Elevator speed governor

A technology of speed limiter and elevator, applied in elevators, transportation and packaging, etc., can solve problems such as difficulty, low degree of freedom of flying pendulum, complicated assembly and adjustment operations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

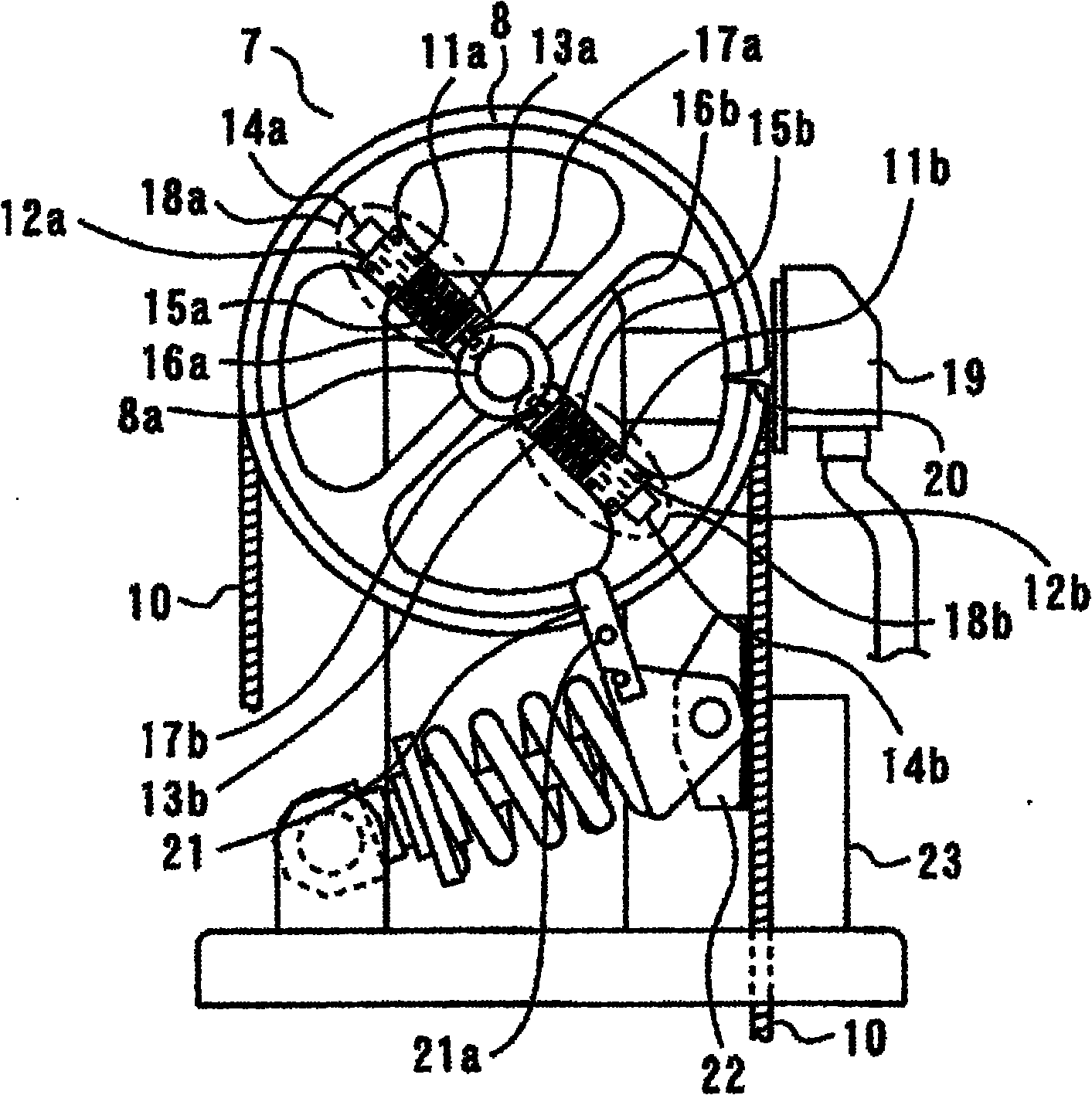

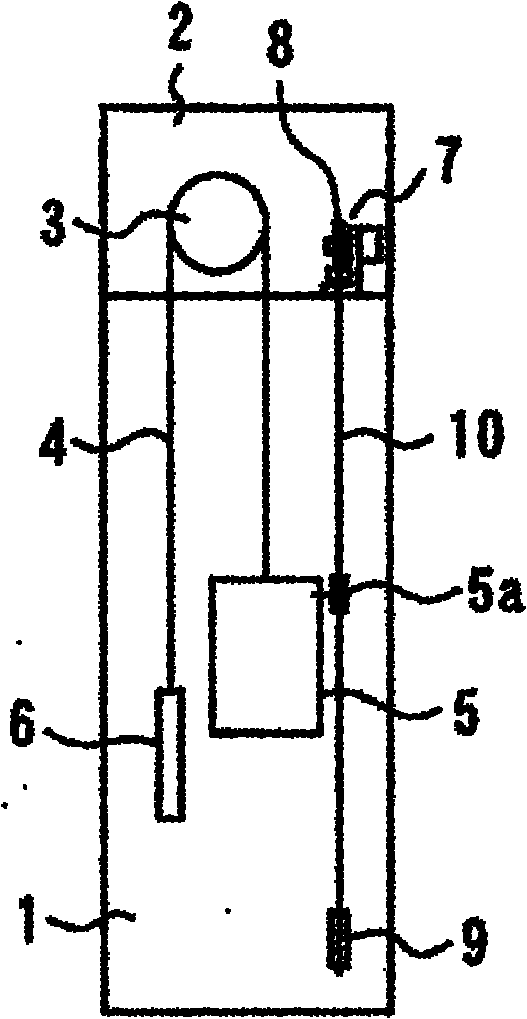

[0022] figure 1 and figure 2 Regarding the first embodiment of the present invention, figure 1 is the front view of the elevator speed limiter, figure 2 It is a schematic configuration diagram showing the outline of the overall configuration of the elevator.

[0023] In the figure, numeral 1 is the shaft of an elevator, and a machine room 2 is arranged at the upper end of the shaft 1 . A driver 3 for electrically driving the elevator is provided in the machine room 2 , and a main rope 4 is wound around a driving sheave of the driver 3 . In addition, a car 5 is connected to one end of the main rope 4, and the car 5 is arranged in the hoistway 1 so as to be able to move up and down freely. A counterweight 6 is connected to the other end of the main rope 4, and the counterweight 6 For the purpose of compensating the weight of the car 5, it is arranged in the hoistway 1 so as to be able to move up and down freely.

no. 2 approach

[0053] image 3 It is a front view of the speed governor for elevators concerning 2nd Embodiment of this invention.

[0054] In the above-mentioned first embodiment, the center of rotation of the sheave is located on the extension line of the movement trajectories of the first flying weight and the second flying weight, in other words, the moving directions of the first flying weight and the second flying weight However, in the second embodiment described here, the center of rotation of the sheave is not located on the extension line of the movement trajectories of the first flying pendulum and the second flying pendulum, in other words , and the moving directions of the first flying pendulum and the second flying pendulum are not arranged on the diameter of the sheave.

[0055] That is, at the spoke portion of the sheave 8, a fan-shaped first bearing fixing portion 11a having a central angle substantially at a right angle is formed, and a first linear motion is fixed to the fi...

no. 3 approach

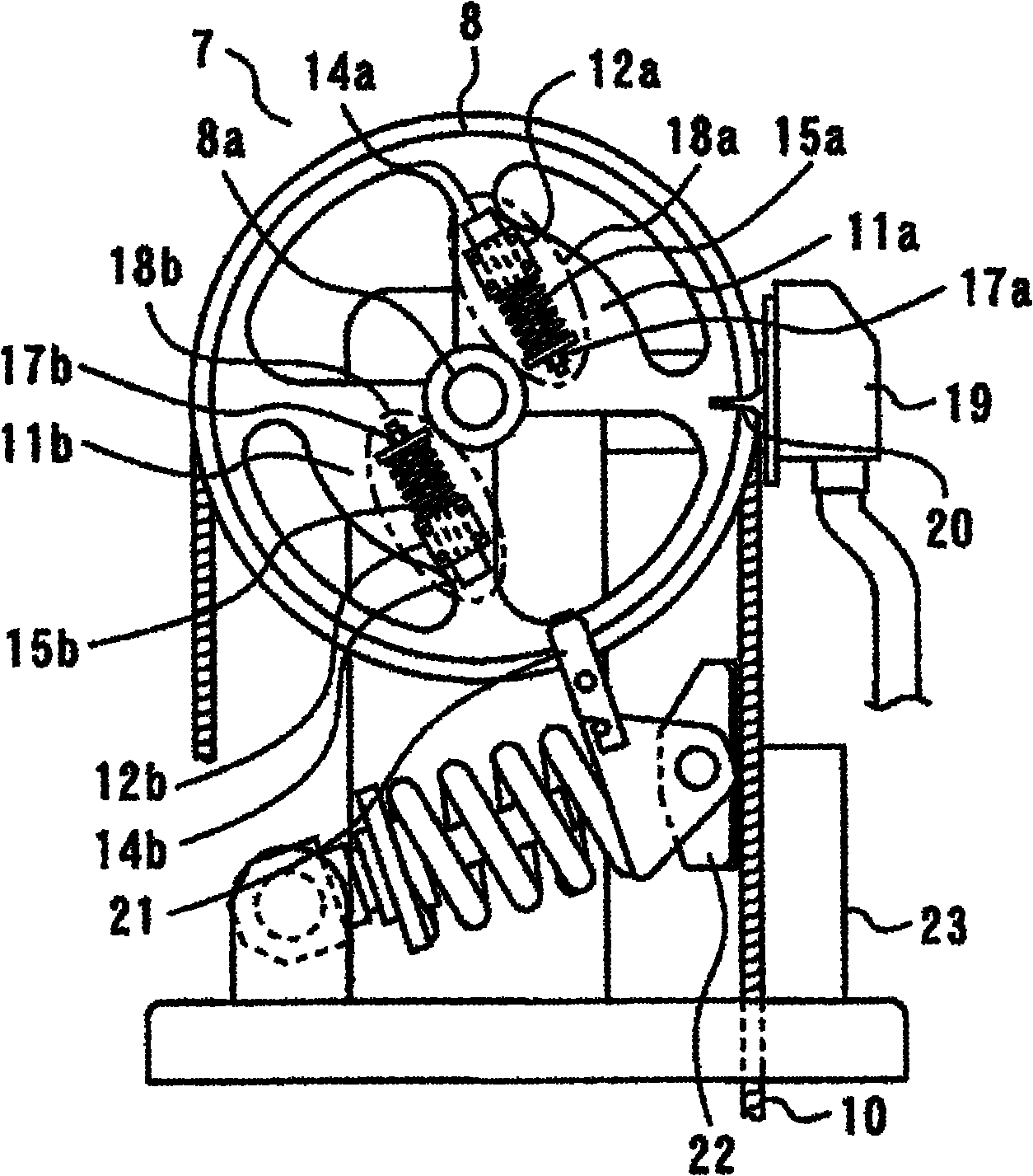

[0063] Figure 4 It is a front view of the speed governor for elevators concerning 3rd Embodiment of this invention.

[0064] In the third embodiment described here, in the above-mentioned second embodiment, a plurality of the first linear motion bearings 12 a and the second linear motion bearings 12 b are respectively provided.

[0065] That is, if Figure 4 As shown, a plurality of (here, two) first linear motion bearings 12a are fixed to the first bearing fixing portion 11a. In addition, accompanying this, the length dimension of the said 1st rod 13a is also longer than 2nd Embodiment. In addition, similarly, a plurality of (here, two) of the second linear motion bearings 12b are fixed to the second bearing fixing portion 11b, and accordingly, the length dimension ratio of the second rod 13b is The second embodiment is long.

[0066] In addition, other structures and operations are the same as those of the second embodiment.

[0067] In the second embodiment, since the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com