Industrial assembly line model mechanism

An assembly line and model technology, applied to teaching models, educational tools, instruments, etc., can solve the problems of different test results, waste of handling, low efficiency, etc., and achieve the effects of accurate test results, improved work efficiency, and stable transmission operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

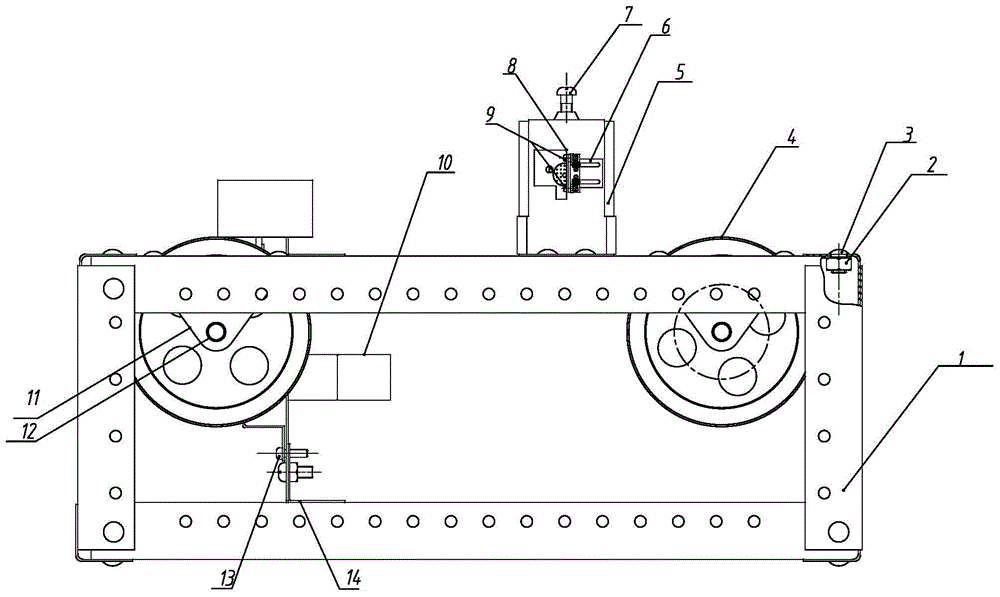

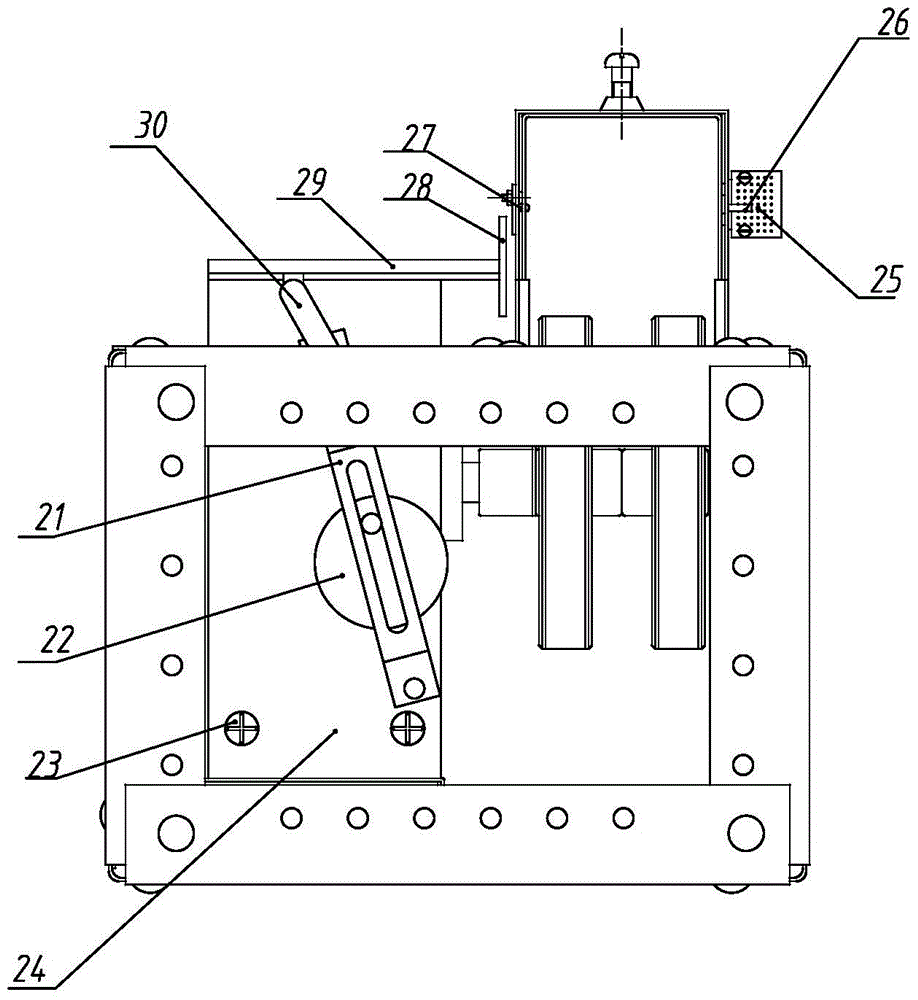

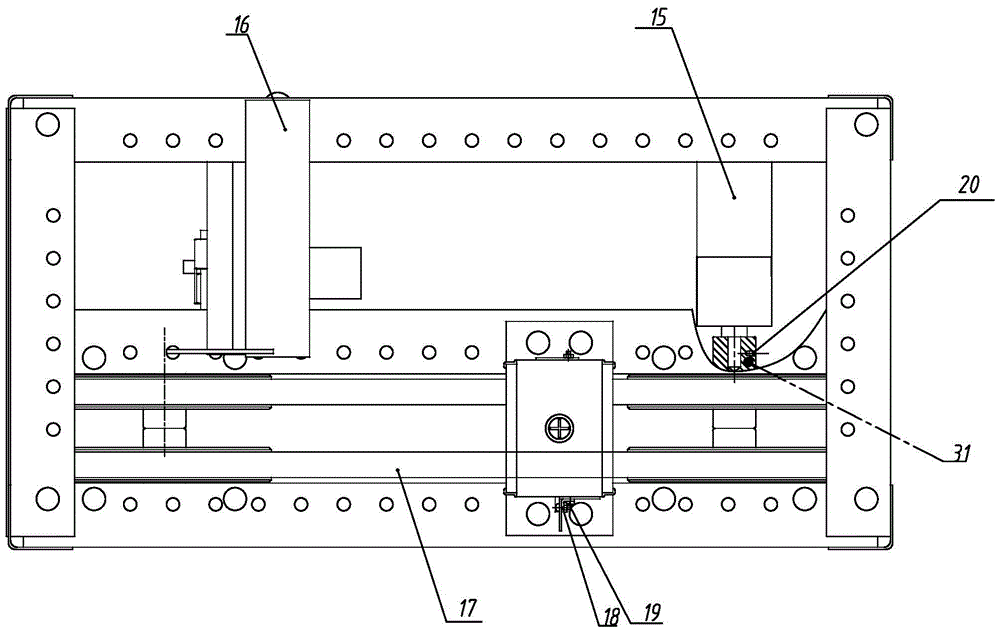

[0020] Such as figure 1 , figure 2 with image 3 As shown, an industrial assembly line model mechanism includes a frame 1, a product conveying system, a sensor module, a product redirection device and a control module.

[0021] Frame 1 is constructed by a plurality of angle steels, which is convenient for cutting and fastening with bolts, and the joints are fastened with screws 1 3 and 1 bolts 2.

[0022] The product conveying system is set in the frame 1 and is driven by a belt pulley. It includes two pulley shafts 12 with one step, and each pulley shaft 12 is provided with two pulleys 4, which rotate together with the pulley shaft 12 and are connected by pins, so that the shaft 12 can be fixed in both direction and circumferential direction. And easy to disassemble. Two belt pulleys 4 outer sides are sleeved with axle support frame 11, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com