Automatic window and railway passenger car with the same structure

A technology of automatic windows and movable sash, which is applied to railway car body parts, power control mechanisms, window devices, etc. It can solve the problems of low automation level and high labor intensity, so as to improve automation level, reduce labor intensity, and improve transmission operation. smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

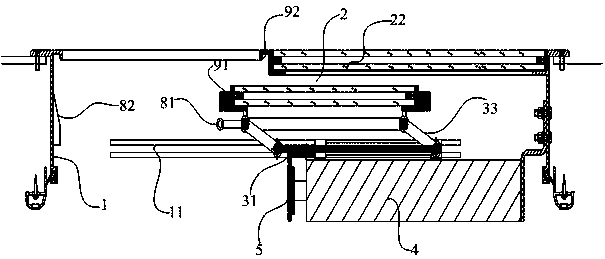

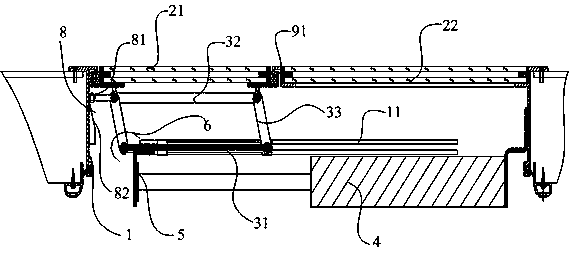

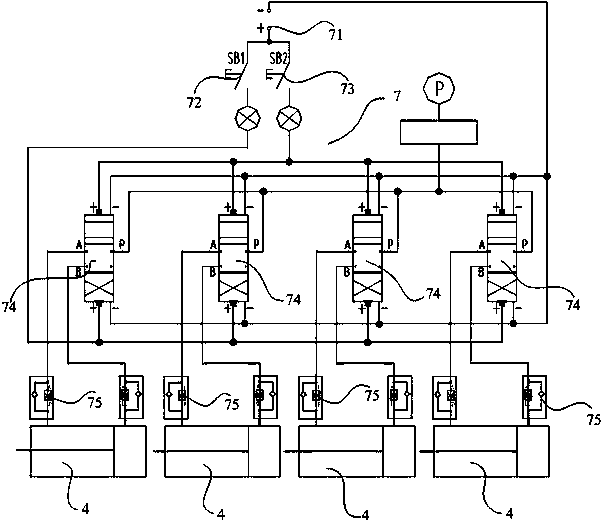

[0020] The technical solution of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. The present invention proposes an embodiment of an automatic vehicle window. Figure 1-Figure 3 As shown, specifically, the automatic vehicle window is an inner plug-type single-leaf sliding door structure as a whole, and the automatic vehicle window includes a window frame 1 , a window sash 2 , a transmission mechanism 3 and a retractable driver 4 . Specifically, the window sash 2 mainly includes two parts: a movable sash 21 and a fixed sash 22. The movable sash 21 can be pushed and pulled back and forth driven by the driving member 4 and the transmission mechanism 3 to realize the closing of the vehicle window. The fixed sash 22 is fixedly installed on the window frame 1, and can cooperate with the movable sash 21 to realize the sealing and closing of the entire vehicle window when the movable sash 21 is close...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com