Transverse cutting device of laminating machine

A laminating machine and cutting technology, which is applied in metal processing and other directions, can solve problems such as difficulty in unifying standards, no cross-cutting device, and low safety performance of manual cutting with scissors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

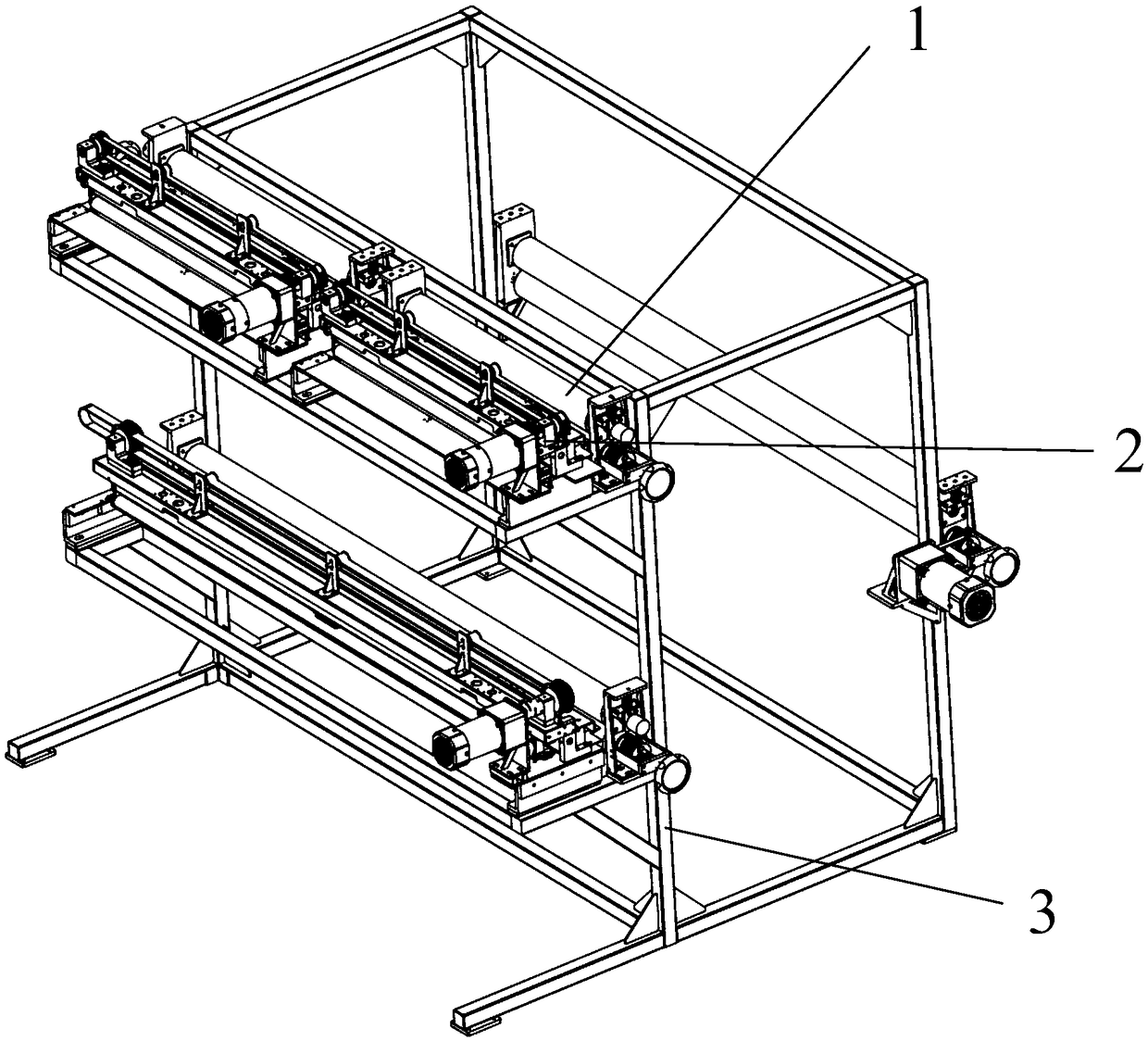

[0013] The transverse cutting device adopts a modular design method, and the whole device can be divided into three modules: a frame (3), a clamping device (1) and a knife assembly (2). The advantage of this design is that when a module is damaged, a good module can be replaced quickly, the product can minimize the maintenance time when it is put into use, and the device is easy and convenient to assemble when mass-produced.

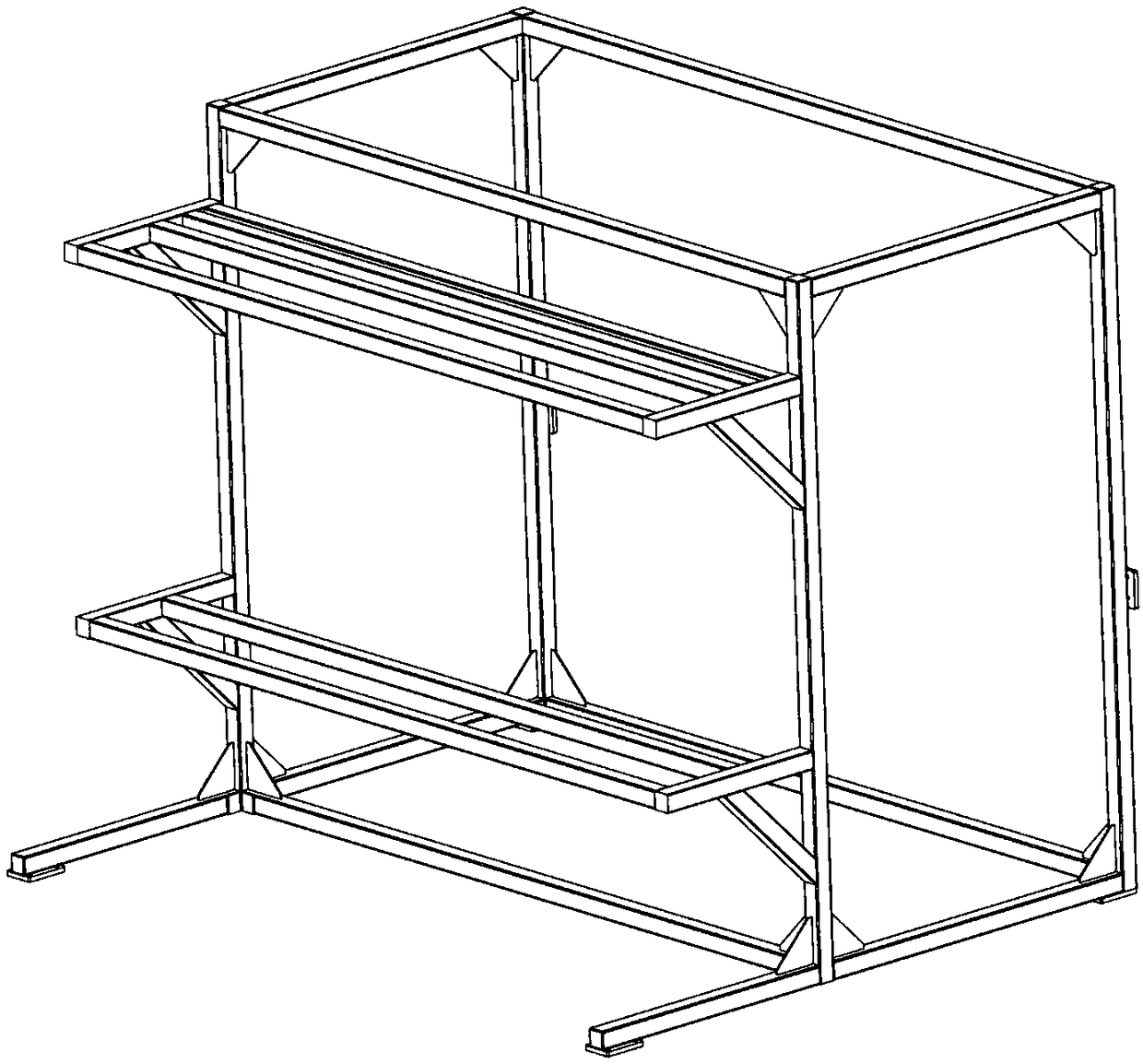

[0014] refer to figure 2 , the frame (3) is welded with square tubes as a whole, and triangular ribs are welded on the top and bottom of the four supporting columns, so that the whole mechanism has strong rigidity and high stability, and ensures that the cross-cutting device will be produced when it is working. The impact of the vibration on the cutting accuracy is minimized, and the bottom wheel plate is welded at the bottom of the frame, and the bottom wheel can be installed during transportation for more convenient transportation. like figure 2 As...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com