Automatic conveying device for compact wafer

An automatic transmission and compact technology, applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problem of reducing the overall height, etc., to achieve the effect of reducing the overall height and width, stable transmission operation, and compact structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

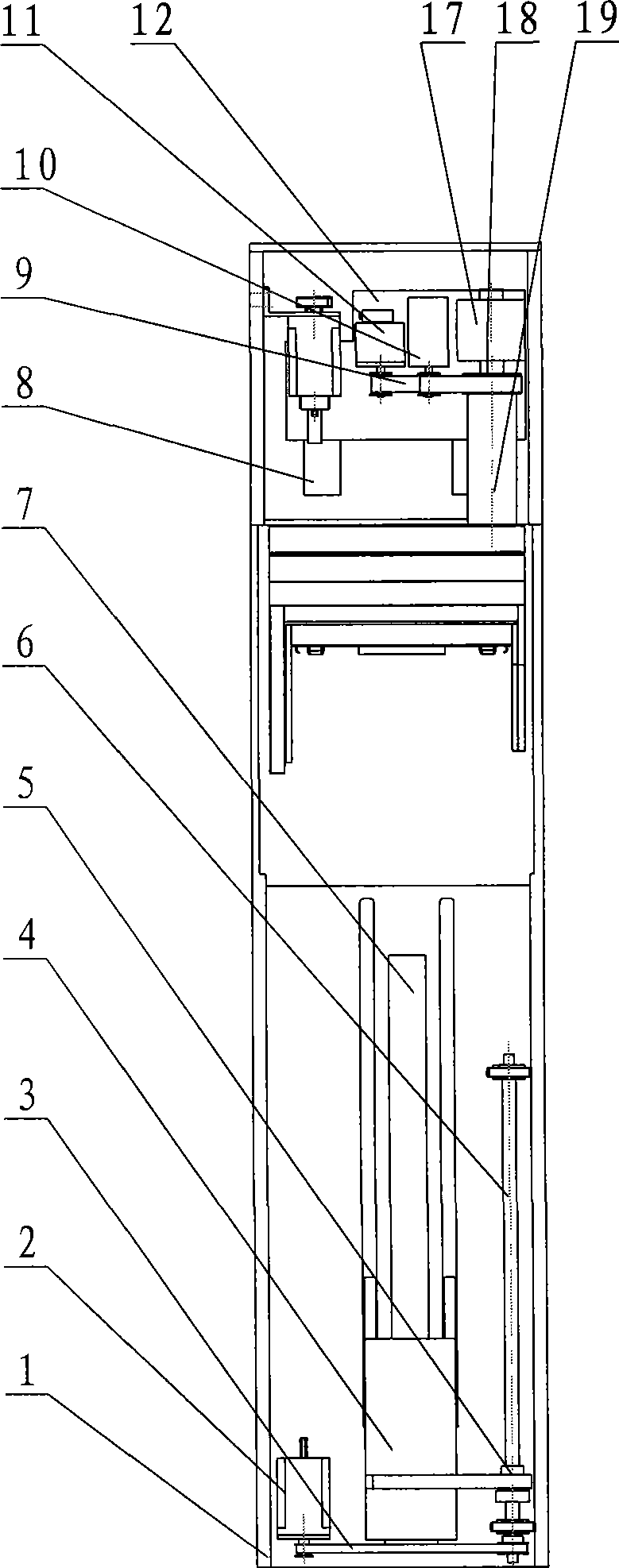

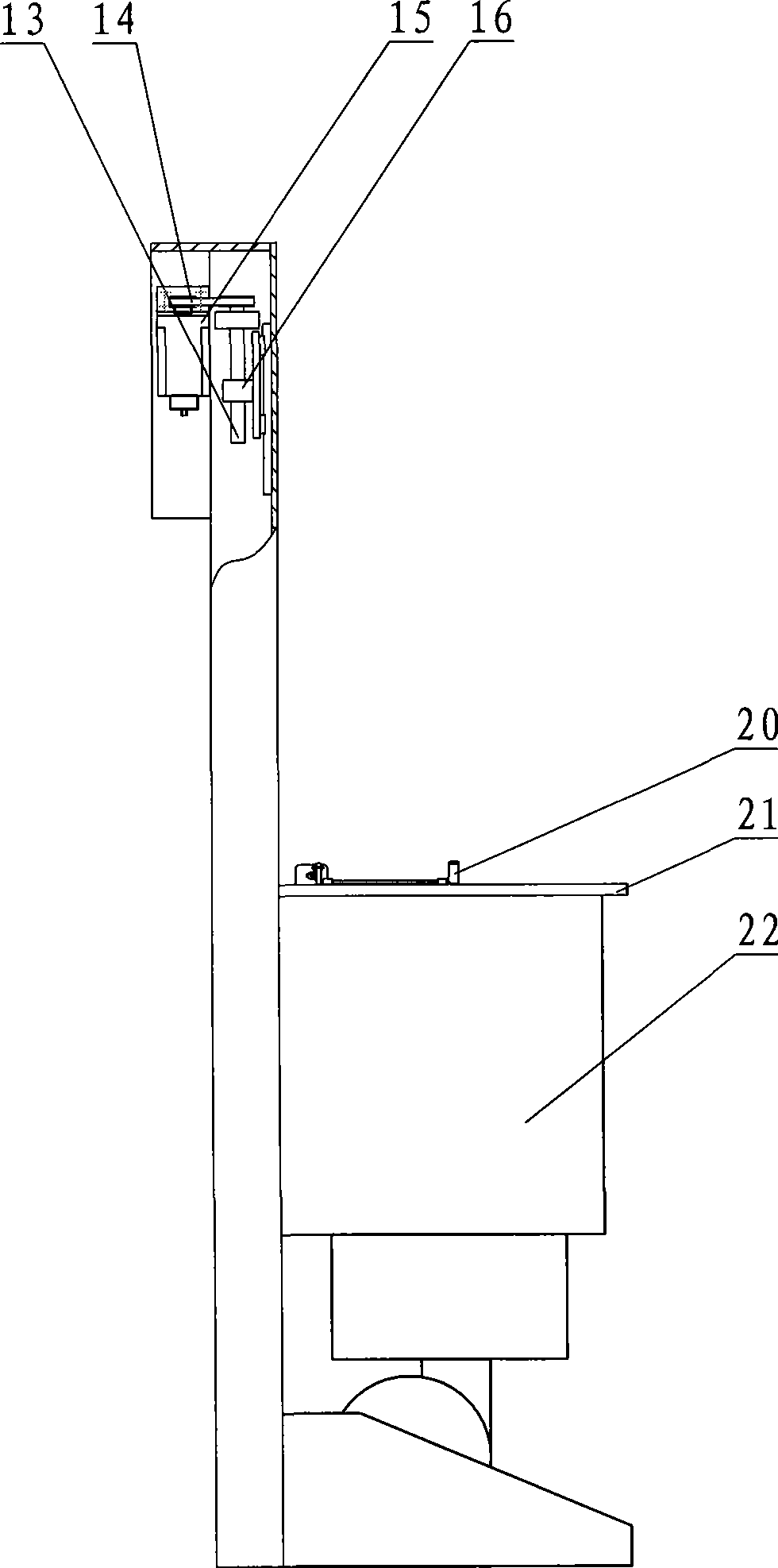

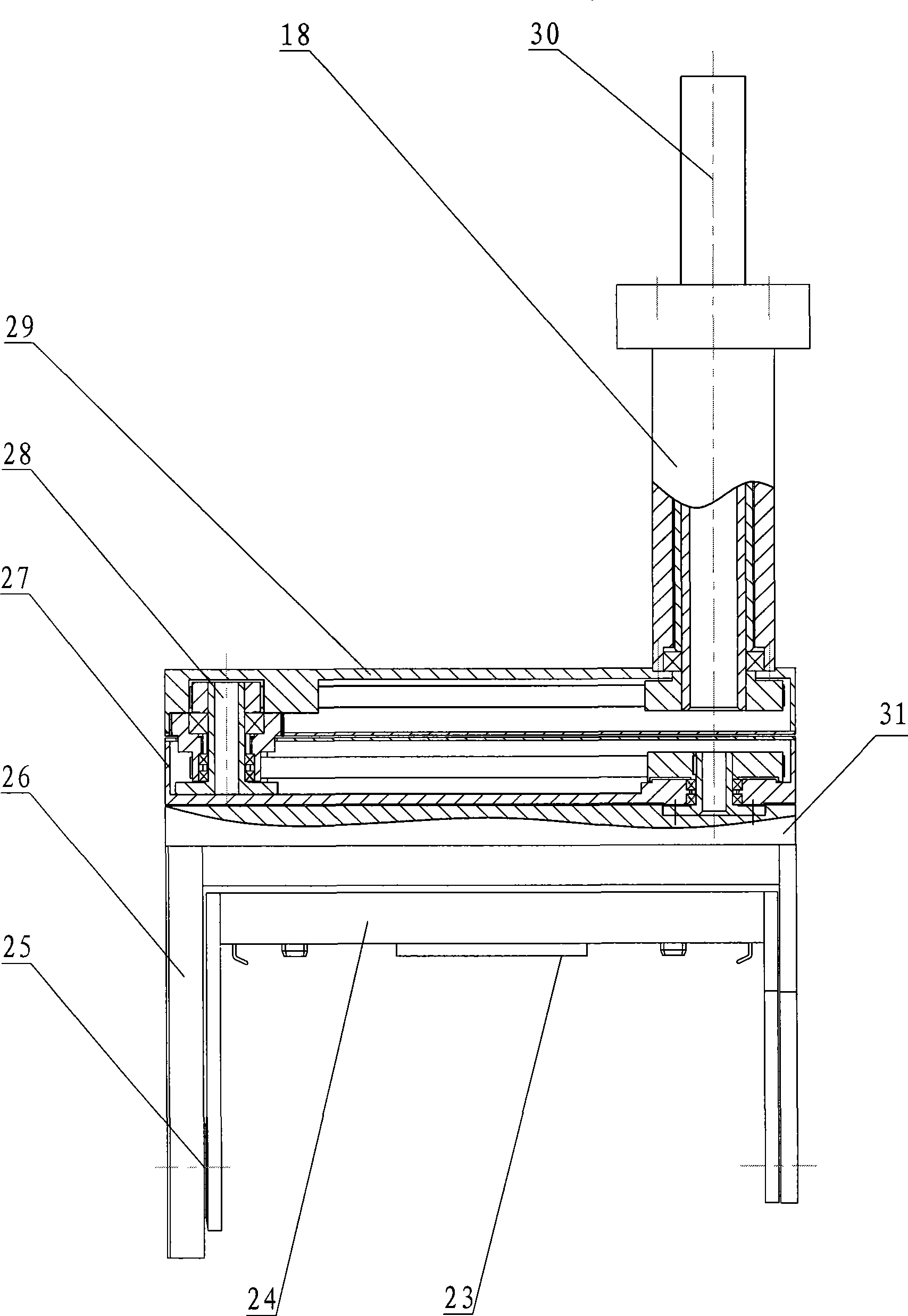

[0035] according to Figure 1-10 The specific structure of the present invention will be described in detail. The flip-type wafer automatic transfer device is based on the advantages of patented technologies such as "a method of delivering wafers for IC manufacturing" in US Patent 6,086,323, and is redesigned according to the defects in the prior art. It includes a frame 1, a feeding platform 21 fixed on the frame 1, a bellows body 22 with a claw mechanism 20 assembled on the frame 1 for lifting and moving, and a bellows body 22 with a claw mechanism 20 for lifting and extending movement. The arm mechanism 19 etc. of mechanism 24. Wherein the wind box body 22 is an integrated air filtration system, which can provide a clean microenvironment. Its working principle is basically the same as the method in the above-mentioned US patent technology, and will not be repeated here.

[0036] Such as figure 1 , 2 As shown, the bellows body 22 is assembled on the bellows body fixing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com