Patents

Literature

61 results about "Product design specification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A product design specification (PDS) is a statement of how a design is made (specify the design), what it is intended to do, and how far it complies with the requirements. Requirements may be gathered in the Product Requirement Specification (PRS). Its aim is to ensure that the subsequent design and development of a product meets the needs (or requirements) of the user. Product design specification is one of the elements of product lifecycle management.

Analytical Software Design System

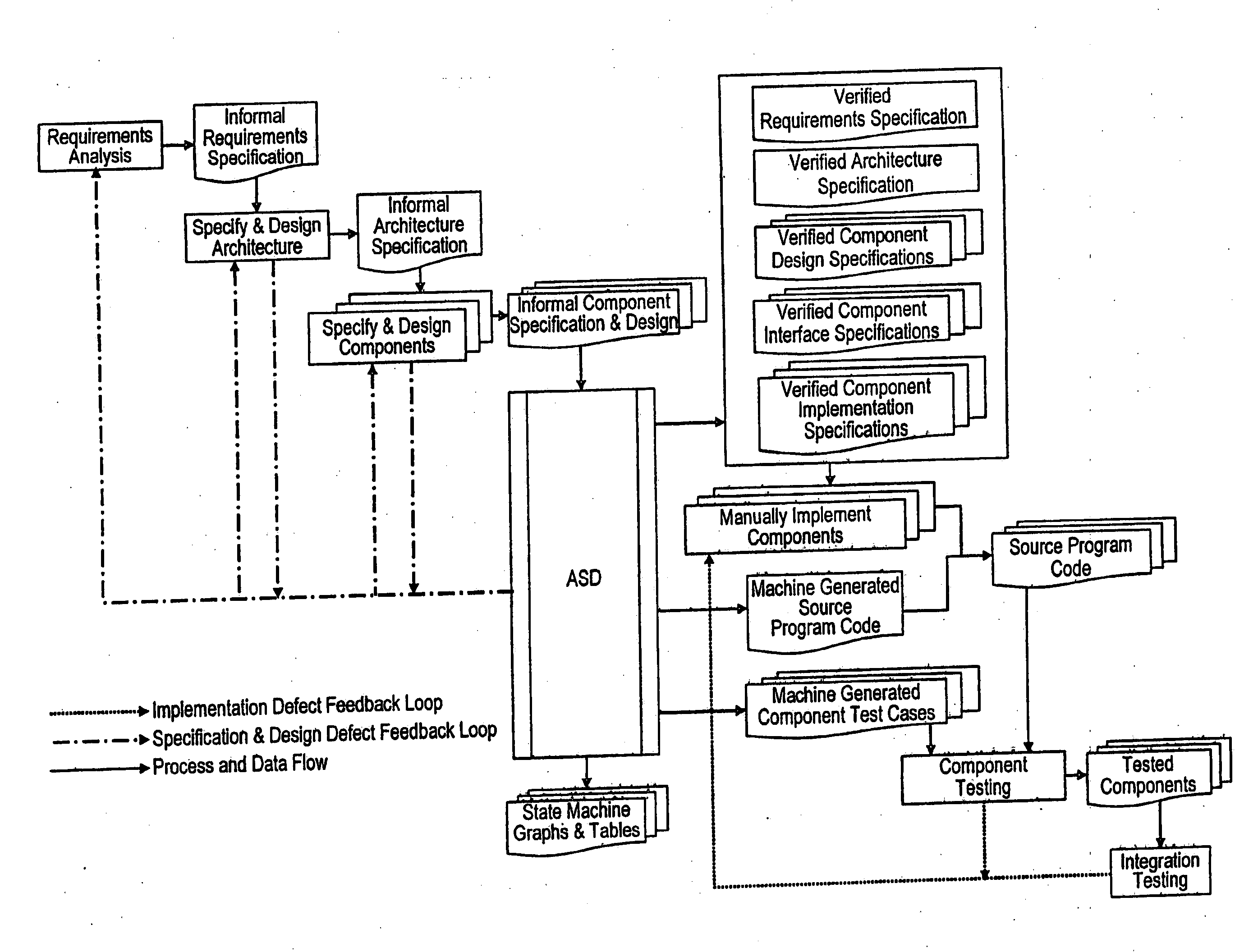

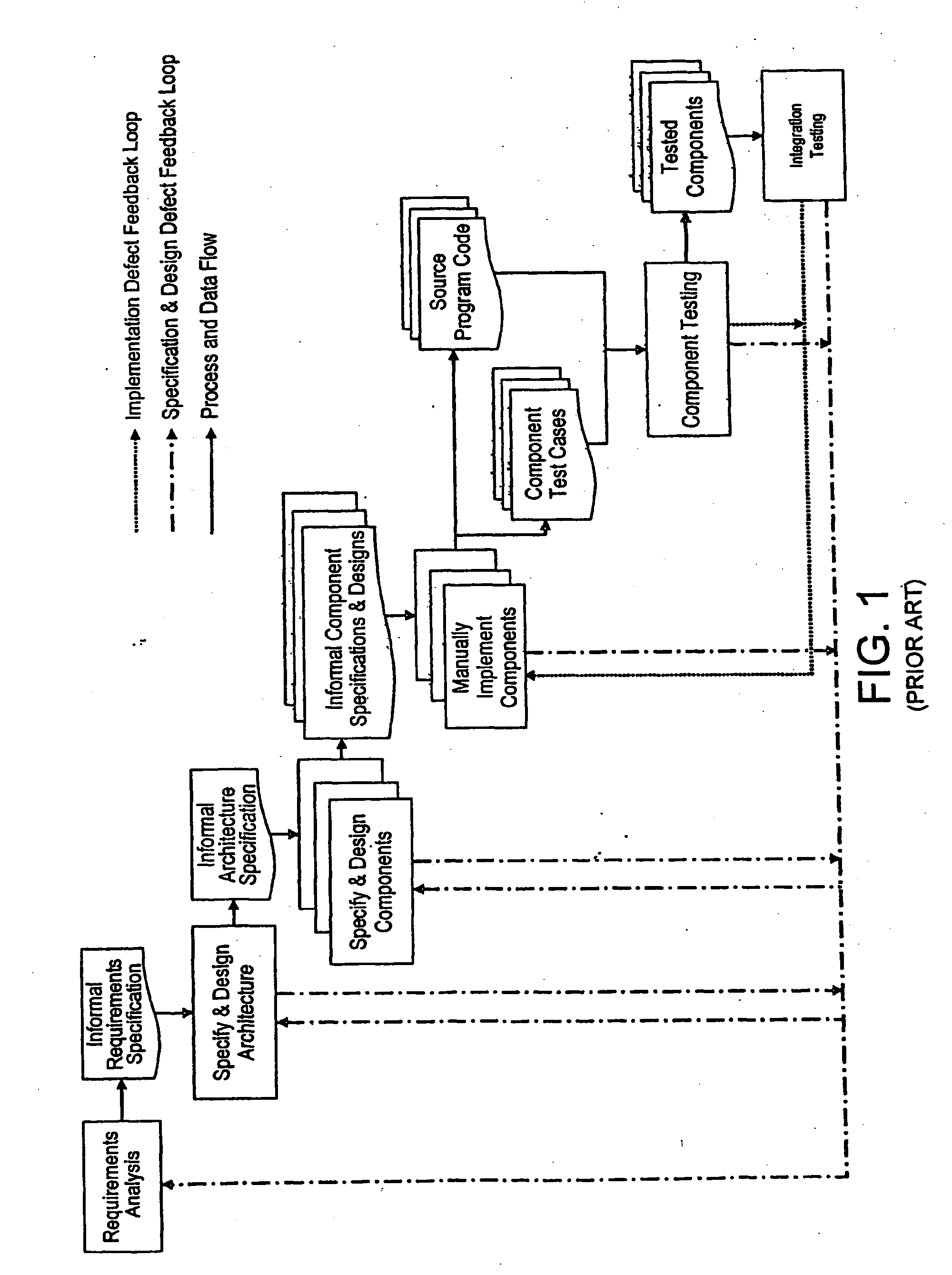

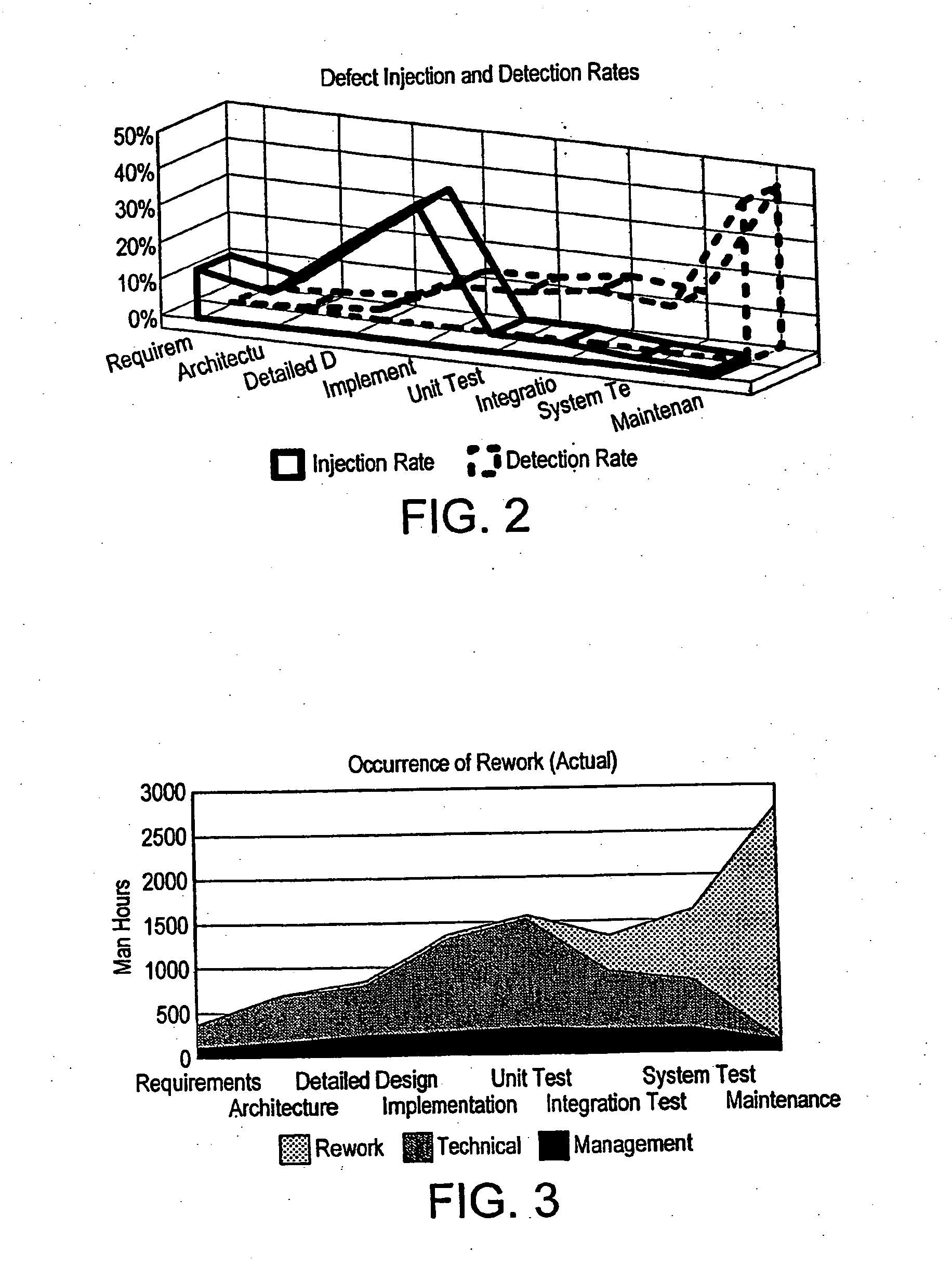

ActiveUS20080263506A1Improve effectivenessExpand coverageSoftware designRequirement analysisSystems designMathematical model

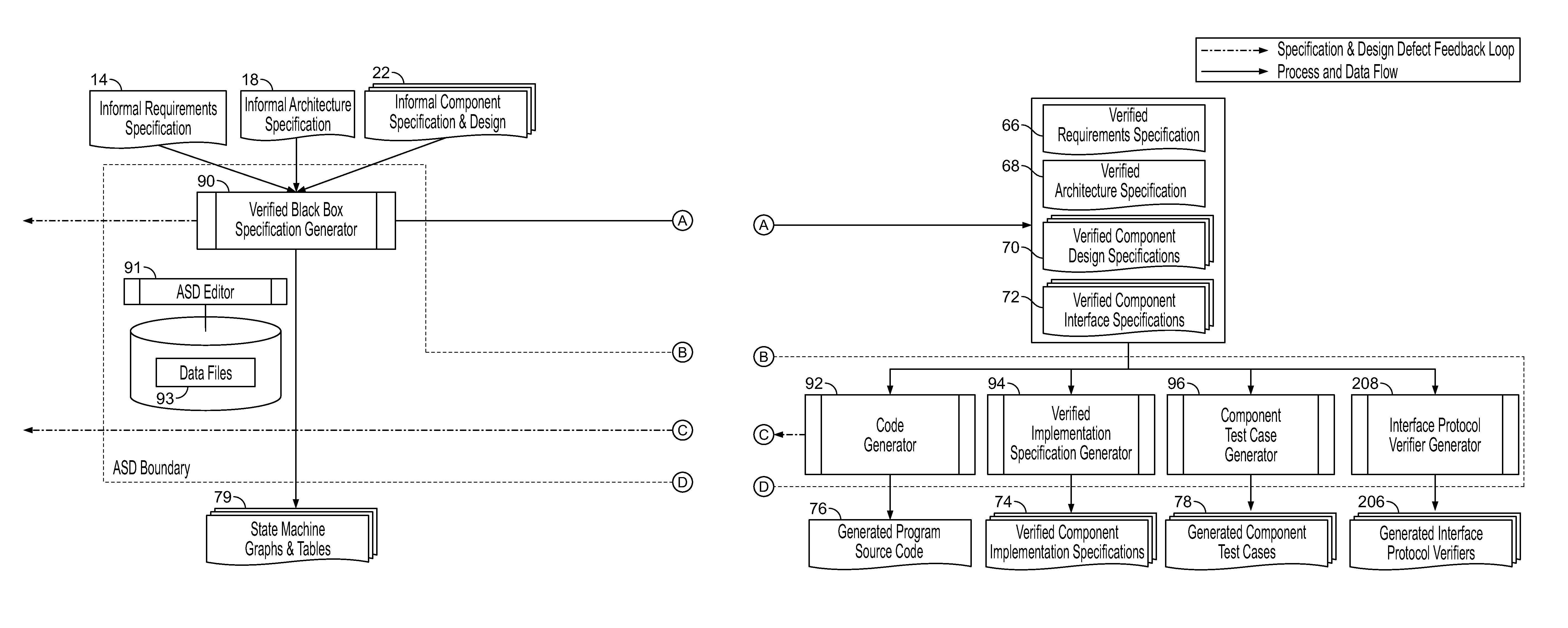

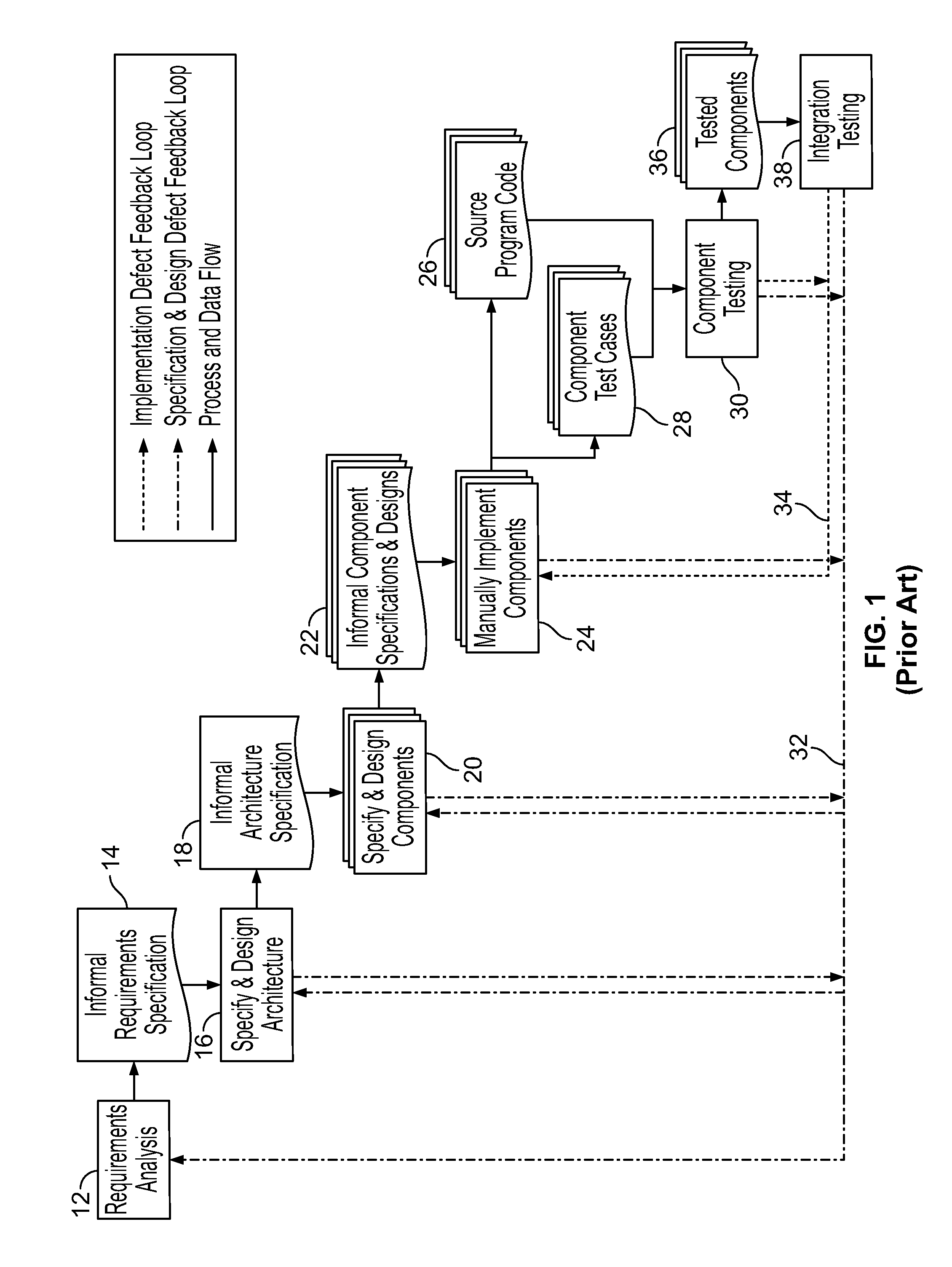

An analytical software design system arranged to receive informal system design specifications and to convert them into verified design specifications for use in creating source code and carrying out implementation testing of the source code is described. The system comprises a verified black box specification generator arranged to process the received informal system design specifications to create formal specifications; to generate from the formal specifications mathematical models representing the system behaviour; to analyse the mathematical models to determine if they have the required behaviour; to adjust the formal specifications until the required behaviour is achieved; and to derive the required verified design specifications from the mathematical models.

Owner:COCOTEC LTD

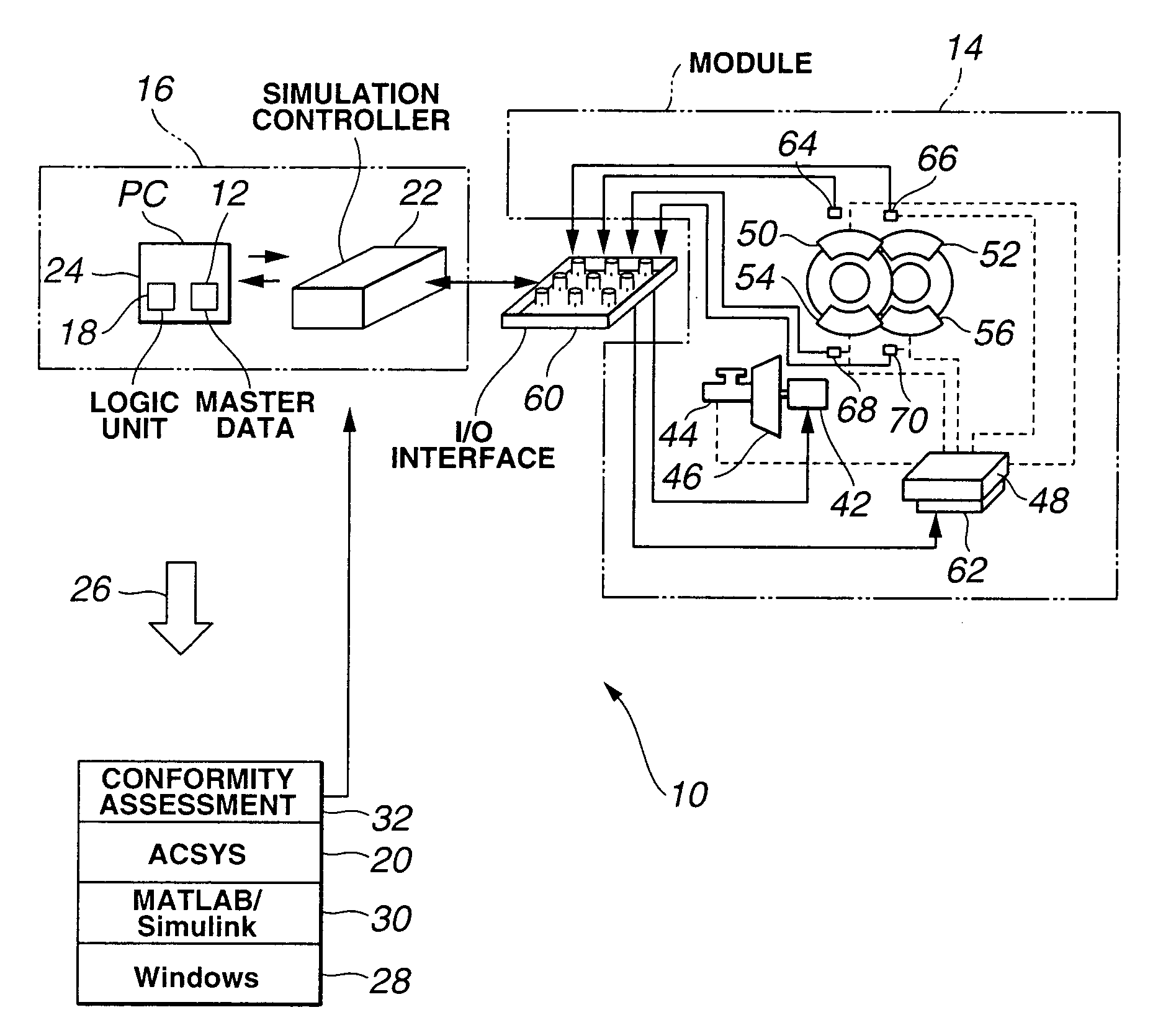

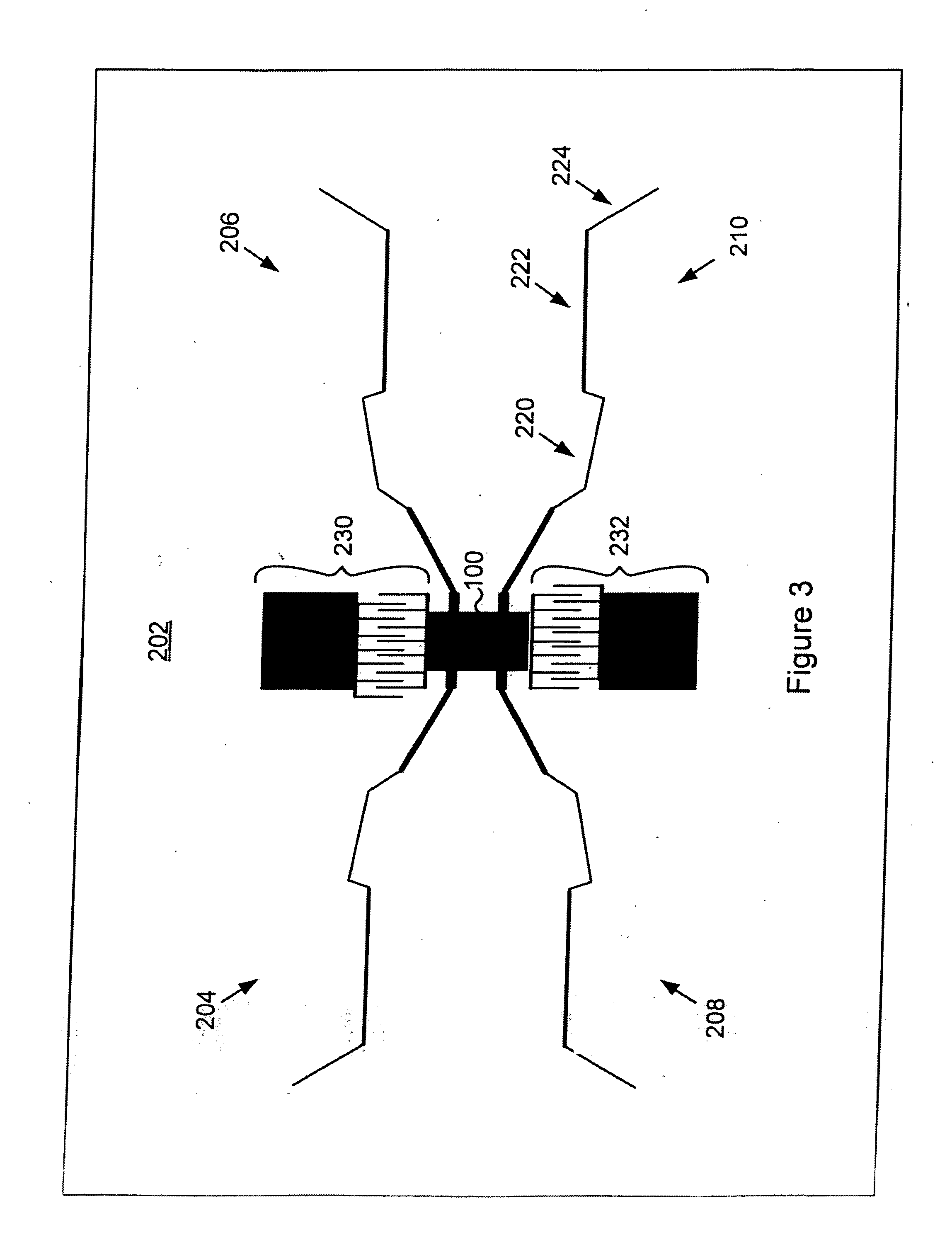

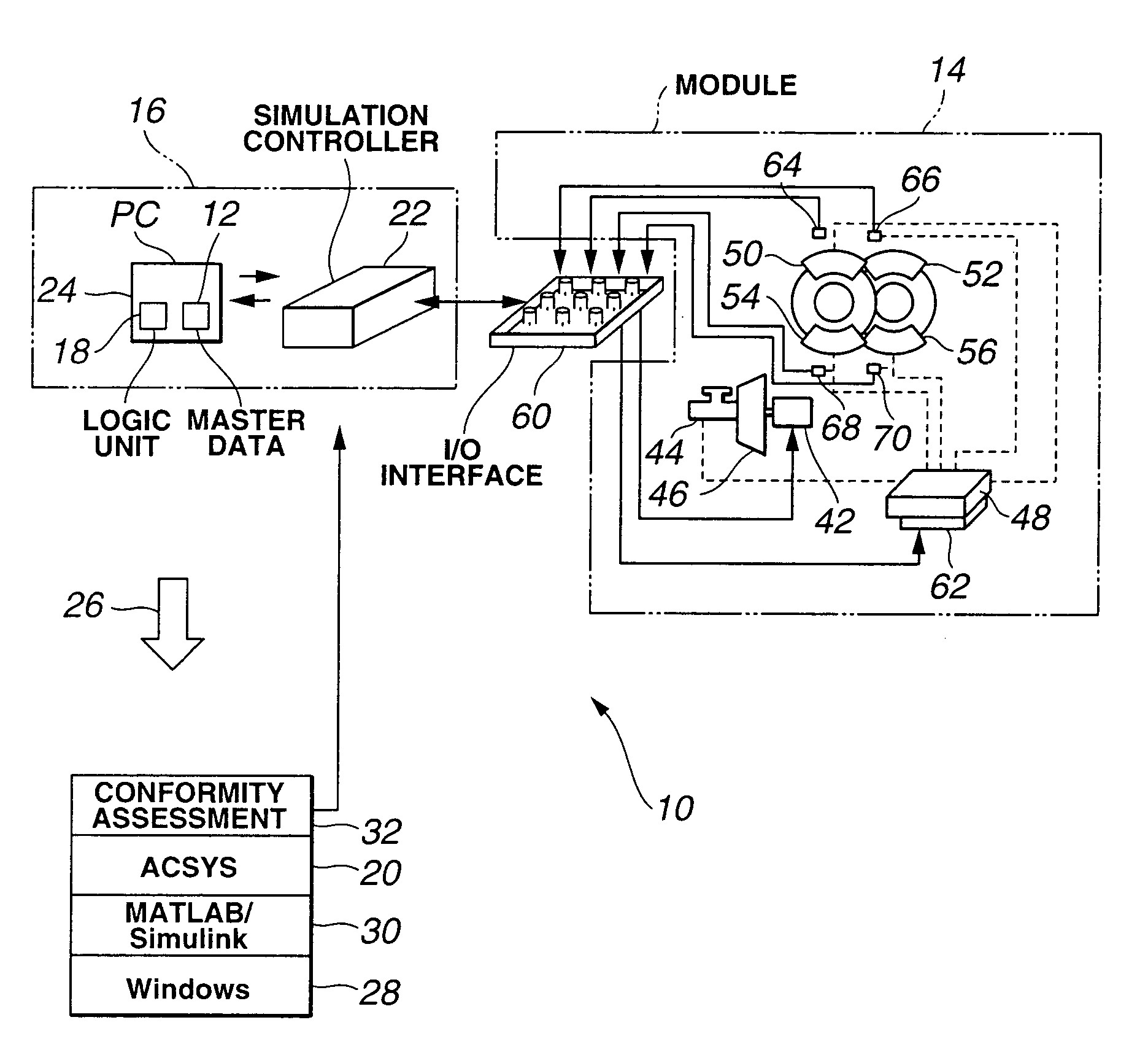

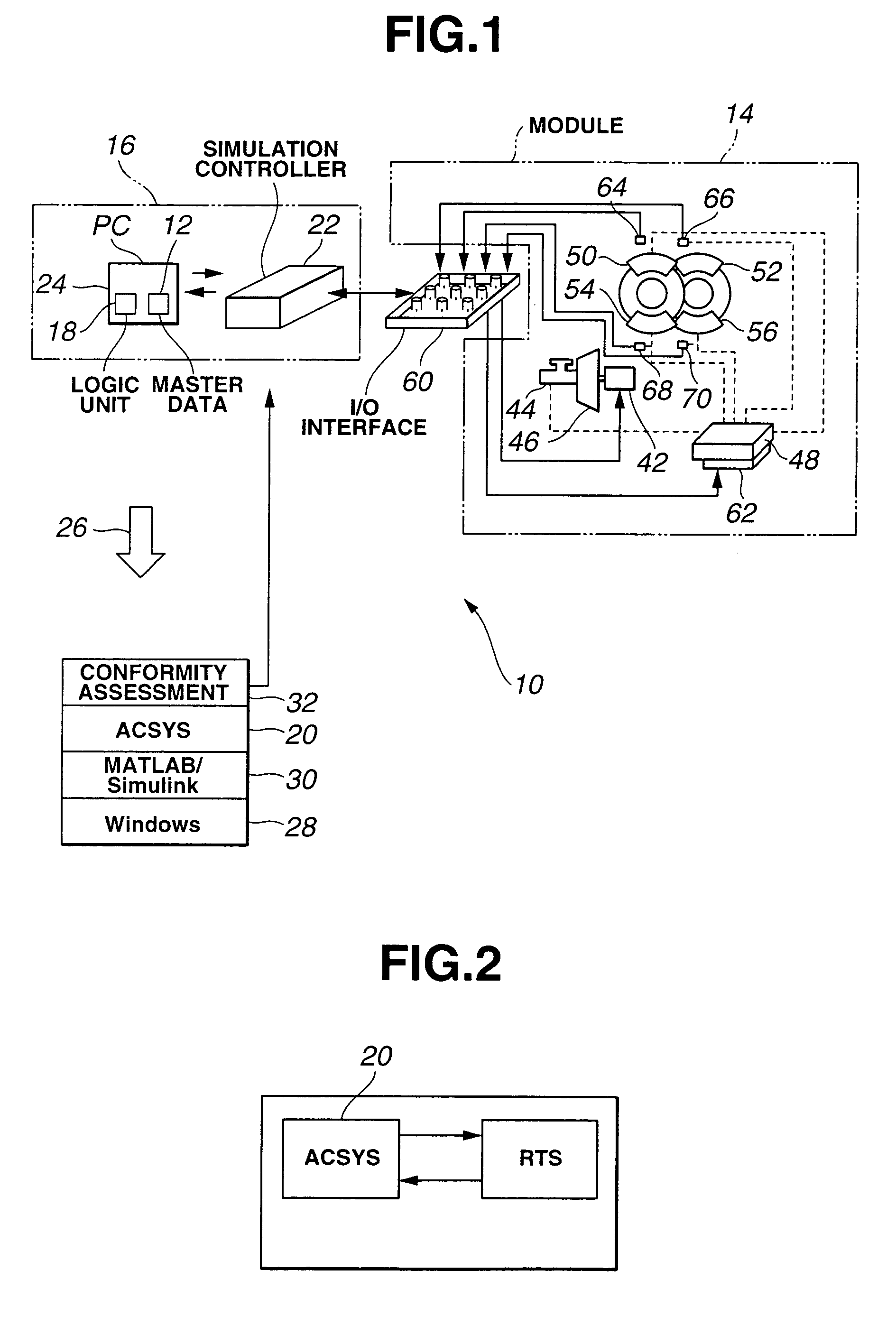

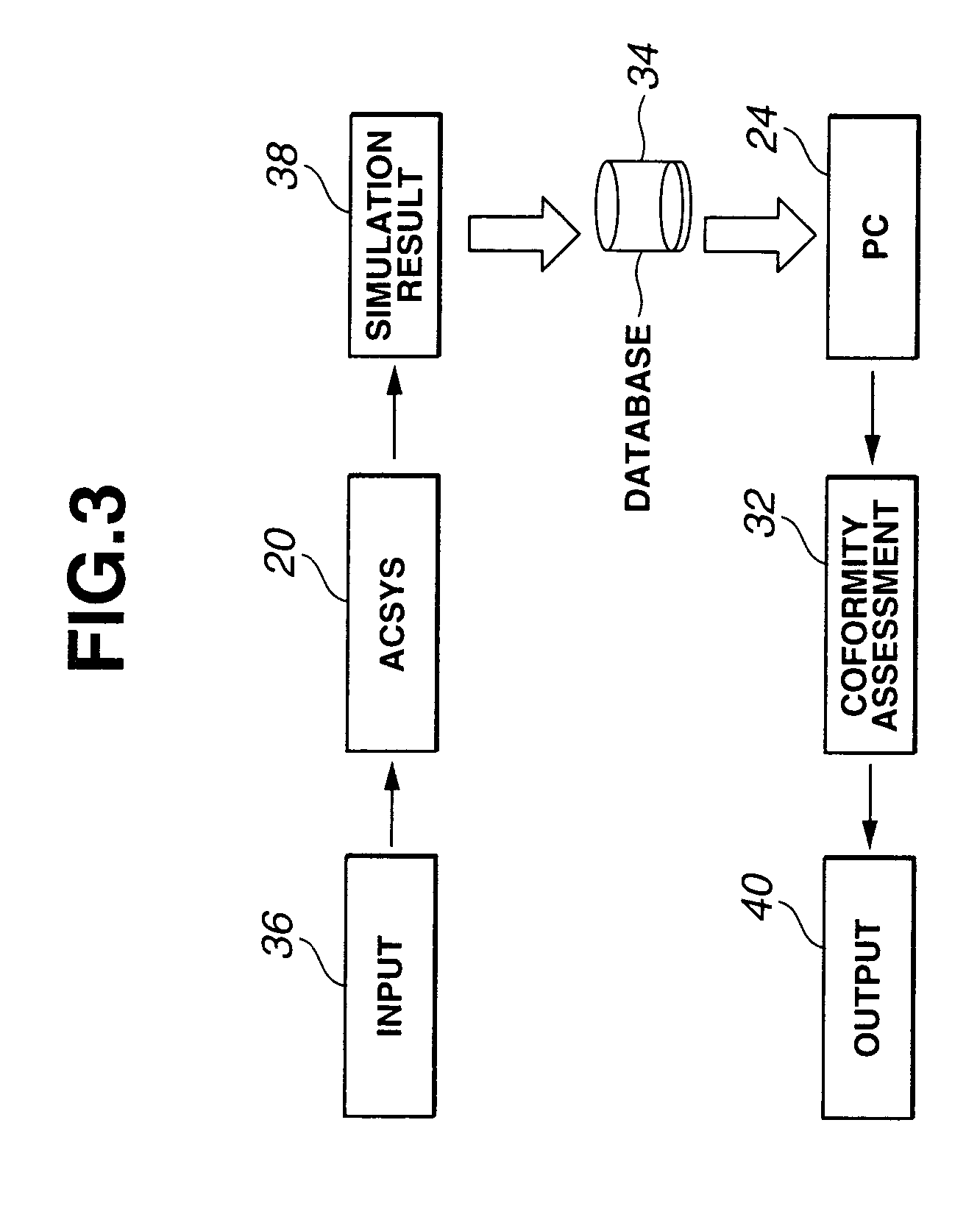

Engineering assist method and system

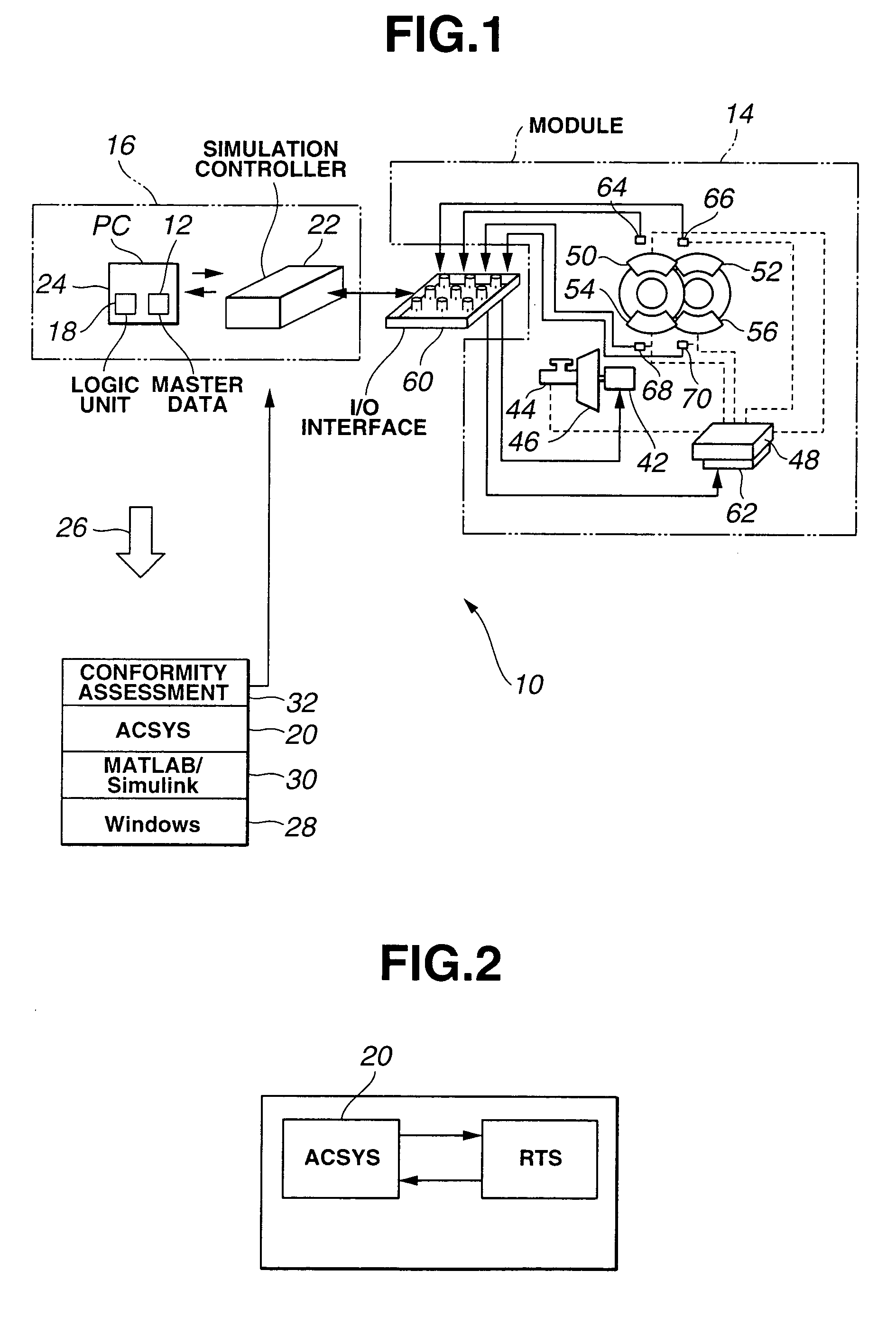

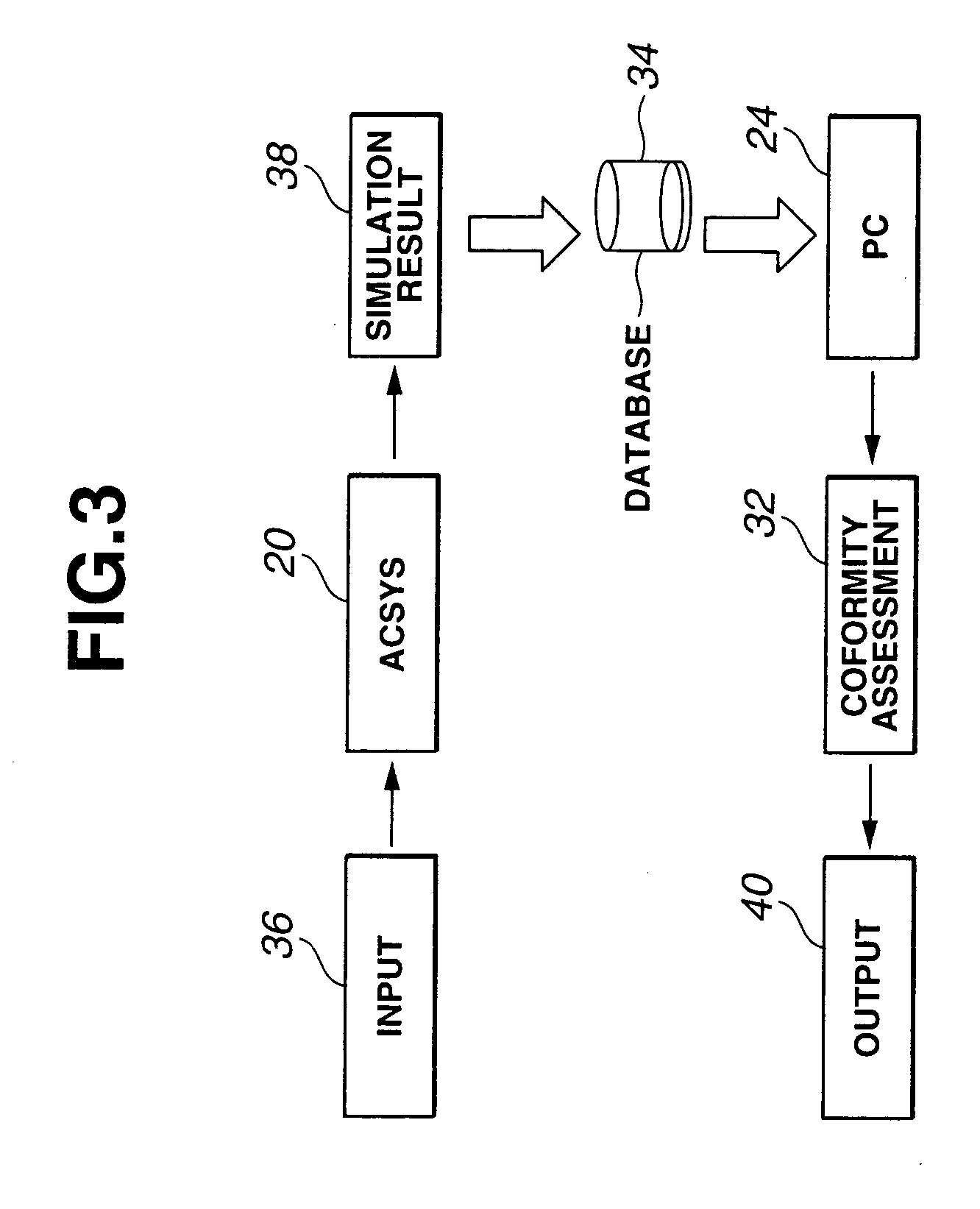

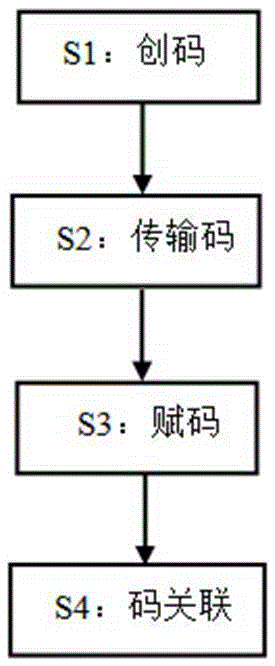

A car engineering assist system and method establish a master data and set a computer-generated virtual car model to represent at least a portion of a product design specification (PDS) of a test car. A real time simulator performs computer simulation of a test module using the car model, which has been set to represent at least the portion of the PDS of the test car, to produce a simulation result. A logic unit performs conformity assessment of the test module based on the simulation result and the master data.

Owner:NISSAN MOTOR CO LTD

Two-dimensional code production method for wine bottle

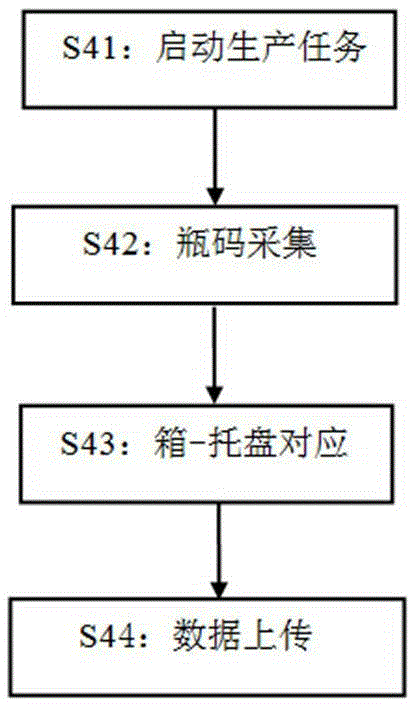

ActiveCN105303220AEasy to participateUniqueness guaranteedCo-operative working arrangementsRecord carriers used with machinesThree levelLogistics management

The invention discloses a two-dimensional code production method for a wine bottle, and belongs to the field of bar code production, for solving the problems of logistics node management, fake and inferior products, out-zone sale and the like in the industry of liquor. Two-dimensional codes are generated by an encryption algorithm and are obtained through secondary encryption, verification and checking through a system, two-dimensional code pictures are generated, each product is endowed with a code, according to a three-level association sequence of bottles, boxes and pallets, the unique two-dimensional code of each wine bottle is acquired on a liquor filling streamline through a gatherer for association, and then the two-dimensional codes are enabled to be associated with such information as product specifications, production time, production batch numbers, groups, dealers, sale orders, delivery orders and the like through production scheduling and delivery, such that tracing of the quality of products in the whole life period, counterfeiting prevention, out-zone sale prevention, logistics monitoring, sale data monitoring, product stock monitoring and establishment of a basis of consumer group terminal client data can be realized, and vast users can rapidly and conveniently participate in quality tracing supervision.

Owner:泸州益和纸品包装有限公司

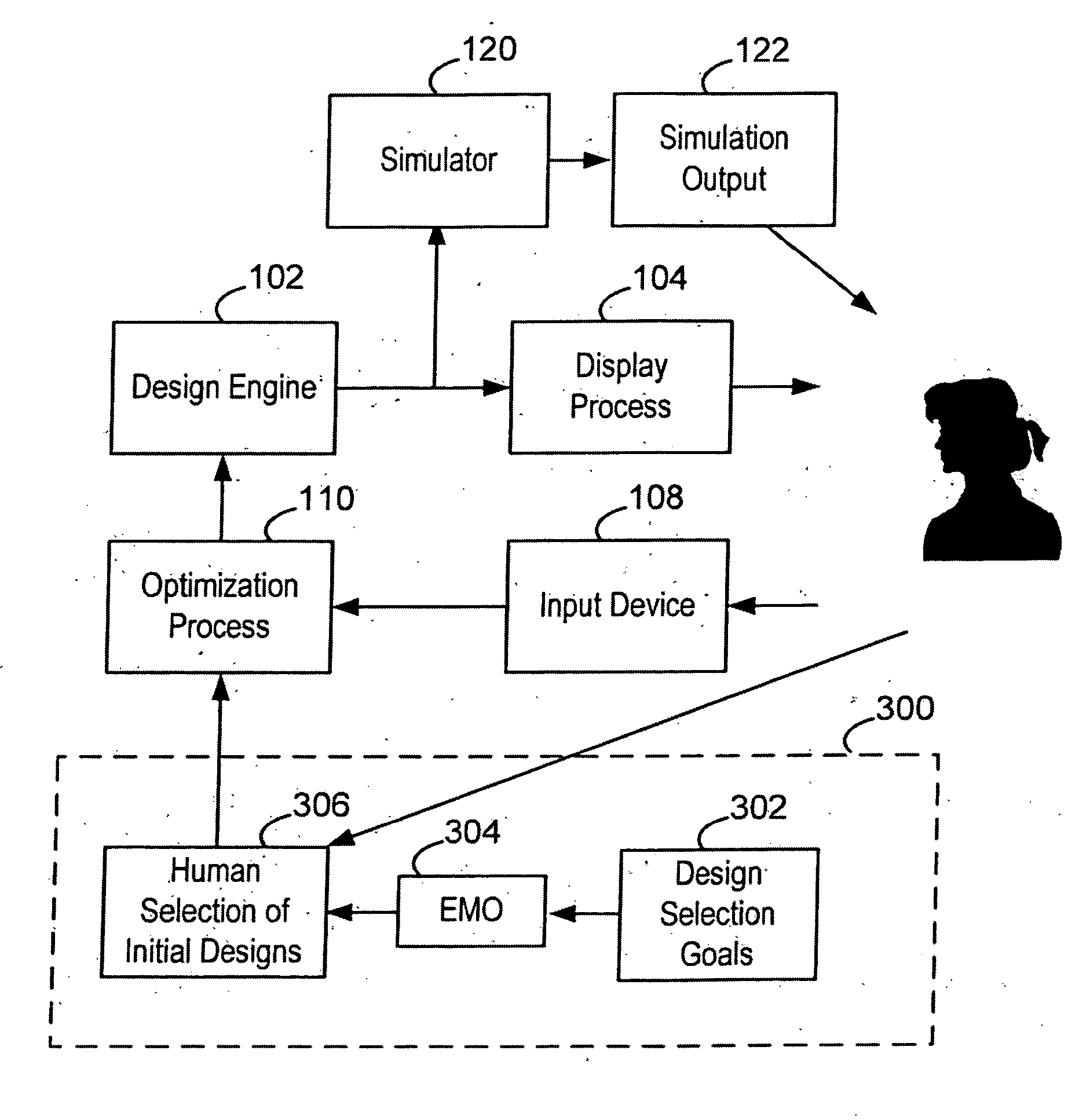

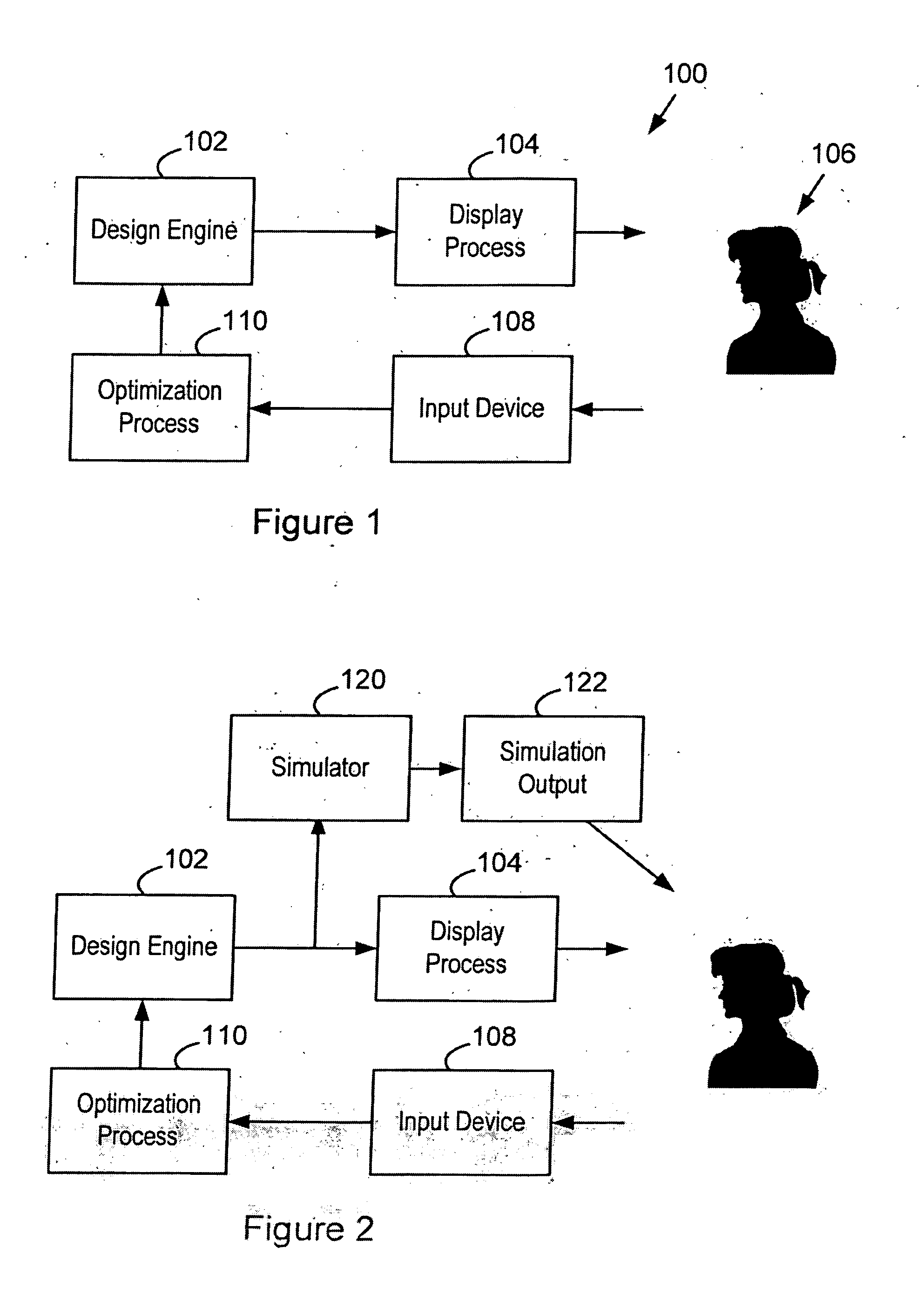

Engineering design system using human interactive evaluation

InactiveUS20060225003A1Detecting faulty computer hardwareComputer programmed simultaneously with data introductionGenerative DesignEngineering design process

A design system includes a design engine for generating designs, an evaluation process for evaluating the generated designs based on human visual inspection and / or domain knowledge, and an optimization process for pruning based at least in part on the evaluation. Generation of additional designs is performed based on optimization. Newly-generated designs are then subjected to the same iterative steps. In one embodiment a simulator is also used to evaluate the generated designs, in part, with numerically designed specification. Subjective human evaluation is used fully or at least in part of an optimization process to obtain final designs. Human visual inspection and domain knowledge is used to evaluate and rate key designs at different points in the evolution of a design.

Owner:RGT UNIV OF CALIFORNIA +1

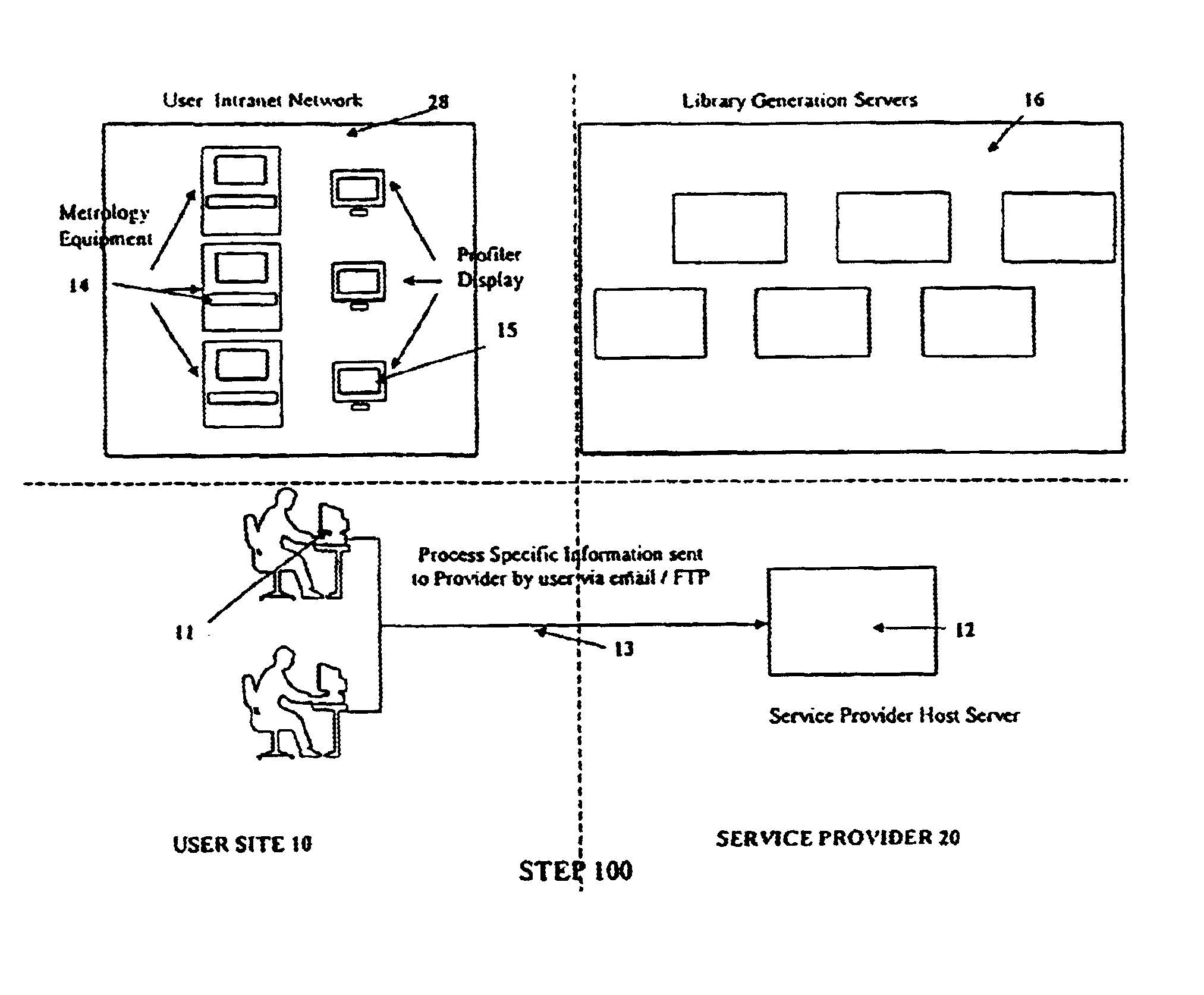

Profiler business model

InactiveUS6694275B1Data processing applicationsSemiconductor/solid-state device testing/measurementService provisionQuality control system

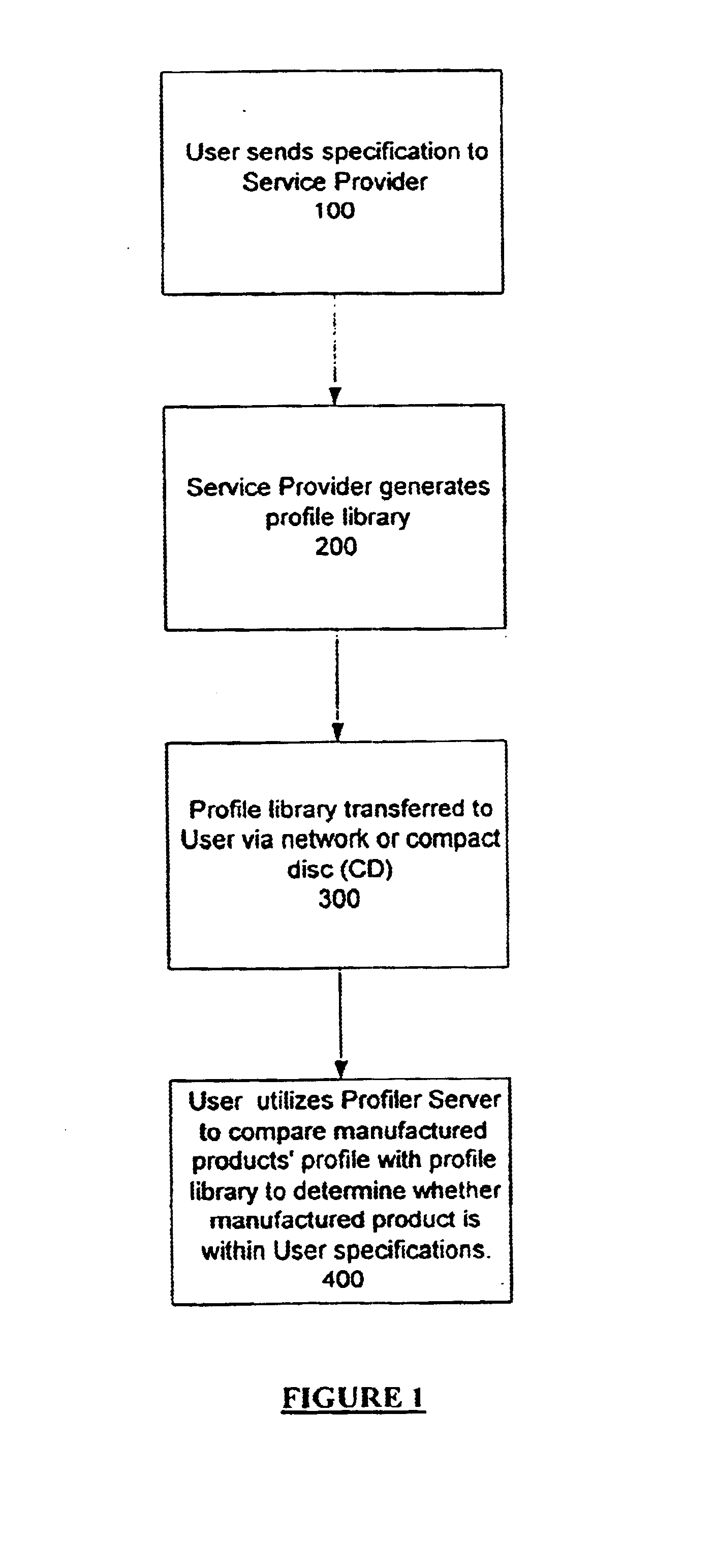

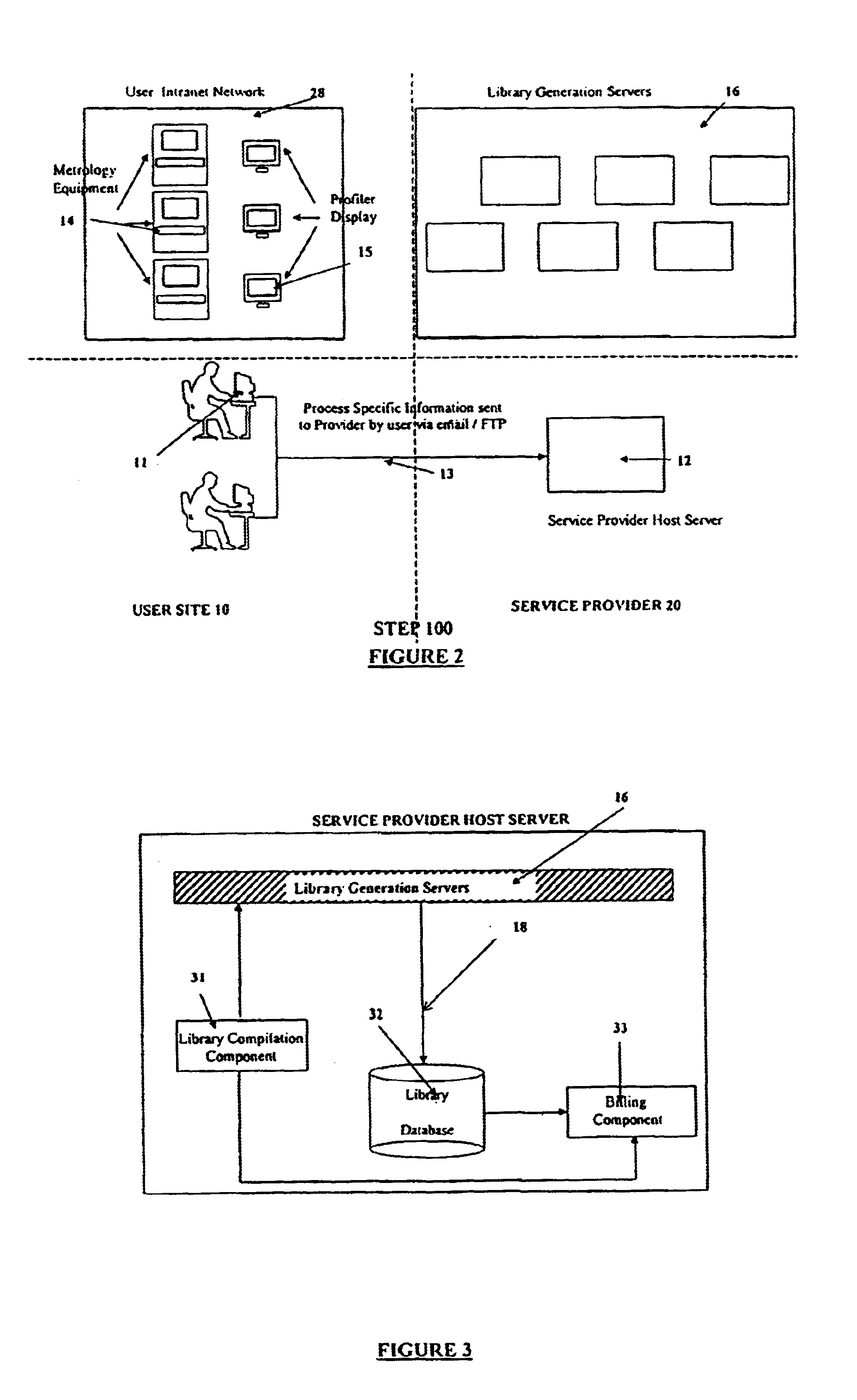

A quality control system implemented by a service provider for a user via the utilization of sophisticated software algorithms in creating a library of profiles based on product specification. These libraries of profiles are compared with profiles of manufactured products to ensure that manufactured products are within the specification. While the measurement of the manufactured products can be taken in real time, the generation of the profile library is very computationally intensive and requires the use of a highly parallel set of computer workstations for its operation. The system allows for the separation of the computational intensive process from the real-time measurement reading, and creates an opportunity for a service provider to generate and maintain the libraries offsite.

Owner:TIMBRE TECH INC

Analytical software design system

ActiveUS8370798B2Low costAvoid excessive errorSoftware designRequirement analysisSystems designMathematical model

An analytical software design system arranged to receive informal system design specifications and to convert them into verified design specifications for use in creating source code and carrying out implementation testing of the source code is described. The system comprises a verified black box specification generator arranged to process the received informal system design specifications to create formal specifications; to generate from the formal specifications mathematical models representing the system behavior; to analyze the mathematical models to determine if they have the required behavior; to adjust the formal specifications until the required behavior is achieved; and to derive the required verified design specifications from the mathematical models.

Owner:COCOTEC LTD

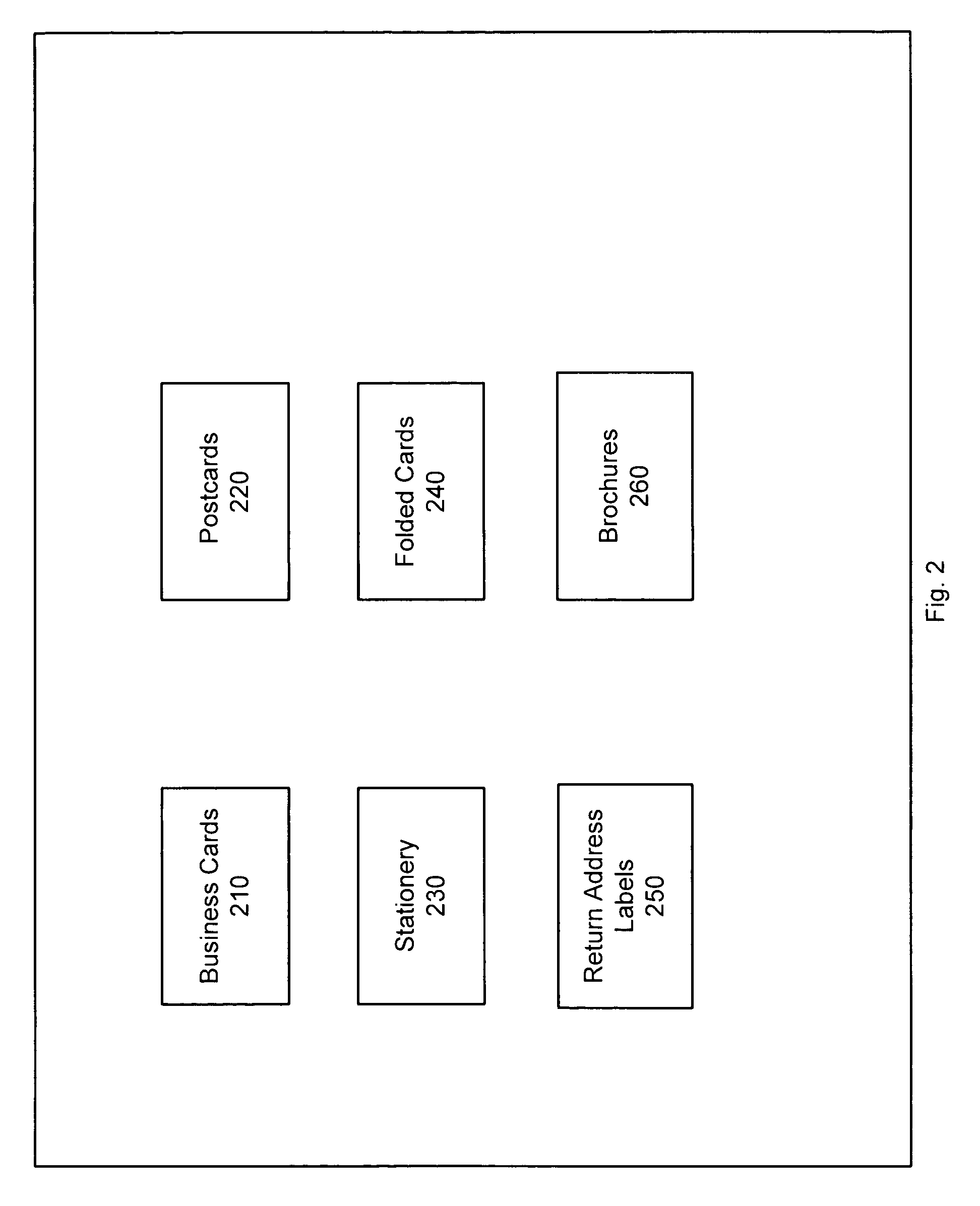

Electronic product design

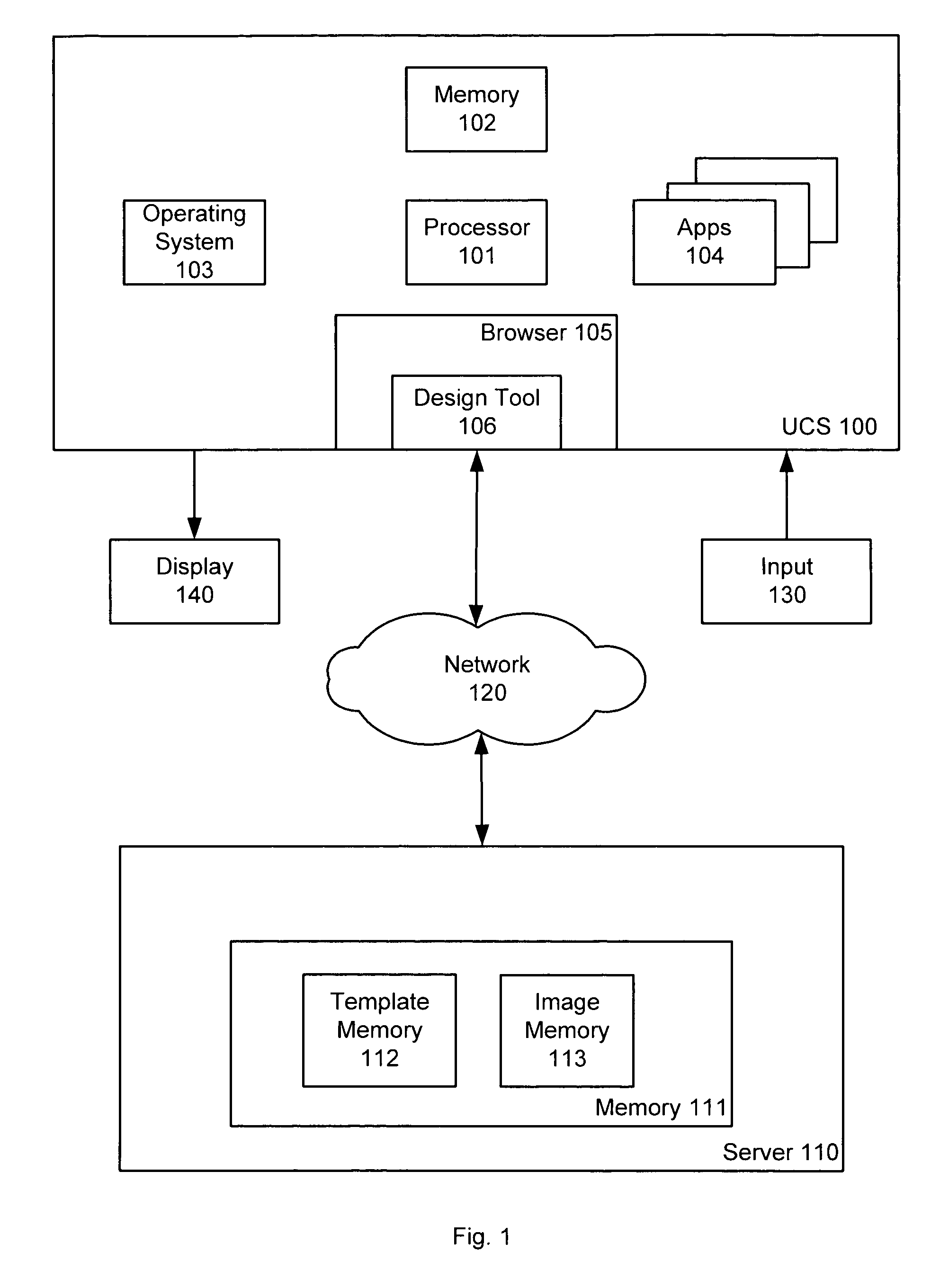

ActiveUS7607084B2Easy to mergeNatural language data processingMarketingElectronic documentComposite element

Automated electronic document design systems and method for designing and modifying product templates. When a user initiates a product design session, a product template is presented for user editing and a product description identifier is assigned to the product being designed. Document templates are assembled from individual composite elements. The individual identifiers of the component elements that make up the template being viewed by the user are associated with the description identifier. Tools are provided to allow a user to change one or more of the composite elements of the template. When a user changes an element, the identifier of the newly selected element is associated with the description identifier. Component elements of one template can be individually used, as appropriate, to prepare customized templates for another part of the same document or for different documents.

Owner:CIMPRESS SCHWEIZ

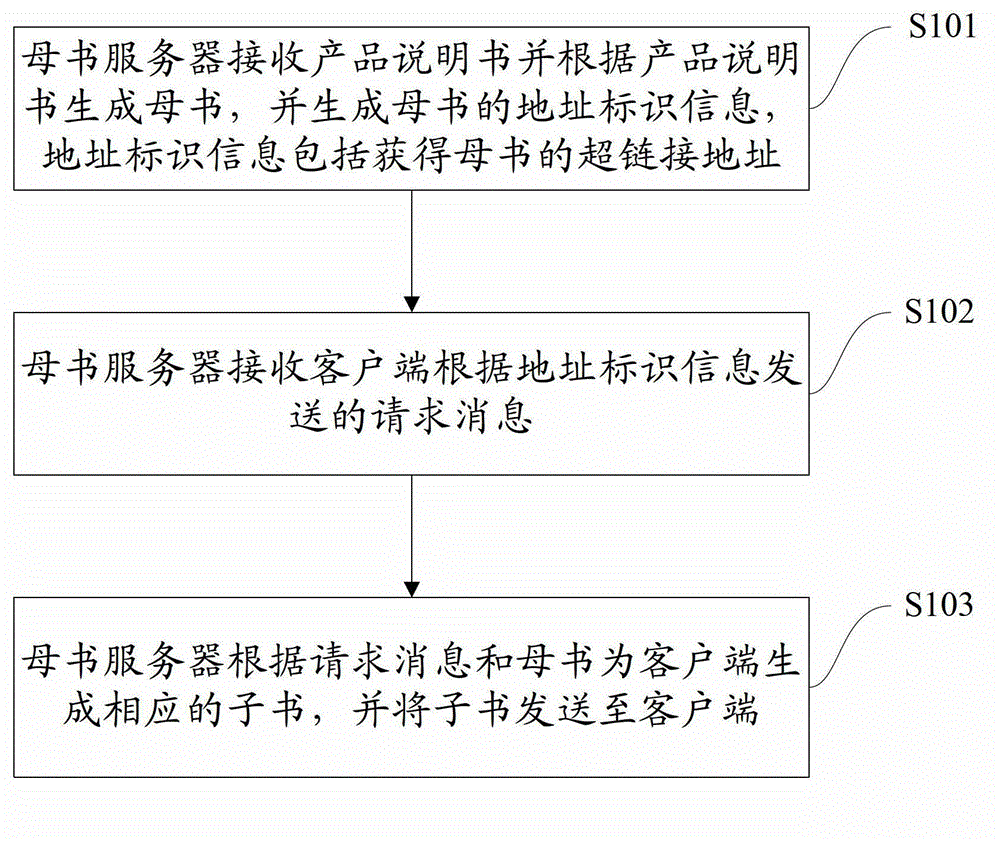

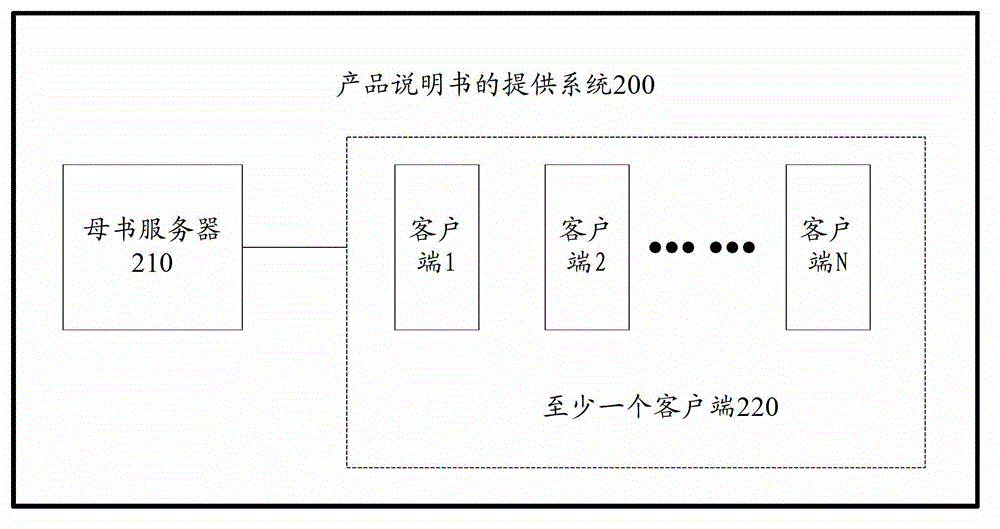

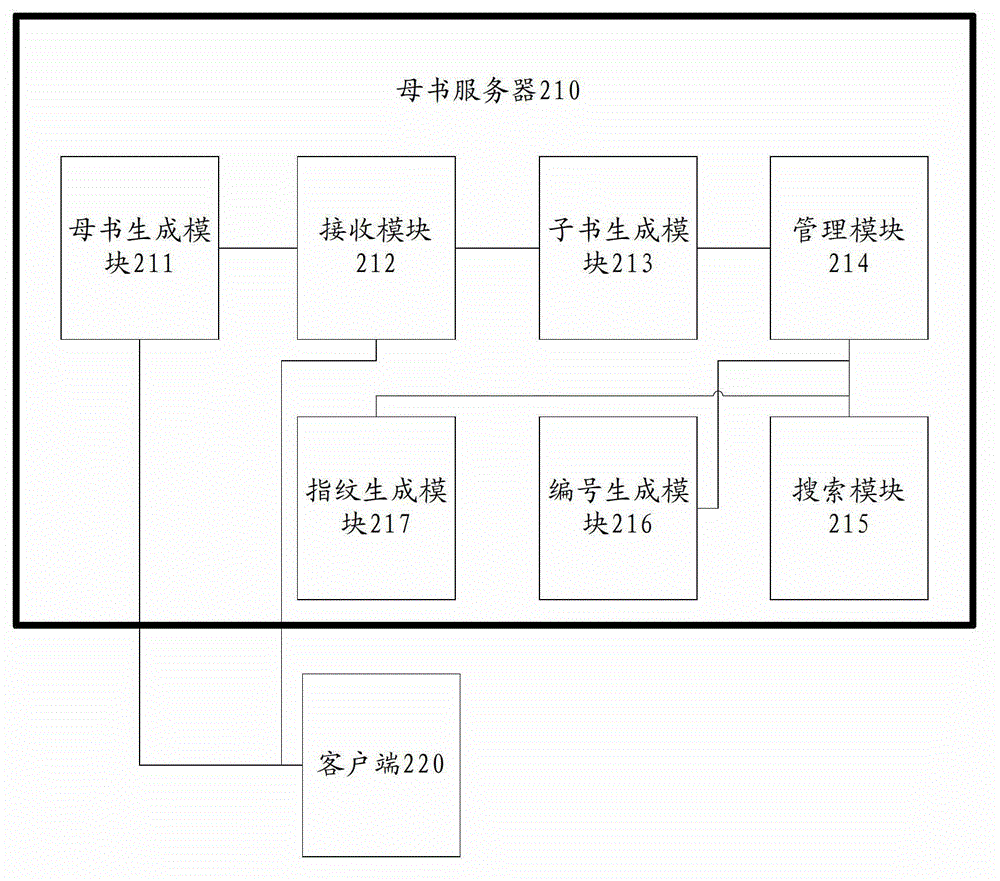

Method and system for providing product specifications and main book server

ActiveCN103150339AEasy accessAccurate acquisitionTransmissionSpecial data processing applicationsHyperlinkService development

The invention provides a method for providing product specifications, which comprises the steps that a parent specification server receives the product specification and generates an address identification information of the parent specification according to the product specification, wherein the address identification information comprises a hyperlink address for obtaining the parent specification; the main specification server receives a request message sent by a client according to the address identification information; and the main specification server generates a corresponding subsidiary specification for the client according to the request message and the main specification, and sends the subsidiary specification to the client. According to an embedment of the invention, the method for providing the product specifications enables clients of different types to obtain corresponding subsidiary specifications according to the hyperlink addresses, has the advantages of low carbon and environmental protection; and meanwhile, the product specifications can be updated timely, so that a user can obtain updating information of the product specifications conveniently and rapidly, the after service development is facilitated, and the after service cost is low. The invention further provides a system for providing the product specifications and the main specification server.

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

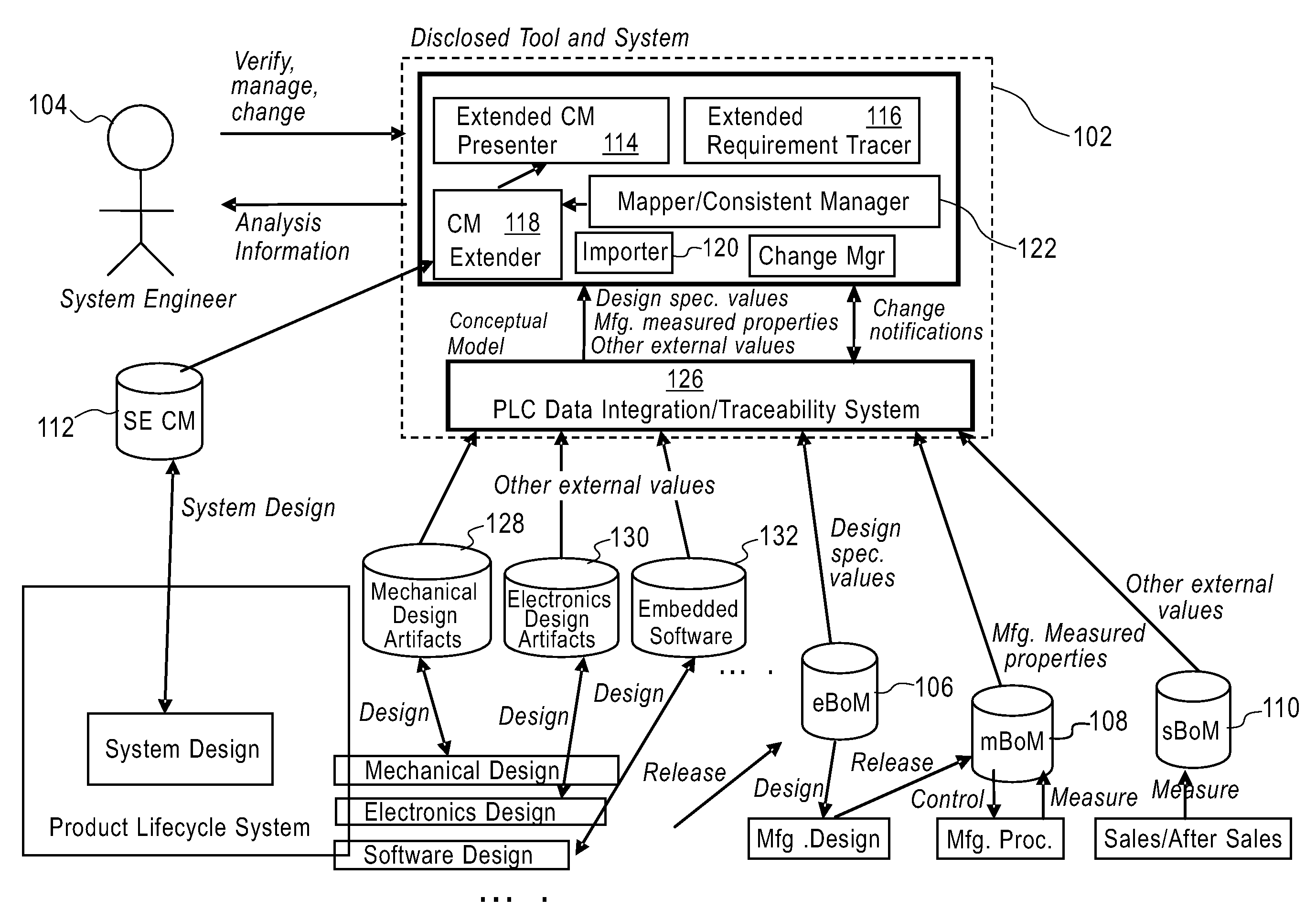

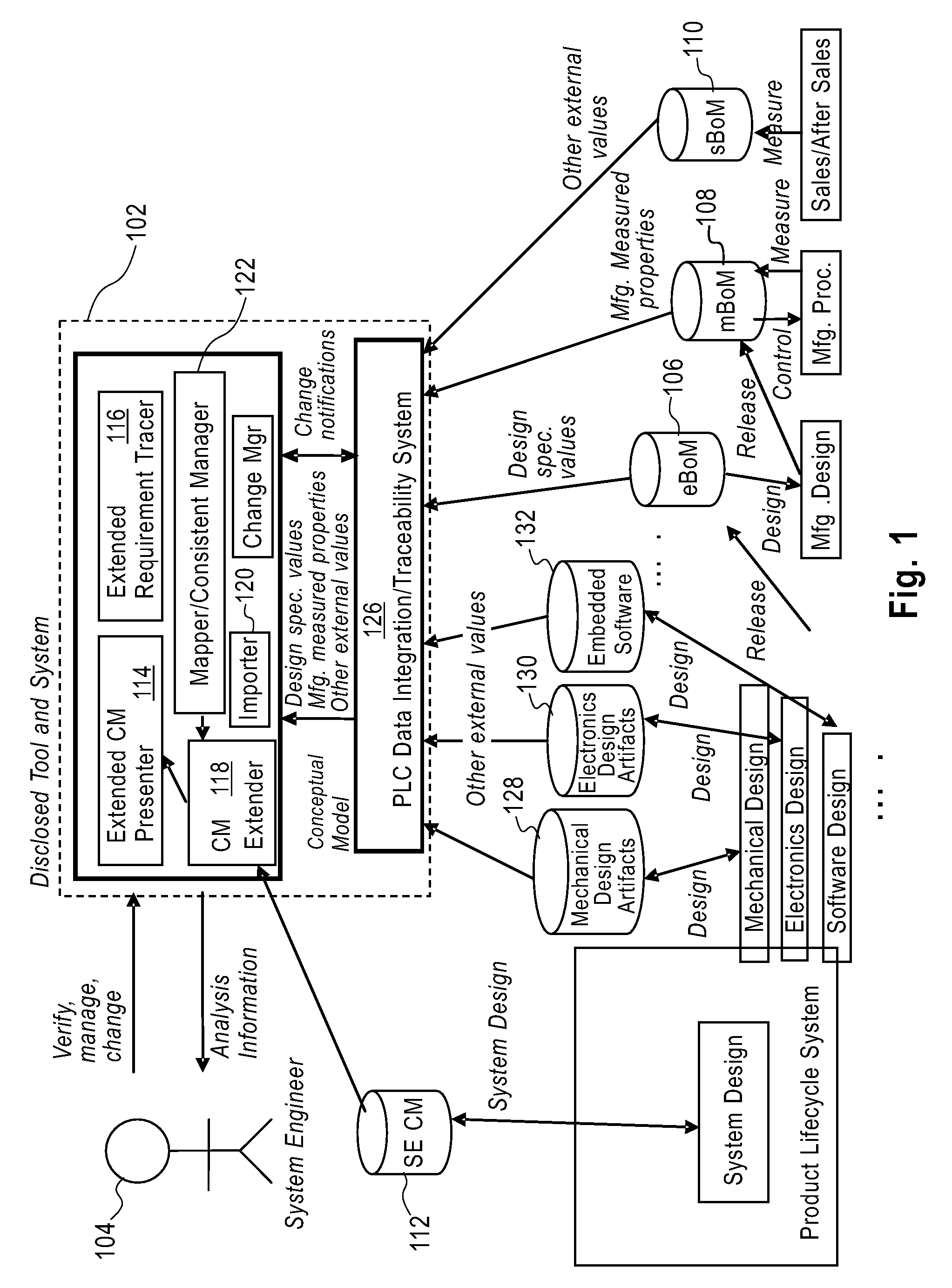

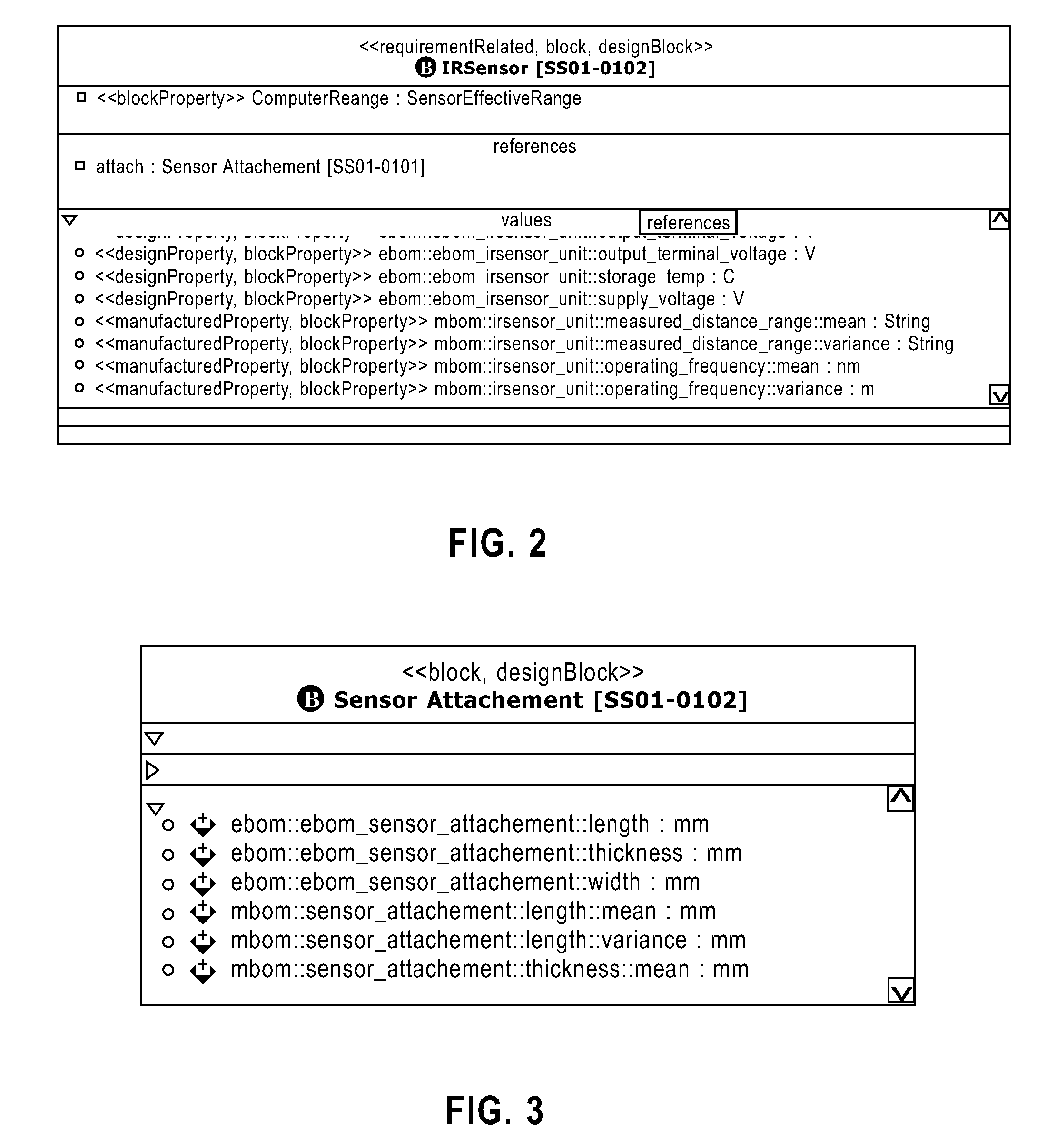

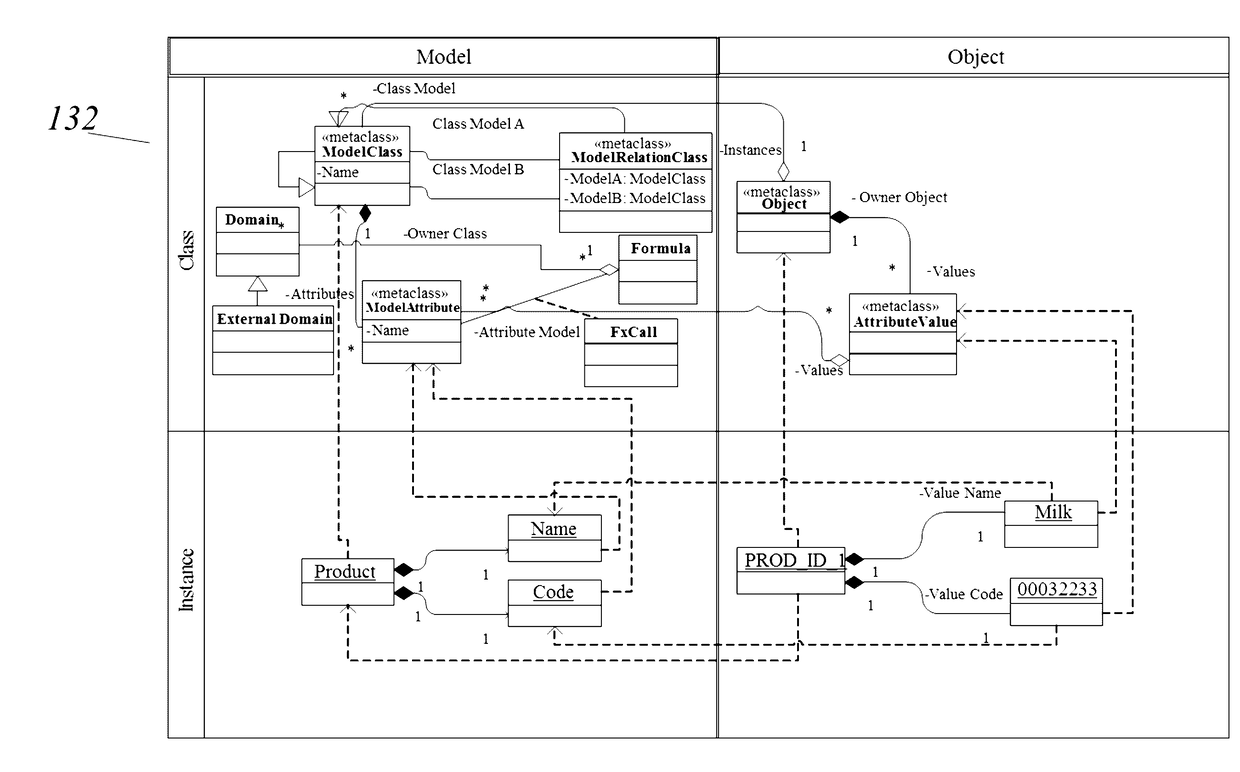

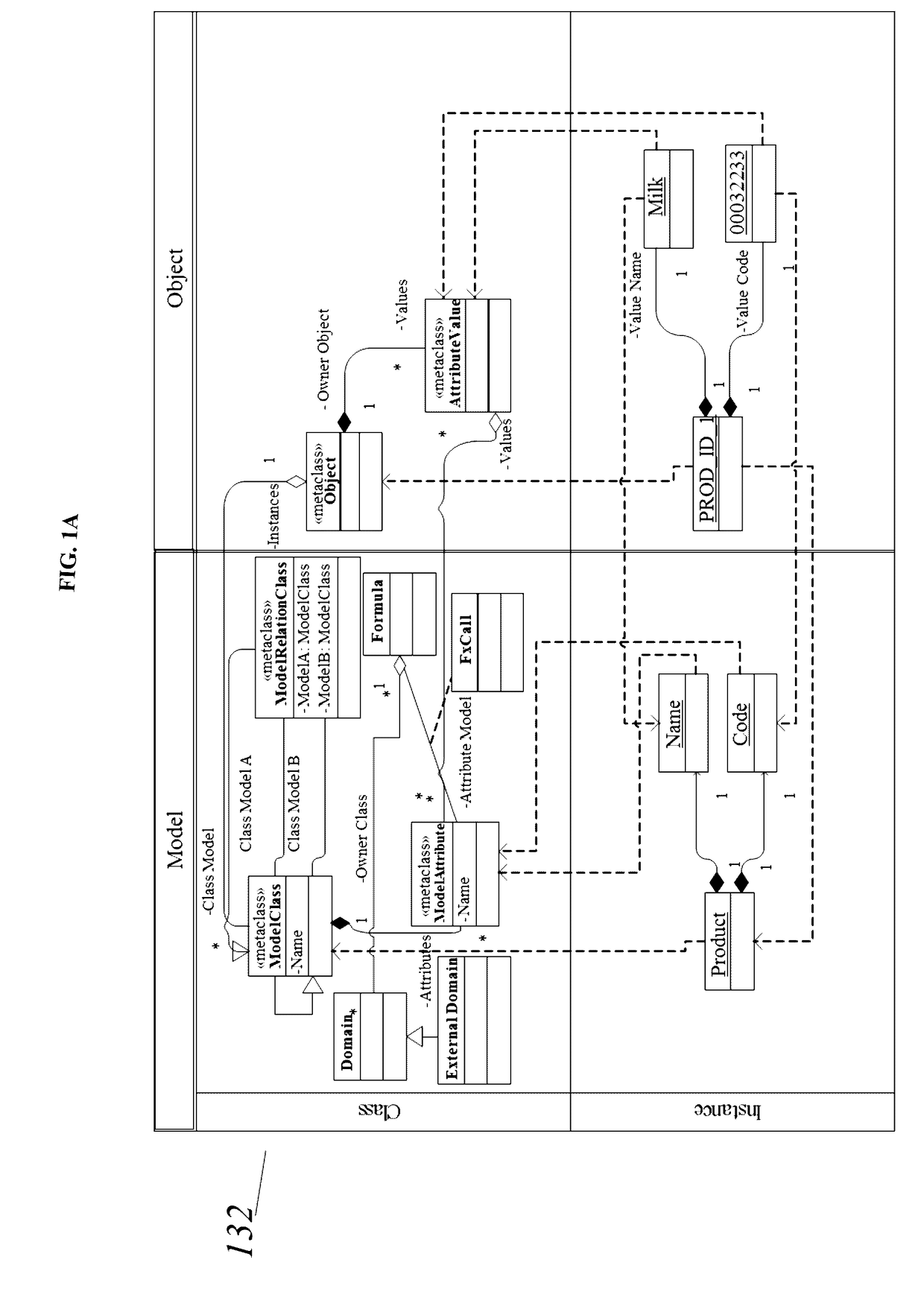

Method and apparatus for using design specifications and measurements on manufactured products in conceptual design models

InactiveUS20090093901A1Computer aided designSpecial data processing applicationsExternal referenceProduct design specification

A system and method for using design specification and measurements on manufactured products in conceptual design model are provided. In one aspect, a conceptual model is extended to map one or more model elements to corresponding external reference values. The corresponding external reference values include at least design specification values and manufacturing properties associated with one or more model elements. The model elements mapped to corresponding external reference values are presented, for example, for identification and consistency checks of attributes at various stages of product life cycle.

Owner:IBM CORP

Engineering assist method and system

A car engineering assist system and method establish a master data and set a computer-generated virtual car model to represent at least a portion of a product design specification (PDS) of a test car. A real time simulator performs computer simulation of a test module using the car model, which has been set to represent at least the portion of the PDS of the test car, to produce a simulation result. A logic unit performs conformity assessment of the test module based on the simulation result and the master data.

Owner:NISSAN MOTOR CO LTD

AR technology-based specification realization method

InactiveCN107870673ALearn about the detailsKnow the detailed features in advanceInput/output for user-computer interactionGraph readingSoftware engineeringSoftware development

The invention discloses an AR technology-based specification realization method. The method comprises the following steps of: 1, extracting an overall product appearance, an internal structure and part composition information in a product specification to serve as a model, an action and special effects; 2, carrying out software development on resources by using a comprehensive 3D development engine; 3, programming AR display software by using a virtual reality software development kit; and 4, applying the AR display software to the product specification and dynamically displaying the product in the specification through an AR technology. According to the method, a 3D information graphical representation system is constructed for pictures through the AR technology; products in specifications are dynamically displayed through the AR technology; part disassembling and assembling indication can be carried out to display mutual combination relationship between different components, so thatgaps in the field of information product specifications are filled, producers can display the characteristics, structures an advantages of products to the users more intuitionally, and the users can know assembling processes of complicated products and various functions of functional products through the technology so as to know detailed characteristics of the product in advance.

Owner:深圳市蓝游网络科技有限公司

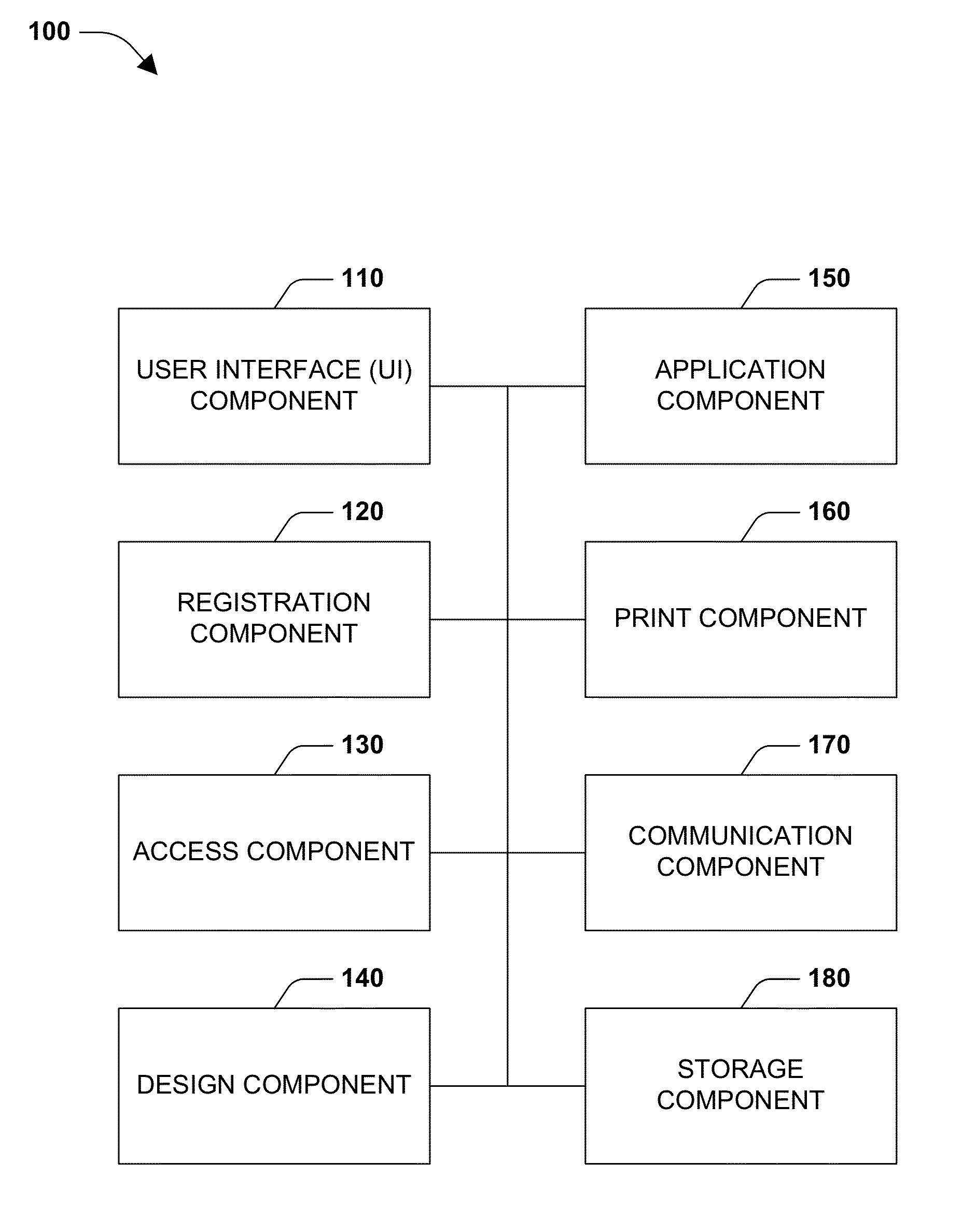

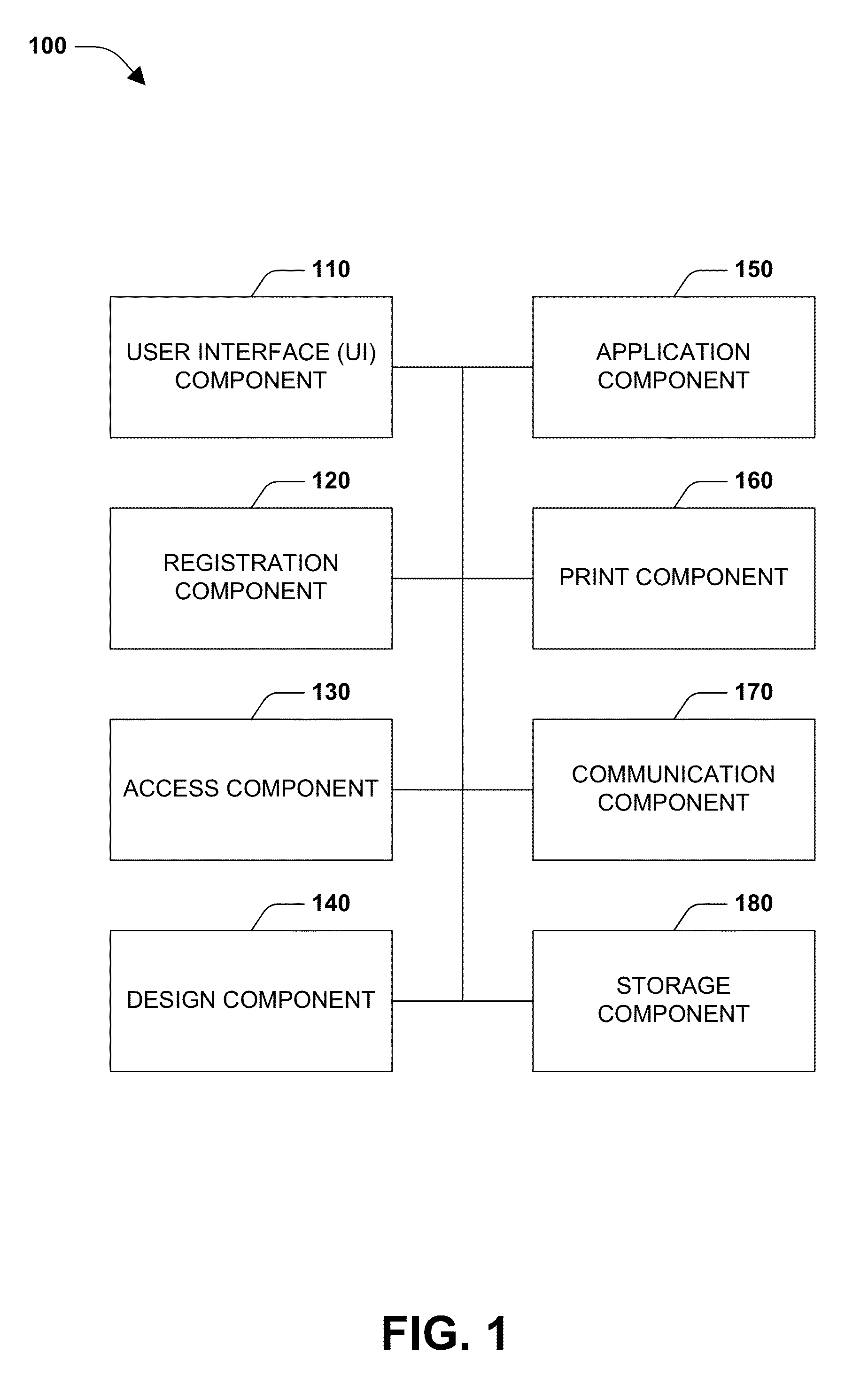

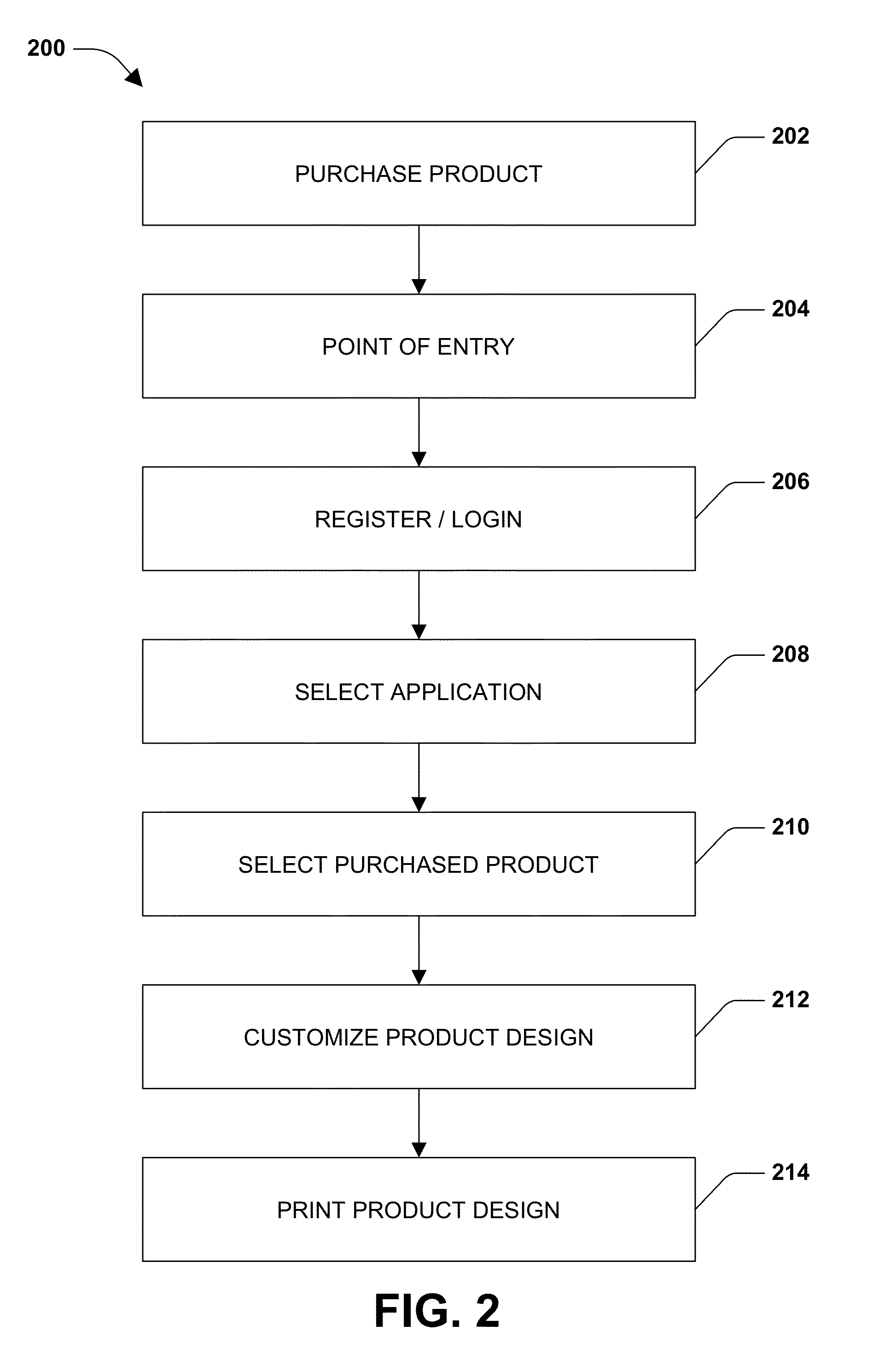

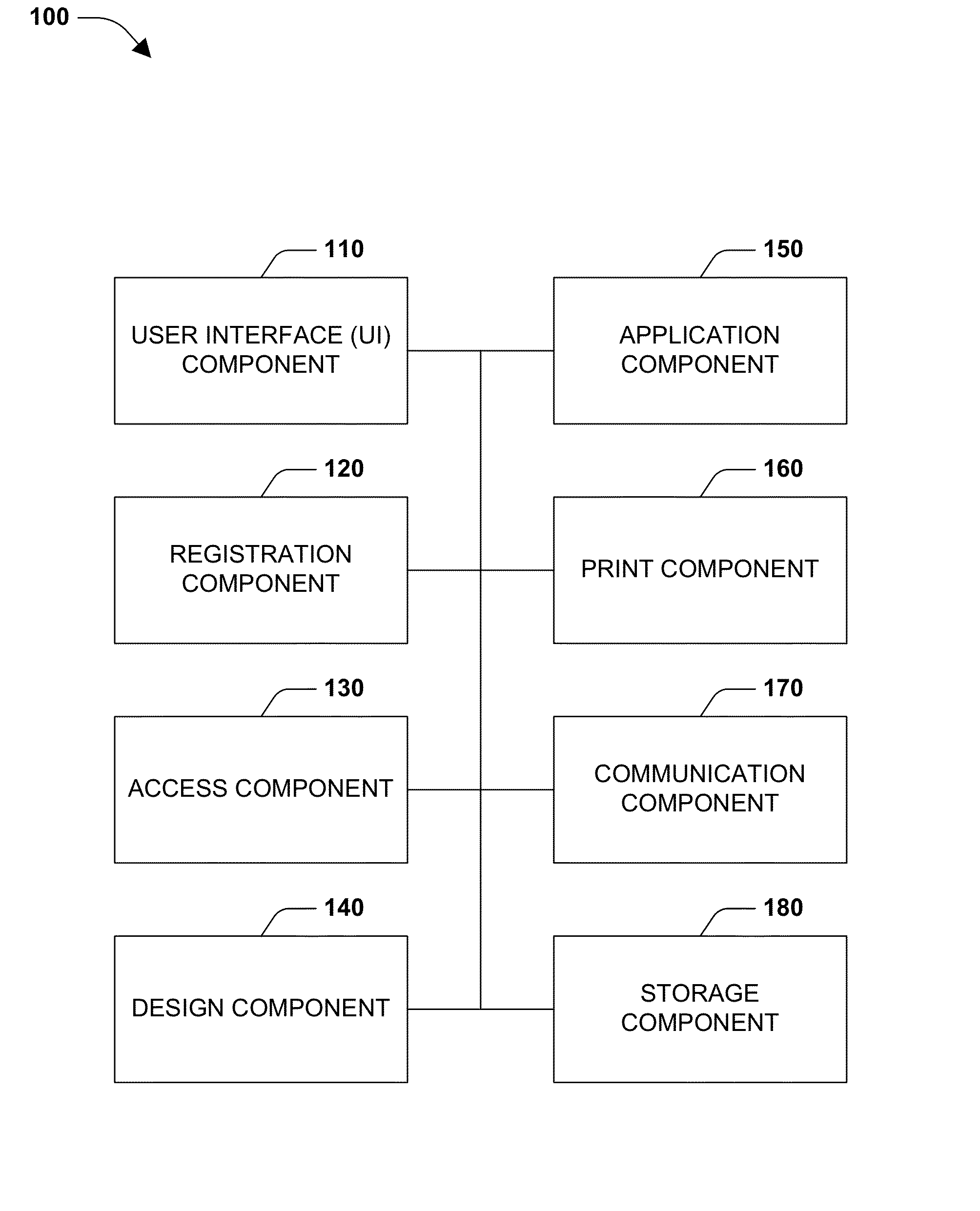

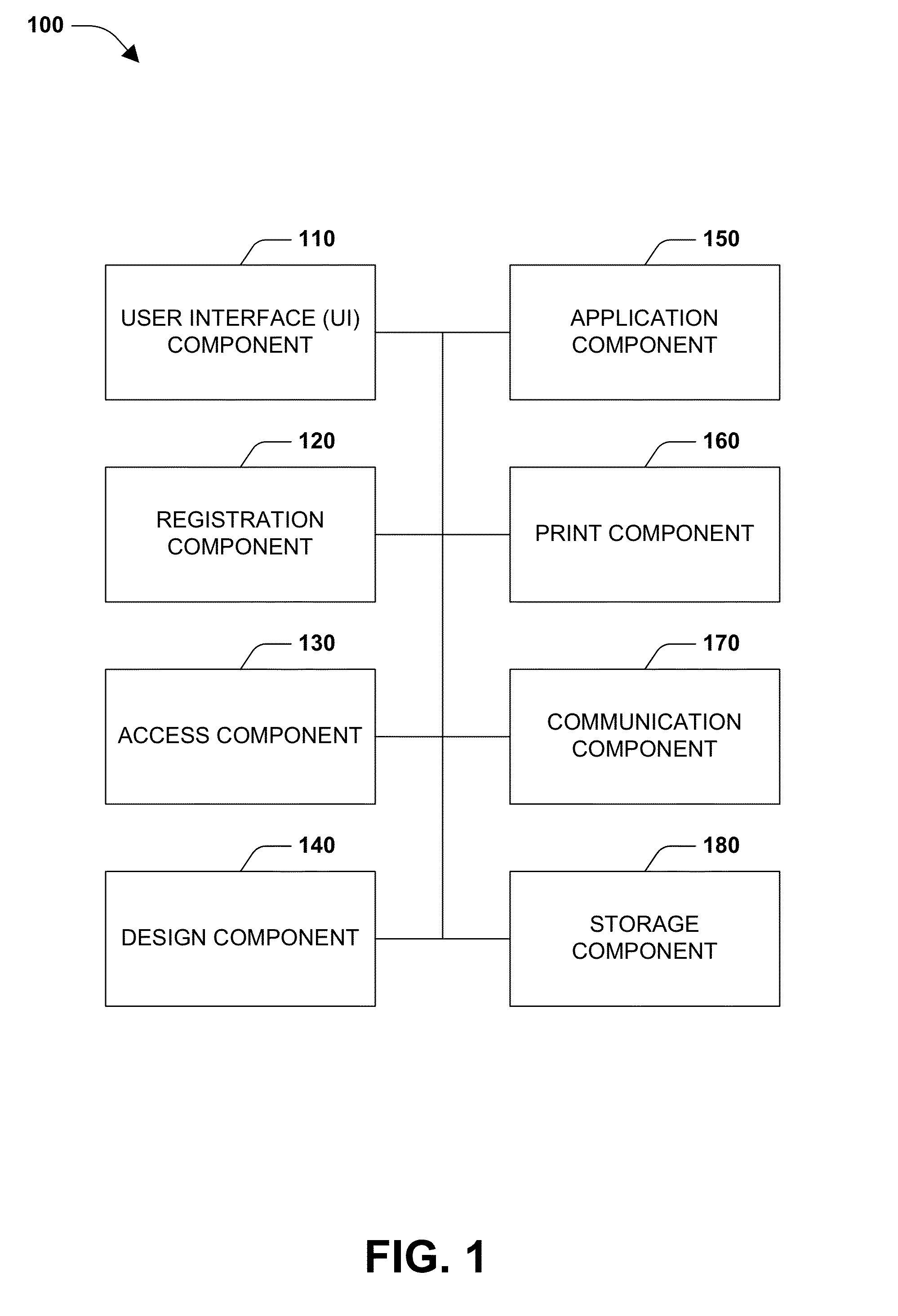

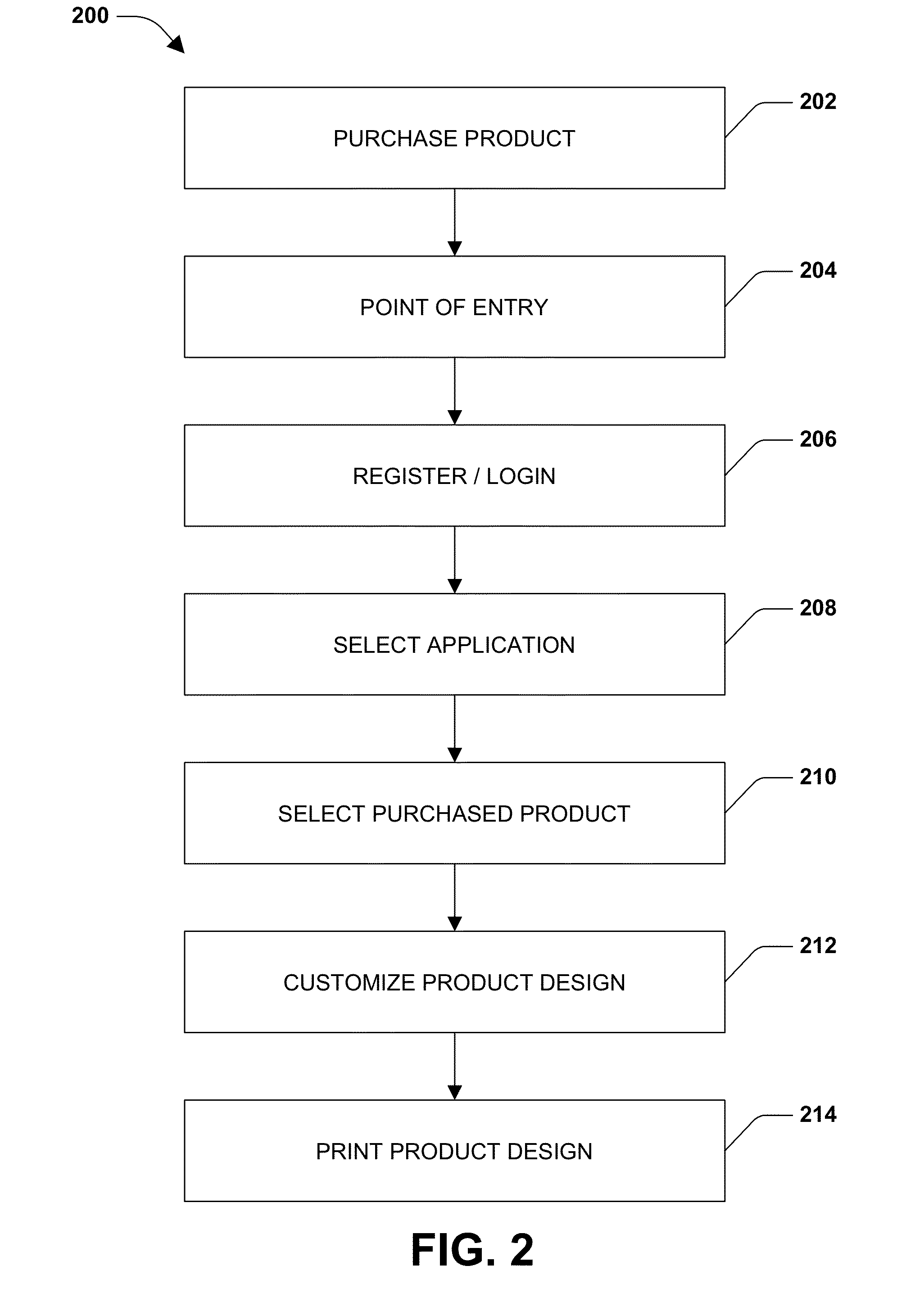

Interface for product design customization

InactiveUS20140067588A1Easy to customizeImage can be createdBuying/selling/leasing transactionsApplication softwareDocumentation

One or more embodiments of techniques or systems for product design customization are provided herein. An interface for product design customization is provided with an application component that can run a stationery application, a merge application, an EZ print application, a photo paper application, etc. These applications may include the ability to insert, modify, or customize design elements. Additionally, these applications may enable a user to divide or split a product design into one or more product design portions, thereby layering the product design. Additionally, data may be merged across one or more documents associated with a product design. Product design reproduction, such as printing, may be limited or controlled according to one or more embodiments.

Owner:MAFCOTE

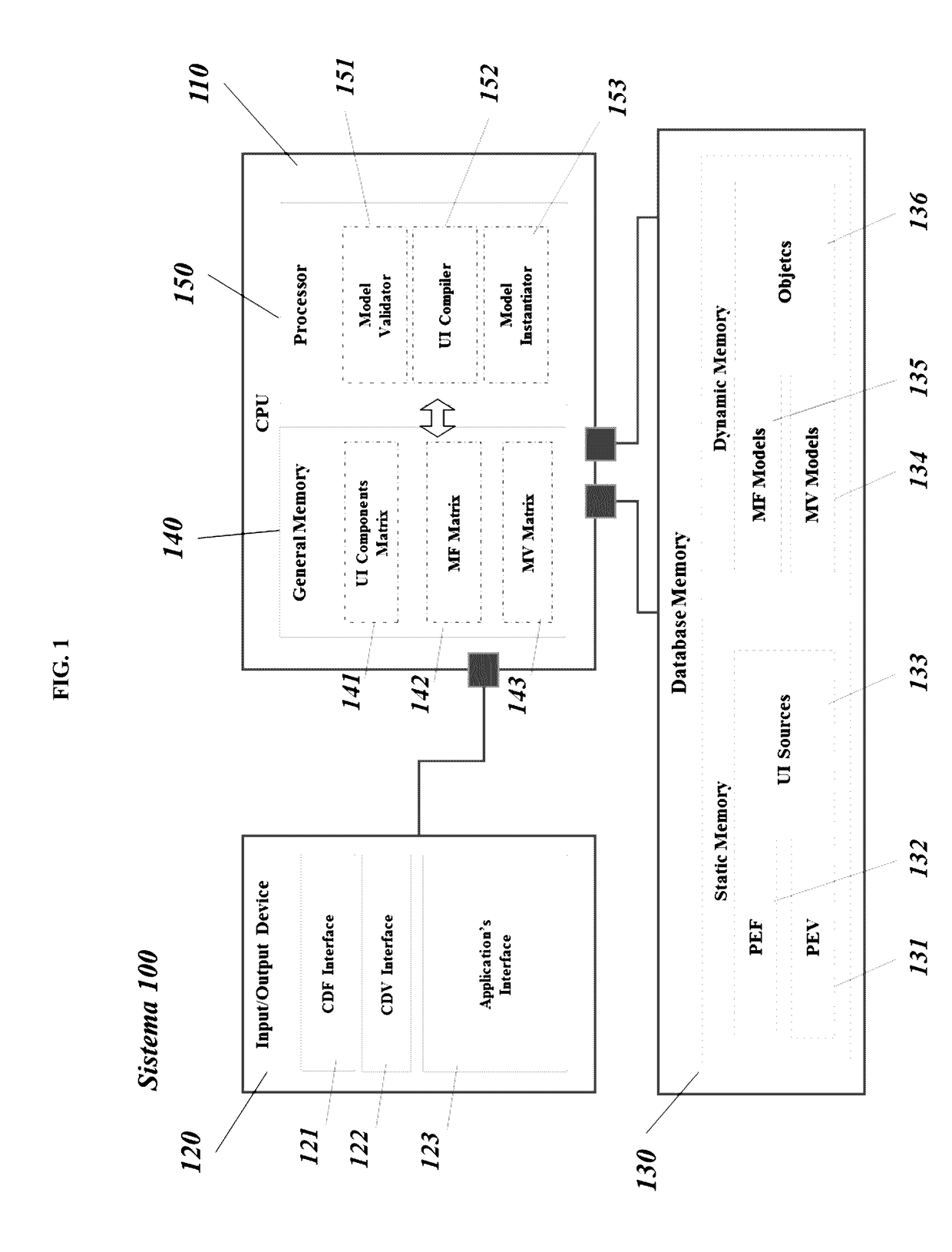

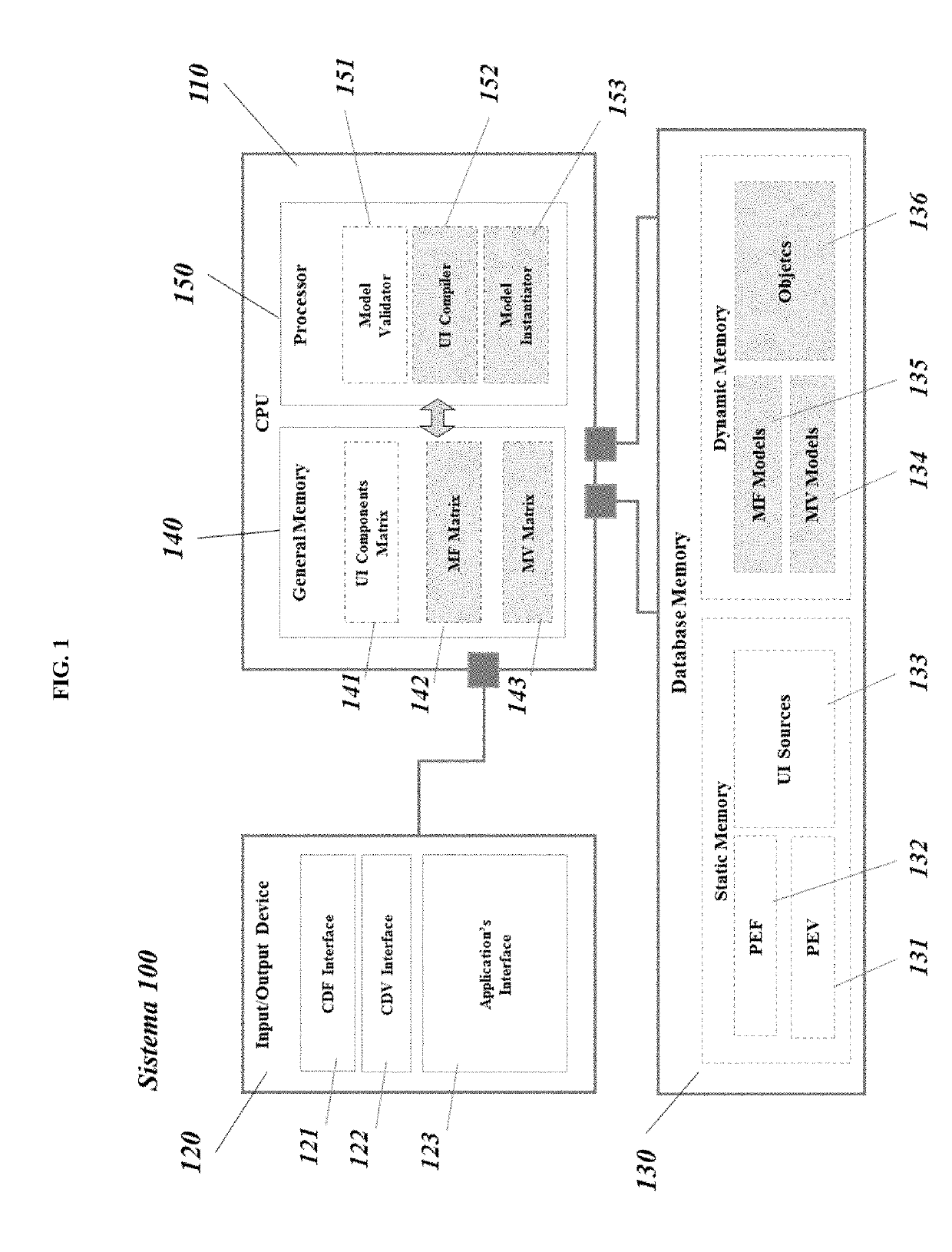

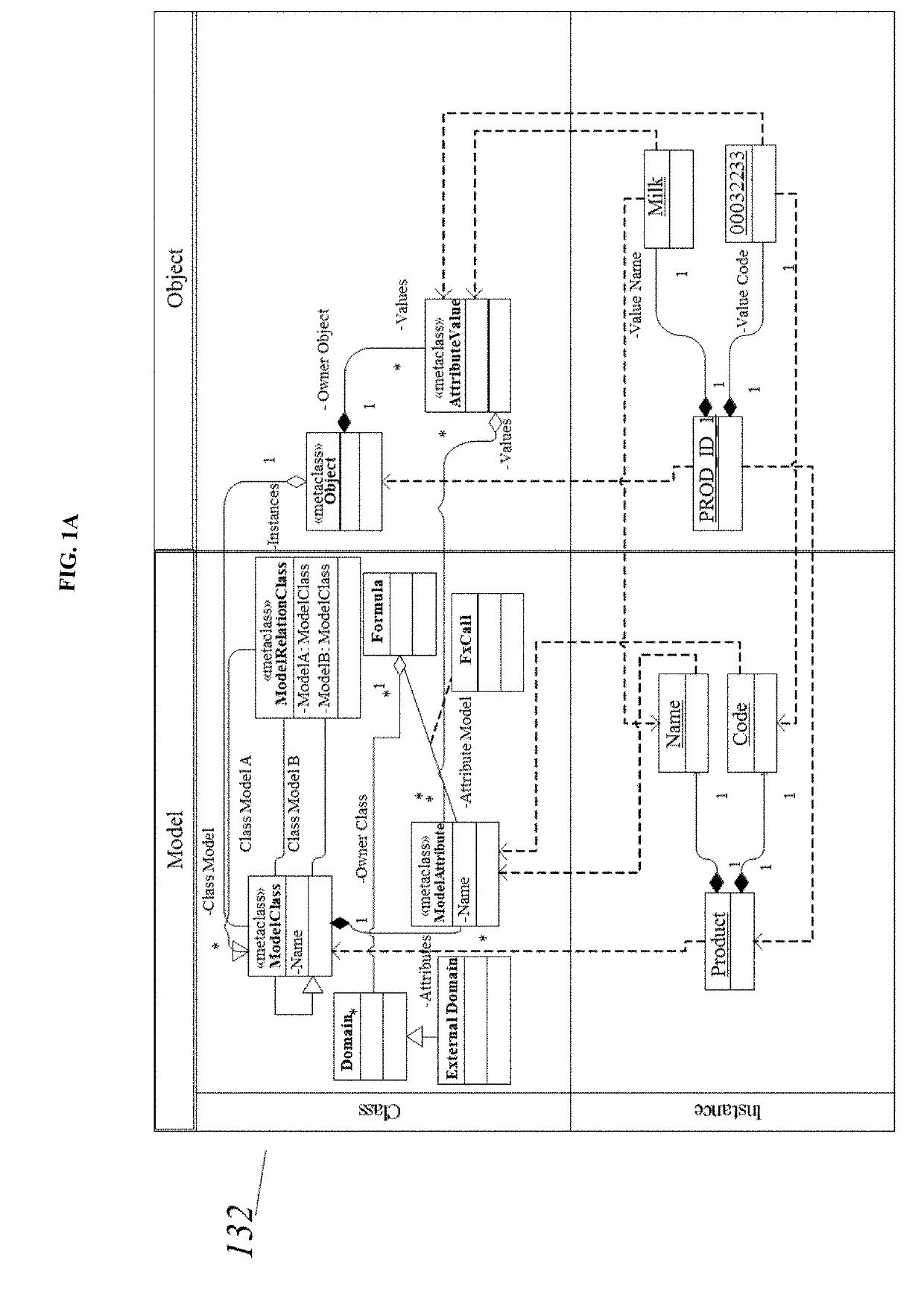

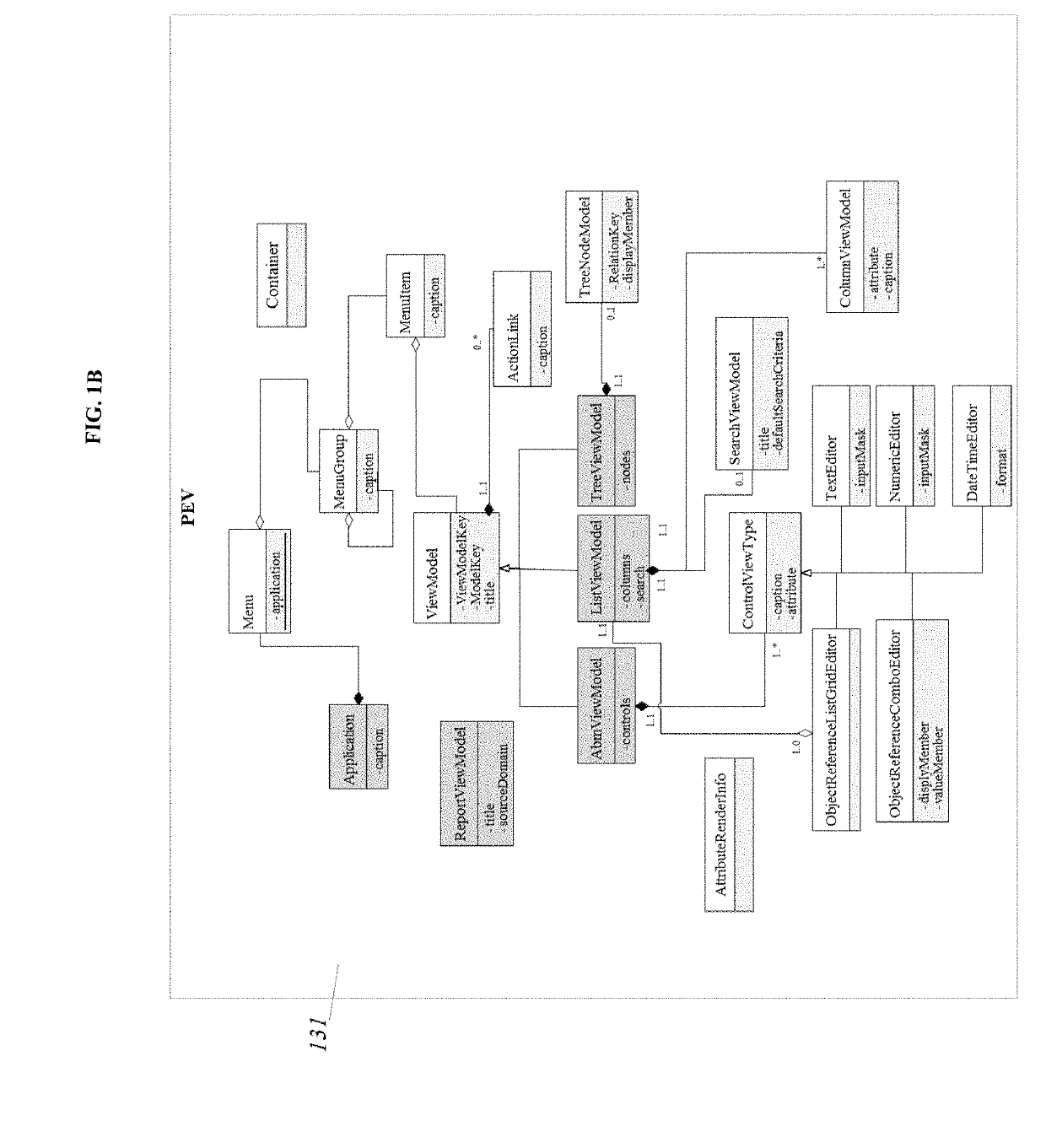

Computer-applied method for displaying software-type applications based on design specifications

The present invention is a system and method that, based on the input of logical structures of information in an electronic device comprising a memory and processor, automatically produces outputs on visual devices that can be operated to create information about business processes, replacing software applications that are normally developed through traditional programming as known in the software industry.Given the information corresponding to the logical structure of a software design, such information is entered into the machine, which stores it on a memory in the form of models. Such models are interpreted by System 100 which automatically produces structures on visual devices that allow replacing software. The invention is the process that System 100 uses to enter, store, interpret and produce visual structures and structural logic that replace software.

Owner:HUEBRA NADIA ANALIA +1

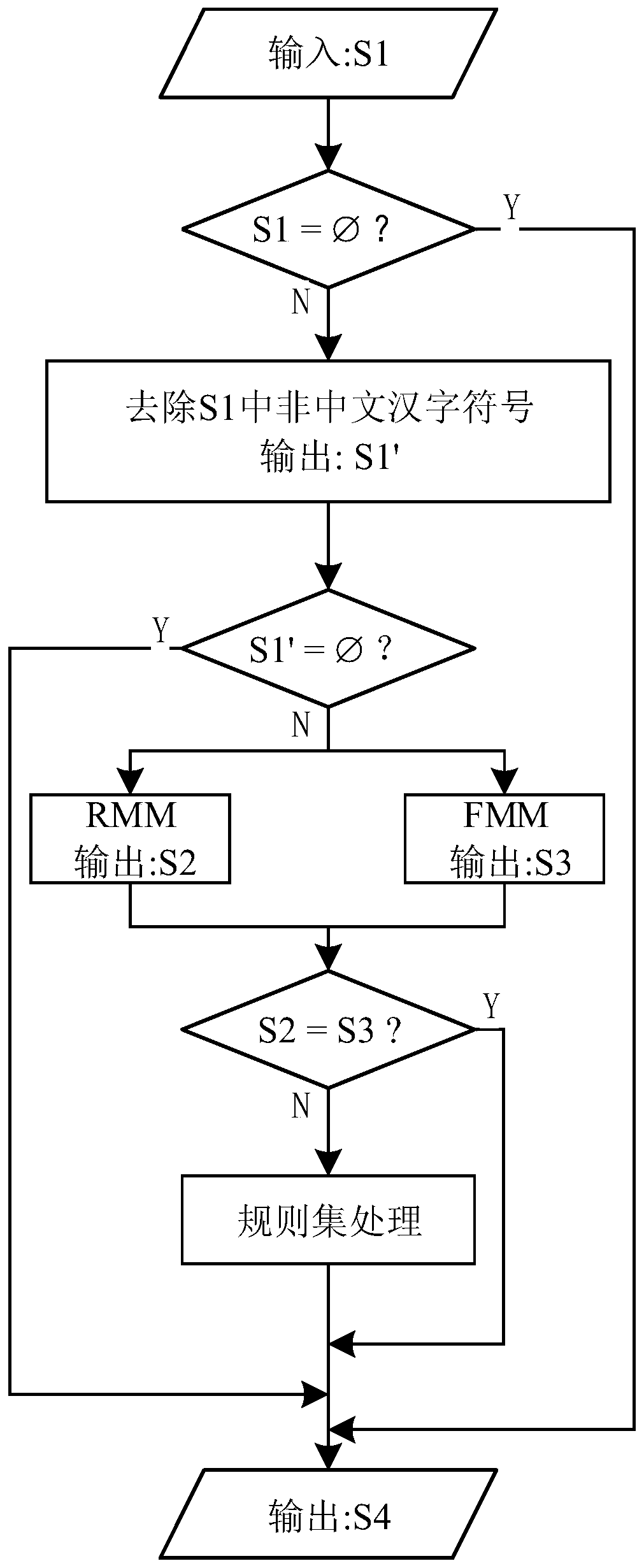

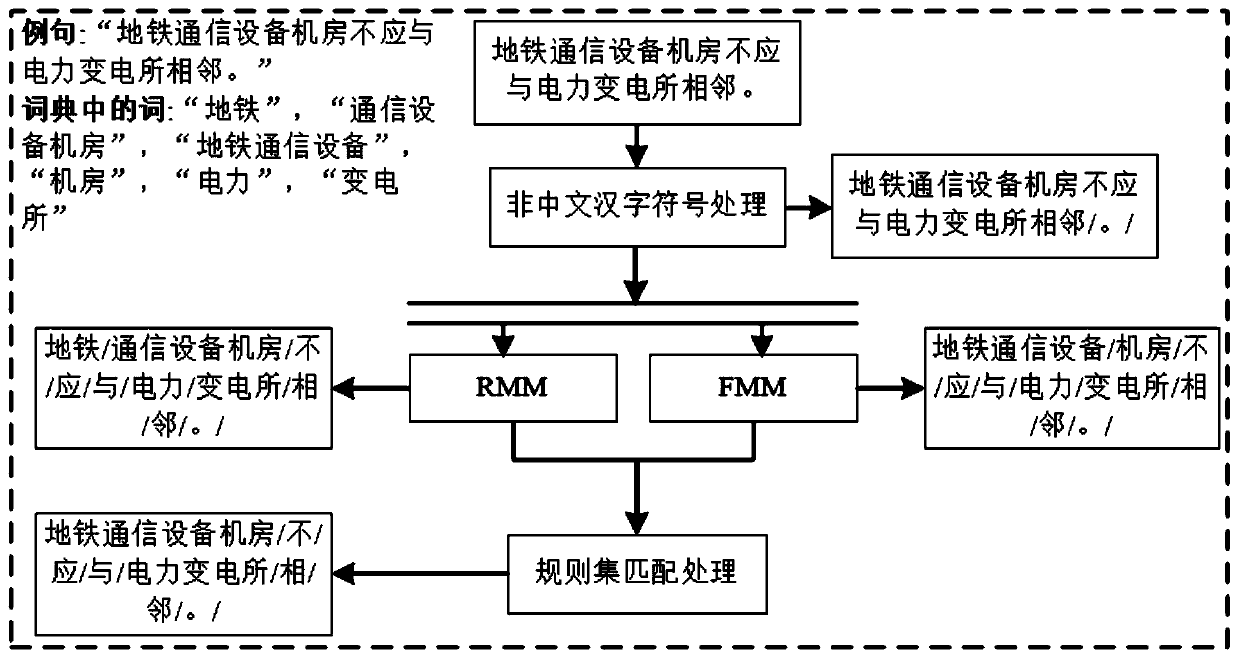

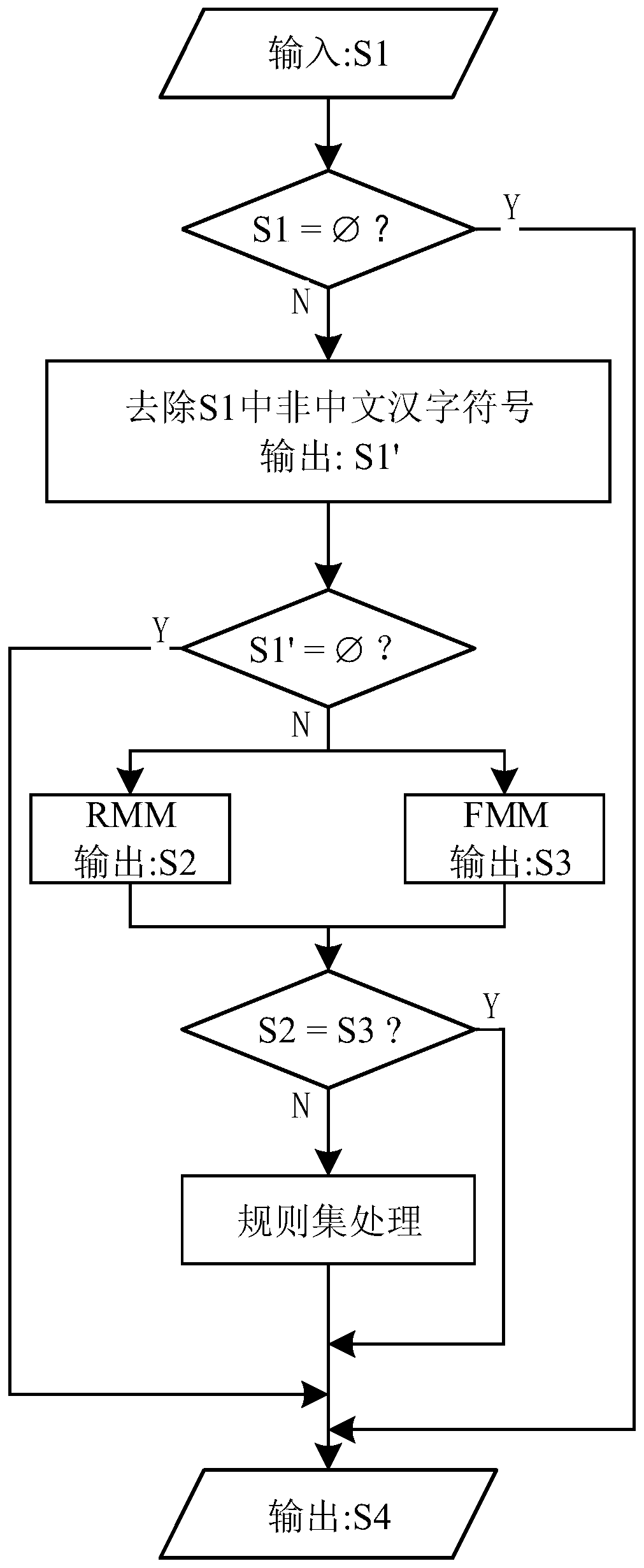

Rule and dictionary-based subject recognition method in subway design specifications

ActiveCN110046348AThe recognition result is accurateReduce the burden onNatural language data processingSpecial data processing applicationsResult setProduct design specification

The invention discloses a rule and dictionary-based subject recognition method in subway design specifications. The method comprises the following steps: 1) constructing a noun hash dictionary index by utilizing a dictionary file; 2) taking a to-be-processed subway design specification text as an input text S1; 3) processing the input text S1, removing Chinese and English punctuation marks, and generating a sentence set S1 '; 4) performing reverse maximum matching algorithm processing on the sentence set S1'to generate a first result set S2; 5) carrying out forward maximum matching algorithm processing on the sentence set S1'to generate a second result set S3, 6) respectively carrying out rule set matching on the first result set S2 and the second result set S3 to generate a final result set S4 of nouns in subway design specifications, and outputting the final result set S4. The method disclosed by the invention has the advantages of high accuracy and convenience in application.

Owner:XIAN UNIV OF TECH

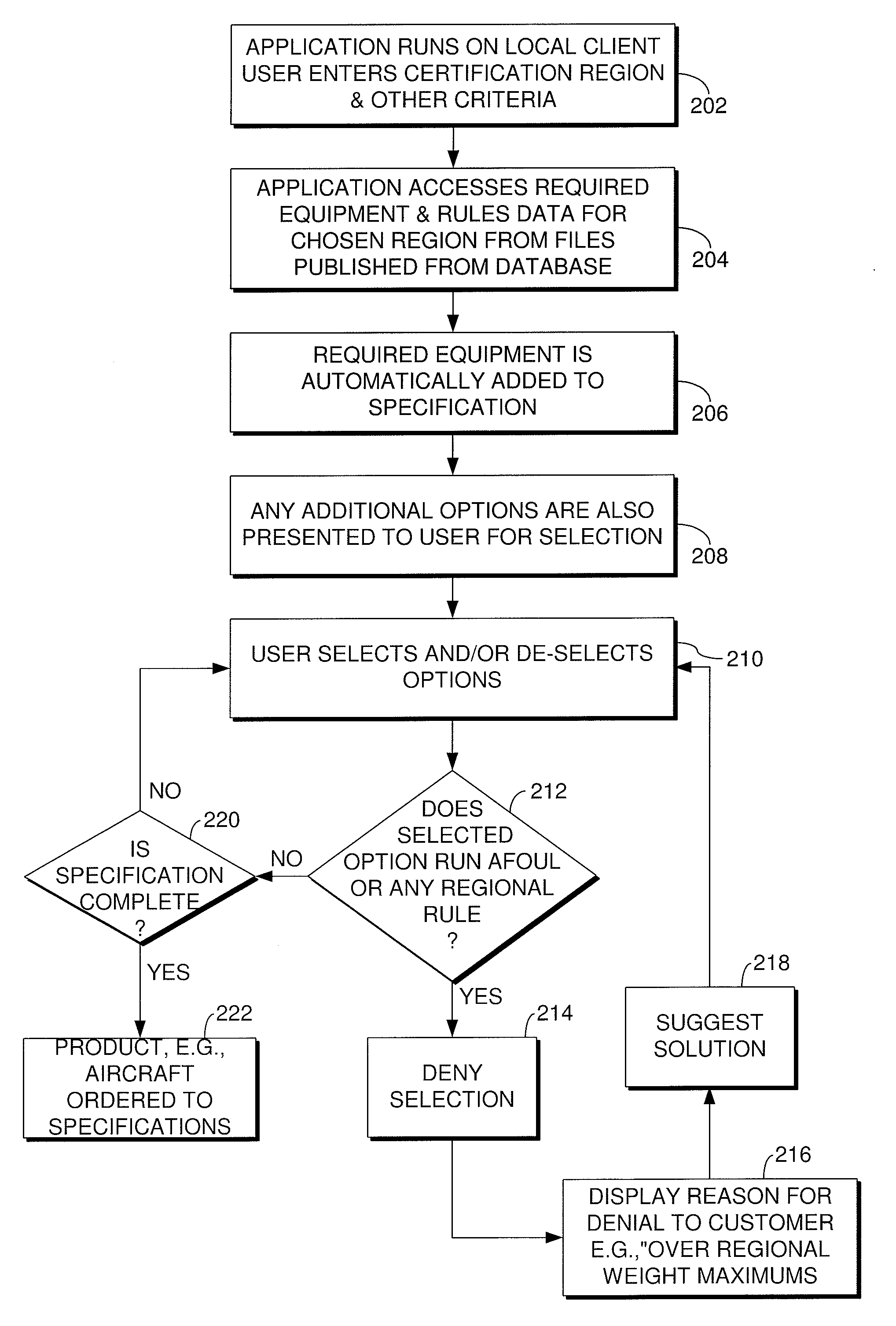

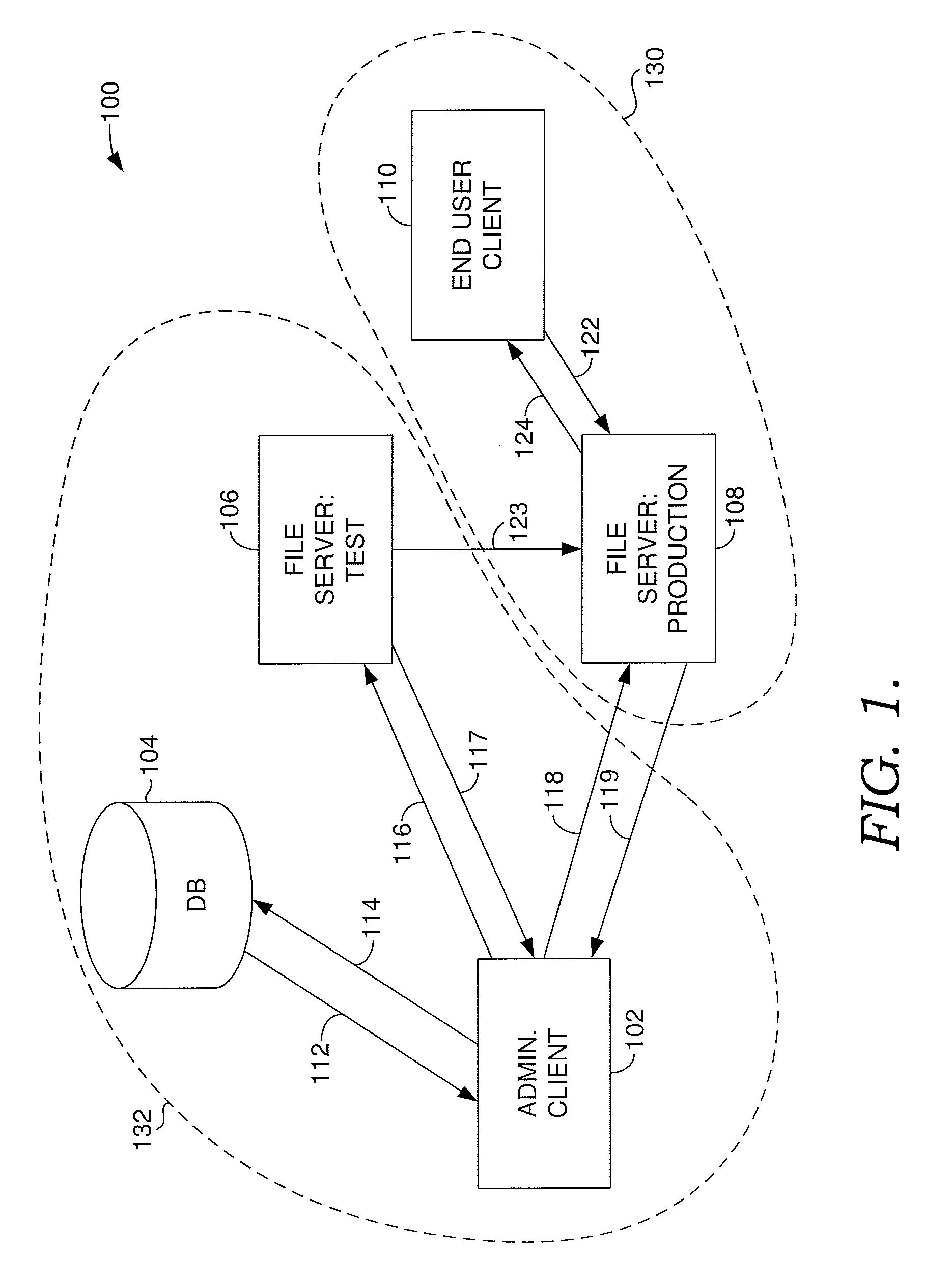

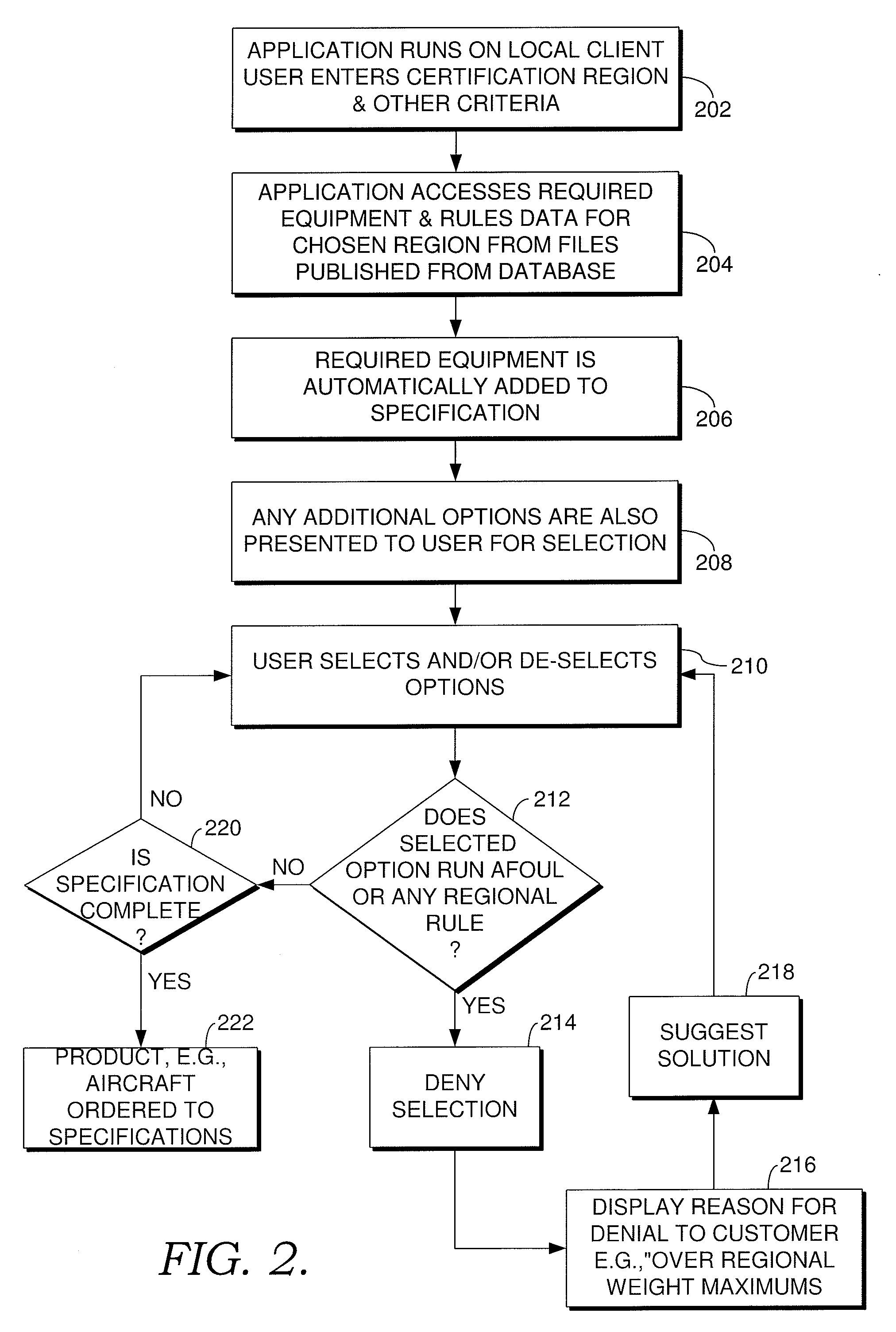

System and method for maintaining a product specification within regional parameters when selecting options

Disclosed is a method of computer generating a product specification. The specification is dependent on the selection of a number of options by a consumer. The method utilizes a computer program which receives from user a location in which said product will be used. After that, the user is allowed to select product options. Information regarding rules and regulations for that particular location is made available from separately identified data files on a server. Options required in that particular locations will be automatically added to the specification. When additional options are selected, the program determines whether the product is still in compliance in the location selected. If the added option results in the specification running afoul of a regional rule or regulation, the user will be notified, and advised as to how the violation can be overcome. Once the user is satisfied with the options, and these options are in compliance, the specification is completed and useful for making an order.

Owner:TEXTRON INNOVATIONS

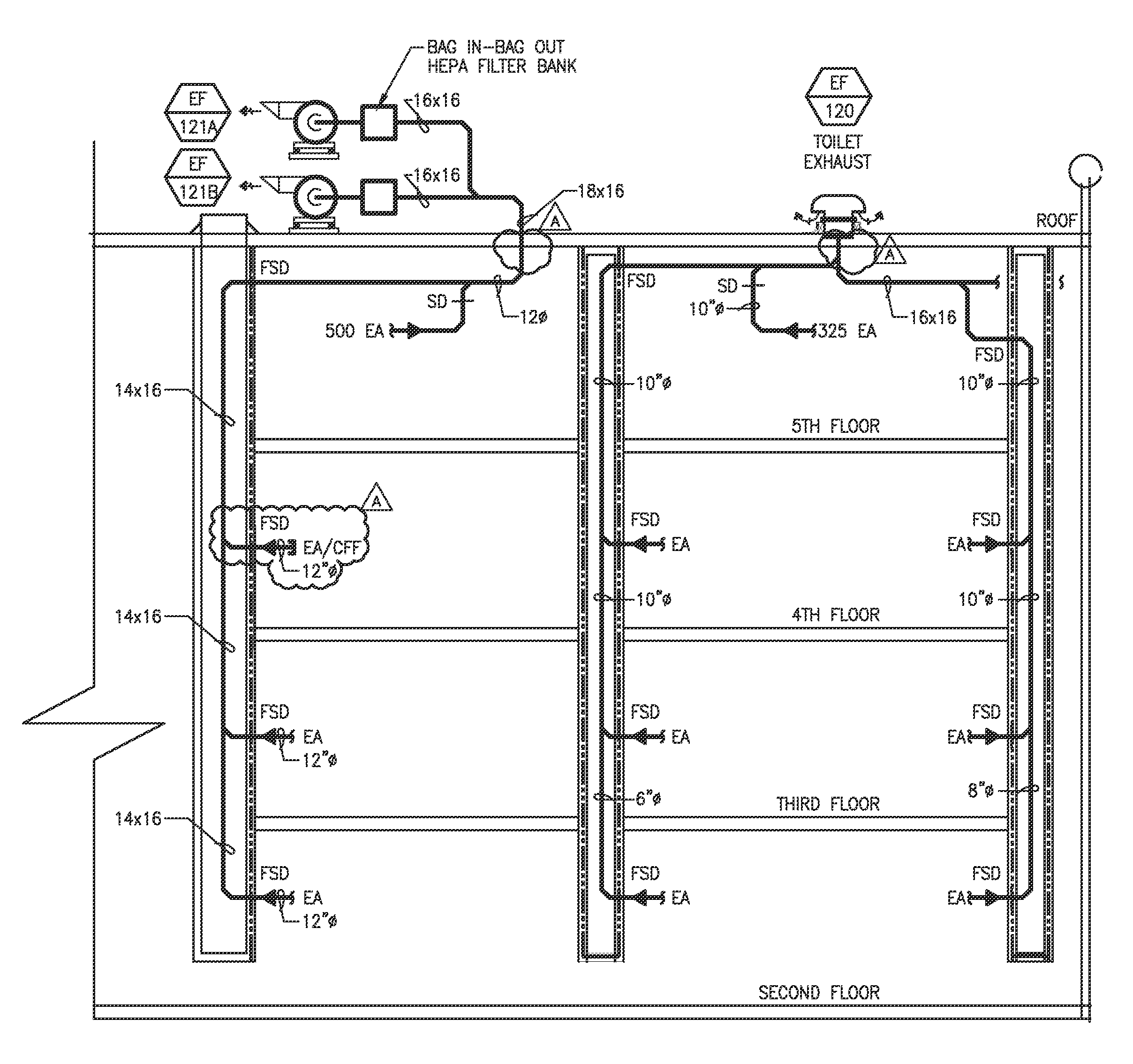

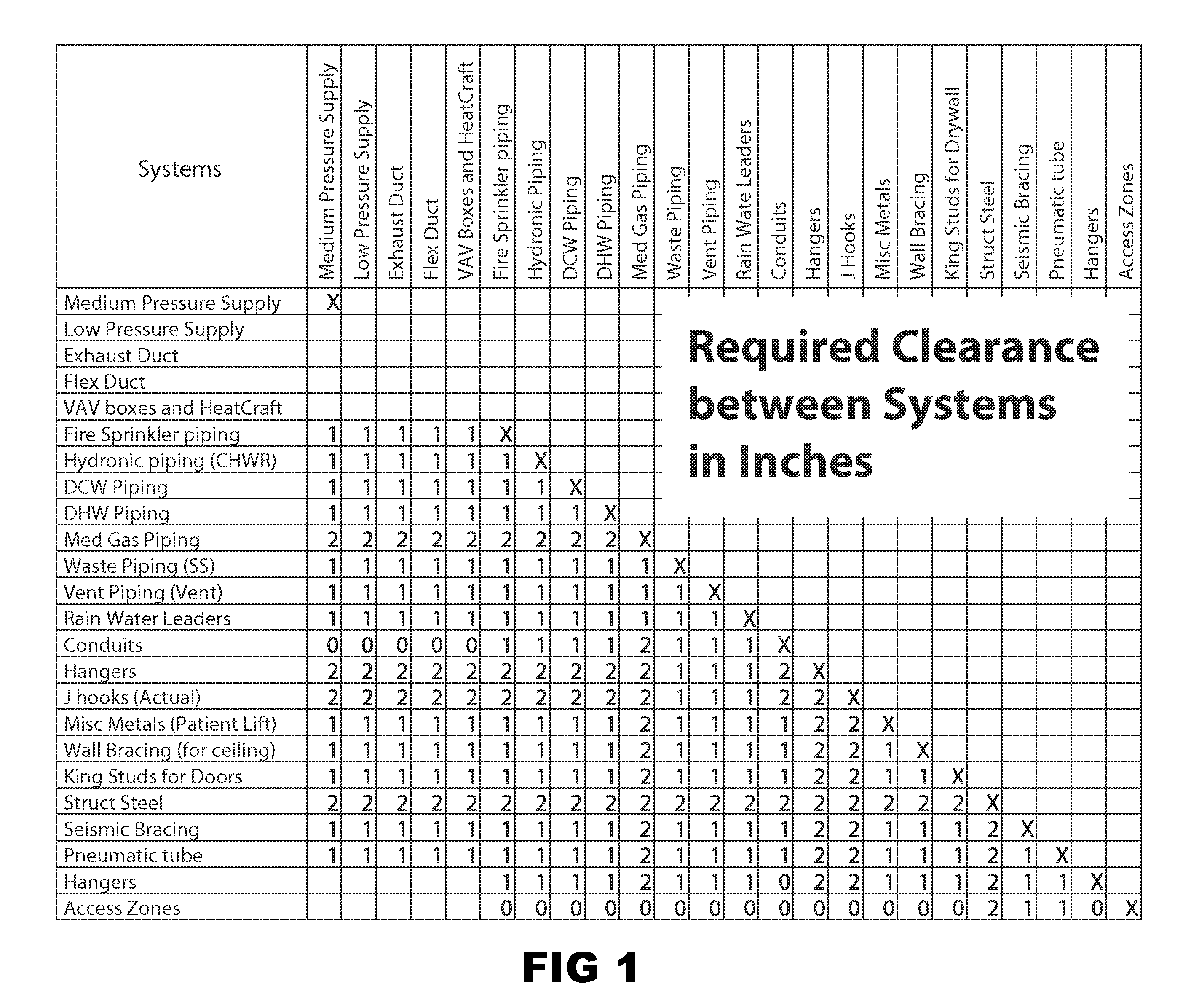

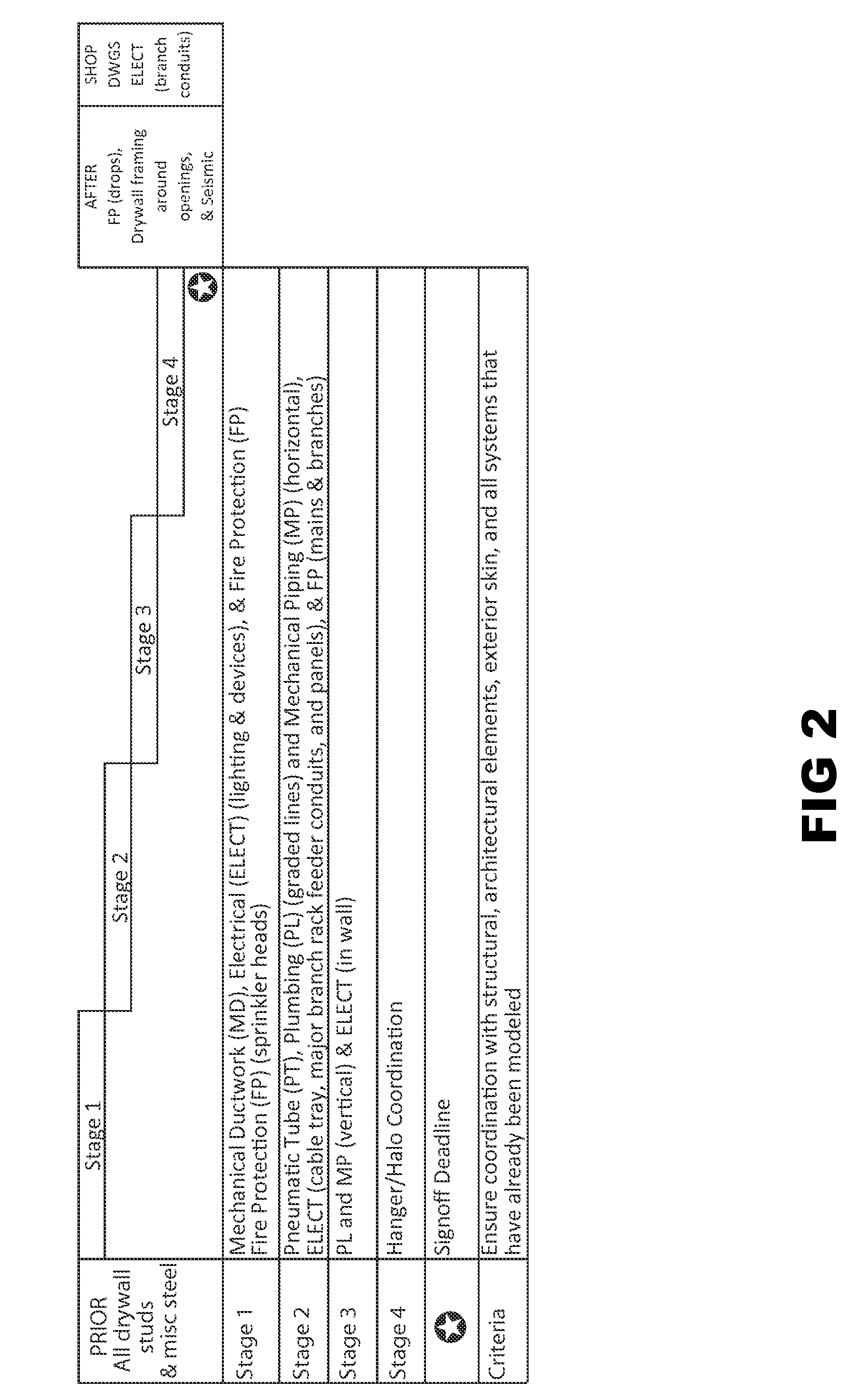

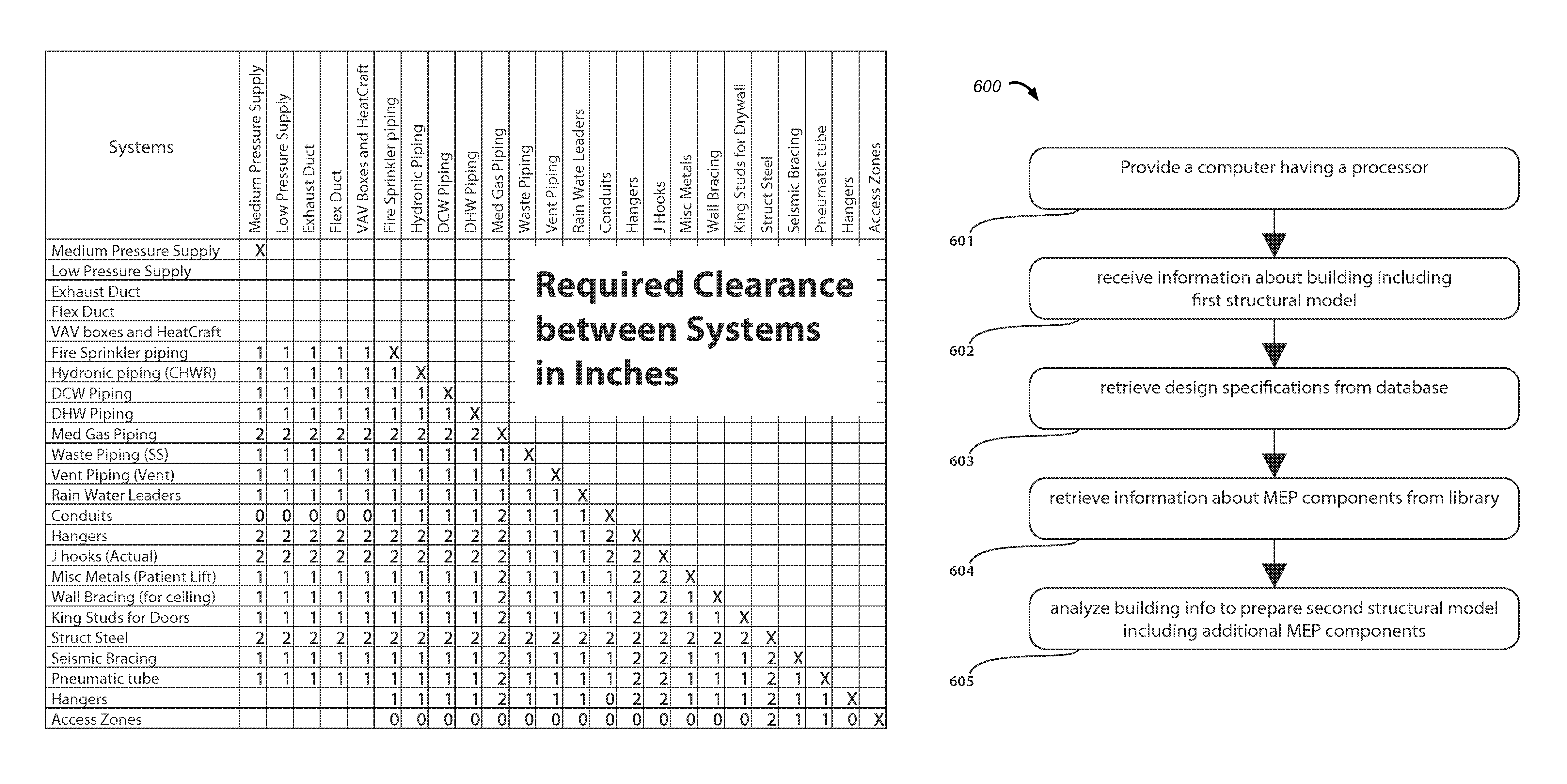

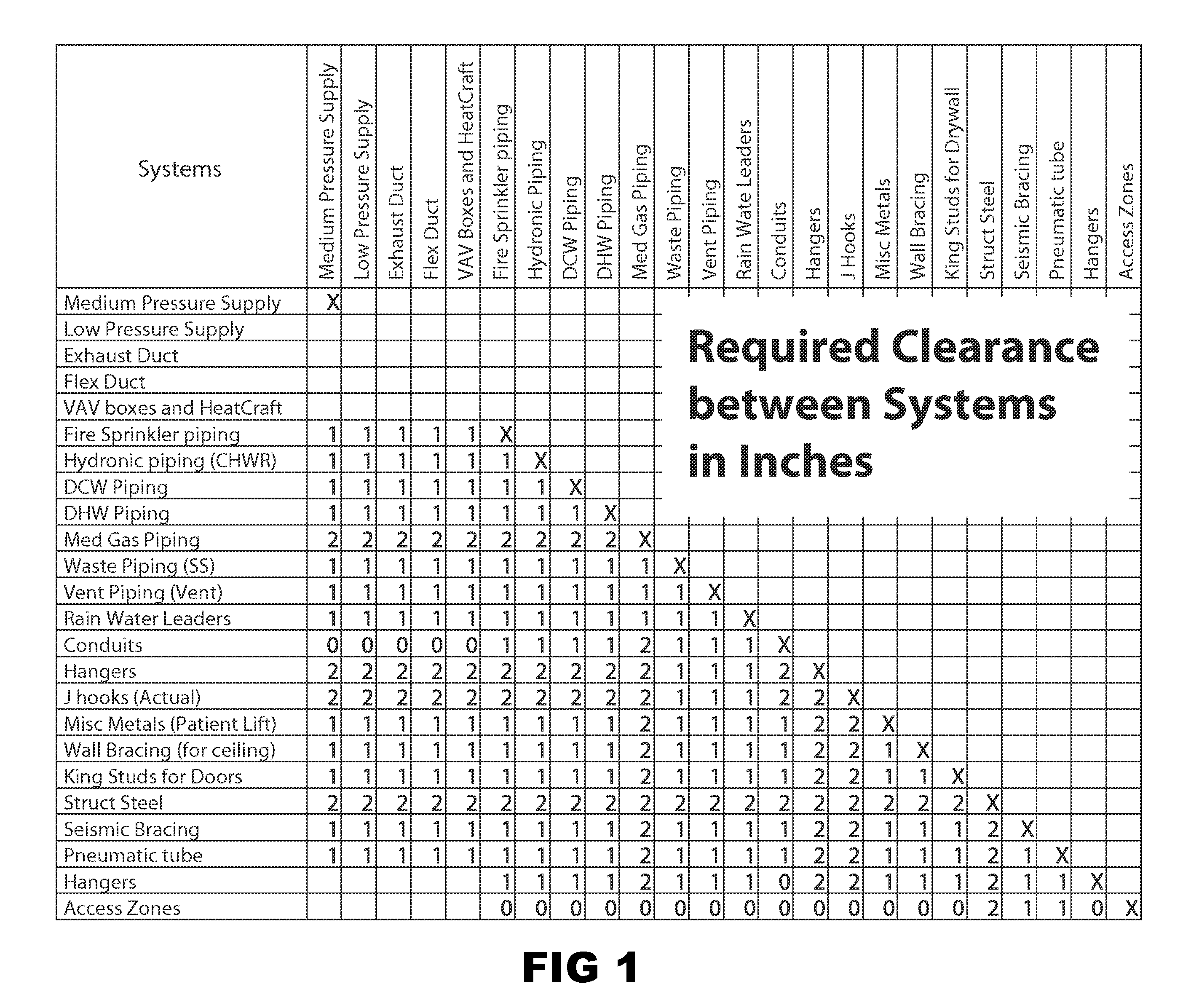

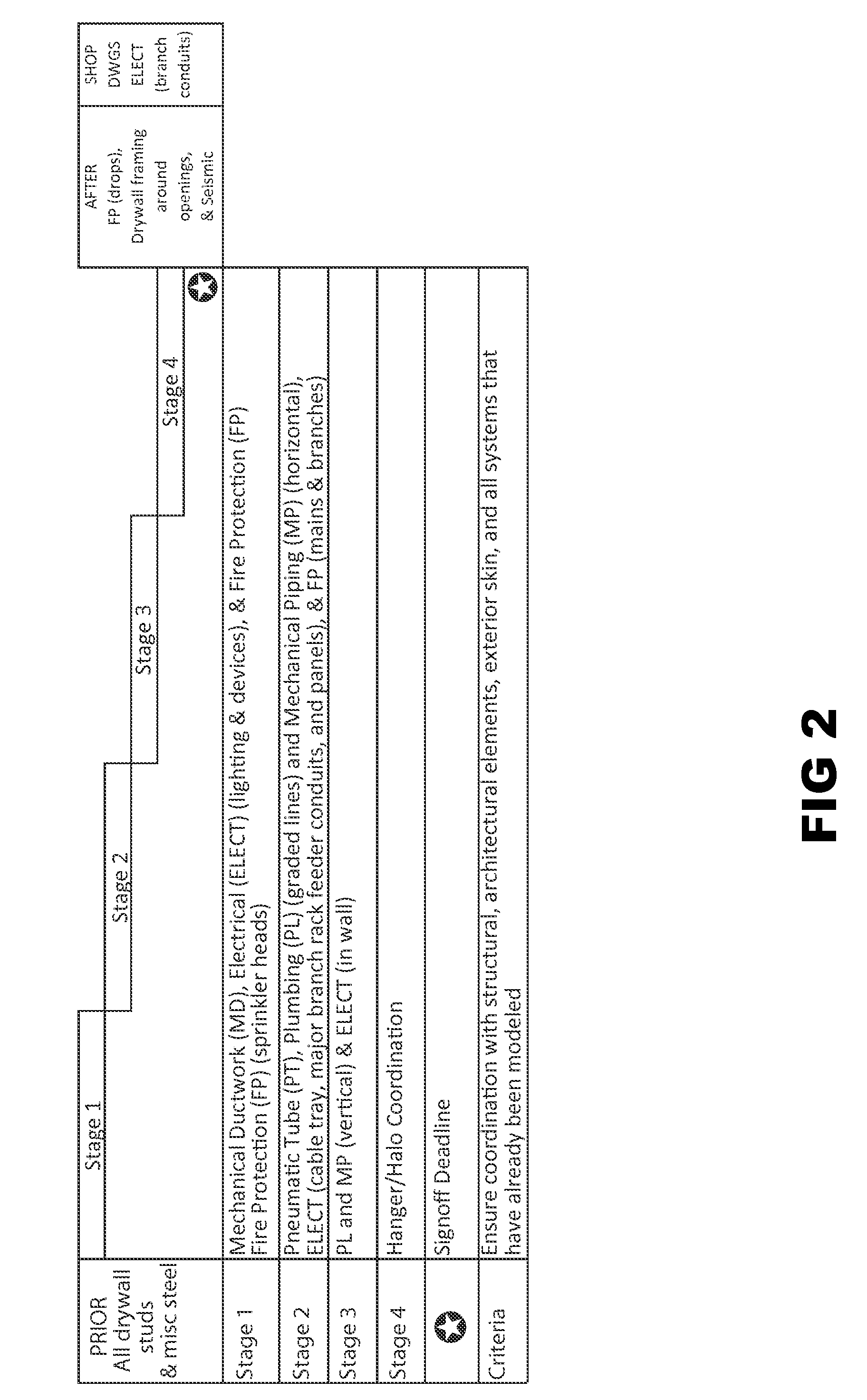

Automated mep design

ActiveUS20150186558A1Geometric CADDesign optimisation/simulationBuilding designLaws of thermodynamics

Embodiments of the present invention include a method for automatically designing MEP for a building. The method may include receiving information about the building including a first structural model of the building, and retrieving design specifications from a database, including information about local building codes, physical laws and building design rules. Information about available MEP components may be retrieved from a component library. The information about the building and the design specifications may be analyzed to determine additional elements for the first structural model of the building. A second structural model of the building including the additional elements may then be prepared.

Owner:DPR CONSTR

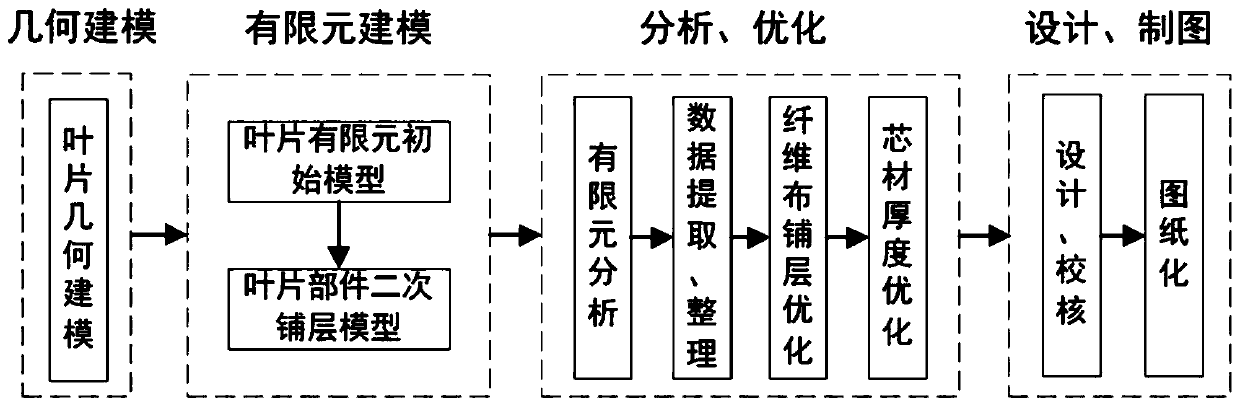

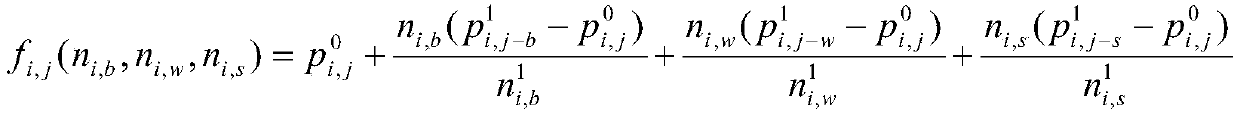

Wind turbine blade laying design method for wind turbine generator system

PendingCN110298097ALight in massAvoid checkingDesign optimisation/simulationSpecial data processing applicationsFiberTurbine blade

The invention discloses a wind turbine blade laying design method for a wind generating set. The method comprises the following steps that (1) a blade geometric model is built; (2) establishing an initial layer laying model, and respectively establishing a beam cap secondary layer laying model, a shear web secondary layer laying model and a shell secondary layer laying model on the initial model;(3) carrying out IFF (inter-fiber failure) analysis; (4) calculating the laying area; (5) summarizing the relation between the blade IFF coefficient and the laying layer and the relation between the blade laying layer and the weight; (6) carrying out fiber cloth laying optimization design; (7) carrying out blade core material optimization design by taking the blade buckling safety coefficient as design constraint and taking the minimum mass as a design target; and (8) carrying out lamination design, finite element checking and drawing according to the technical requirements of blade design specifications, manufacturing processes and the like. According to the method, the optimal solution is searched in the whole domain range, so that the blade laying layer is optimized, the blade quality is reduced, complex design and checking processes are avoided, and the research and development efficiency is improved.

Owner:中科国风科技有限公司

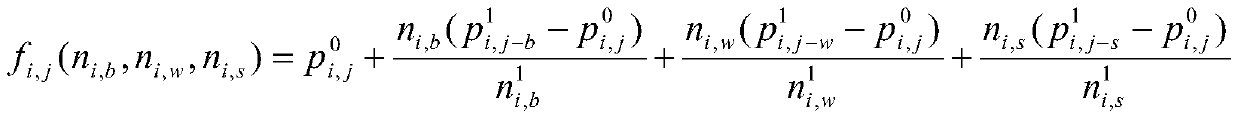

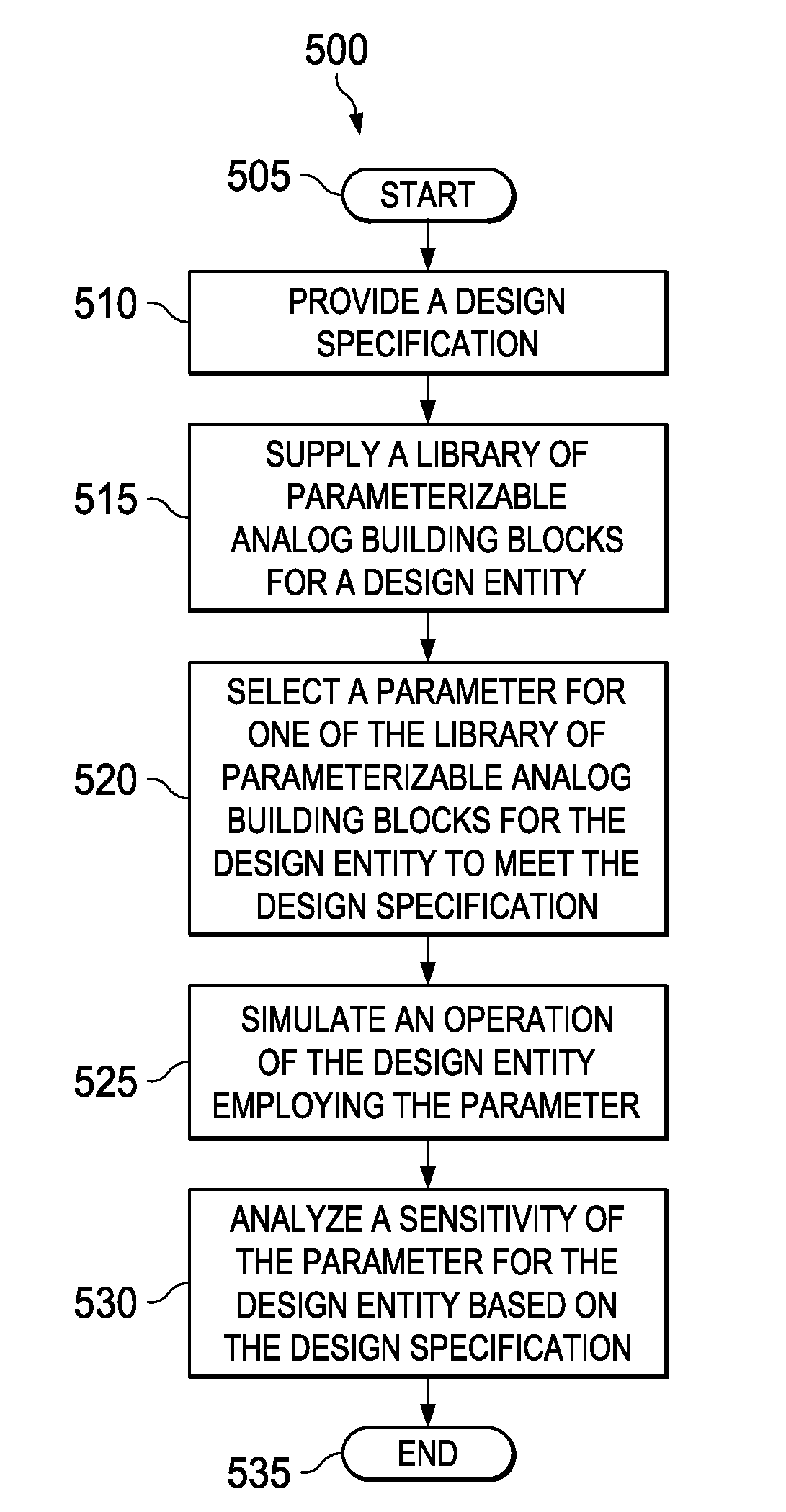

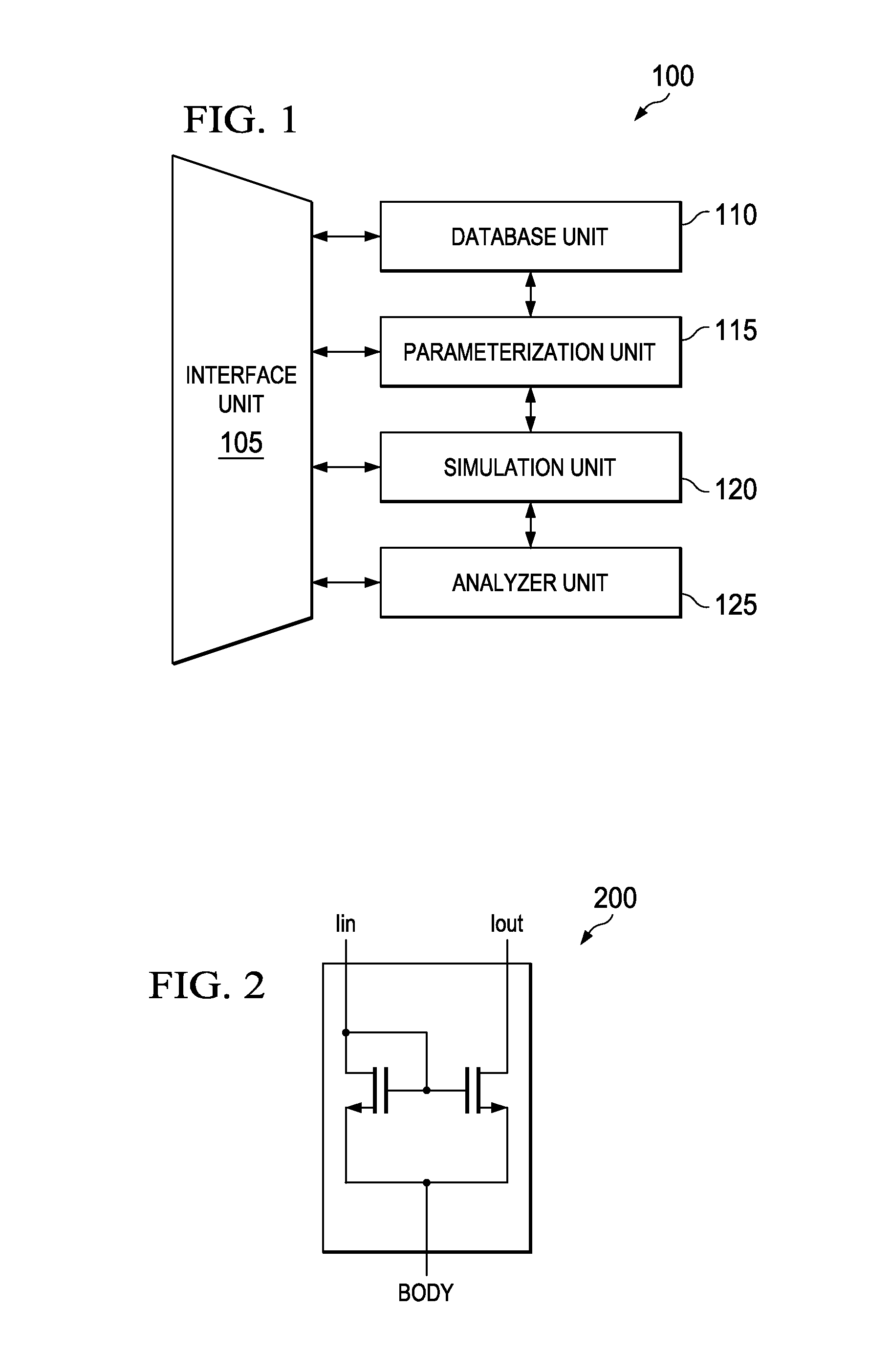

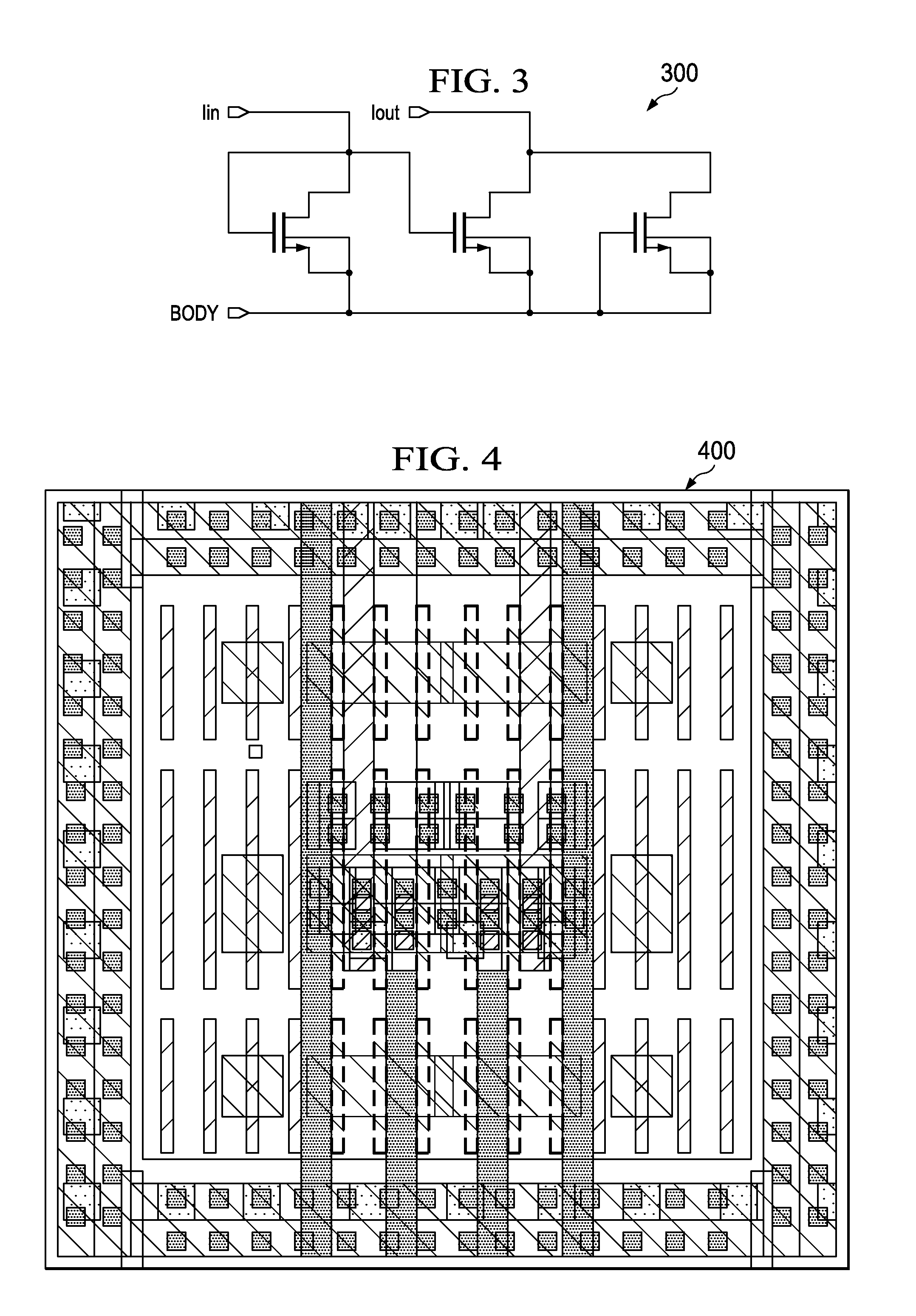

Fully parameterizable representation of a higher level design entity

ActiveUS20120304140A1Computer programmed simultaneously with data introductionCAD circuit designEngineeringHigh-level design

A parameterizable design system is for use with semiconductor analog circuits and includes an interface unit connected to provide access to the system, a database unit connected to supply a library of parameterizable analog building blocks for a design entity, and a parameterization unit connected to select a parameter for one of the library of parameterizable analog building blocks to meet a design specification of the design entity. Additionally, the parameterizable design system may also include a simulation unit connected to simulate an operation of the design entity employing the parameter, and an analyzer unit connected to analyze a sensitivity of the parameter for the design entity based on the design specification. A method of designing a semiconductor analog circuit is also included.

Owner:BELL SEMICON LLC

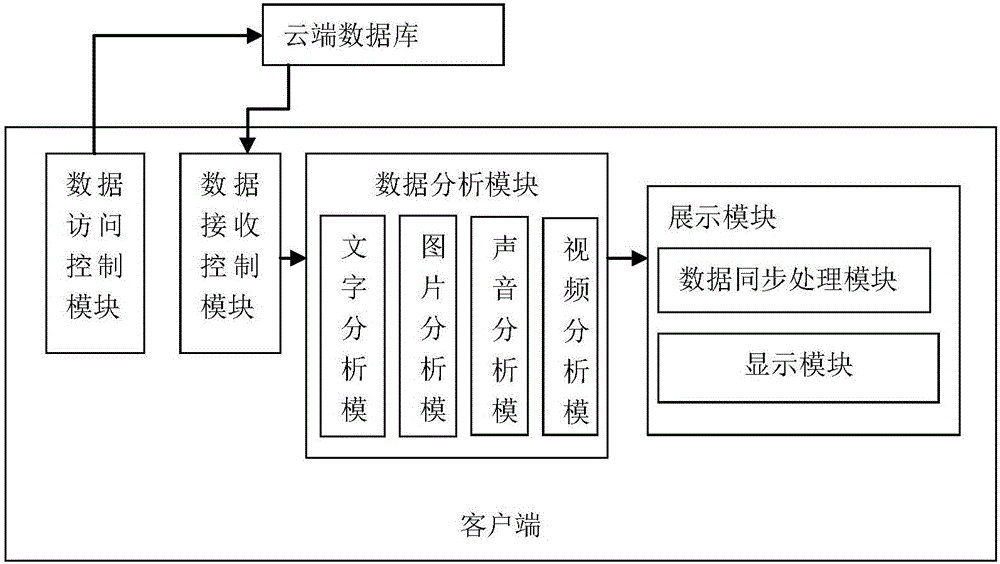

3D specification display system

InactiveCN106599225ADon't worry about losingMultimedia data queryingSpecial data processing applicationsUser needsComputer graphics (images)

The invention discloses a 3D specification display system. When a user accesses a specific product, a cloud database is accessed by executing a js script of a client; specification data of the product meeting user demands is obtained and downloaded; synchronous matching processing is performed according to the data such as pictures, texts, sounds, videos and the like configured in the specification; the data is embedded in a same display page in an H5 way; the 3D data in the page is loaded and rendered through webgl; and then all the data is integrated and presented to the user. By adopting the 3D specification display system, an original paper specification is showed to the user in a 3D way by adopting text, picture, sound and video multimedia; the user can obtain the product specification dynamically displayed in the 3D way without reading the dull paper product specification; the 3D specification is intuitive and understandable; and the loss of the specification does not need to be worried.

Owner:CHENGDU JUNQIAN INFORMATION TECH CO LTD

Computer-applied method for displaying software-type applications based on design specifications

System and method that automatically instantiates and displays software-type applications based on software design specifications that based on the input of logical structures of information in an electronic device, automatically identifies, validates and store functional and visual design component based on software specifications stored on a database memory. The method automatically creates functional and visual models and store those models and finally automatically display on a device the application interface, functional and visual models combined with other protocols stored in memory using the processor as an instantiator.

Owner:HUEBRA NADIA ANALIA +1

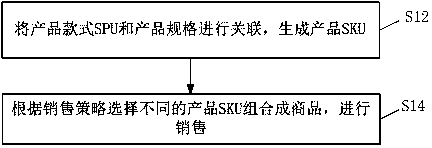

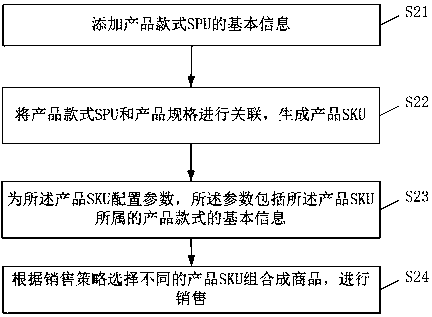

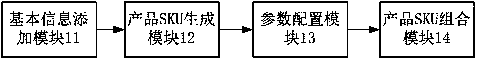

Three-tier architecture commodity management method and system

InactiveCN107767219AImprove reusabilityReduce configuration costsBuying/selling/leasing transactionsApproaches of managementReusability

The invention relates to a three-tier architecture commodity management method and system, and the method comprises the steps: adding the basic information of a product style SPU; enabling the productstyle SPU to be correlated with a product specification, and generating a product SKU; configuring parameters for the product SKU, wherein the parameters comprises the basic information of the product style where the product SKU belongs; selecting different product SKUs to form a commodity according to a sales strategy, and carrying out the selling. The product style SPU is correlated with the product specification, and the product SKU is generated. Different product SKUs are selected to flexibly form the commodity according to the sales strategy, and countless types of commodity combinationscan be generated for the same product SKU, thereby improving the reusability of the SKUs. In addition, during the configuration of the parameters of the product SKU, the method can achieve the directadding of the basic information of the product style where the product SKU belongs, reduces the configuration cost, and improves the operation efficiency.

Owner:广州市万表科技股份有限公司

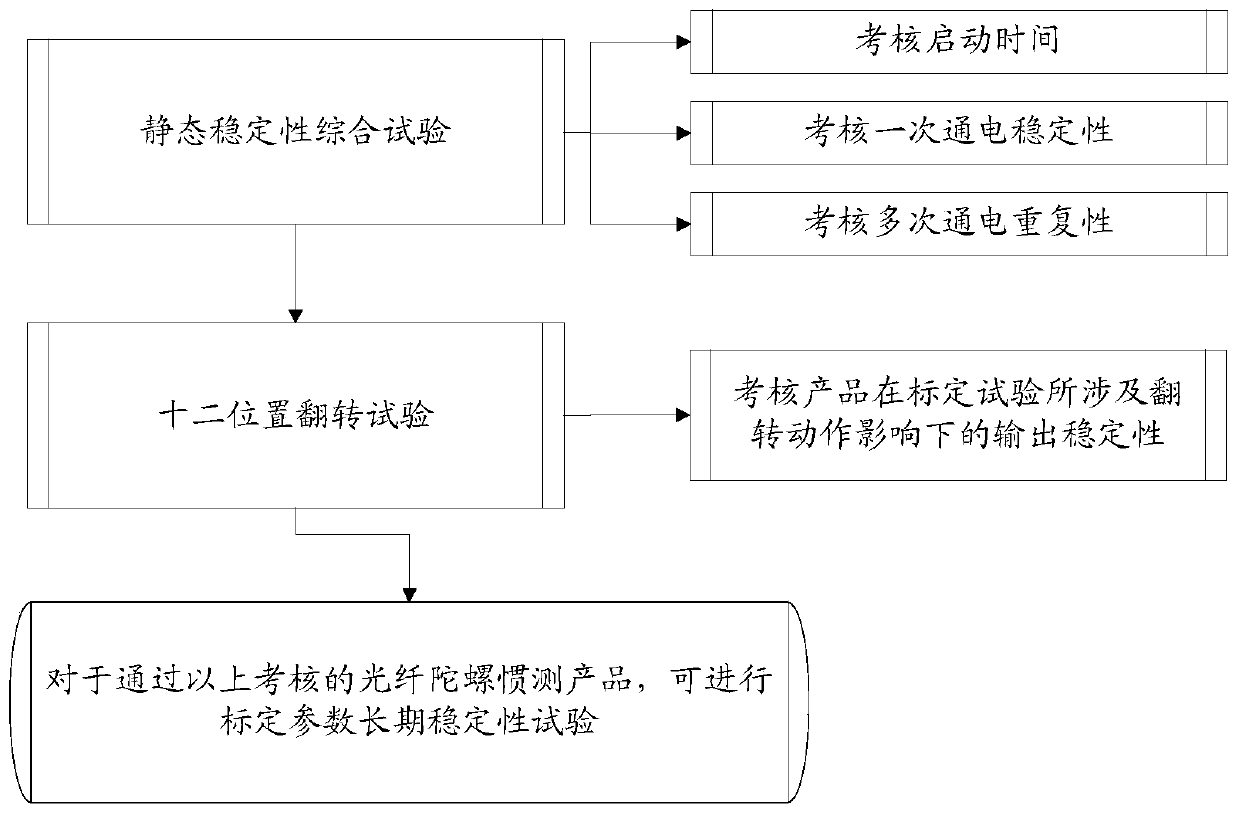

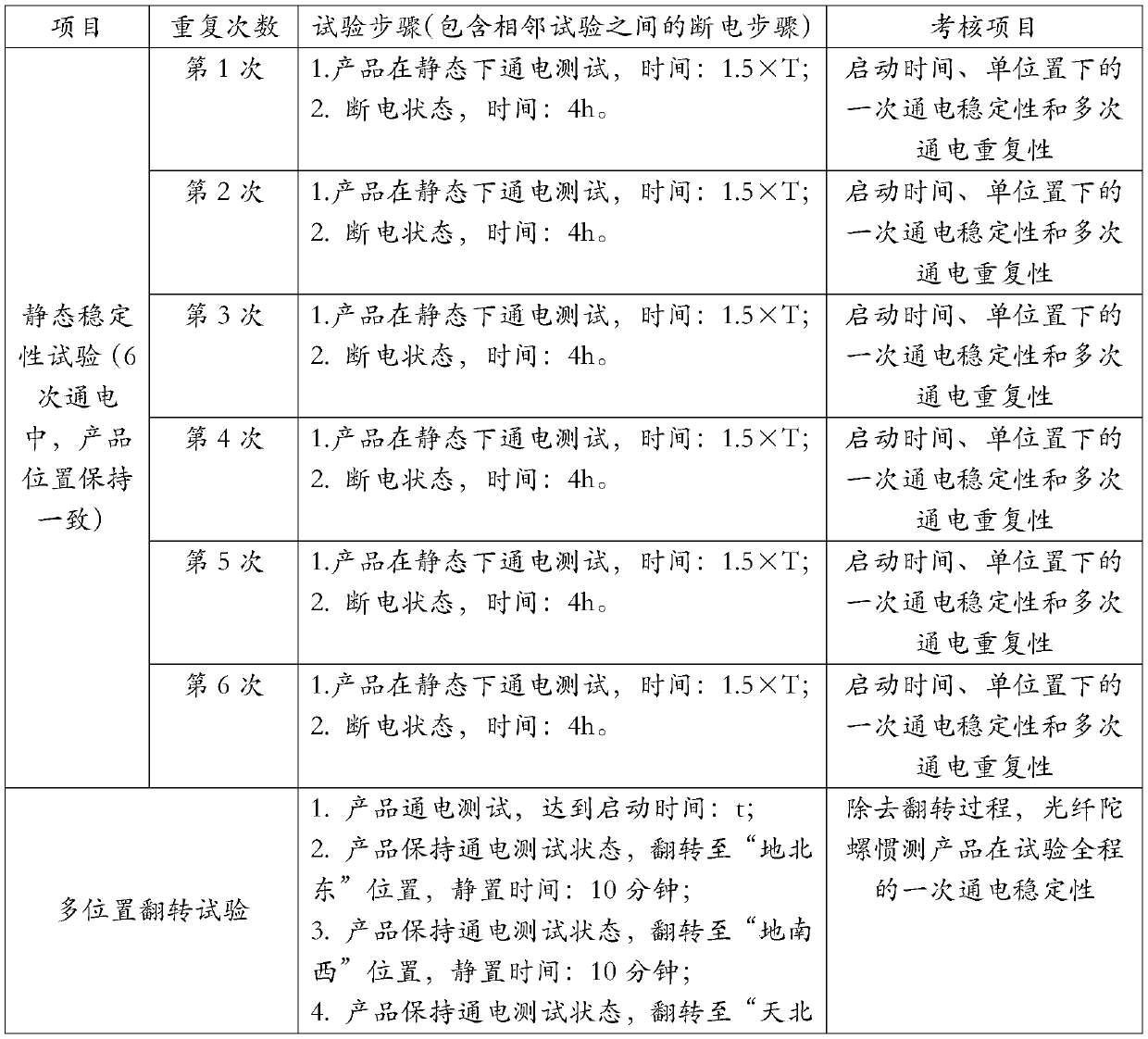

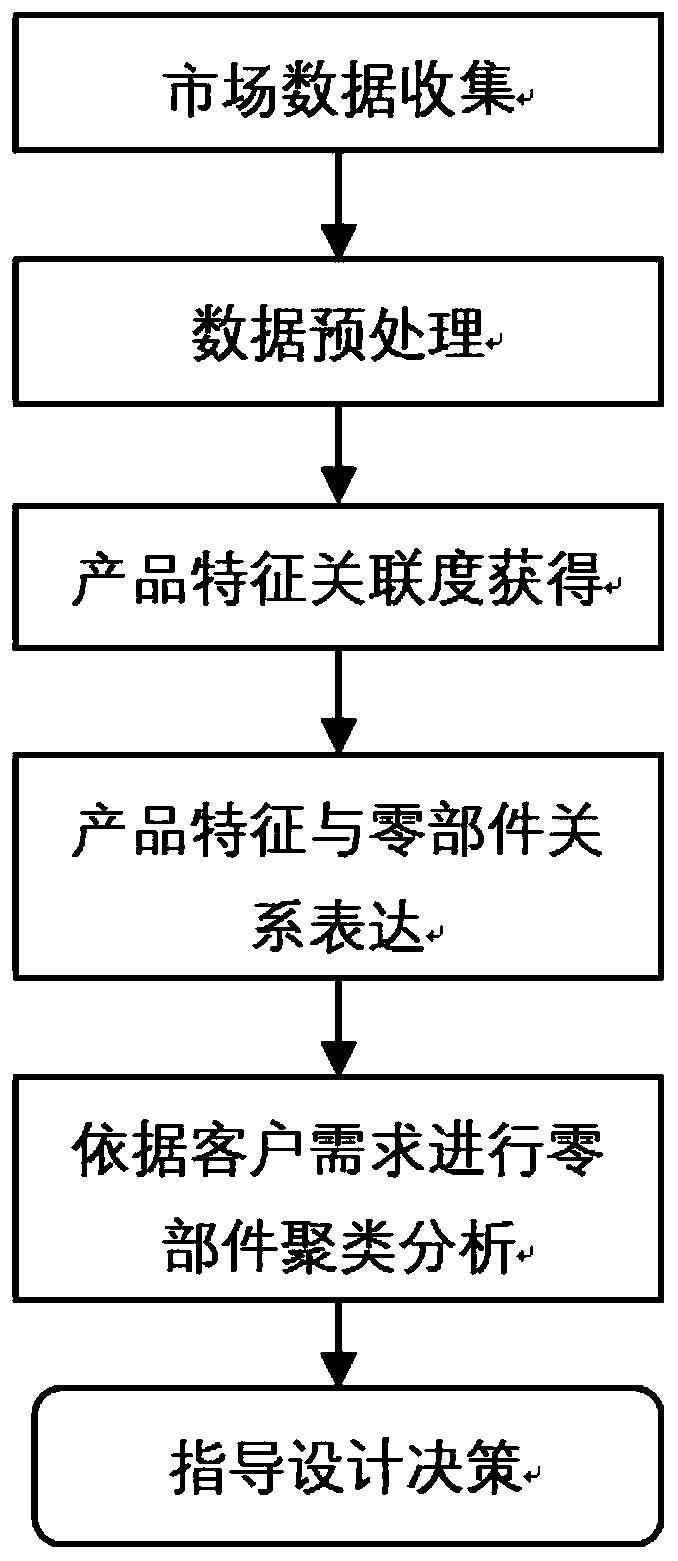

Fiber optic gyro inertial measurement product calibration parameter long-term stability defect detection method

ActiveCN110285832AImprove efficiencyGuaranteed accuracy and reliabilityMeasurement devicesFiberStart up time

The invention provides a fiber optic gyro inertial measurement product calibration parameter long-term stability defect detection method. Firstly, the static stability comprehensive test is performed on a fiber optic gyro inertial measurement product under the long-term stability test, and whether the start-up time, one-time power-on stability and multiple-time power-on repeatability of the product meet the technical requirements of the product specification is assessed synchronously; then the position flipping test is performed to confirm whether the fiber optic gyro inertial measurement product can keep stable after the flipping operation involved in the parameter calibration test, i.e., whether it meets the requirement of the primary power-on stability of the product specification is confirmed; and the calibration parameter long-term stability test is performed on the fiber optic gyro inertial measurement product passing the test. The method detects whether the fiber optic gyro inertial measurement product has the hidden trouble of over-poor long-term stability of the calibration parameters through the short-term and low-frequency tests so as to improve the success rate of the product passing the long-term stability test, save the equipment resources and the time cost and accelerate the production efficiency of the product.

Owner:BEIJING AEROSPACE TIMES OPTICAL ELECTRONICS TECH

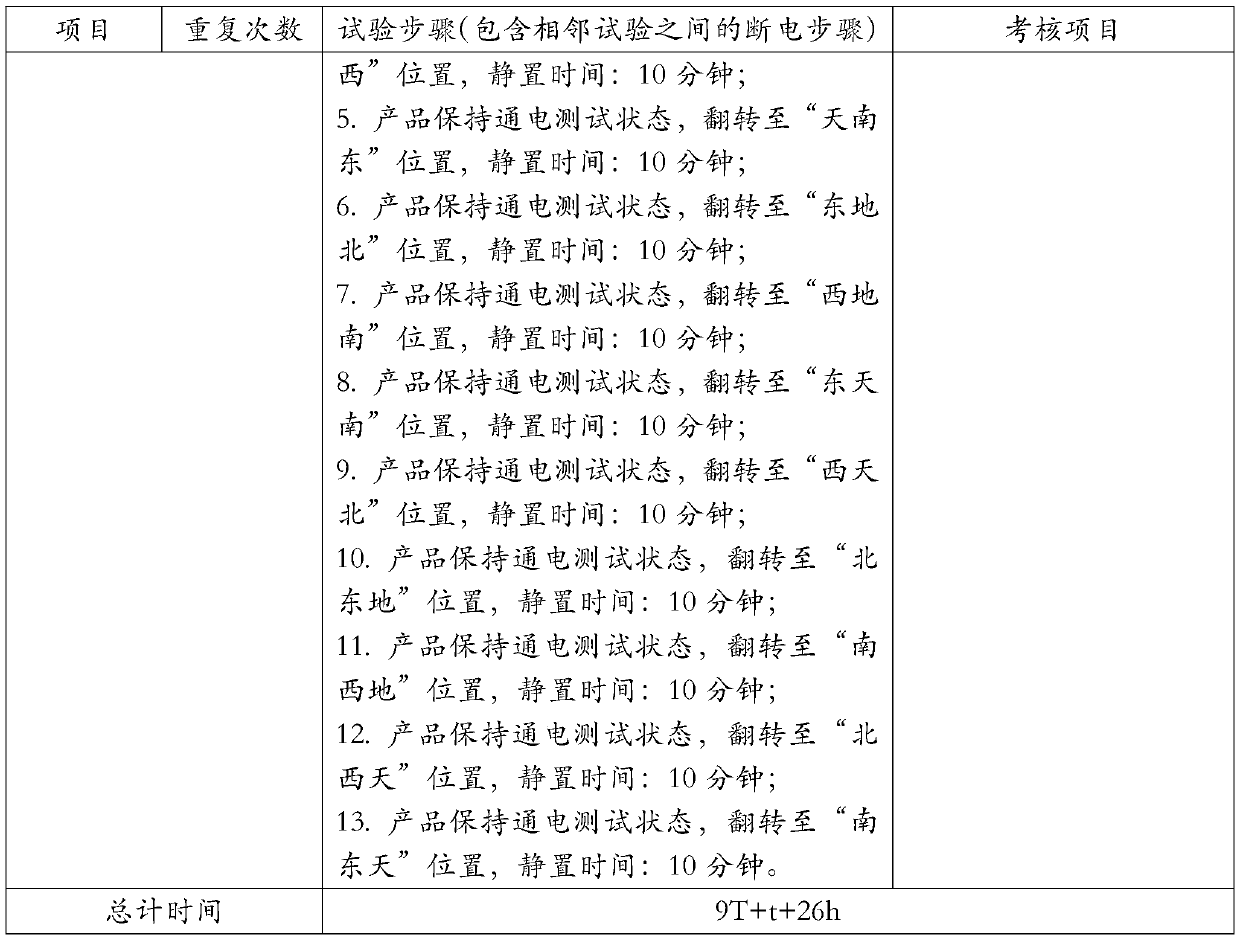

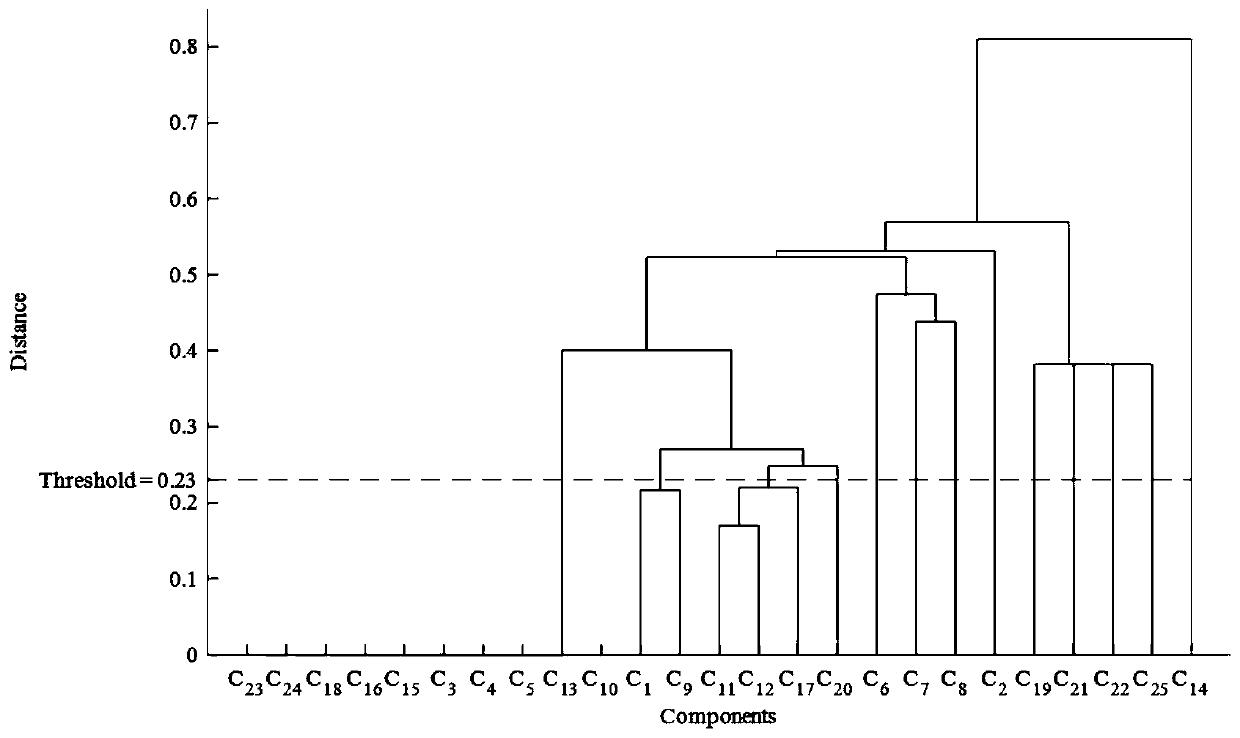

Design decision-making guidance method based on product feature association degree

PendingCN110427667AOvercome limitationsSupport Design DecisionsData processing applicationsSpecial data processing applicationsCustomer requirementsRelational model

The invention relates to a design decision guidance method based on product feature correlation. The method comprises the steps of collecting and processing market data; establishing a product featureassociation degree matrix; establishing a product feature and part relationship model; establishing a product part correlation degree matrix; performing clustering analysis according to customer requirements or designer requirements; and providing guidance for product design decisions according to clustering results. According to the method, the correlation degree of the product characteristics and the parts is calculated according to the market data by applying a mathematical statistics method, different combinations of the product parts are obtained under the condition of avoiding the influence of subjective factors of designers, and guidance is provided for product design decisions.

Owner:SHANTOU UNIV

Limited reporduction of product designs

InactiveUS20140067591A1Reduce time delayExpensive to useBuying/selling/leasing transactionsProduct design specificationReproduction

One or more embodiments of techniques or systems for product design customization are provided herein. An interface for product design customization is provided with an application component that can run a stationery application, a merge application, an EZ print application, a photo paper application, etc. These applications may include the ability to insert, modify, or customize design elements. Additionally, these applications may enable a user to divide or split a product design into one or more product design portions, thereby layering the product design. Additionally, data may be merged across one or more documents associated with a product design. Product design reproduction, such as printing, may be limited or controlled according to one or more embodiments.

Owner:MAFCOTE

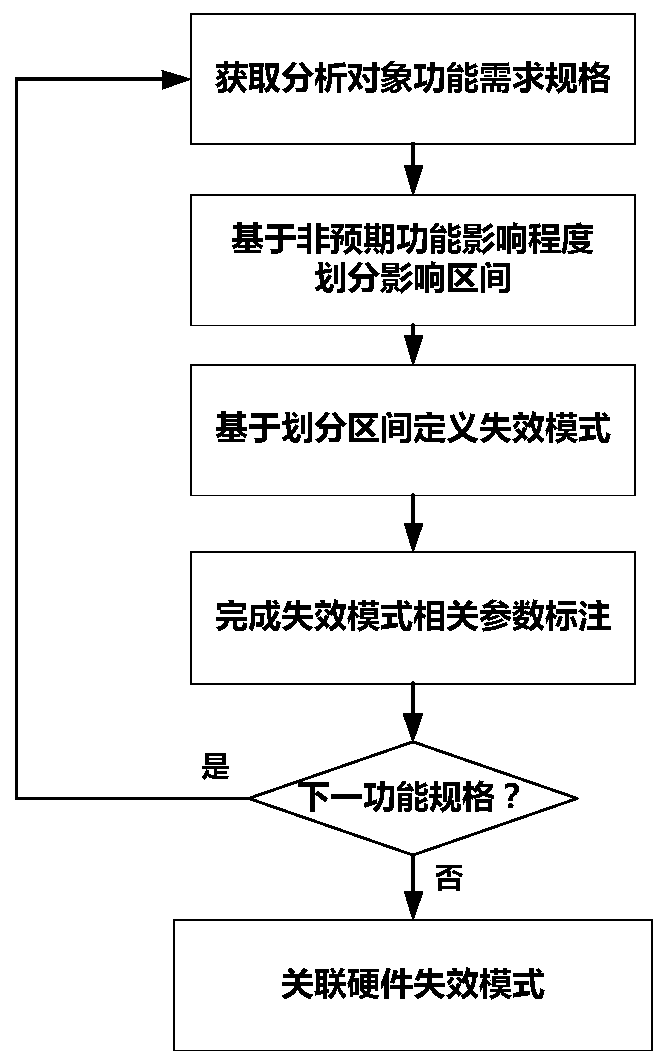

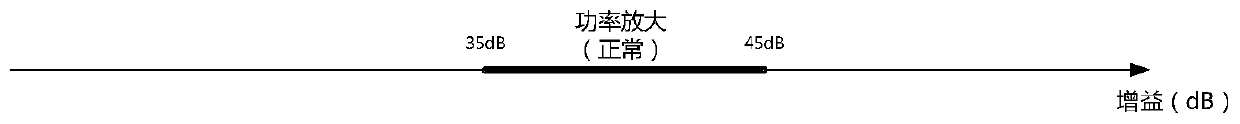

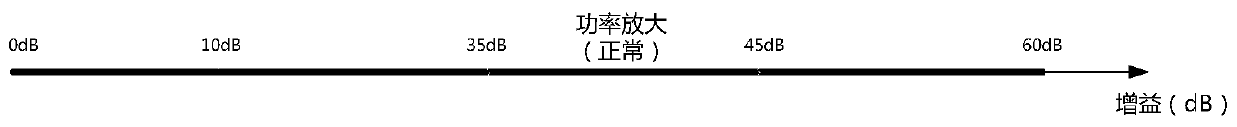

Auxiliary identification method for failure mode

ActiveCN110135029AImprove analysisImprove timelinessSpecial data processing applicationsDecompositionComputer aid

The invention discloses an auxiliary identification method for a failure mode. The method comprises the steps of obtaining a function requirement specification of an analysis object, dividing an influence interval based on an unexpected function influence degree, and defining the failure mode based on the divided interval, carrying out failure mode labeling and associating a hardware failure mode.The invention provides a standardized computer-aided failure mode definition technology. A failure mode is defined based on an unexpected representation form of a function specification, and a failure mode association relationship between an upper layer and a lower layer and mapping of the function failure mode to hardware are established through relevance of the failure mode and the function specification, decomposition and distribution of product design function specifications and design definition of hardness. Compared with the existing failure mode analysis method, the failure mode definition method based on the function specification is realized, and the problems of incomplete analysis and low efficiency caused by the fact that the traditional failure mode analysis depends on empirical analysis are improved.

Owner:SOUTHWEST CHINA RES INST OF ELECTRONICS EQUIP

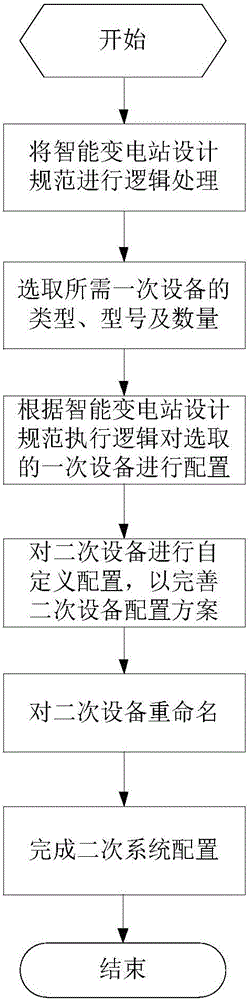

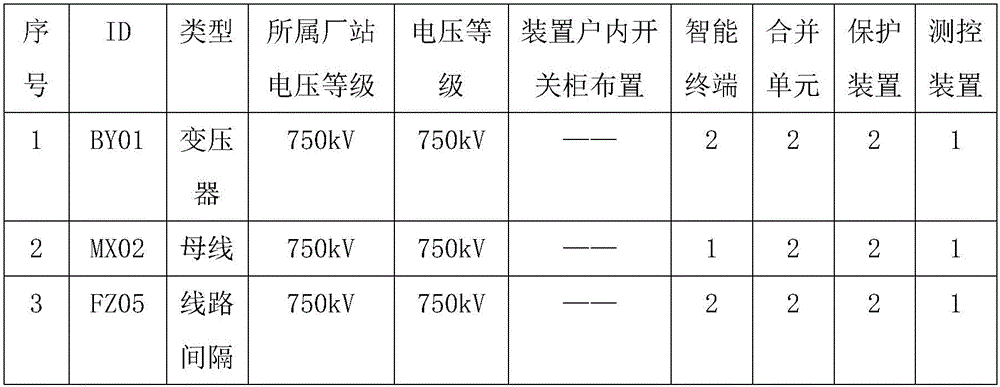

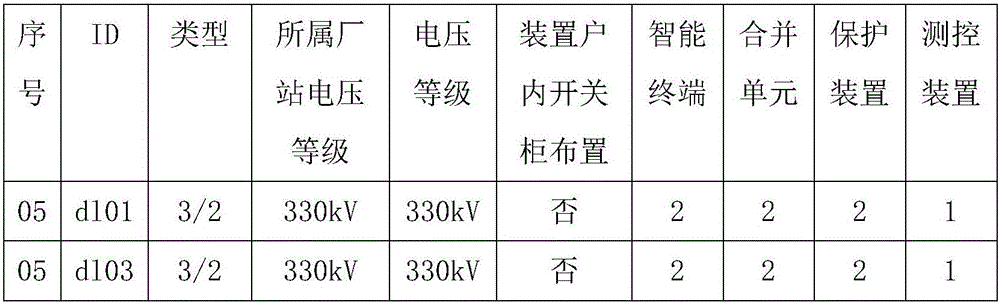

Transformer-station secondary-system configuration scheme constructing method based on design specification

ActiveCN105678028AReduce workloadAvoid secondary device entry processData processing applicationsSpecial data processing applicationsSmart substationTransformer

The invention relates to the technical field of transformation-station secondary system configuration, in particular to a transformer-station secondary-system configuration scheme constructing method based on a design specification. The method includes he steps that the design specification of an intelligent transformer station is subjected to logical processing to generate intelligent-transformer-station design specification execution logic; the types, the models, the number and the serial numbers of required primary devices are selected according to practical conditions of the transformer station, and the intelligent-transformer-station design specification execution logic is run to generate a corresponding secondary-device configuration result; configurable naming specifications provided by different scheduling mechanisms are subjected to logical processing to generate naming specification execution logic; the naming specification execution logic is run, and configured secondary devices are named and described to generate a transformer-station secondary-system configuration scheme. The information of the required primary devices is selected, and a computer can automatically generate the secondary device configuration result. The workloads of an engineer are greatly reduced, the complex secondary-device inputting process is avoided, working efficiency is improved, and the configuration error rate is also reduced.

Owner:HUBEI ELECTRIC ENG CORP +1

Simulation based product design method

InactiveCN107391878AOptimize dataSimple designDesign optimisation/simulationSpecial data processing applicationsAnalysis dataSimulation based

The invention discloses a simulation based product design method. The method includes the steps of S1, platform construction, namely constructing a simulation based knowledge driven platform; S2, target recognition, namely analyzing requirements of a product and establishing relevant specifications; S3, data acquisition, namely collecting actual product features and production process and analysis data prior to comparing, initializing the knowledge driven platform and inputting basic standards and specifications; S4, data optimization, namely performing comparison and extraction through the actual production features and production process and analysis data, optimizing design and determining the optimum production process; S5, result transformation, namely transforming the optimum production process into product / mold design specifications and molding specifications through the knowledge driven platform; S6, interaction sharing, namely interacting experiences through the knowledge driven platform to ensure uniformed design and manufacturing standards which are used globally. The design is further standardized and simplified, loss of key technologies is avoided, development cycle is shortened, cost is saved, and the competitive power of enterprises is ensured.

Owner:上海澎睿信息技术有限公司 +1

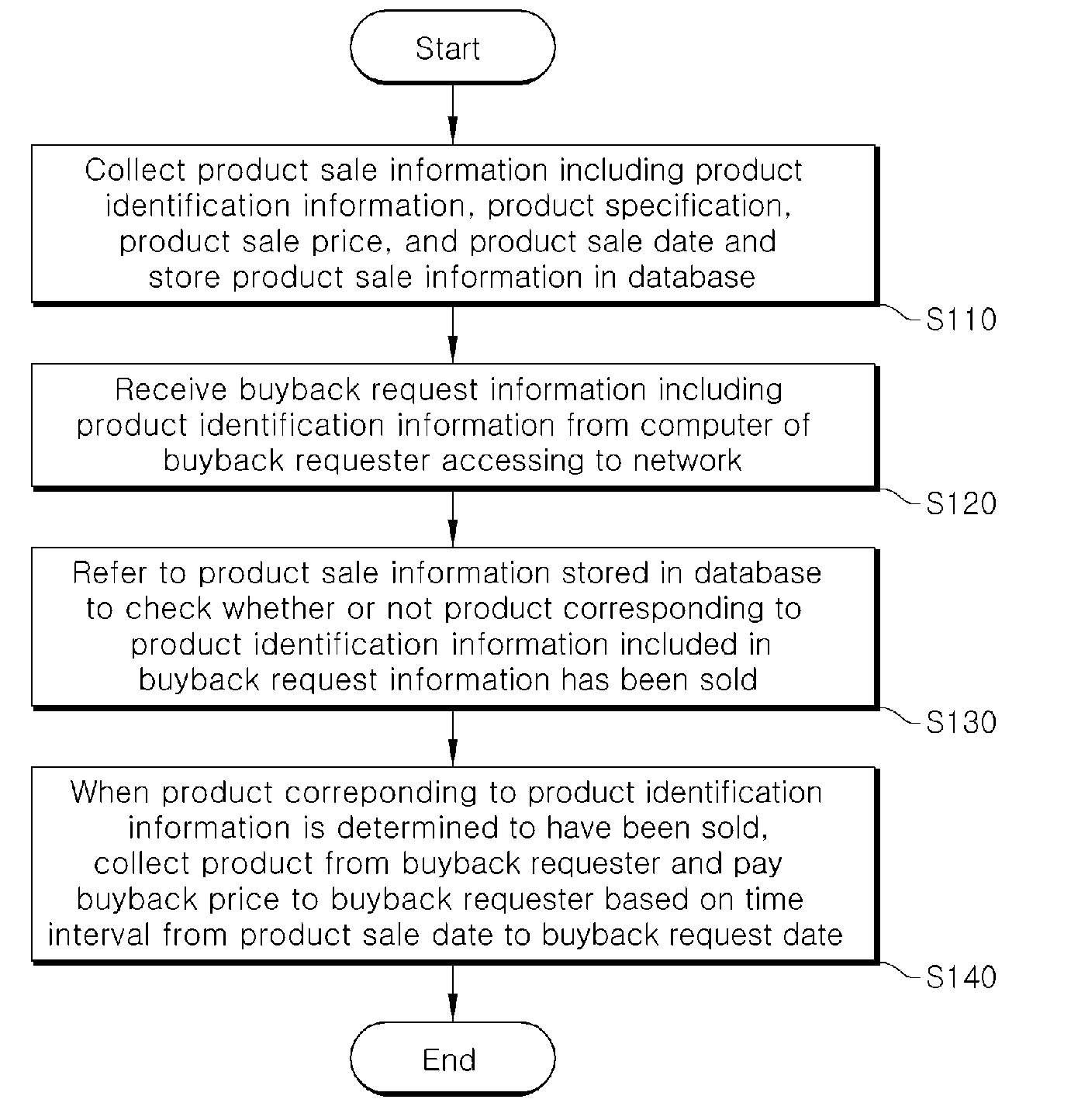

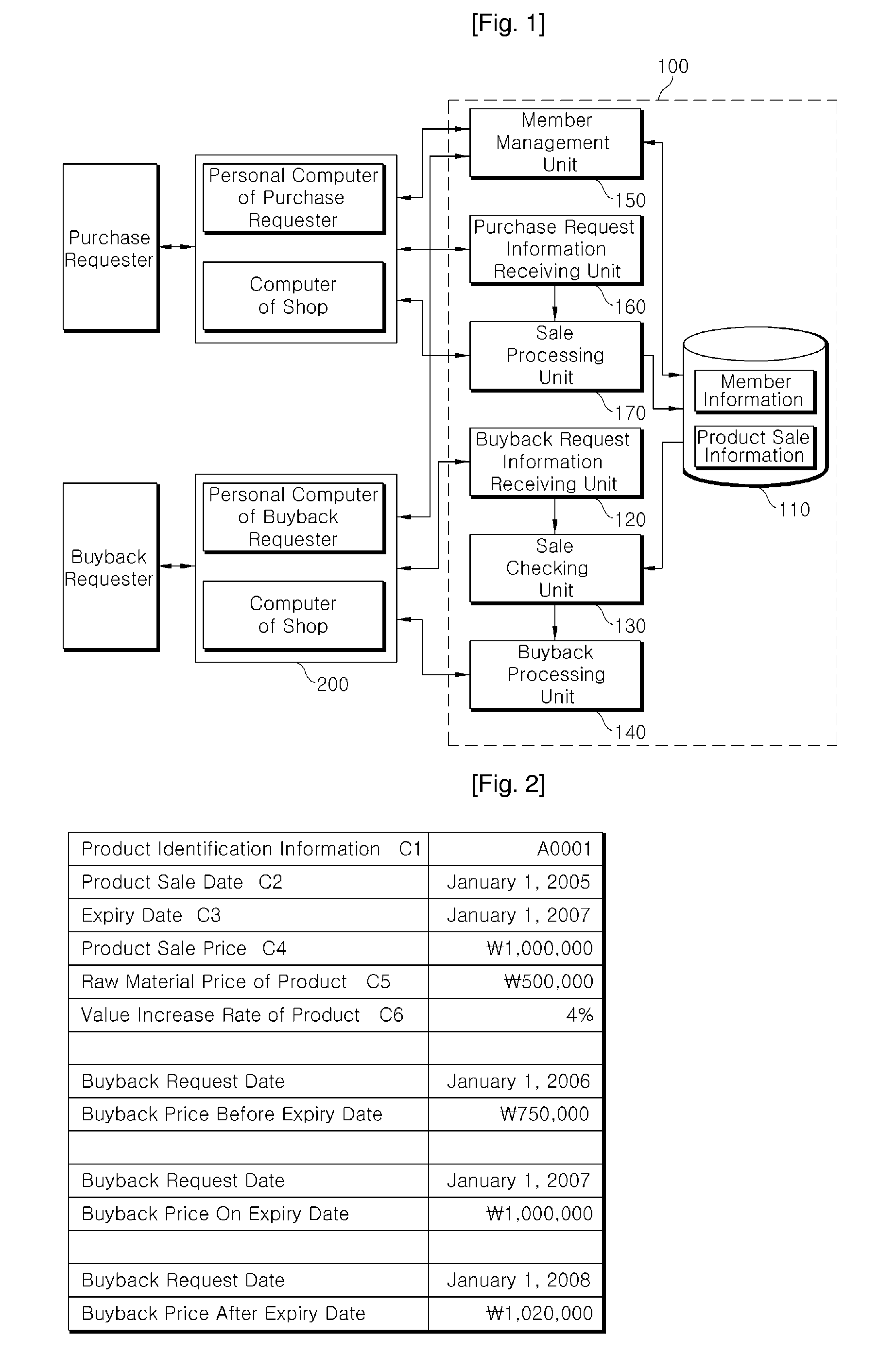

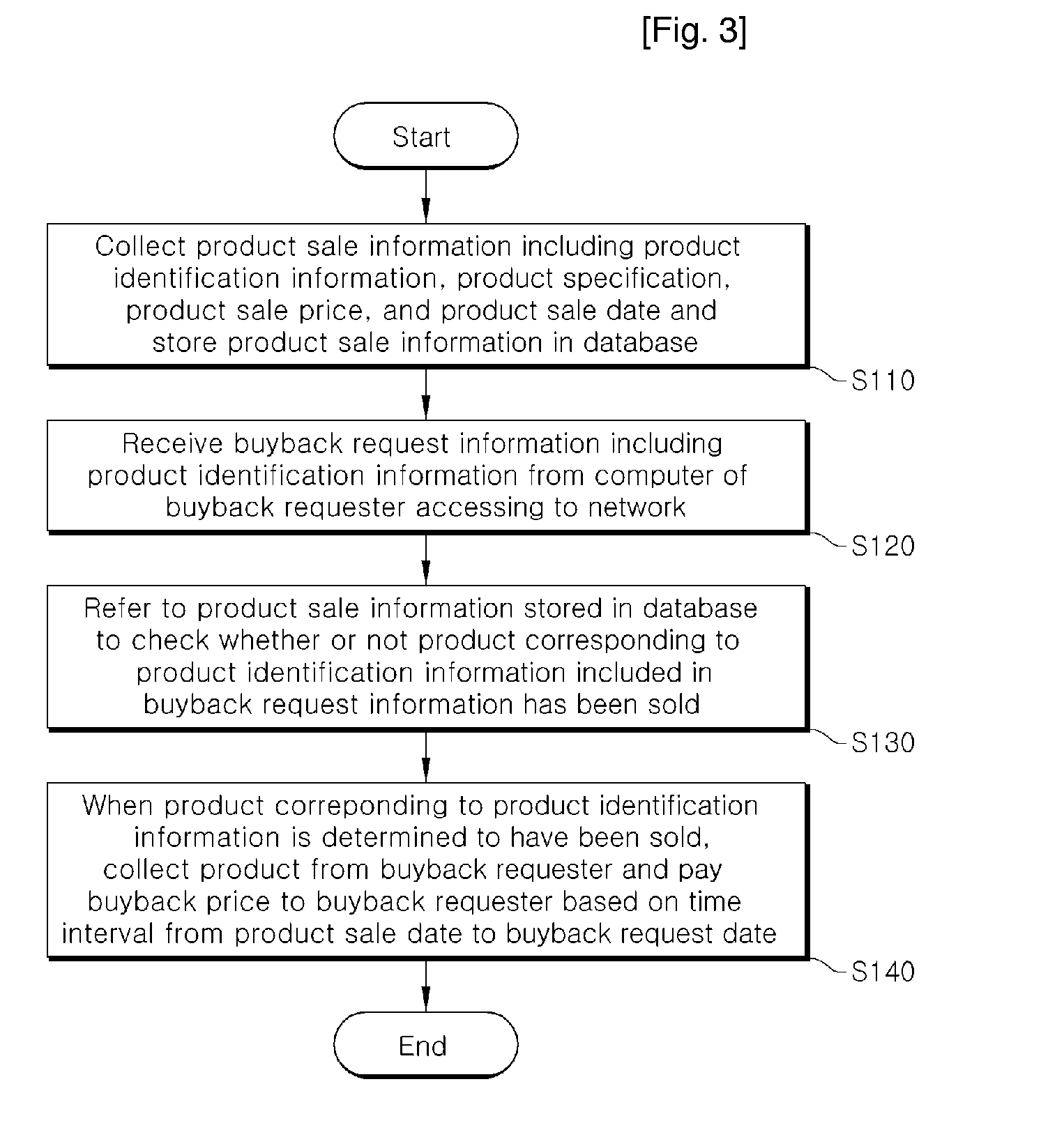

Online buyback system

InactiveUS20100217683A1Reasonable priceComplete banking machinesFinanceLibrary scienceProduct design specification

An online buyback system is provided, including: a database storing product sale information including product identification information, product specification, product sale price, and product sale date; a buyback request information receiving unit receiving buyback request information including product identification information from a computer of a buyback requester accessing a network; a sale checking unit referring to the product sale information stored in the database to check whether or not a product corresponding to the product identification information contained in the buyback request information has been sold; and a buyback processing unit processing such that the product corresponding to the product identification information is collected from the buyback requester when the product is determined to have been sold, and a buyback price of the product is paid to the buyback requester based on a time interval from the product sale date to buyback request date.

Owner:KANG IN GU

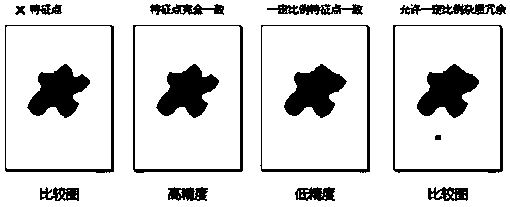

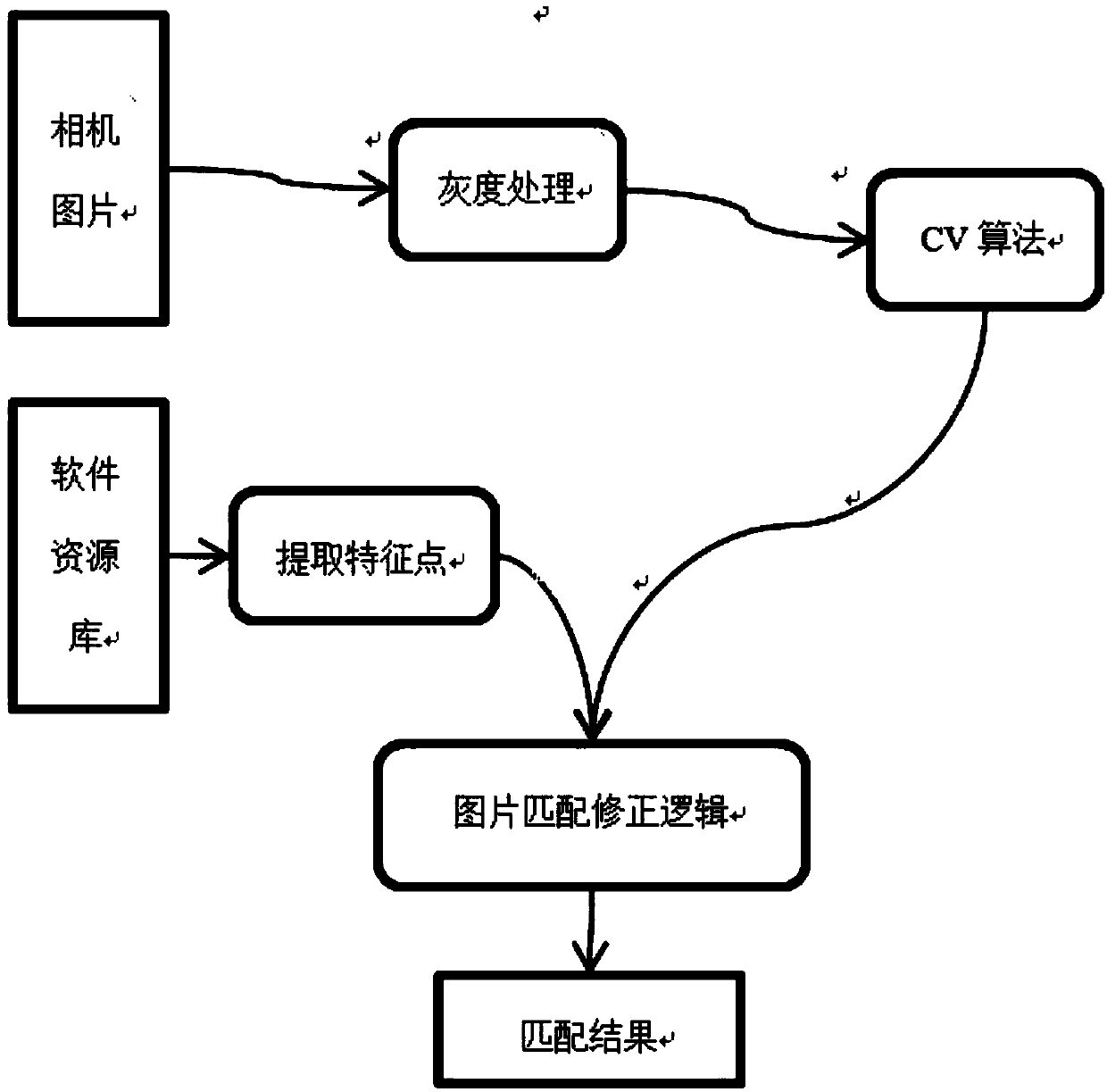

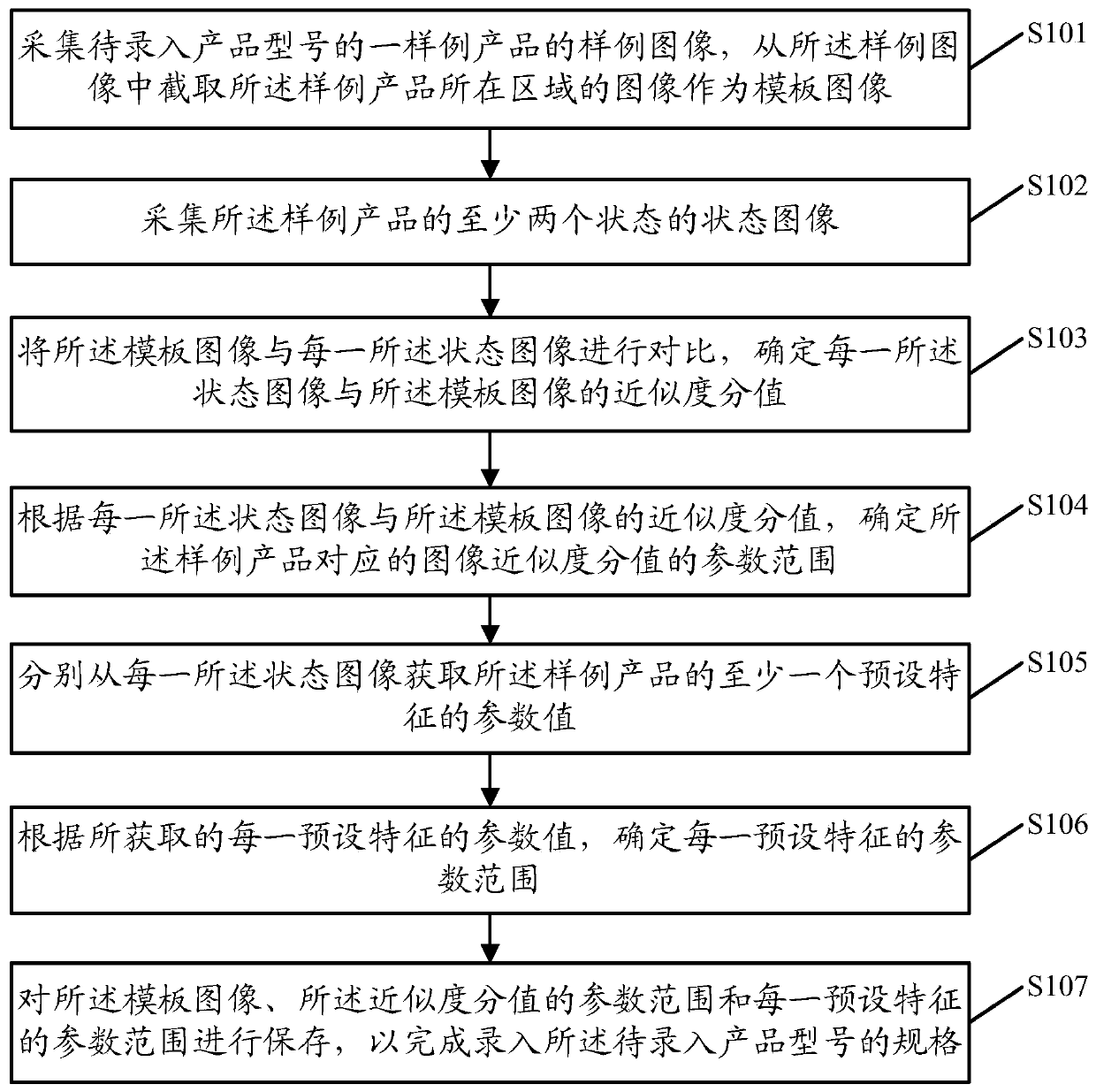

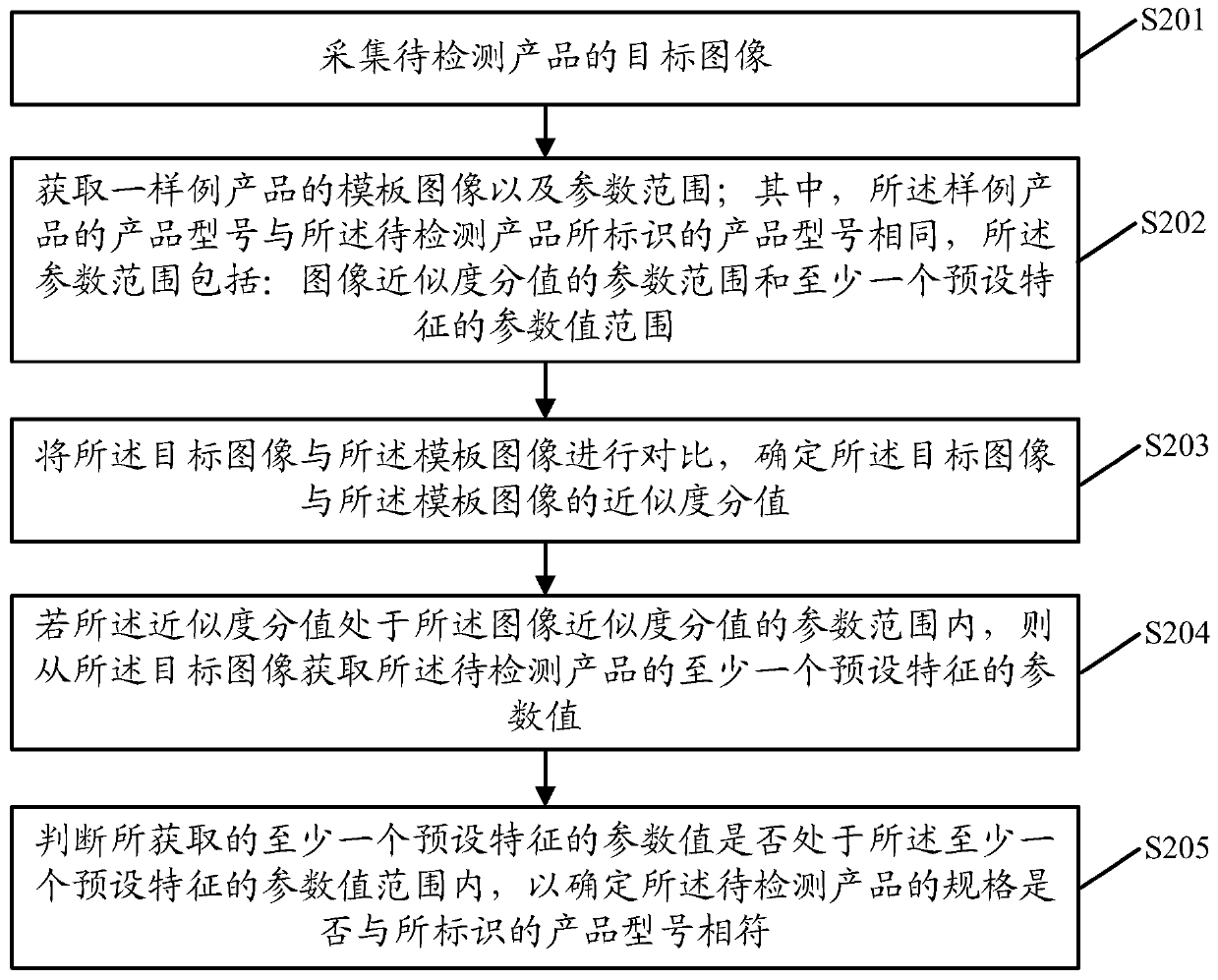

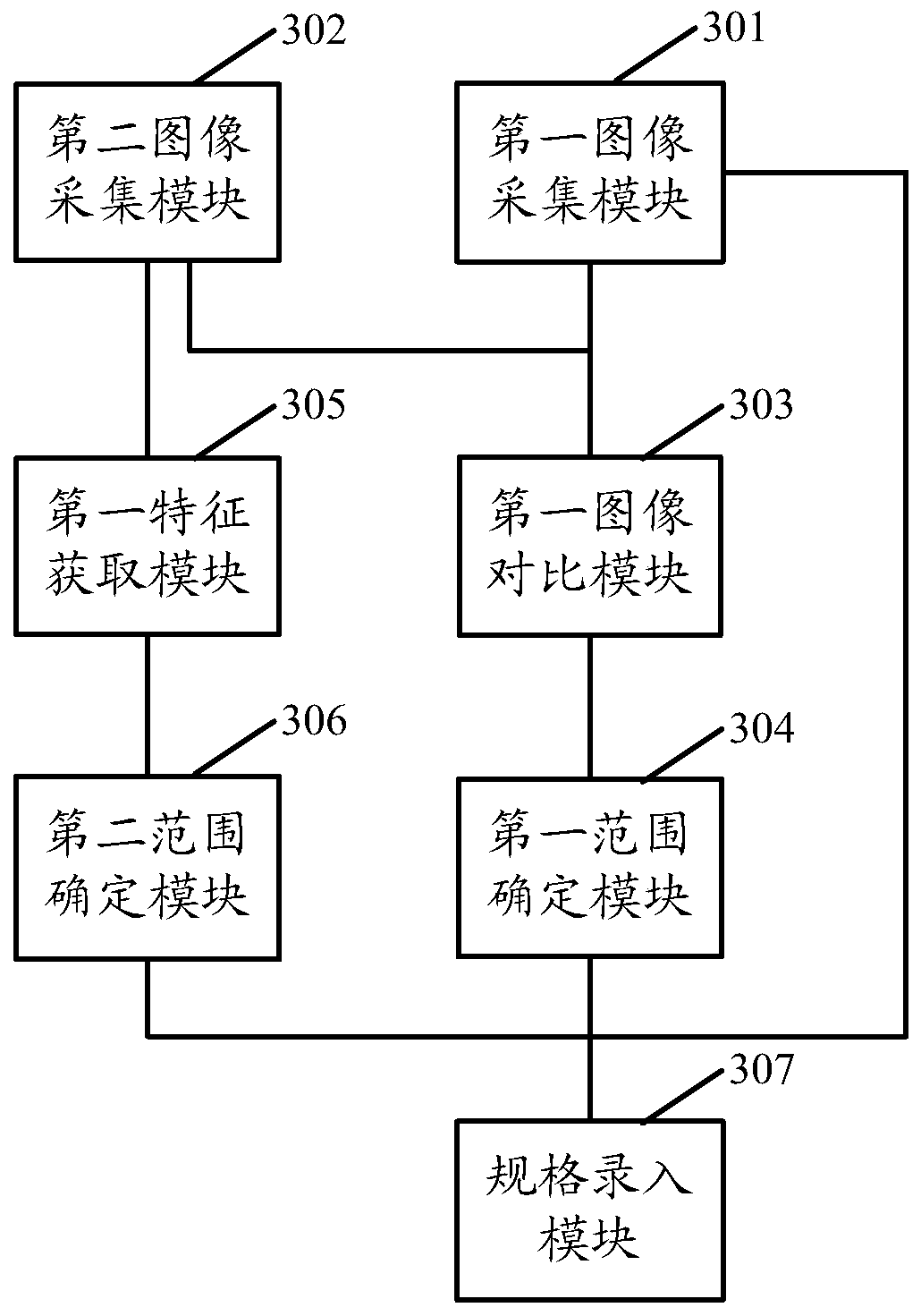

Product specification inputting and detecting method and system

ActiveCN110147838ARealize automatic entryImprove input speedImage enhancementImage analysisAlgorithmSample image

The invention provides a product specification inputting and detecting method and system. The product specification input method and system comprises the following steps: acquiring a sample image of asample product of a to-be-input product model and state images of at least two states; processing based on the images to obtain a template image and a parameter range corresponding to the model of the to-be-input product, and storing the template image and the parameter range as specification data of the model of the to-be-input product so as to provide preconditions for subsequent product specification detection; the product specification detection method and system acquire a target image of a to-be-detected product, call a template image of a corresponding sample product and a correspondingparameter range; through the target image, the template image and the corresponding parameter range, whether the specification of the to-be-detected product is consistent with the identified productmodel is determined, the specification of the to-be-detected product is effectively identified, the identification efficiency is high, whether the product package is correct or not can be convenientlychecked, and the probability of product package errors is reduced.

Owner:SUZHOU MICROPORT ORTHORECON CO LTD

Automated MEP design

ActiveUS9477790B2Geometric CADDesign optimisation/simulationBuilding designProduct design specification

Owner:DPR CONSTR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com