Tool clamp for transverse automatic welding of large spherical shell structure and assembling method

A spherical shell structure and automatic welding technology, applied in the direction of welding equipment, manufacturing tools, auxiliary welding equipment, etc., can solve the problem of inability to realize positioning, measurement, adjustment and assembly functions, inability to realize external indirect connection and fixation of spherical shell structure, spherical shell The structure has no problems such as positioning, adjustment and measurement position, which is beneficial to deformation control, improving process space margin, and improving processing margin.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

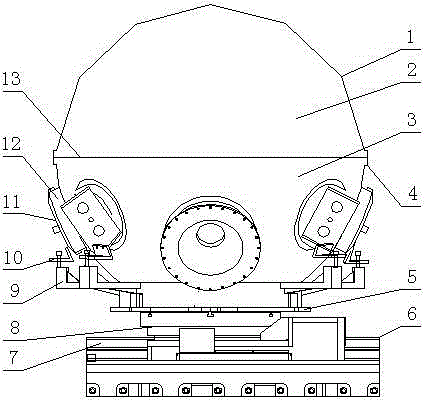

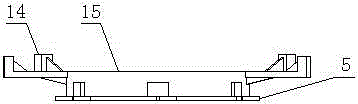

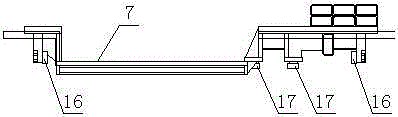

[0031] Such as figure 1 As shown, a tooling fixture for horizontal automatic welding of a large spherical shell structure includes a fixture body, the fixture body includes a spherical shell 1 and a welding fixture 6, the spherical shell 1 includes an upper hemispherical shell 2 and a lower hemispherical shell 3, and the upper hemispherical shell 2 and the lower hemispherical shell 3 is provided with an equatorial weld 13, the equatorial weld 13 is provided with a boss 4, the outer surface of the lower hemispherical shell 3 is provided with a window 12, and the end of the window 12 located at the outer side of the spherical shell 1 is provided with The outer pressure plate 11 and the end of the window 12 located inside the spherical shell 1 are provided with an inner pressure plate, the outer pressure plate 11 and the inner pressure plate are connected with the window 12 by bolts, and the welding fixture 6 includes a lifting fixture 9 connected with the lower hemispherical shel...

Embodiment 2

[0034] Such as figure 1As shown, a tooling fixture for horizontal automatic welding of a large spherical shell structure includes a fixture body, the fixture body includes a spherical shell 1 and a welding fixture 6, the spherical shell 1 includes an upper hemispherical shell 2 and a lower hemispherical shell 3, and the upper hemispherical shell 2 and the lower hemispherical shell 3 are provided with an equatorial weld 13, and a boss 4 is arranged on the equatorial weld 13. The boss 4 not only ensures the supporting effect on the welding pool, but also increases the welding processing allowance and improves the size. The processing margin ensures the finished product rate of the parts, and provides a reference position for the assembly of the parts. The outer surface of the lower hemispherical shell 3 is provided with a window 12, and the end of the window 12 located on the outer side of the spherical shell 1 is provided with an outer pressure plate. 11. The end of the window ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com