Fiber optic gyro inertial measurement product calibration parameter long-term stability defect detection method

A fiber optic gyroscope and a technology for calibrating parameters, applied in the field of inertial measurement, can solve the problems of poor long-term stability, long production cycle, and difficulty in analyzing various factors of long-term stability, and achieve the effect of easy implementation and improved efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

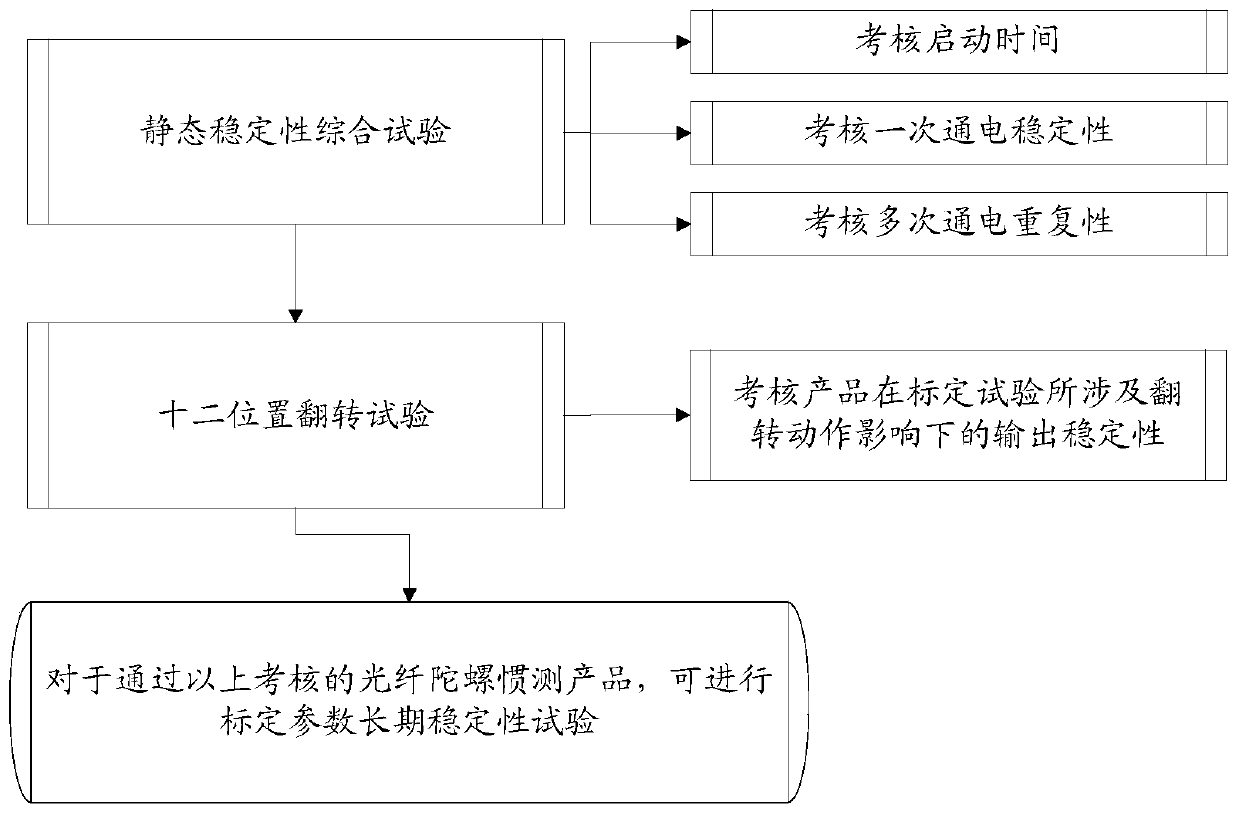

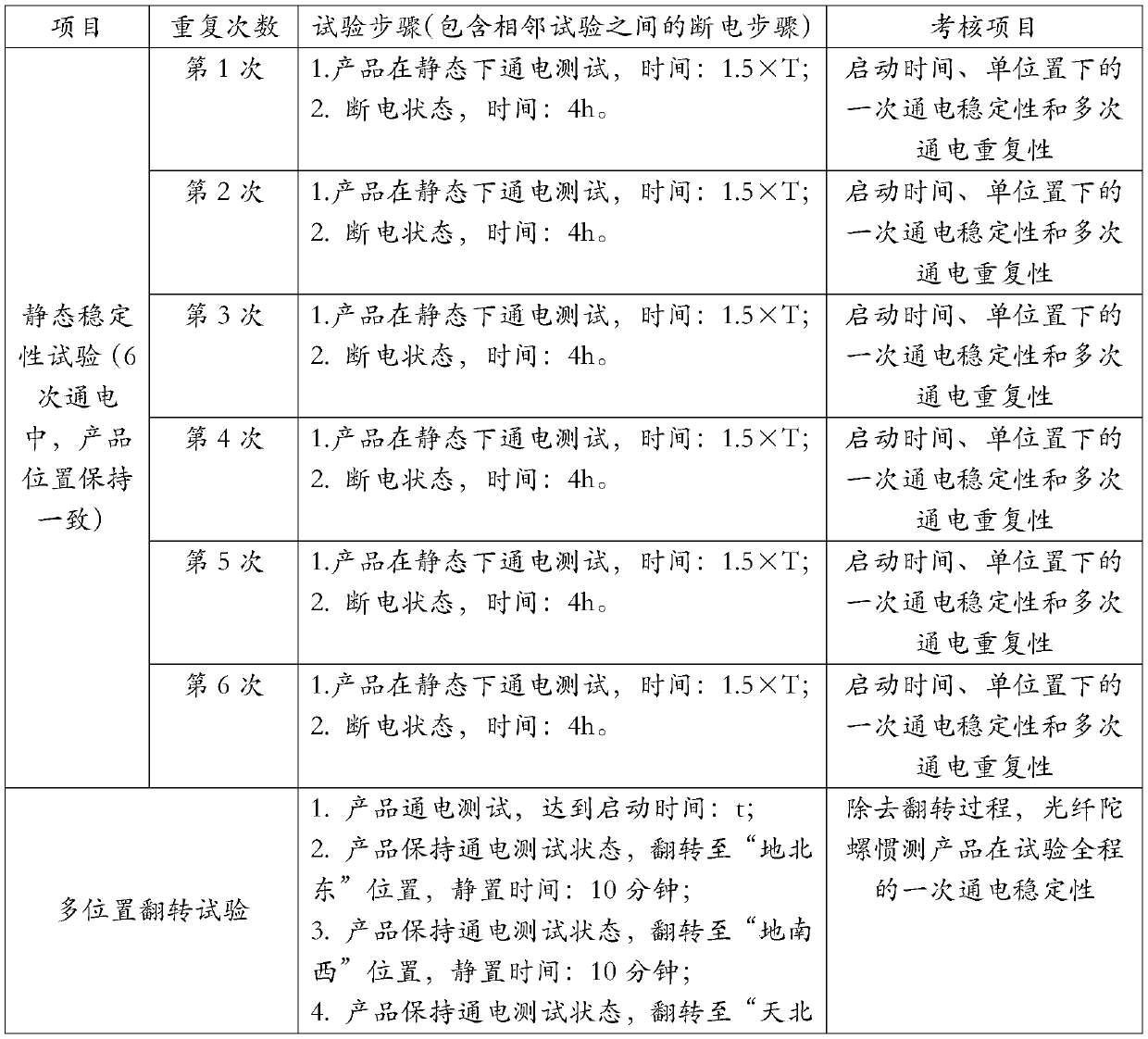

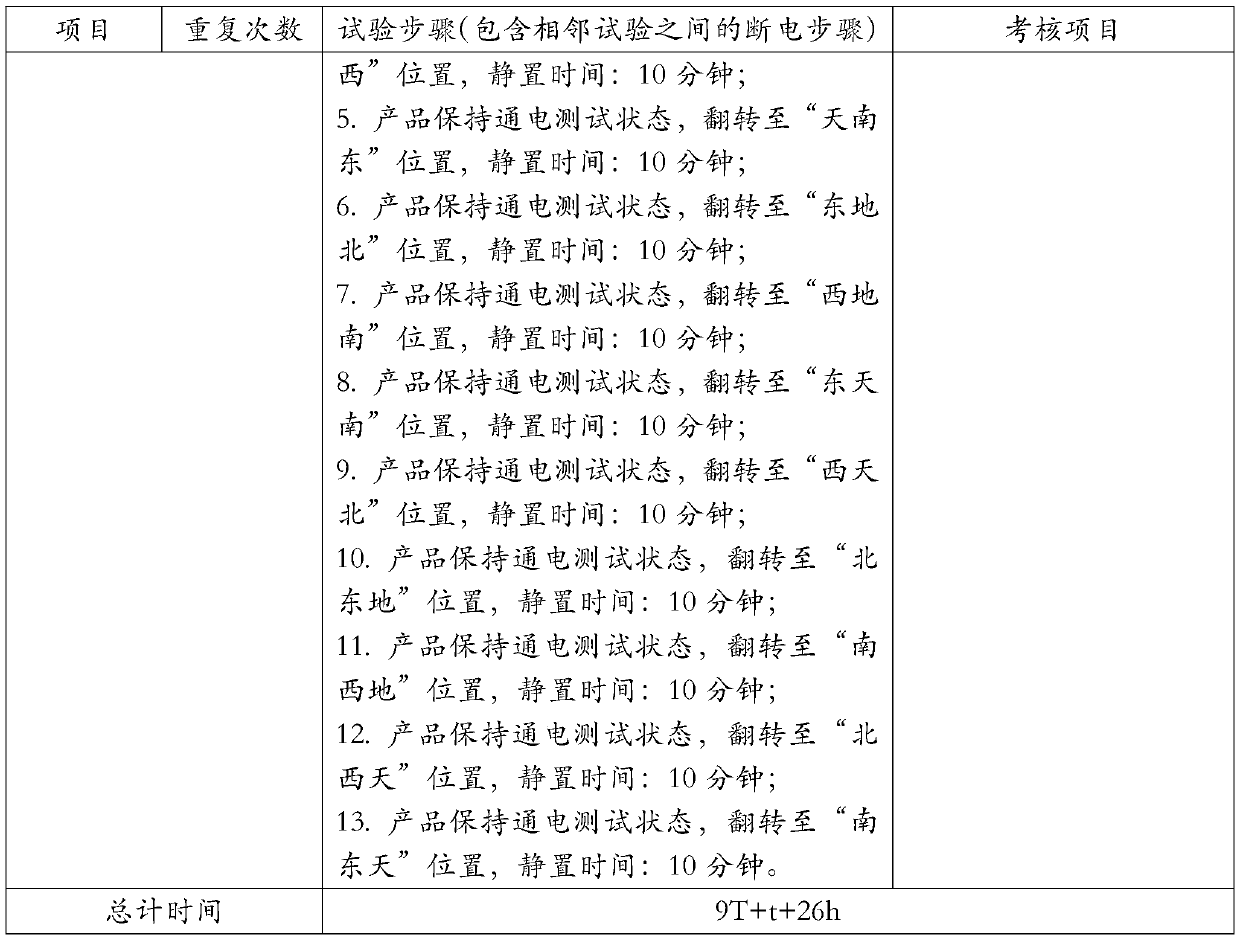

[0020] The test steps of this method can be carried out according to Table 1.

[0021] Table 1. Test steps of the rapid detection method for long-term stability defects of calibration parameters

[0022]

[0023]

[0024] In Table 1, t is the start-up time specified in the technical requirements, and T is the time required for the product to perform a calibration test.

[0025] The realization process of the present invention is described in detail below:

[0026] 1) Through the static stability comprehensive test, check whether the actual start-up time of each product meets the start-up time requirements in the product task book;

[0027] In order to ensure the stability of the calibration parameters, it should first be ensured that the fiber inertial group has entered the output stable state at the beginning of each calibration test. Especially for inertial measurement products used in harsh thermal environments, temperature control is often used to ensure inertial g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com