Two-degree-of-freedom automatic control scissor-type material conveying device

A technology of conveying device and degree of freedom, which is applied in the direction of hoisting device, lifting frame, etc., can solve the problems of low degree of automation and single movement direction of scissor working platform, and achieve the effect of improving movement efficiency, increasing automation degree and saving cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing and embodiment, the present invention is described in further detail:

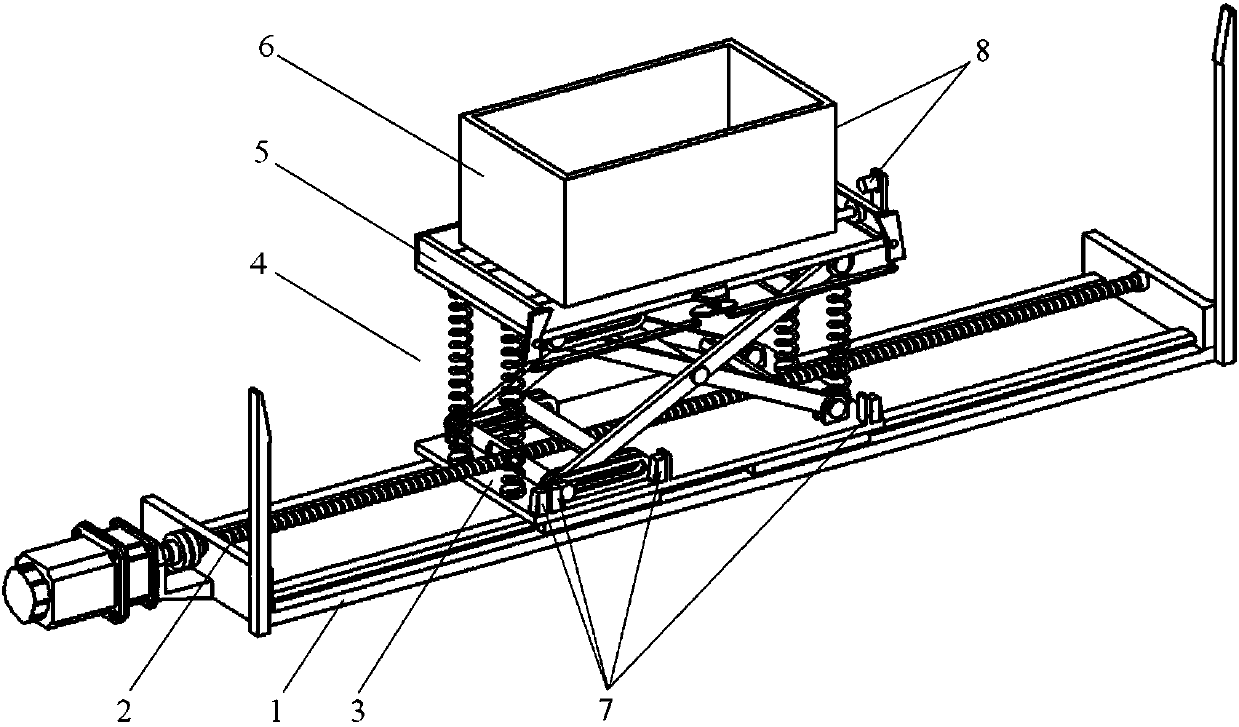

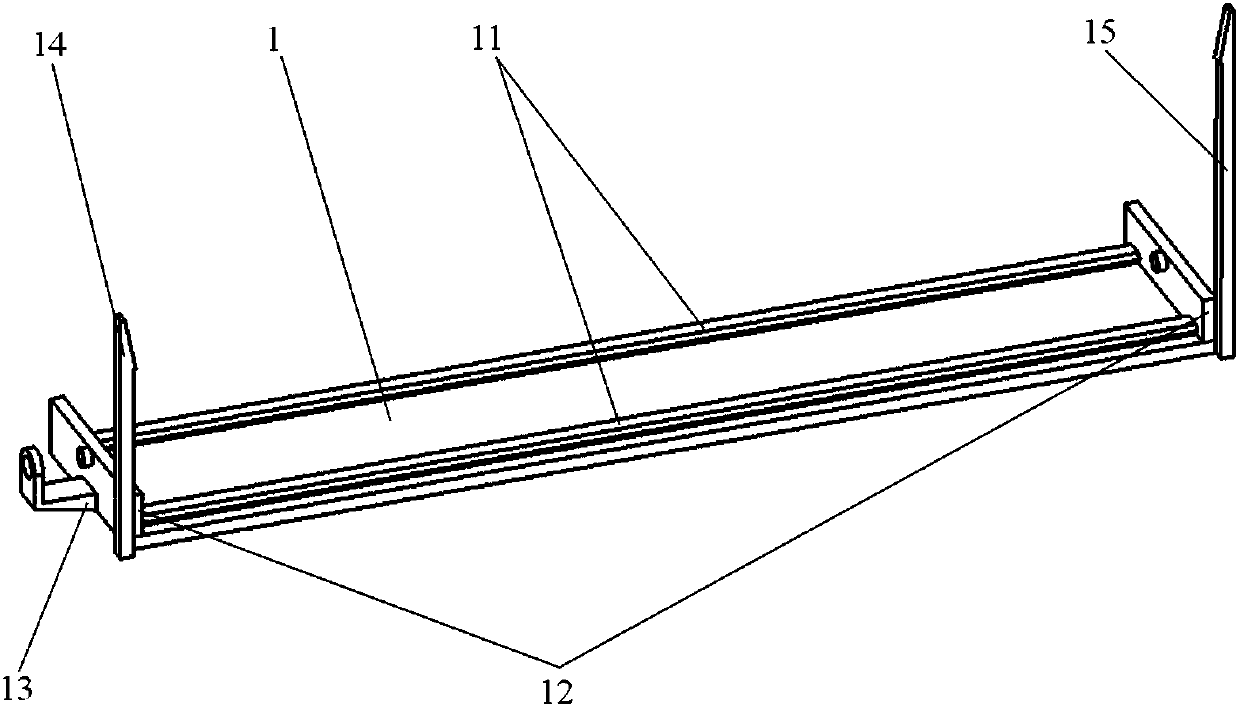

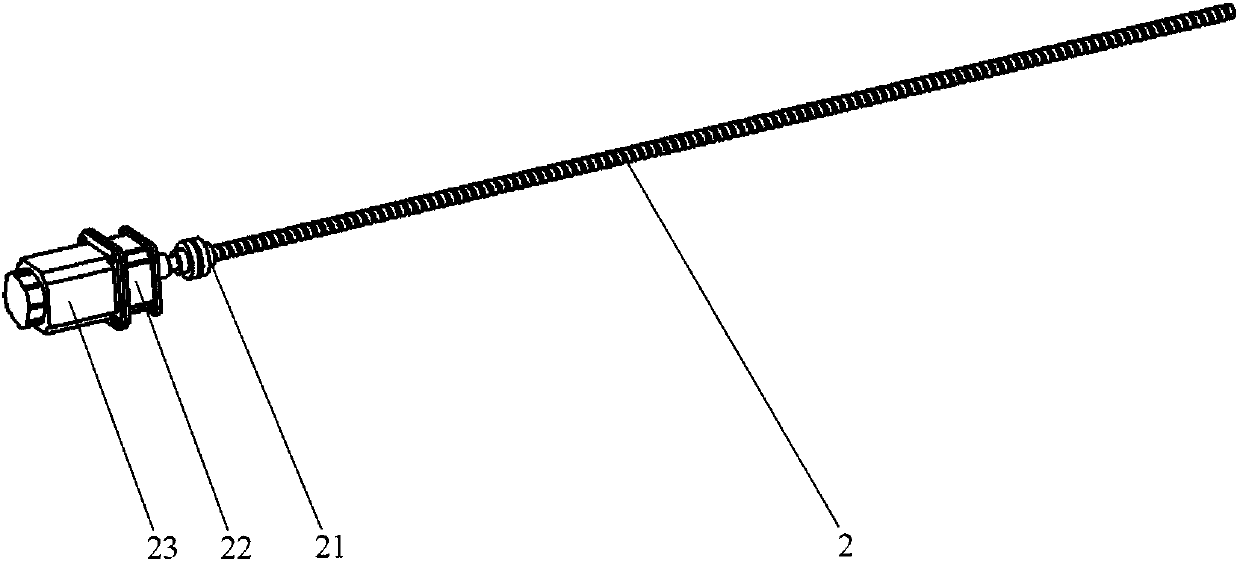

[0030] refer to figure 1 , the present invention includes a base assembly, a driving mechanism, a scissor mechanism, a material delivery mechanism and a control assembly; the base assembly includes a base 1, and the base 1 is a cuboid plate, which has relatively high rigidity and requires high parallelism on the upper surface , used to carry the weight of the driving mechanism, the scissor mechanism, the material transport mechanism and the material, and ensure the horizontal and linear motion of the scissor mechanism; the driving mechanism includes a lead screw 2, which is installed on the base assembly, and is used to transmit the driving force smoothly and accurately The scissors mechanism includes the lower platform 3, the upper platform 5 and the telescopic mechanism 4 connecting the two platforms 3 and 5, which are arranged above the base assembly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com