Supporting and driving device for rotating bodies in sterilization kettle

A transmission device and internal rotation technology, applied in food science, food preservation, application, etc., can solve the problems of difficulty in maintenance and replacement of parts, unbalanced axial force of the rotating body, large transmission torque, etc., and achieve easy maintenance and replacement of parts , The transmission structure is novel and simple, and the equipment has a long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

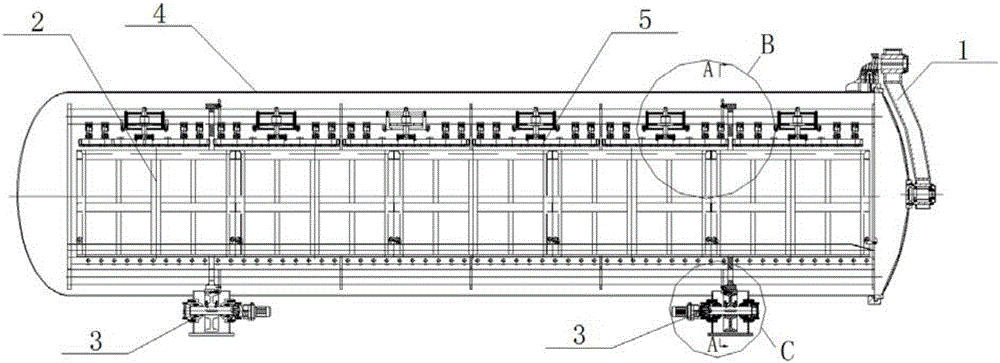

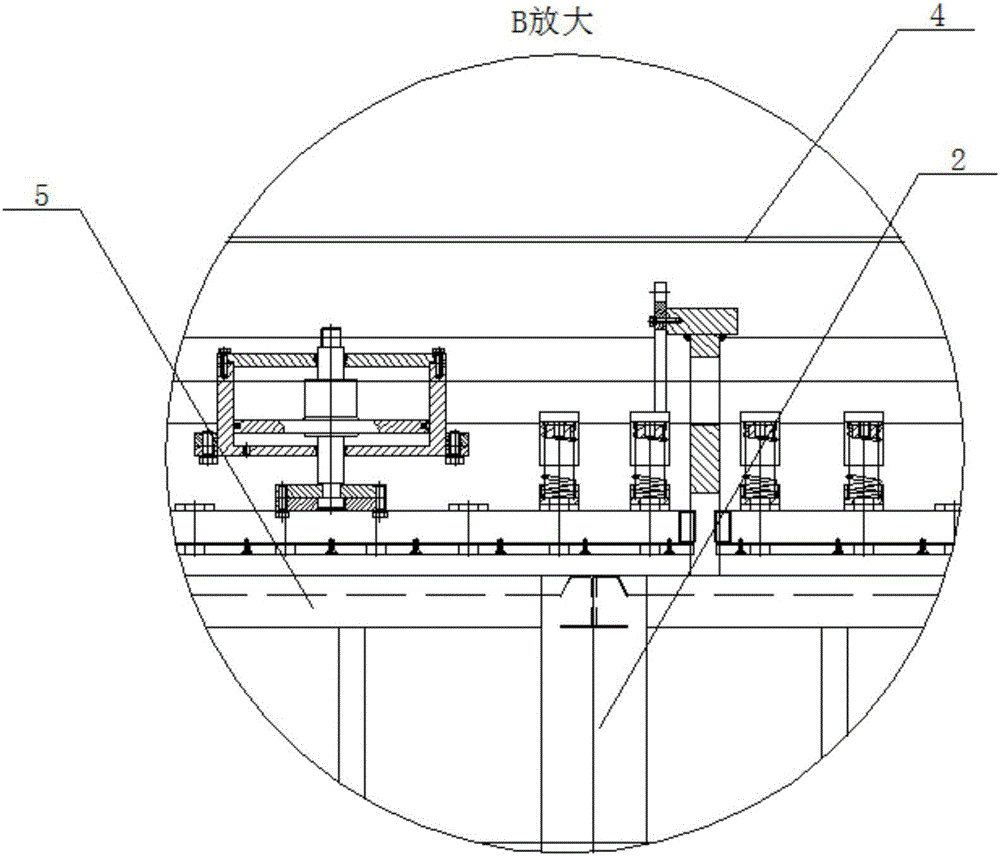

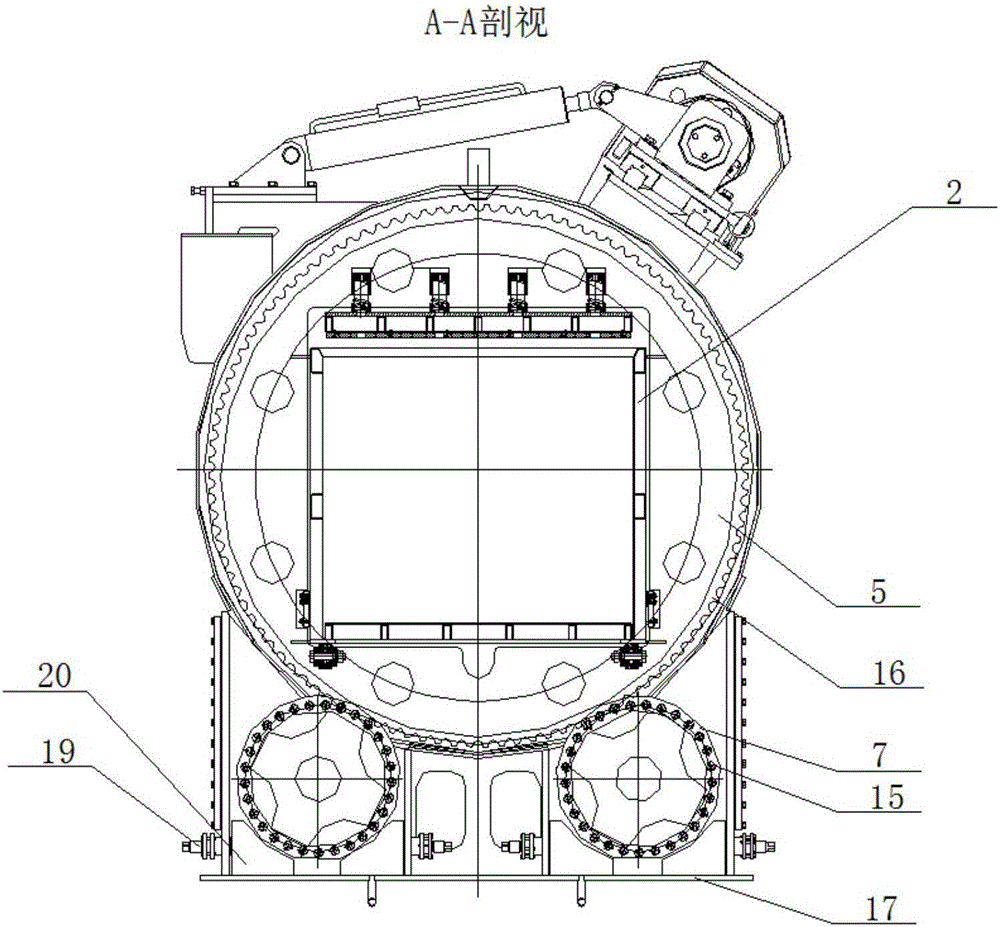

[0018] see Figure 1-4 As shown, the technical solution adopted in this specific embodiment is: it includes a quick door opening device 1, a cage basket 2, a saddle device 3, a cylinder body 4, and a rotating body 5, and the quick door opening device 1 is arranged on one side of the cylinder body 4, The other side of the cylinder 4 is airtight, the rotating body 5 is arranged inside the cylinder 4, and the basket 2 is arranged inside the cylinder 4, and two saddle devices 3 pass through the cylinder 4 and are arranged below the both sides of the cylinder 4.

[0019] The saddle device 3 includes a rotating body supporting wheel 6, several driving wheels 7, a mechanical seal fixing seat 8, a mechanical seal 9, a transmission shaft 10, a bearing 11, a key 12, a reducer motor 13, an end cover 14, a pin Shaft 15, pin wheel 16, saddle body 17, bearing seat 18, main wheel support block 19, support block adjustment screw 20, saddle body 17 and cylindrical body 4 are connected by weldi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com