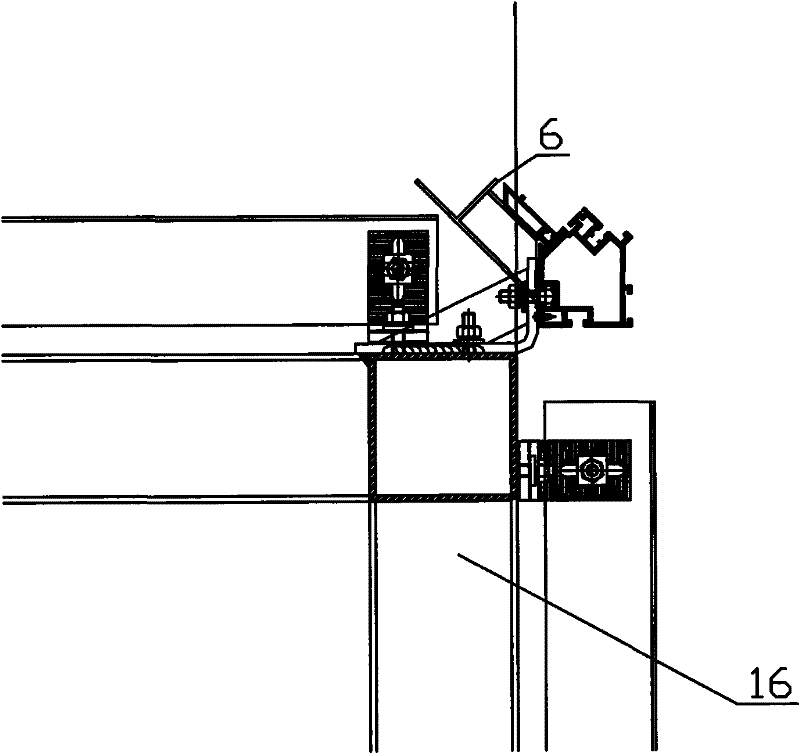

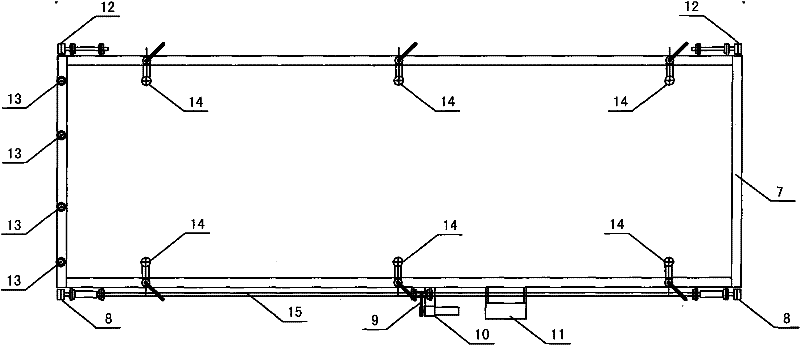

[0018] The following figures further illustrate the present invention in conjunction with the accompanying drawings, figure 1 , 2 In 3, the self-propelled track installation system for the special-shaped frame glass curtain wall includes a special-shaped frame pipe truss 16, which is composed of a lifting device, a track device, and a self-propelled glass installation vehicle. The track device includes two parallel tracks 6, the track The two ends of 6 are respectively connected to the special-shaped frame pipe truss 16, the lifting device is installed on the special-shaped frame pipe truss, and the self-propelled glass installation vehicle slides through the driven wheel 12 on the frame, the driving wheel 8 and the two parallel rails 6 touch.

[0019] The hoisting device is composed of a winch 1, a fixed frame 2, a pole boom 3, a fixed pulley 4, and a steel wire rope 5. The pole boom 3 is fixedly connected to the pipe truss through the fixture 2, and the hoist 1 is installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com