Patents

Literature

31results about How to "Stable output force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

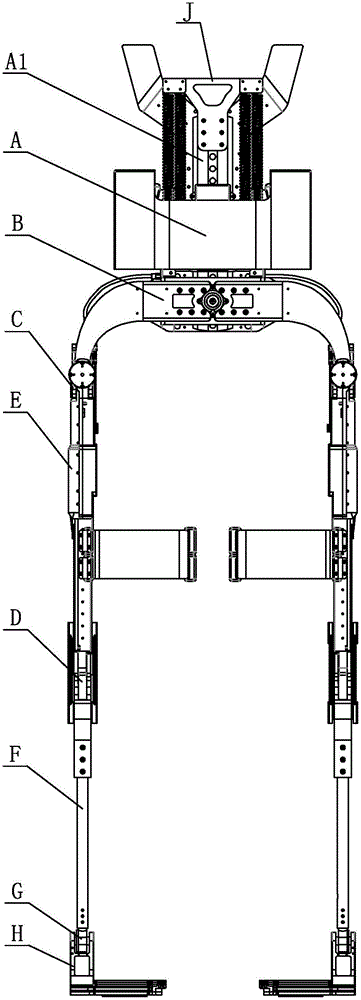

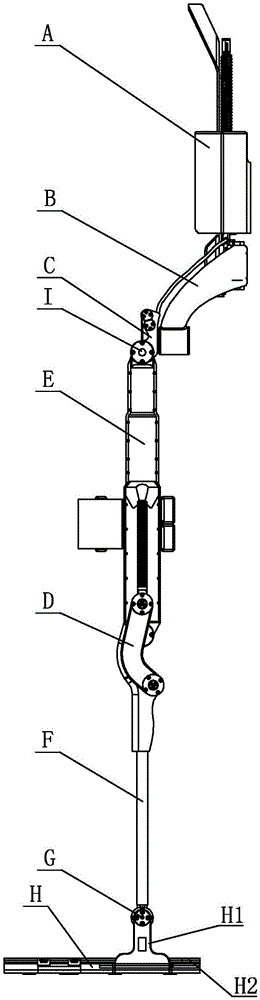

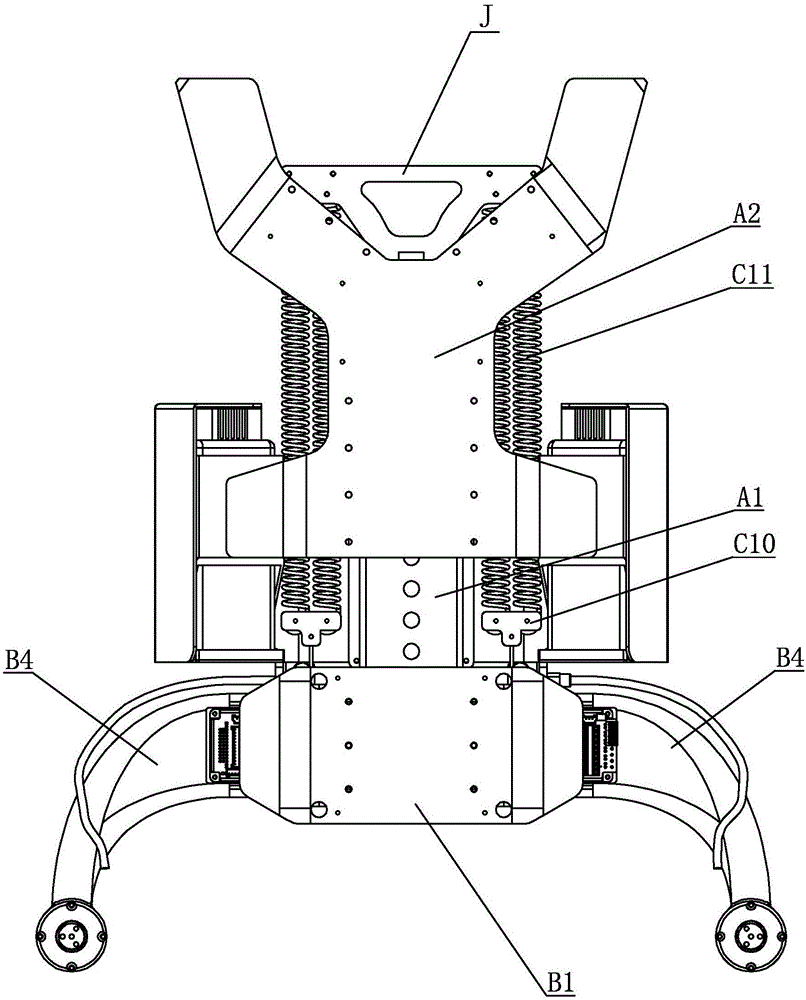

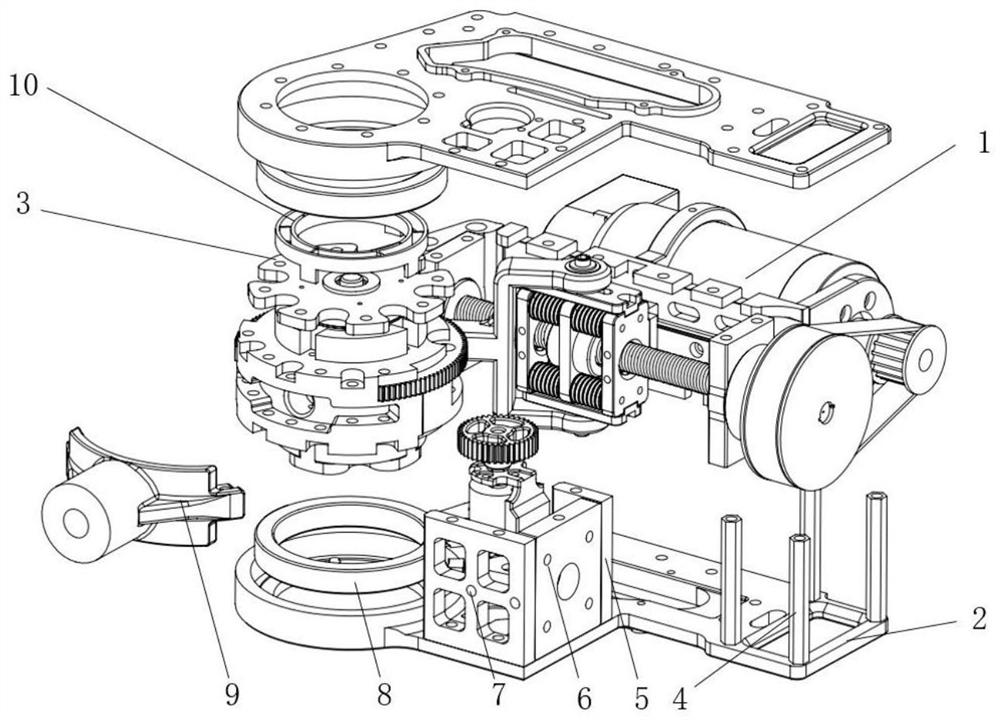

Light active and passive combined lower-limb power-assisted exoskeleton robot

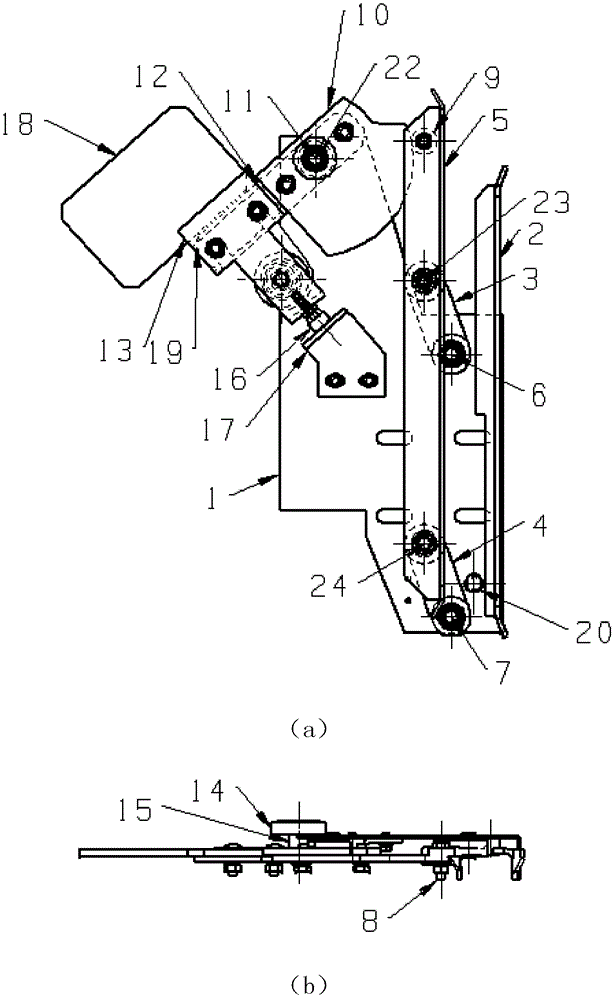

The invention discloses a light active and passive combined lower-limb power-assisted exoskeleton robot. A back and a waist are arranged up and down; a waist bundling connecting piece on the waist is connected with a back supporting piece on the back; hip joint rotary shafts on hip joints are hinged to waist hip connecting pieces on the waist; a spring upper pressing plates on the hip joints are connected with a spring adjusting plate; the spring adjusting plate is positioned at the upper end of the back supporting piece and is connected with the back supporting piece; leading pulley seats are fixedly connected with a waist fixing plate on the waist; the upper ends of thighs are hinged to connecting plates on the hip joints through leg hip connecting shafts; steel wire fixed parts on the hip joints are fixedly mounted on outer walls of thighs; the lower ends of the thighs are hinged to the upper ends of knee joint supporting shells through knee joint connecting shafts; a motor encoder, a motor, a speed reducer, a coupler and a lead screw are sequentially arranged in a knee joint from top to bottom; the upper end of shanks are connected with the knee joint supporting shells; and the lower ends of the shanks are hinged to feet through foot joint shafts. The light active and passive combined lower-limb power-assisted exoskeleton robot is used for military loadbearing.

Owner:HARBIN INST OF TECH

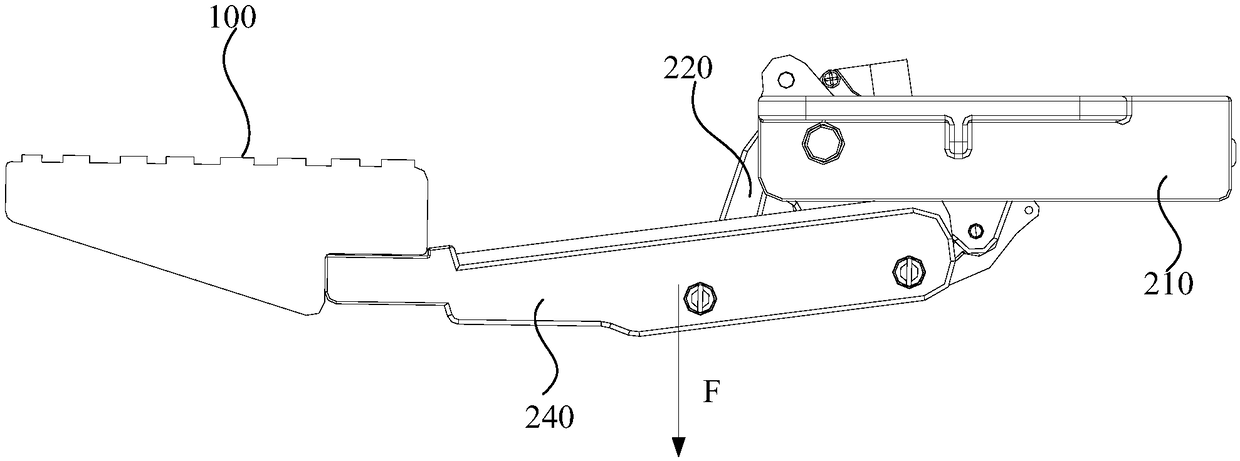

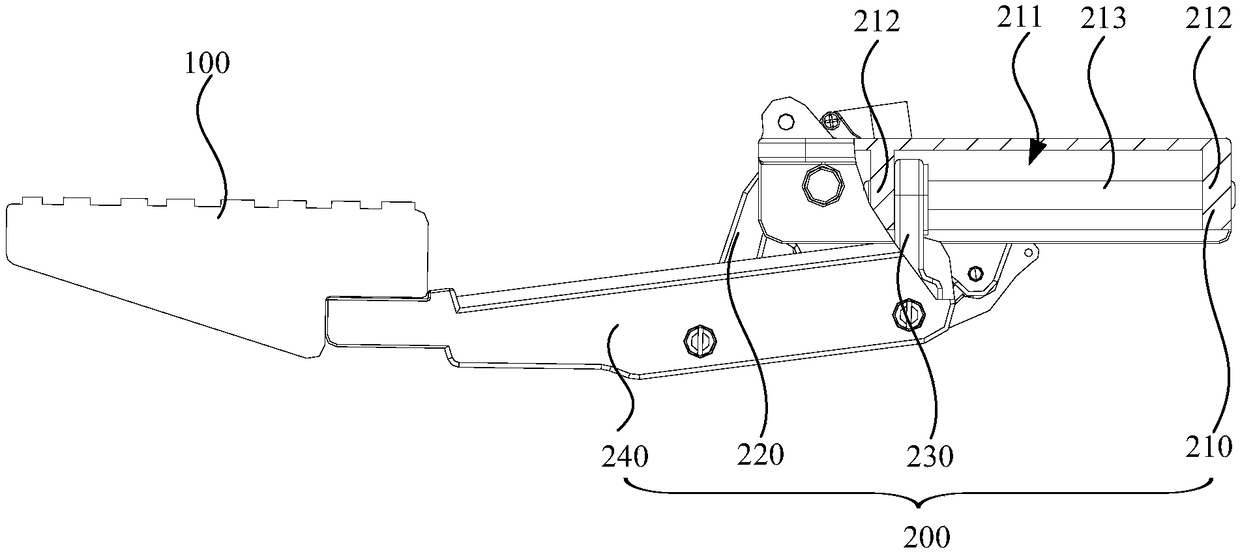

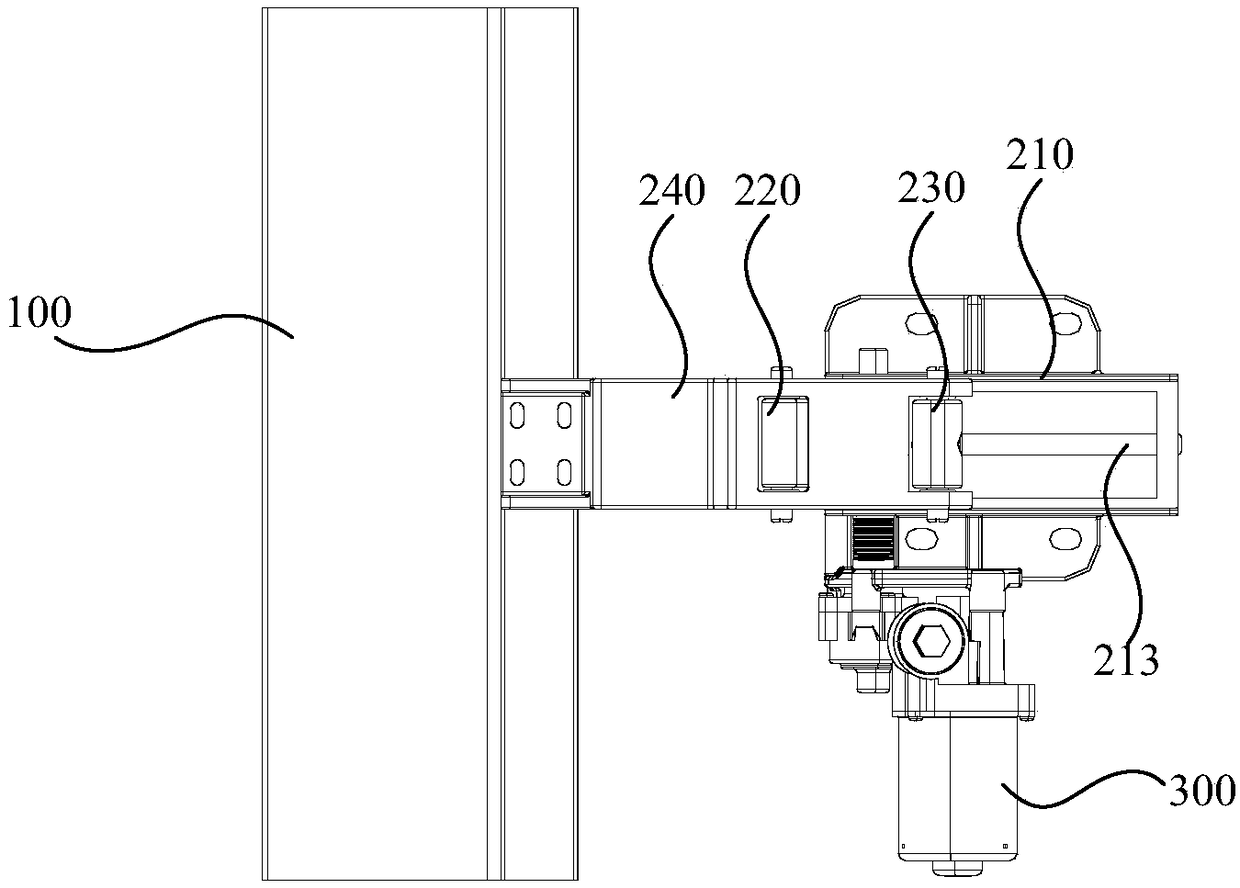

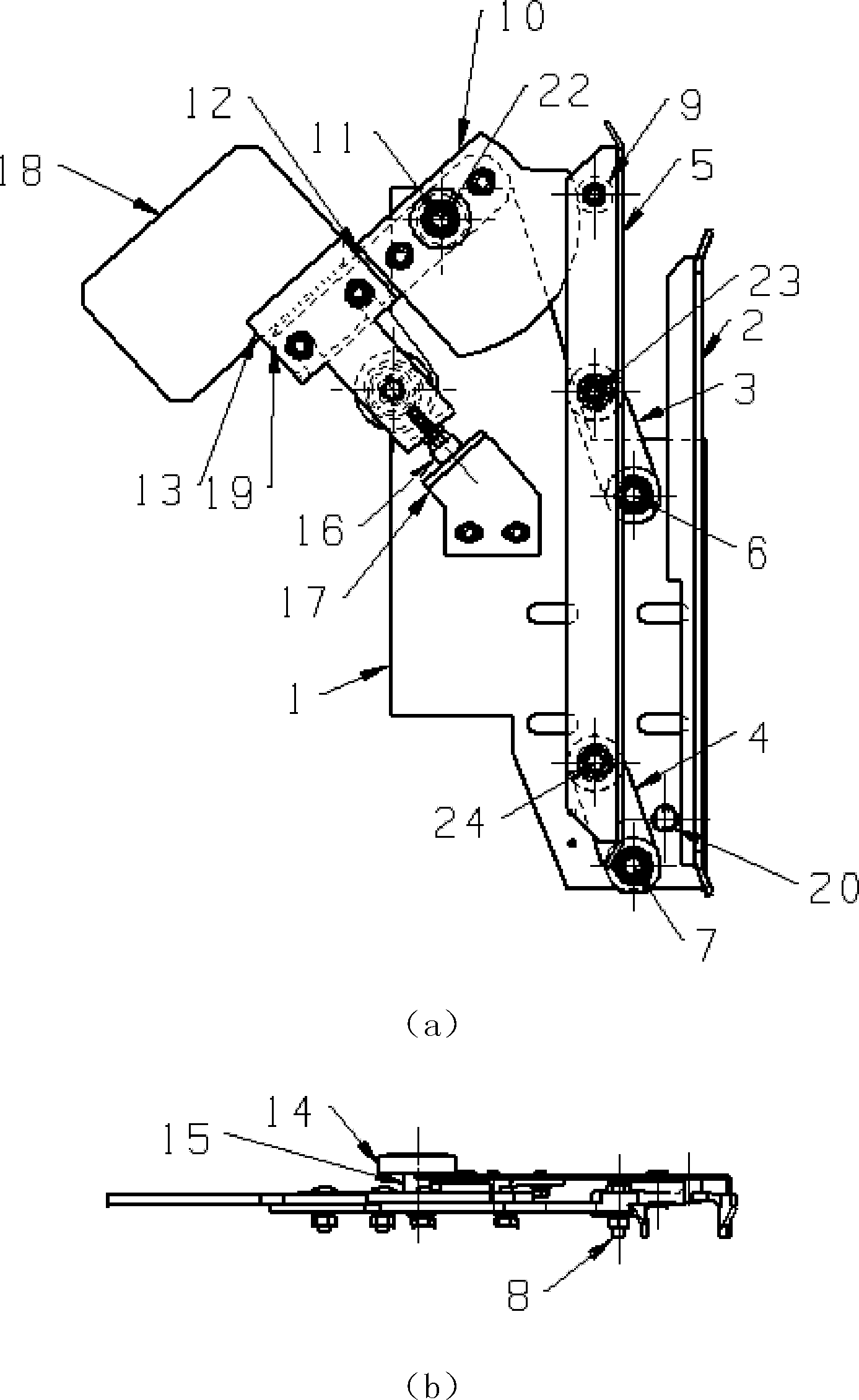

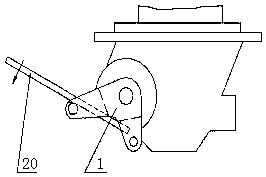

Vehicle step tread device

ActiveCN108791086AConstant output forceEasy to controlSteps arrangementElectric machineryDrive motor

The invention discloses a vehicle step tread device. The vehicle step tread device comprises a stepping plate, a telescopic mechanism and a driving motor. The telescopic mechanism comprises a fixed seat, a driving swing arm, a driven sliding arm and a connecting seat, one end of the driving swing arm is rotatably connected with the fixed seat, the other end of the driving swing arm is rotatably connected with the connecting seat. One end of the driven sliding arm is in sliding fit with the fixed seat, and the other end of the driven sliding arm is rotatably connected with the connecting seat.The driving swing arm and the driven slide arm are rotatably connected to different positions of the connecting seat, the stepping plate is fixed to the connecting seat, and a driving motor is used for driving the driving swing arm to rotate in a reciprocating mode. According to the vehicle step tread device, the stepping plate can automatically extend to assist the step tread and automatically retract to hide, meanwhile, the output force of the driving motor is relatively constant, the control process of the driving motor is simplified, the damage probability of the driving motor is reduced,and the service life of the driving motor is prolonged.

Owner:WINBO DONGJIAN AUTOMOTIVE TECHNOLOGY CO LTD

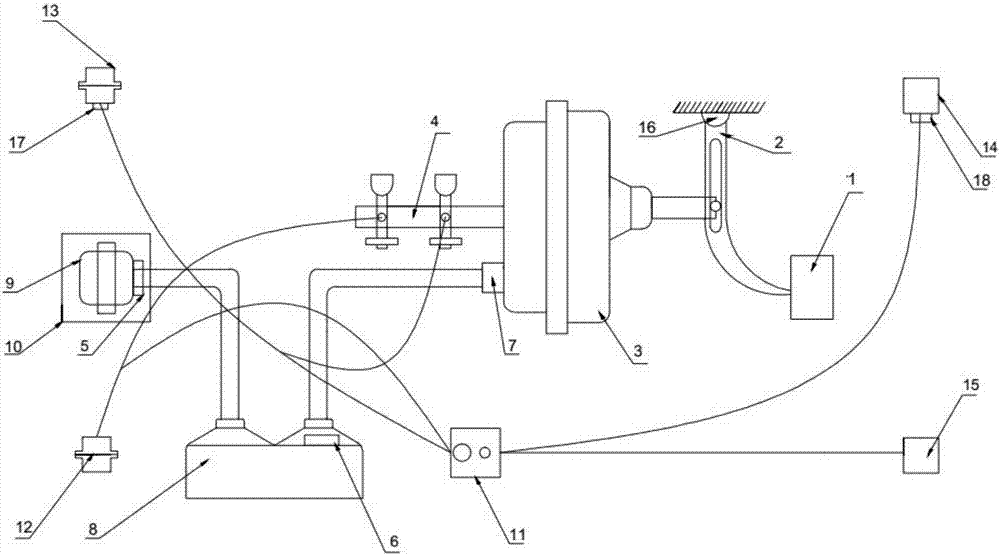

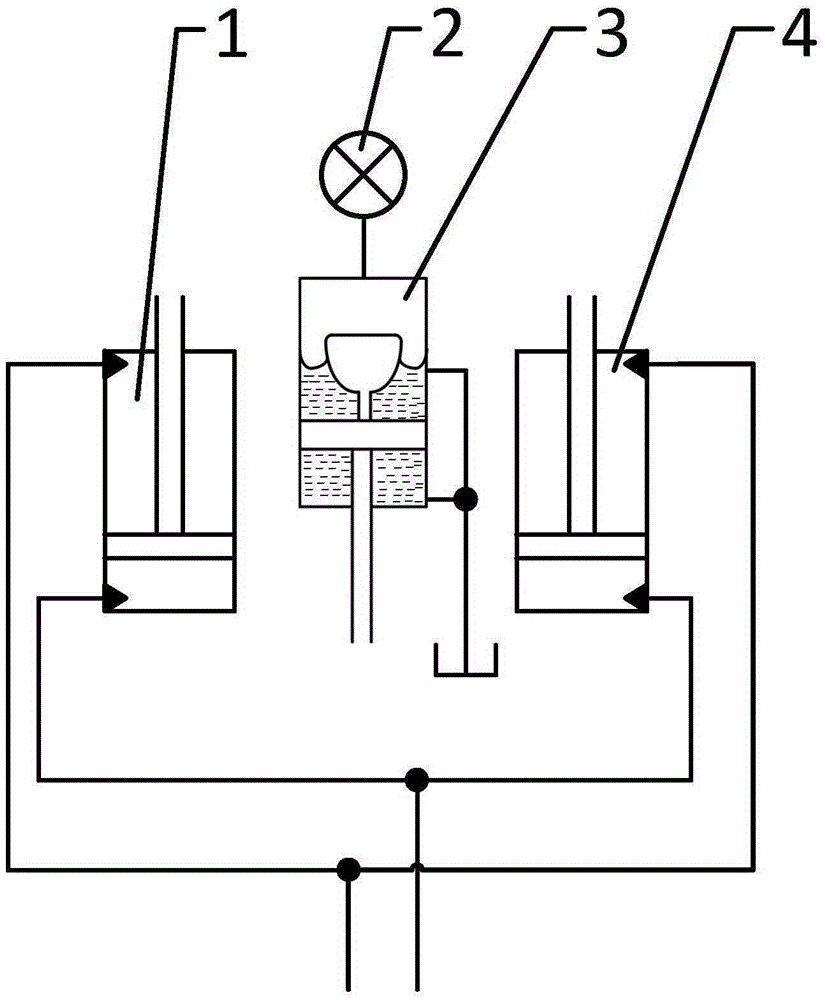

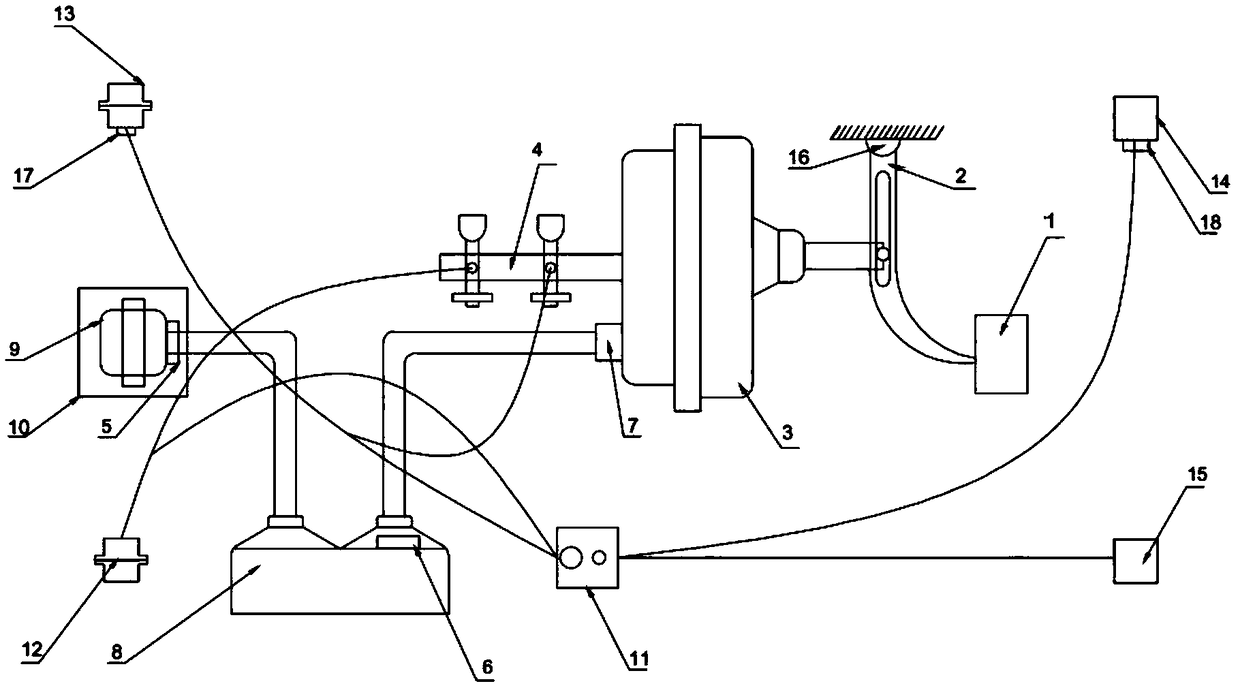

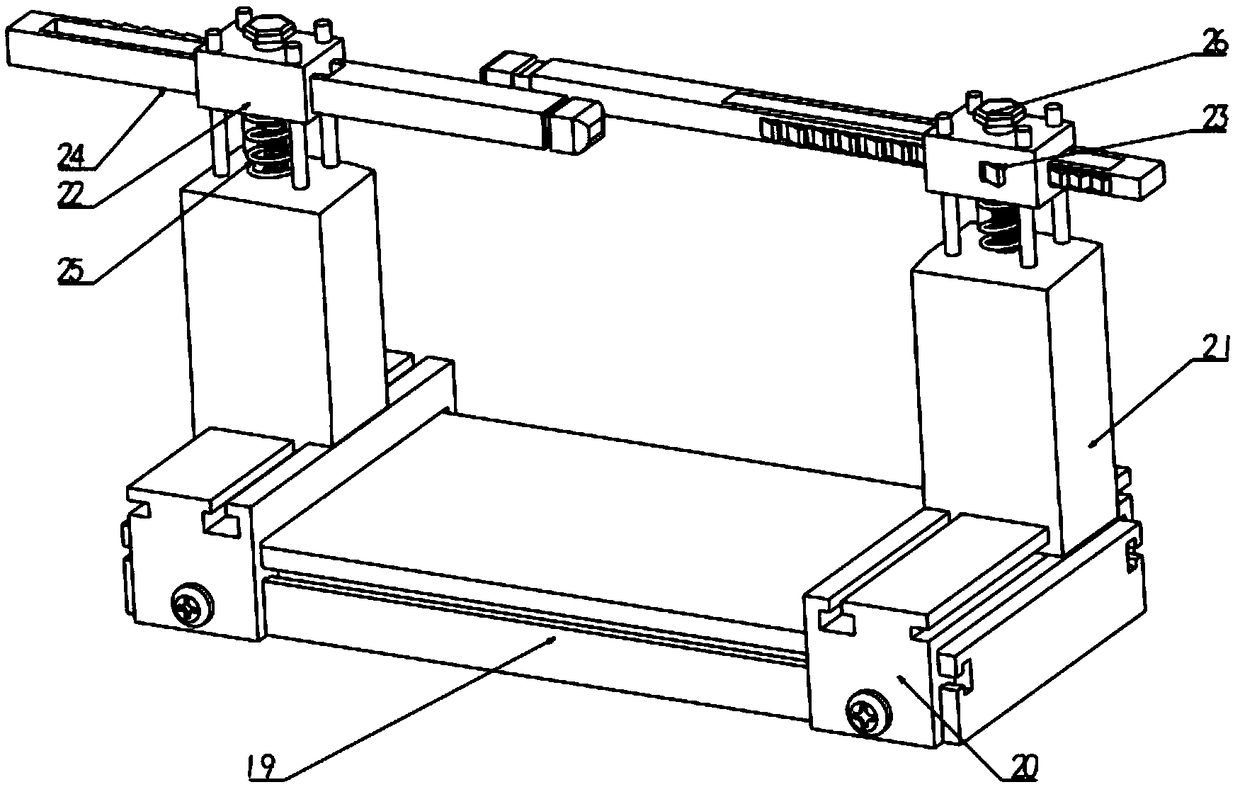

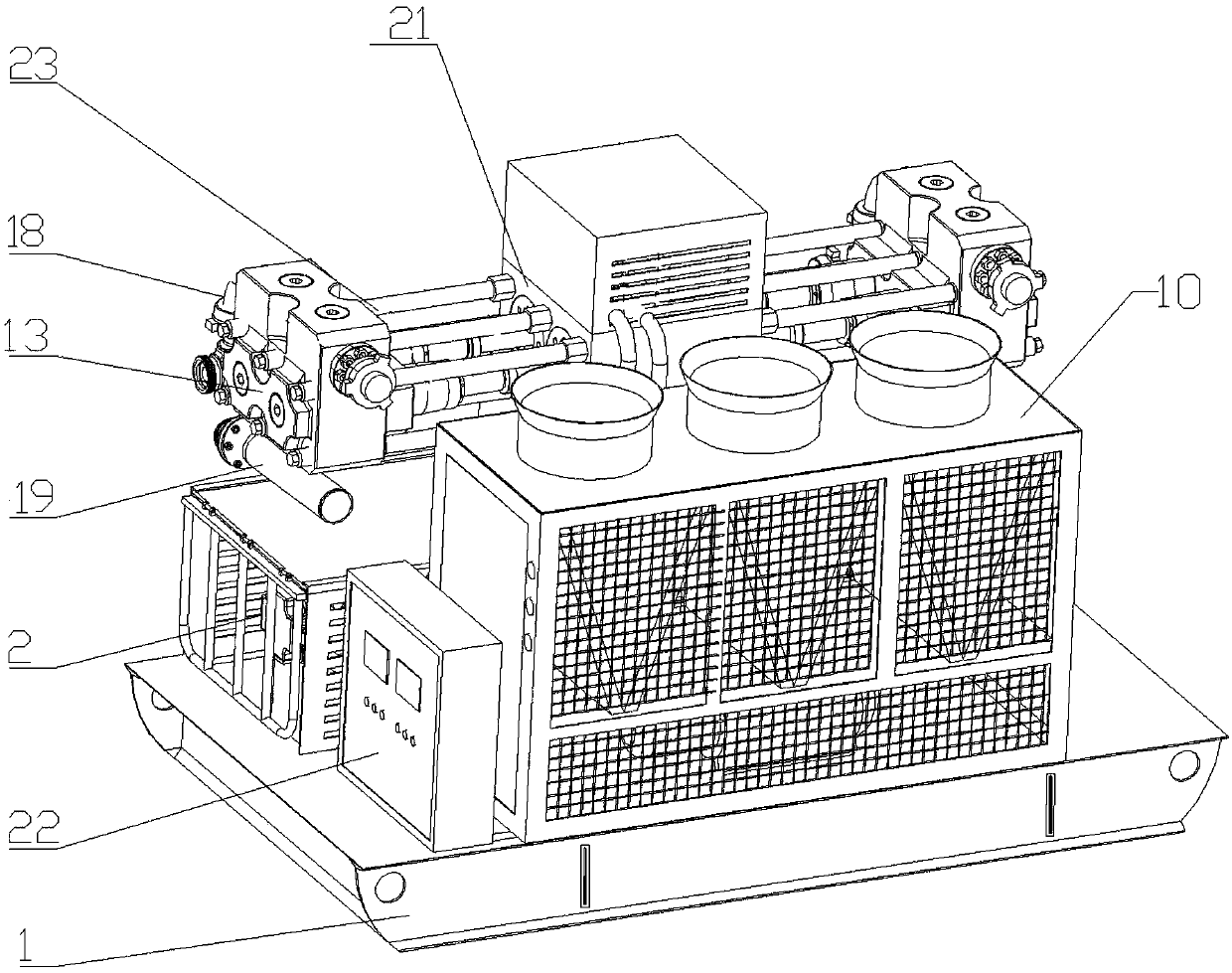

Automobile electric vacuum pump test system

ActiveCN106939884AAccurate data collectionEasy to assemble and disassemblePump testingPump controlLoad sensingMaterial resources

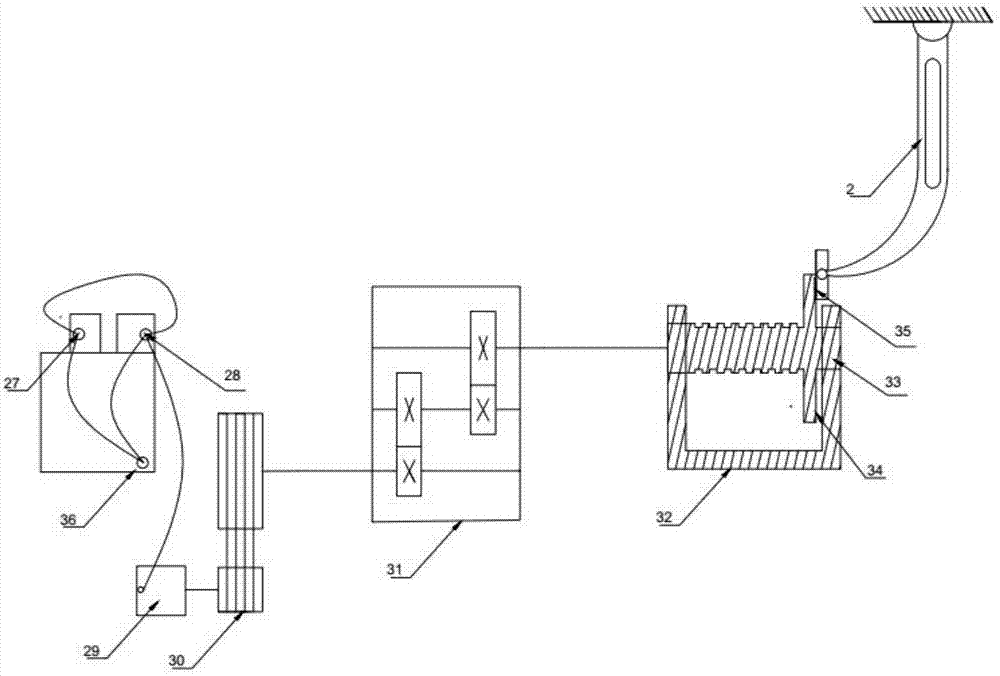

The invention provides an automobile electric vacuum pump test system. The automatic electric vacuum pump test system comprises a pedal force loading system, a pedal, a vacuum booster, a braking main cylinder, a vacuum air storage tank, an electric vacuum pump, a vacuum pump fixing device, a load-sensing proportion valve, a left front wheel cylinder, a right front wheel cylinder, a left rear wheel cylinder, a right rear wheel cylinder and the like, wherein the pedal force loading system is used for exerting loading forces with different torques onto the pedal; and the vacuum pump fixing device is used for fixing electric vacuum pumps in different shapes and with different specifications and sizes onto a rack which is used for test. The electric vacuum pump is placed in the automobile electric vacuum pump test system to be measured, so that the electric vacuum pump is approximate to a service status to the utmost extent, and meanwhile, various index data during test can be output; as the fixing device which can be matched with various electric vacuum pumps is adopted, the electric vacuum pump can be mounted and dismounted conveniently and quickly, and accordingly, the troublesome step of replacing the fixing device during test on different electric vacuum pumps is omitted; the efficiency within unit time is higher; and manpower and material resources in the test process are greatly saved.

Owner:JILIN UNIV

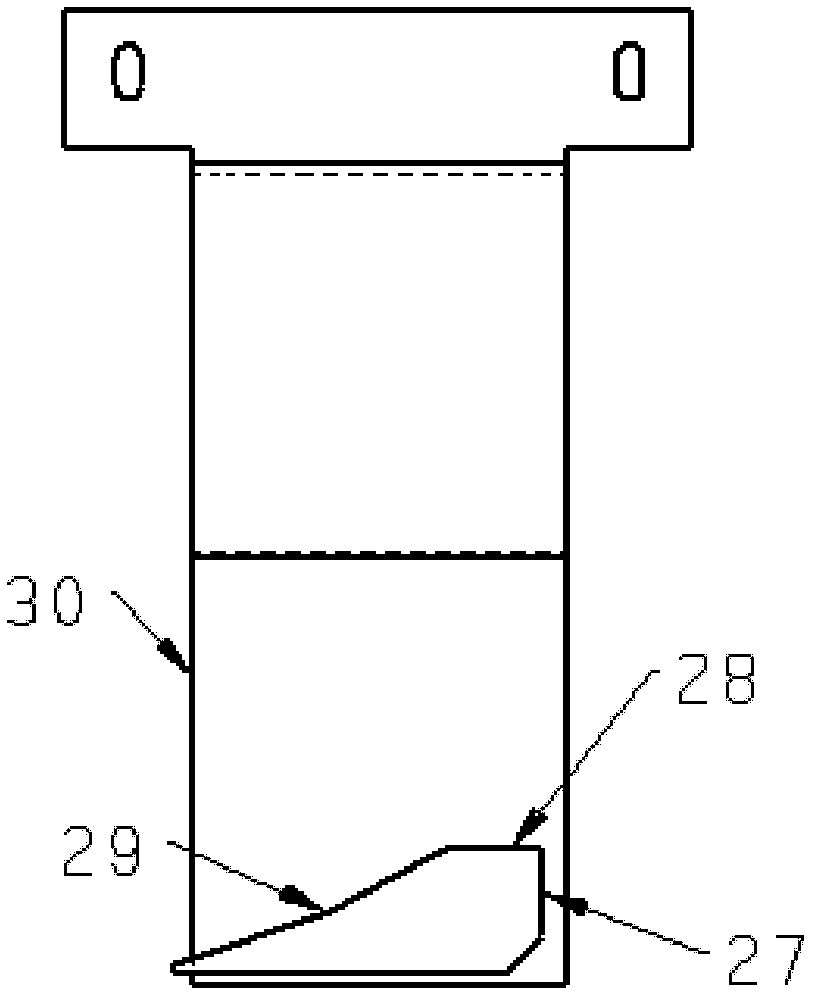

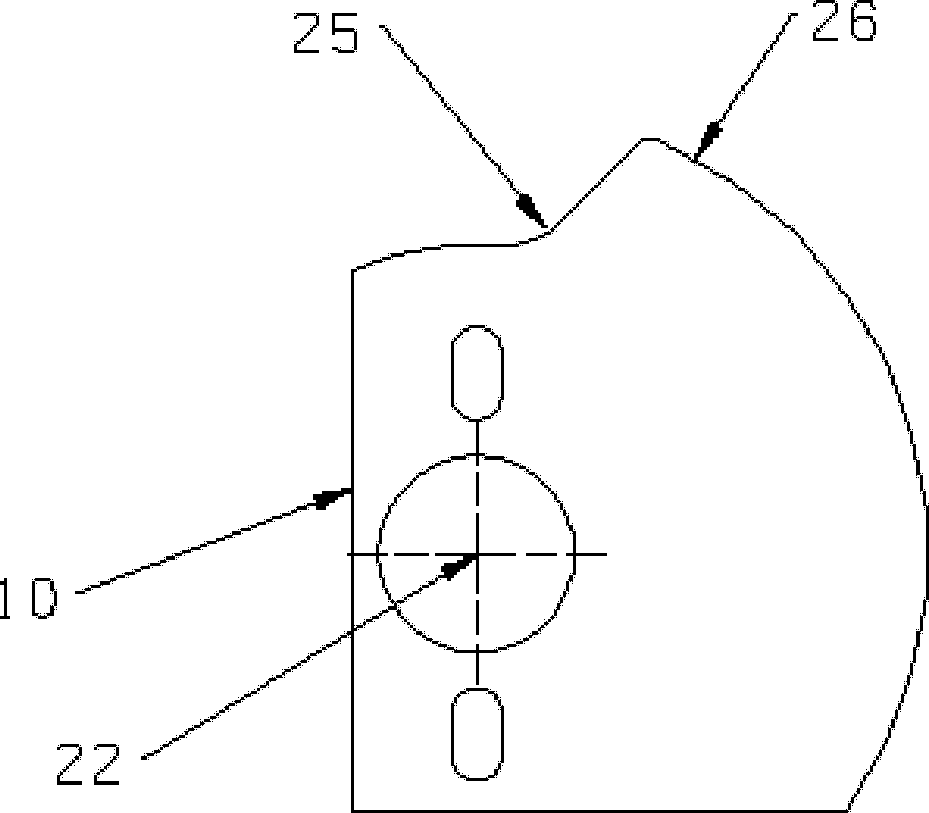

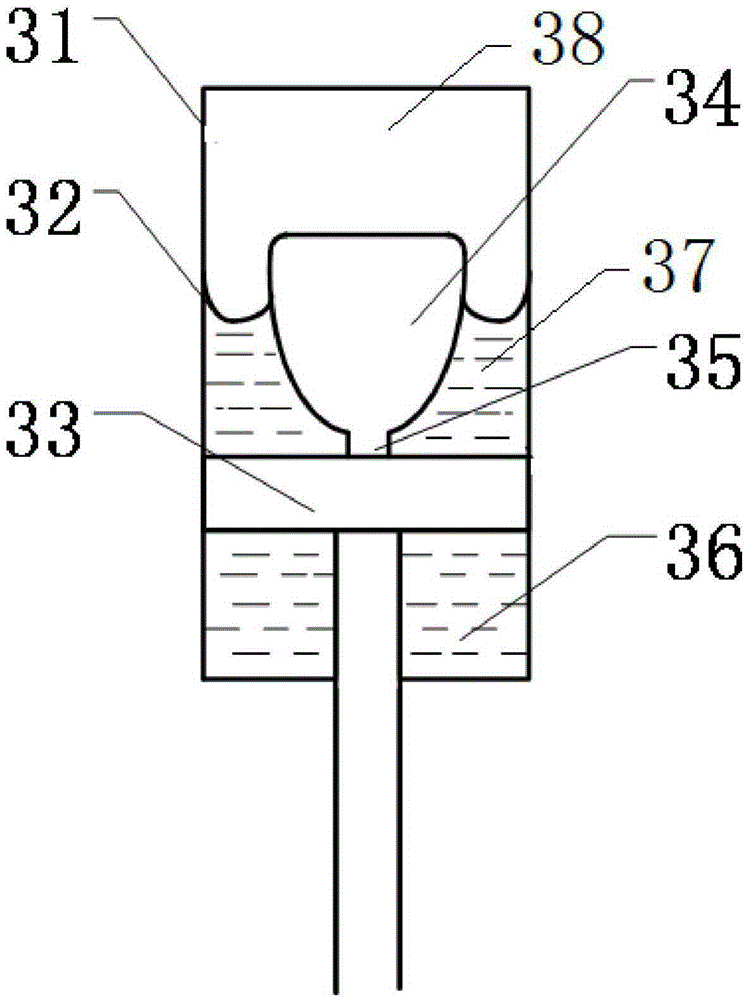

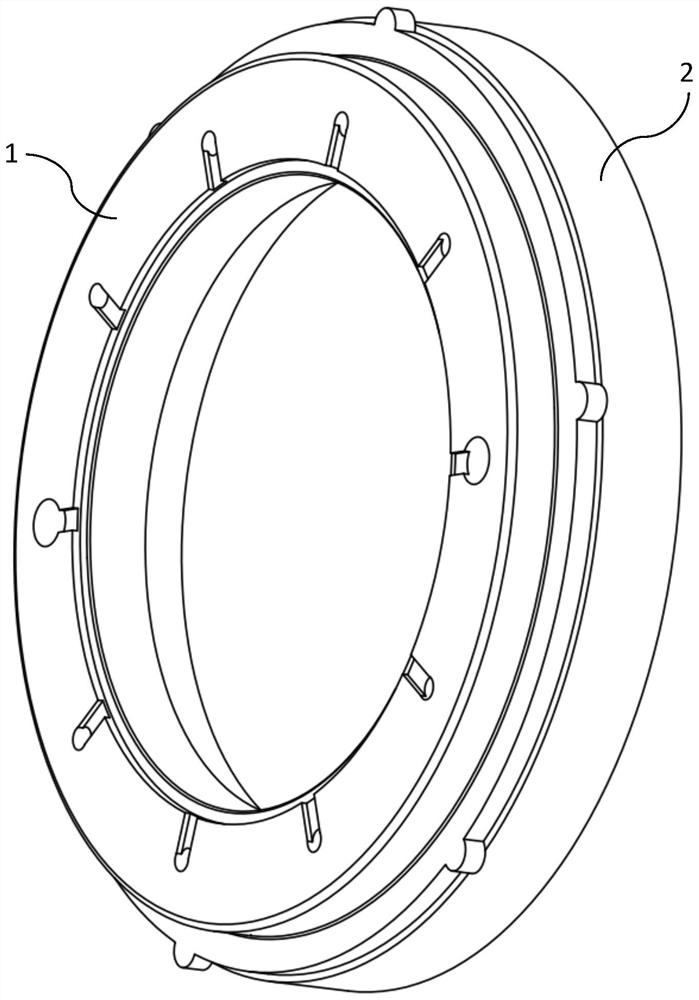

Asynchronous door knife of elevator door machine

ActiveCN102862904AStable output forceMeet the needs of large stroke door openingBuilding liftsEngineeringElectrical and Electronics engineering

The invention discloses an asynchronous door knife of an elevator door machine. The clamping action for a landing door linked door ball is realized through the cooperation of a door knife assembly and a cam device, so that the linkage of a carriage door and the landing door can be realized. The door knife assembly is installed on a movable part, and the cam device is installed on a stationary part. In the closing process for opening and closing the linked door, the door knife assembly clamps the landing door linked door ball, and the asynchronous door knife is self-locked, so that the thrusting force for the landing door linked door ball can be continuously and stably supplied; when the door is about to close, the cam device acts on the door knife assembly, a gap needed by the asynchronous door knife and the landing door linked door ball is formed, and the asynchronous door knife is released; and when the door is completely closed, the door knife assembly is subjected to the cam device and cannot produce the action for clamping the landing door linked door ball, and the gap between the door knife assembly and the landing door linked door ball is reliable. The landing door linked door ball is always clamped by the asynchronous door knife in the door closing process, so that a stable drive force is supplied for a landing door.

Owner:SHANGHAI MITSUBISHI ELEVATOR CO LTD

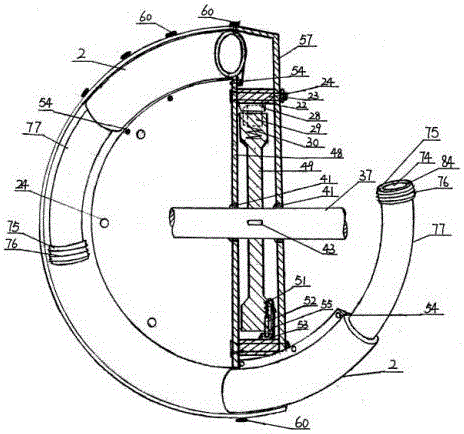

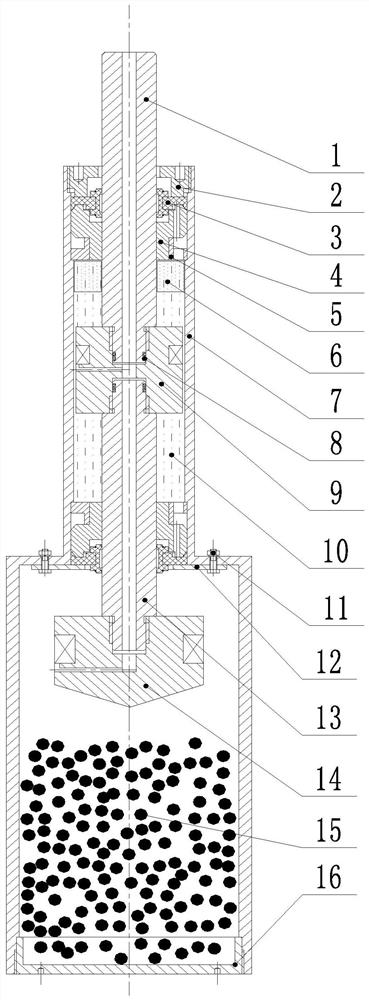

Novel damping and cushioning integrating device

ActiveCN110701239AChange the size of the currentAchieving semi-active controlSpringsNon-rotating vibration suppressionFrictional coefficientEngineering

The invention discloses a novel damping and cushioning integrating device. The novel damping and cushioning integrating device comprises a cylinder with the variable cross-section, a first piston arranged in the cylinder, a first piston rod connected to the first piston, a second piston rod connected to the first piston, a second piston arranged at the end of the second piston rod, and an upper end cover and a lower end cover arranged at the end of the cylinder, the cylinder comprises a damping section and a buffering section, and a gap is kept between the first piston and the inner wall of the cylinder; and the second piston is arranged in the buffering section, the second piston can move in the axial direction of the cylinder, and the buffering section is filled with ferromagnetic particle small balls. According to the technical scheme of the novel damping and cushioning integrating device, the performance of a magnetorheological damper is used, a variety of external working conditions can be adapted, and the high damping performance is achieved; and during buffering, the particle damper performance is used, the output force value is stable, a magnetic field is changed by adjusting the coil current, the friction coefficient of the second piston and particles is adjusted, a variety of buffering conditions can be adapted, and the novel damping and cushioning integrating deviceis compact in structure and simple in mounting form.

Owner:CHONGQING UNIV

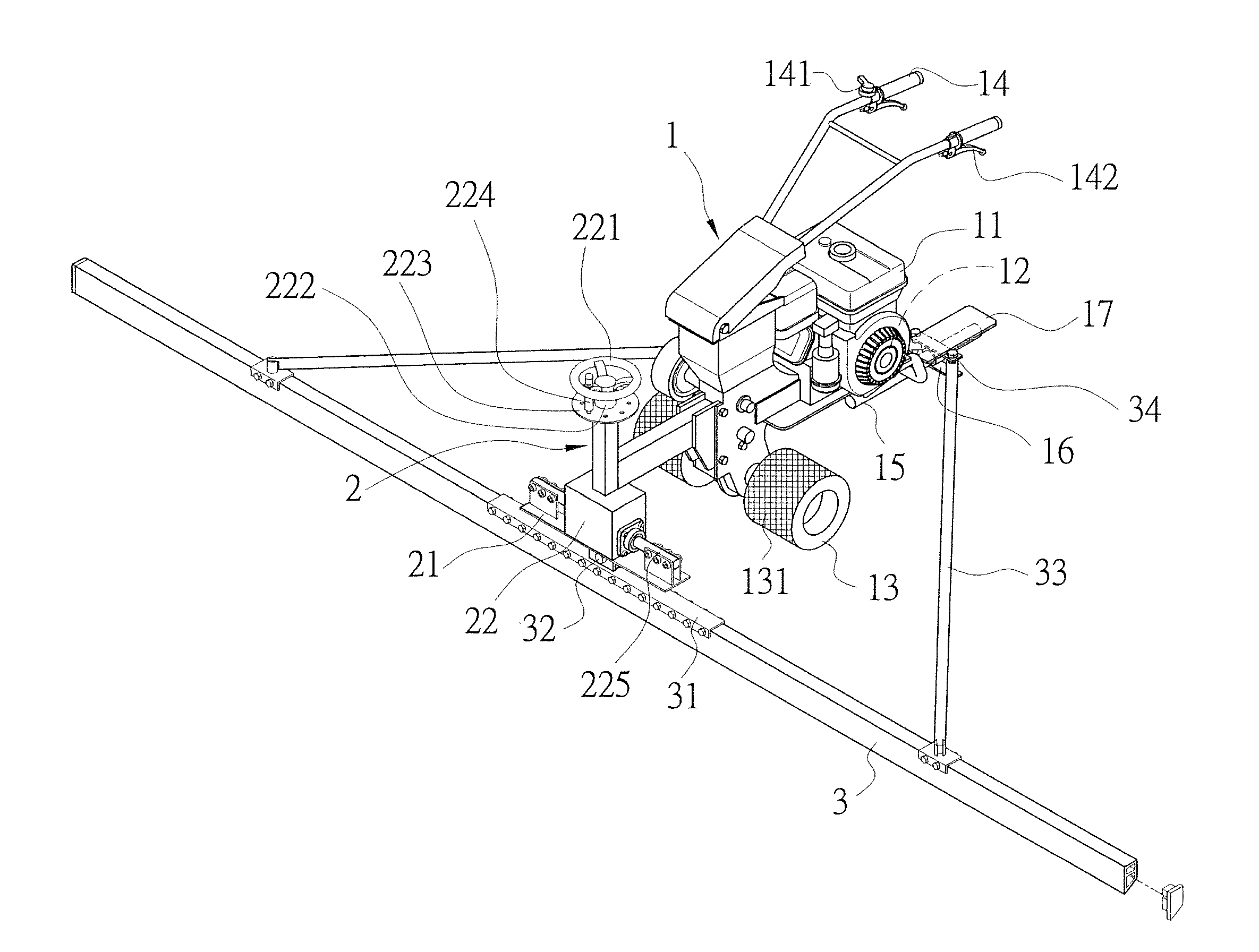

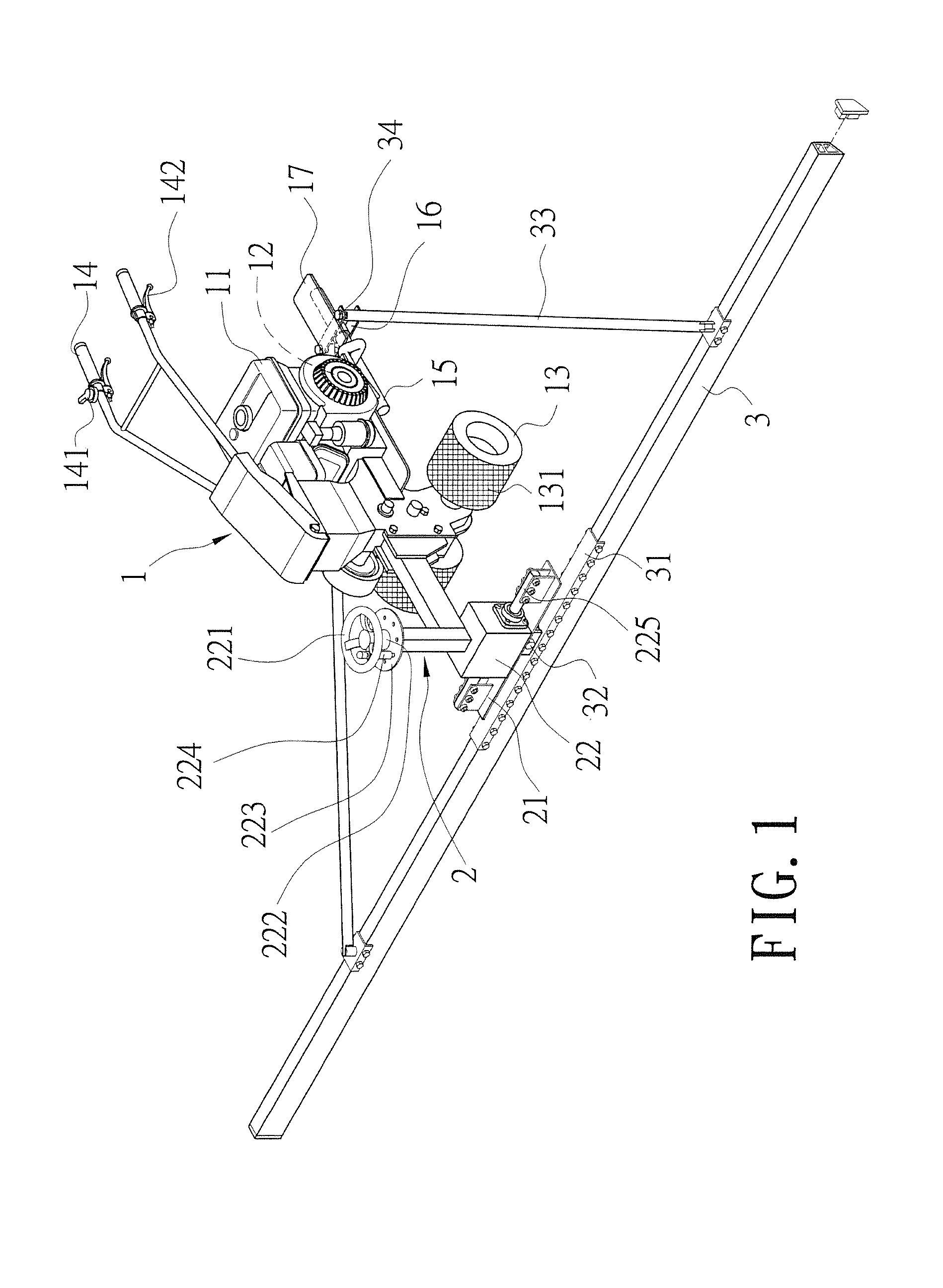

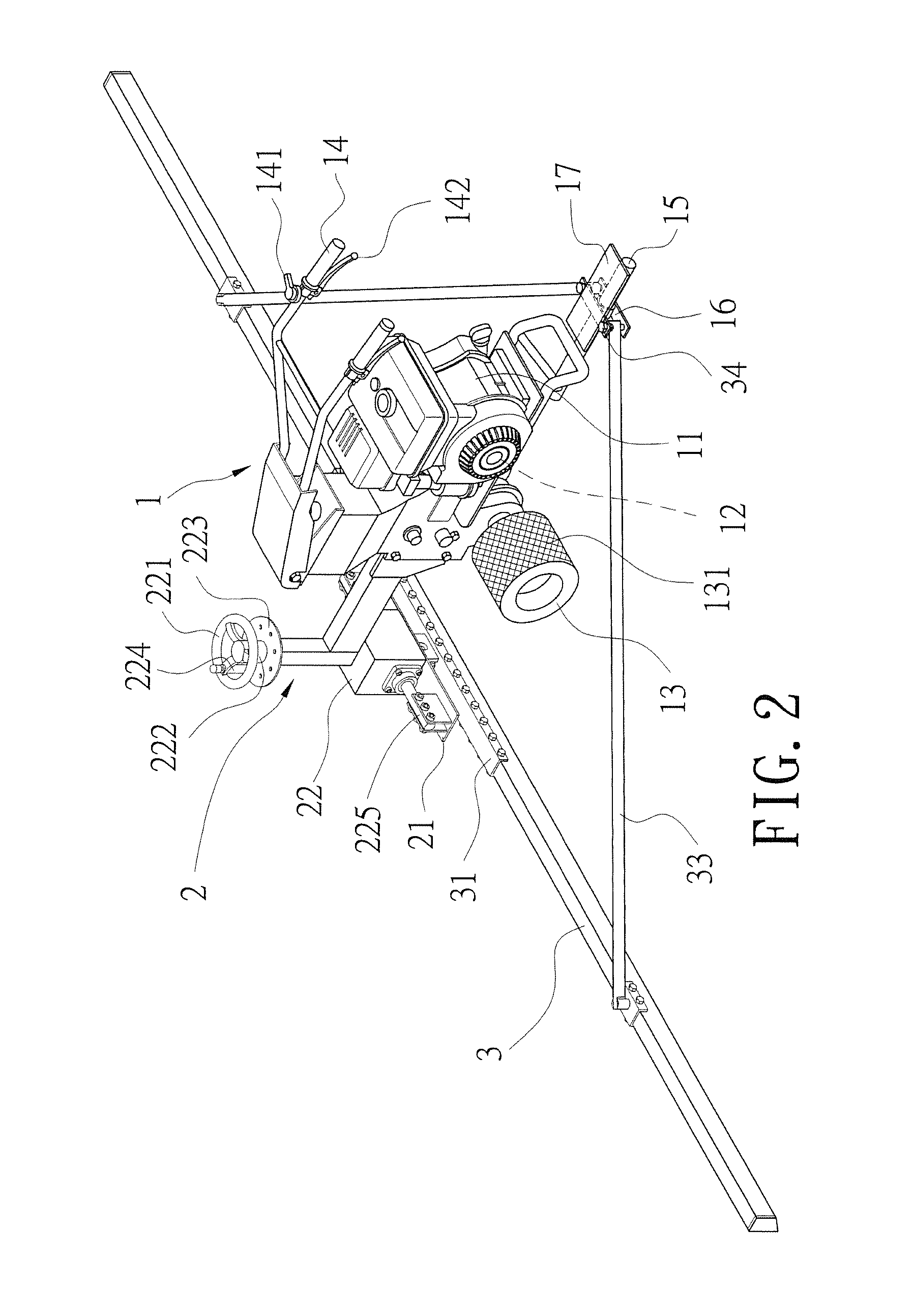

Leveling device for poured concrete floors

ActiveUS20130294834A1Ensure levelingQuality is obtainedRoads maintainenceBuilding material handlingFloor levelElectrical and Electronics engineering

Owner:PAI MING CHENG

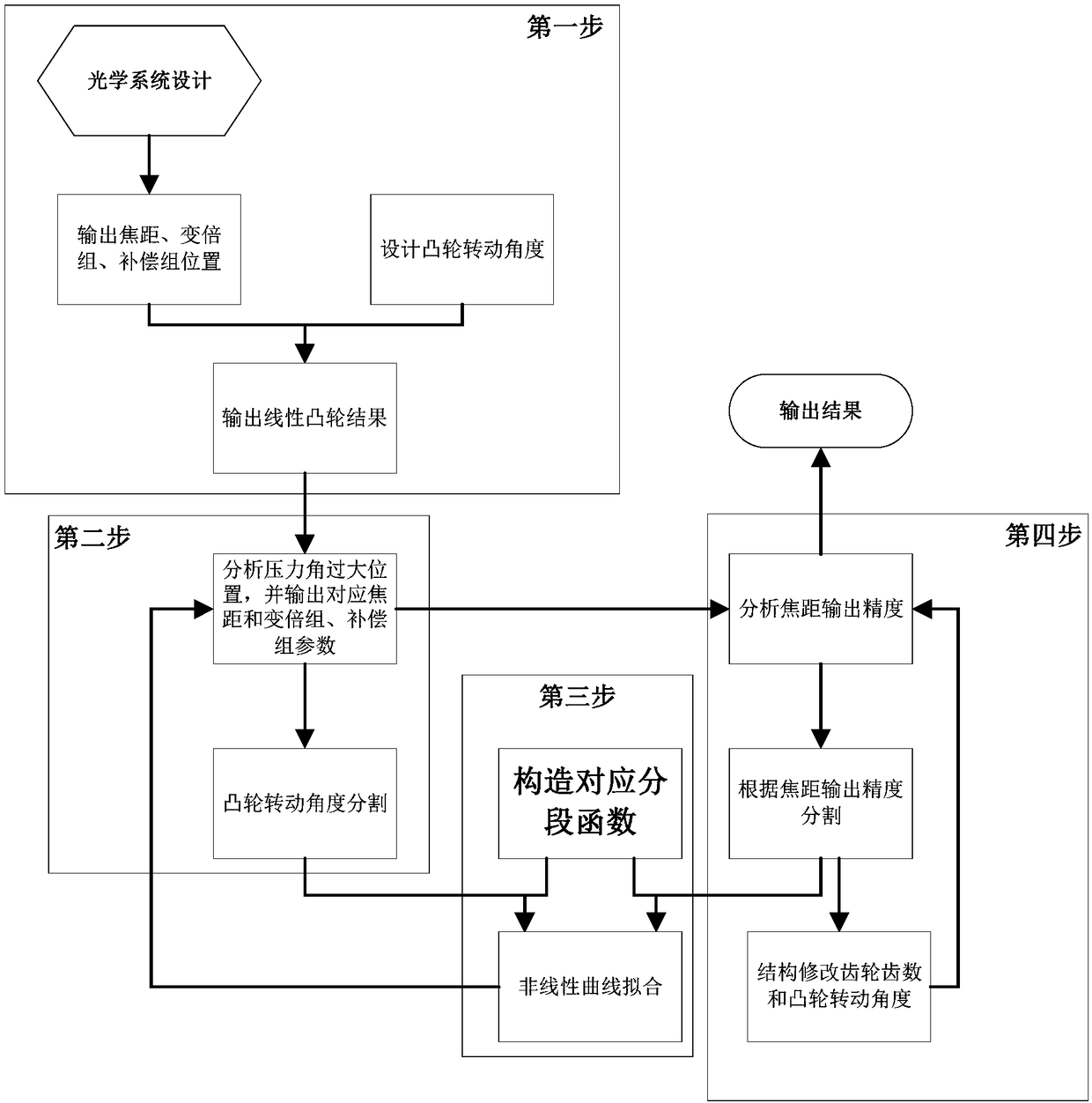

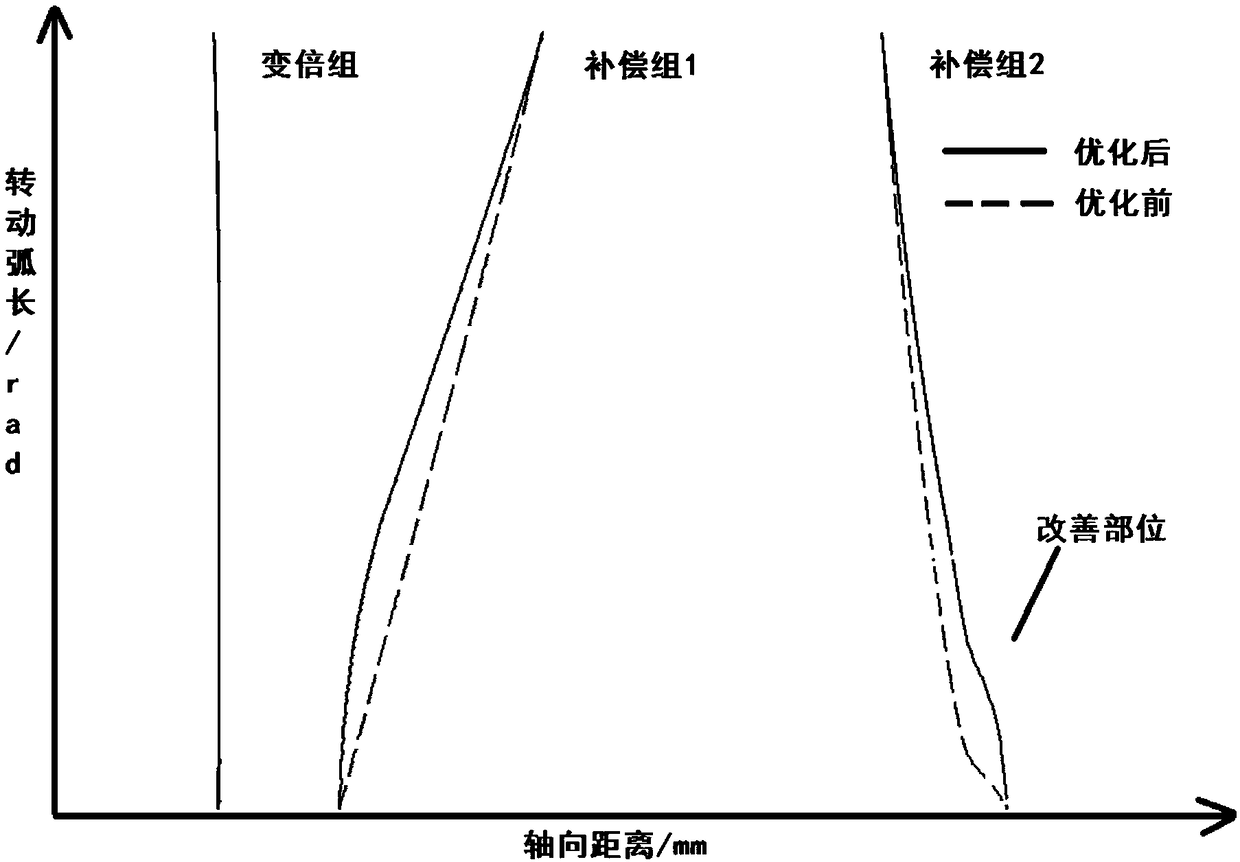

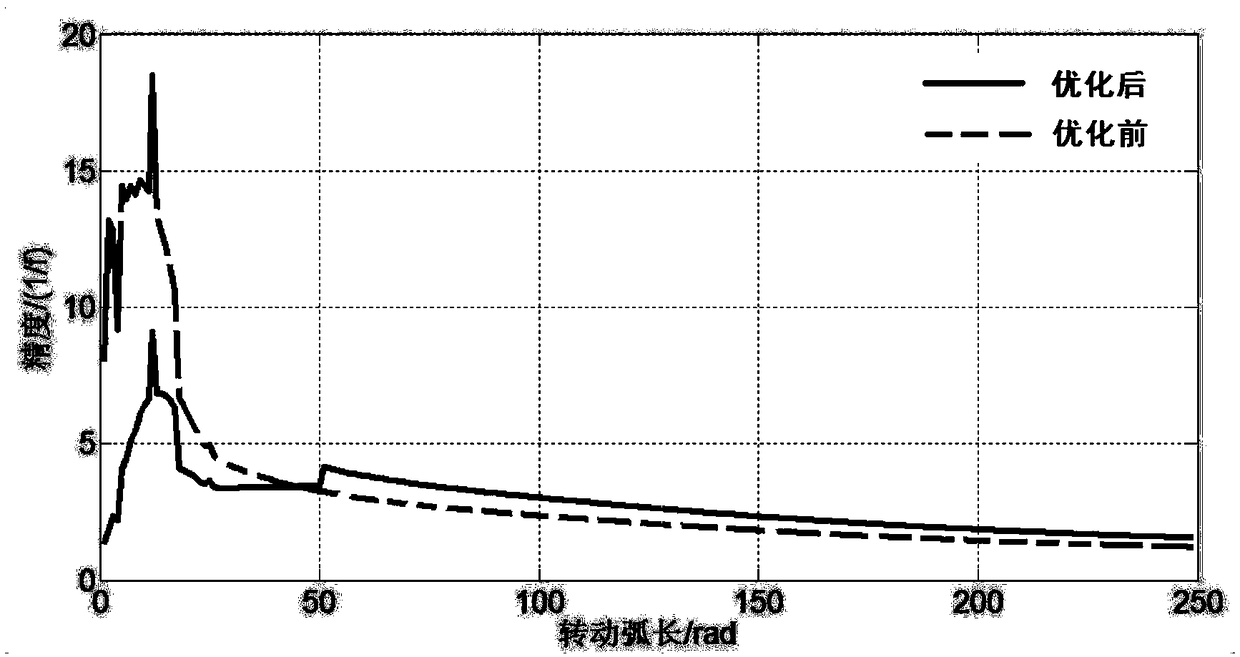

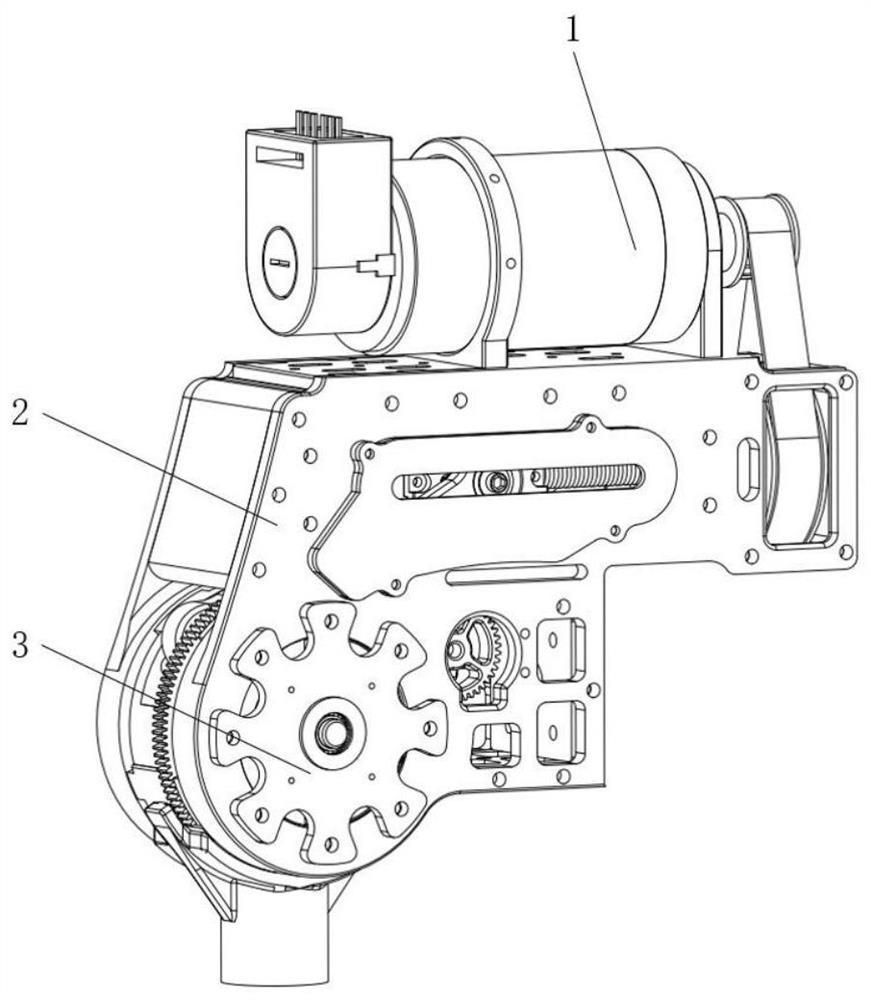

Zoom lens zooming cam optimization method

The present invention belongs the field of photoelectronic imaging devices, and especially relates to a zoom lens zooming cam optimization method. The problems are solved that a zoom lens zooming camis not smooth, low in zooming precision, low in speed and prone to get stuck. The method concretely comprises the steps of: 1, optical system design; 2, analysis of a cam pressure angle; 3, construction of a piecewise function for the whole cam according to a trend displayed by the cam pressure angle; and 4, analysis of focal length output precision.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

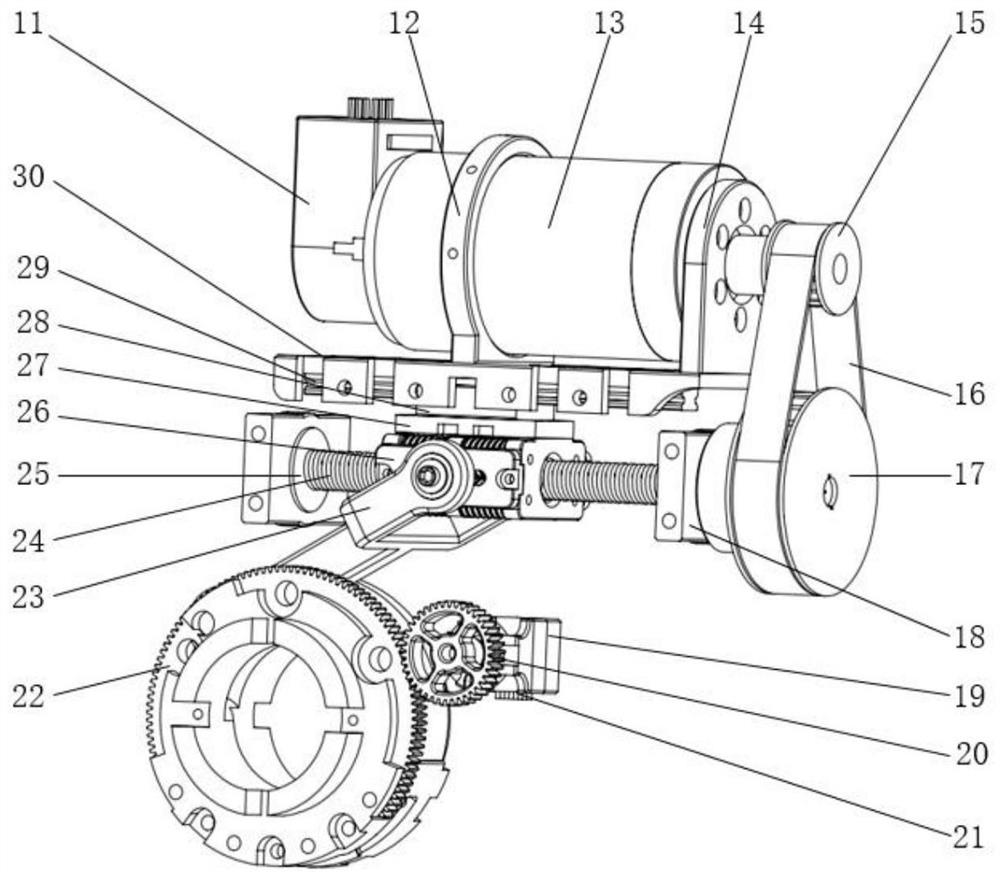

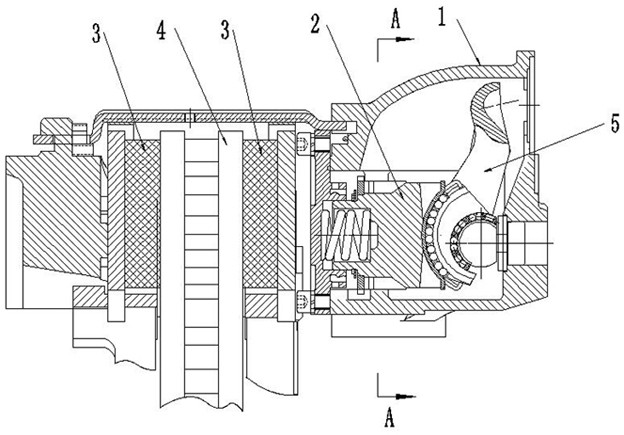

Variable-damping flexibly-driven exoskeleton joint

ActiveCN114211523AImprove wearing comfortEasy to realize force controlProgramme-controlled manipulatorJointsRolling-element bearingEngineering

The invention discloses a variable-damping flexibly-driven exoskeleton joint. The variable-damping flexibly-driven exoskeleton joint comprises a crank-slider series elastic driver, an exoskeleton joint shell and a magnetorheological damper, two joint rolling bearings are placed in the exoskeleton joint shell and used for supporting a joint center rotating body in the crank sliding block series connection elastic driver, other rod pieces or joints are connected through joint connecting pieces, and elastic elements are connected with the exoskeleton joint shell and the joint center rotating body respectively. A first magneto-rheological damper connecting block in the magneto-rheological damper is connected with an exoskeleton joint shell, a second magneto-rheological damper connecting block in the magneto-rheological damper is connected with a joint center rotating body, and the crank sliding block is connected with the elastic driver in series, and the magneto-rheological damper and the elastic element are connected in parallel. According to the invention, the mechanism can realize flexible driving and can resist external impact, so that the wearing comfort of the exoskeleton is improved.

Owner:XI AN JIAOTONG UNIV

Twin-turbine internal combustion engine

ActiveCN105781621AImprove noiseReduce noiseNon-positive displacement enginesExhaust valveExternal combustion engine

The invention discloses a twin-turbine internal combustion engine. The twin-turbine internal combustion engine is characterized in that a power shaft is in contact with left and right turbine racks for supporting through a sliding bearing, the power shaft is in contact with a housing through a rolling bearing, the power shaft and a ratchet fly wheel are in bonding through a ratchet fly wheel key, a round steel plate and turbine discs are fixedly connected to arc-shaped cylinders of turbines through screws, a cylinder sleeve is arranged in each cylinder, a piston is mounted at one end of an arc-shaped cylinder of the piston, a piston ring is arranged next to the piston, the other end of the arc-shaped cylinder is propped against a cylinder cover, an exhaust valve is arranged on the cylinder cover, oil injection holes are formed in the periphery of the exhaust valve, an inlet valve is arranged on the piston, and water spray holes are formed in the periphery of the inlet valve. The twin-turbine internal combustion engine disclosed by the invention solves the problem of high internal combustion waste heat and severe pollution. The twin-turbine internal combustion engine is small in noise, small in vibration and long in service life. The power shaft is straight, the output force is steady, the weight of the twin-turbine internal combustion engine is half of that of a crankshaft internal combustion engine, and the effective work can reach 90%.

Owner:陈名碧

Asynchronous door knife of elevator door machine

ActiveCN102862904BStable output forceMeet the needs of large stroke door openingBuilding liftsEngineeringElectrical and Electronics engineering

The invention discloses an asynchronous door knife of an elevator door machine. The clamping action for a landing door linked door ball is realized through the cooperation of a door knife assembly and a cam device, so that the linkage of a carriage door and the landing door can be realized. The door knife assembly is installed on a movable part, and the cam device is installed on a stationary part. In the closing process for opening and closing the linked door, the door knife assembly clamps the landing door linked door ball, and the asynchronous door knife is self-locked, so that the thrusting force for the landing door linked door ball can be continuously and stably supplied; when the door is about to close, the cam device acts on the door knife assembly, a gap needed by the asynchronous door knife and the landing door linked door ball is formed, and the asynchronous door knife is released; and when the door is completely closed, the door knife assembly is subjected to the cam device and cannot produce the action for clamping the landing door linked door ball, and the gap between the door knife assembly and the landing door linked door ball is reliable. The landing door linked door ball is always clamped by the asynchronous door knife in the door closing process, so that a stable drive force is supplied for a landing door.

Owner:SHANGHAI MITSUBISHI ELEVATOR CO LTD

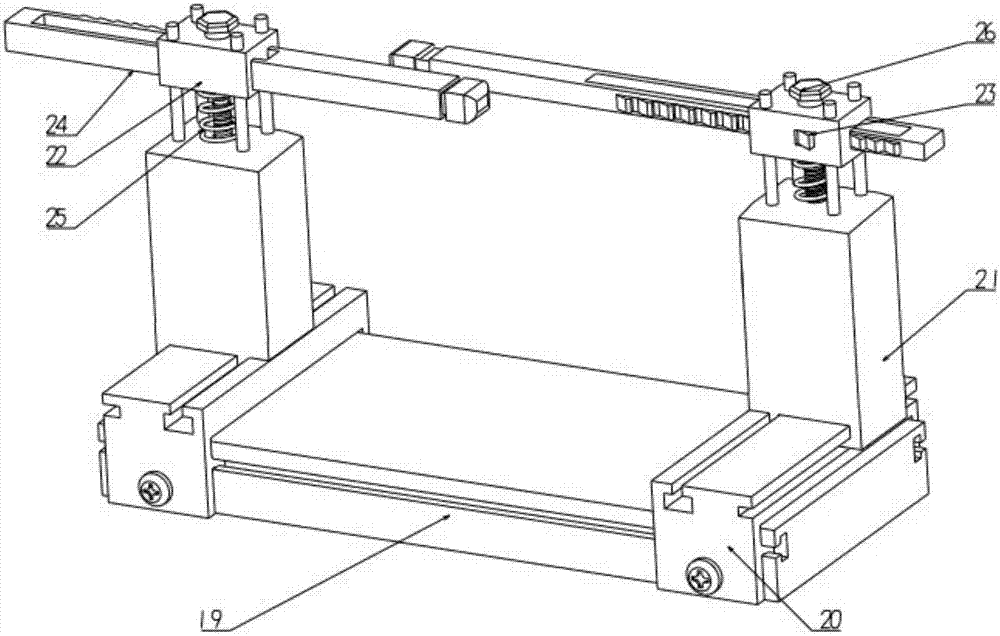

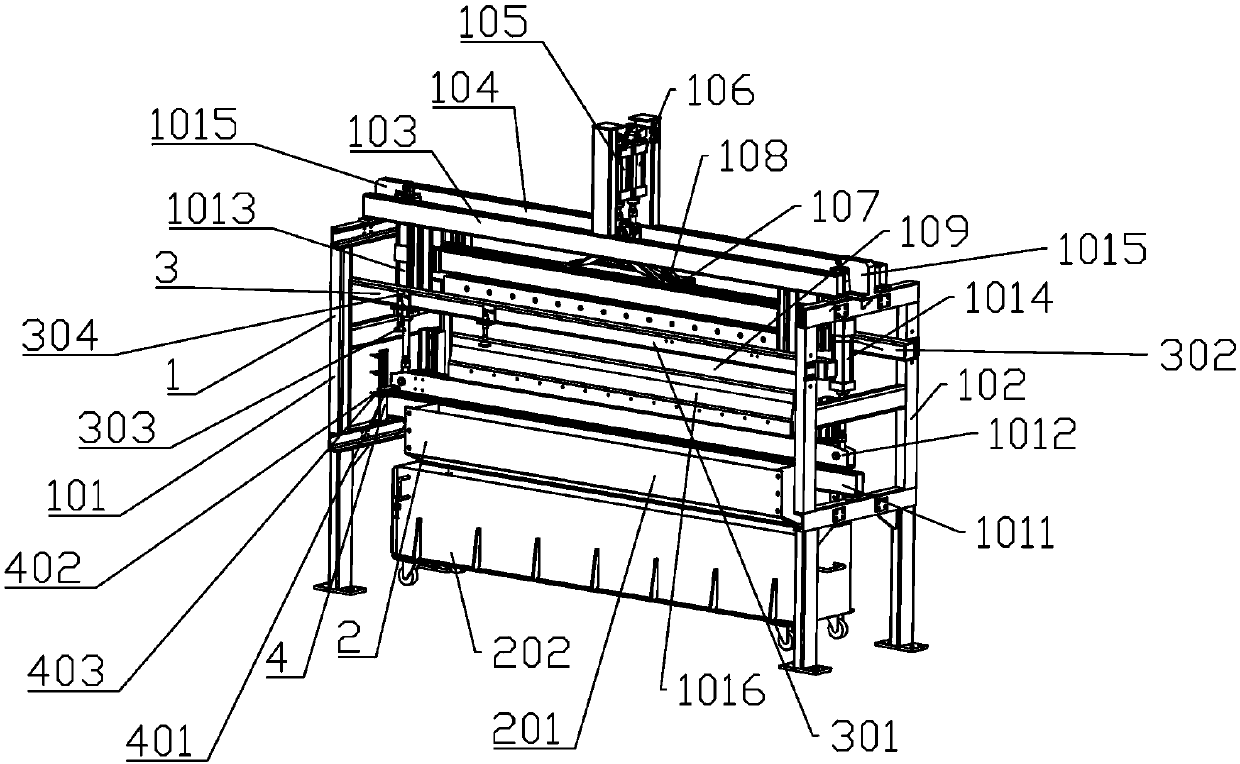

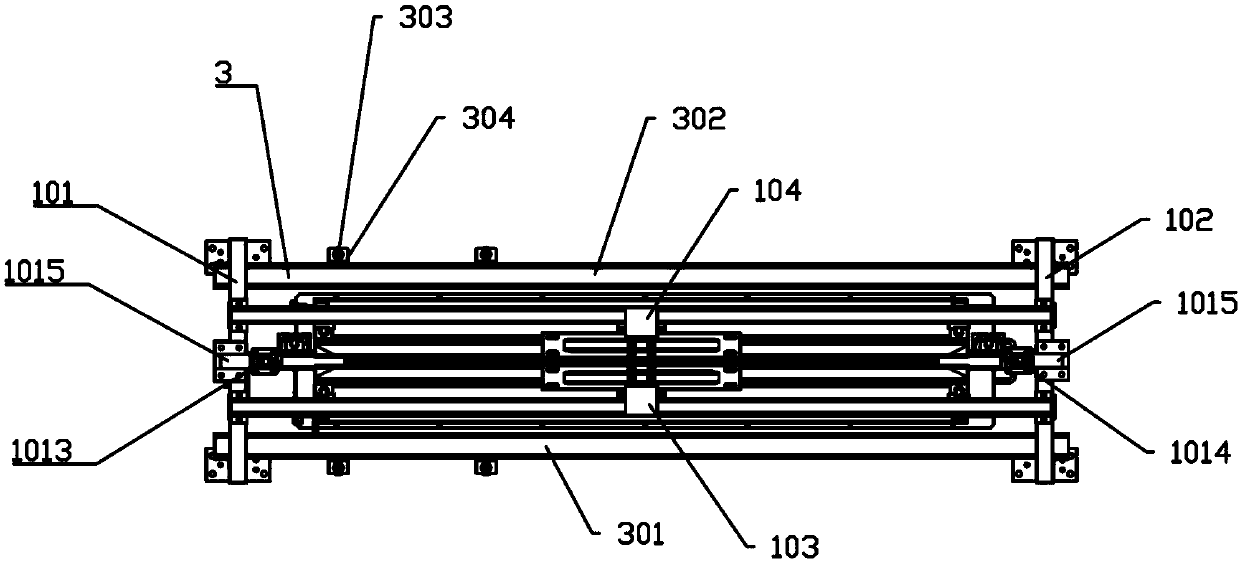

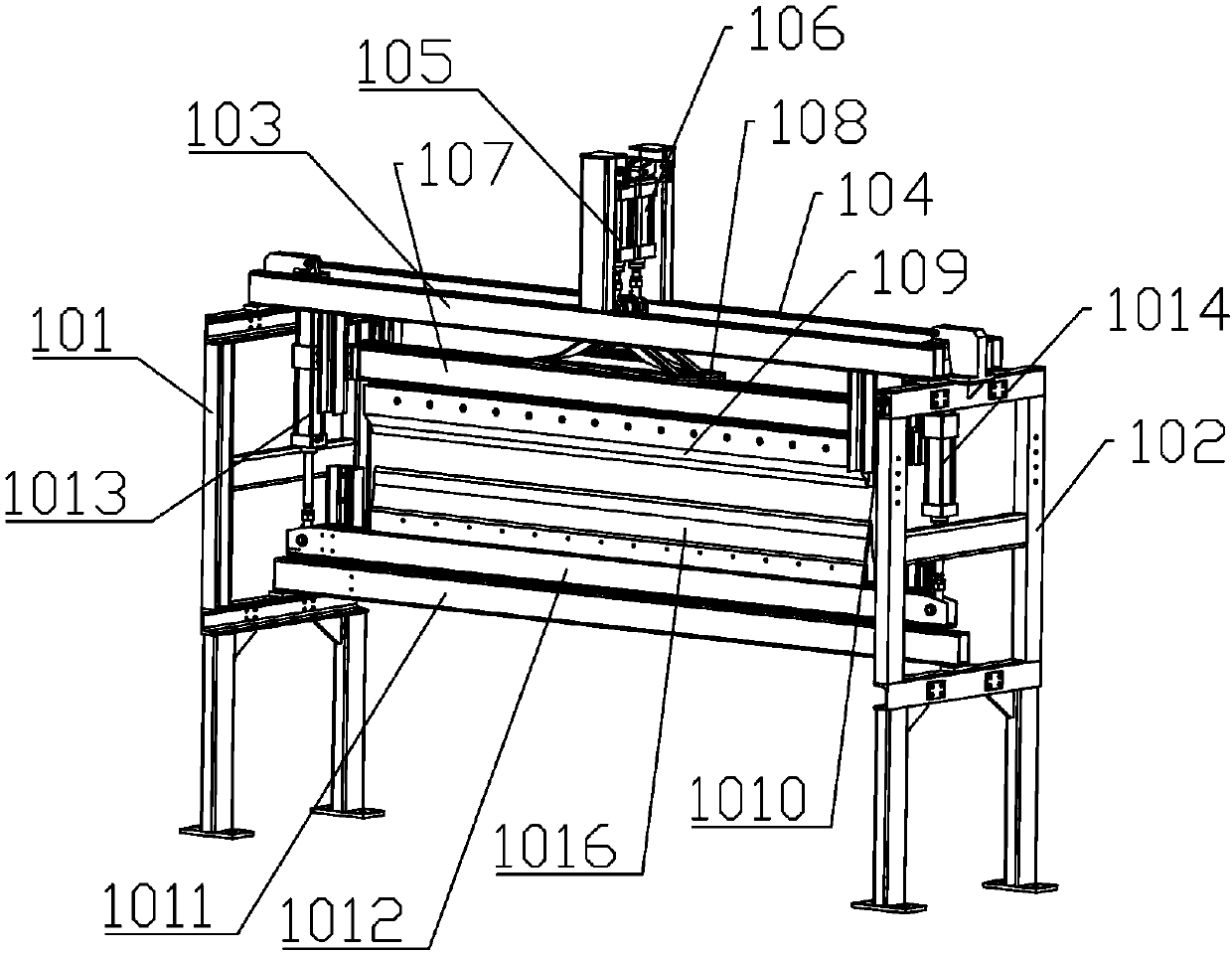

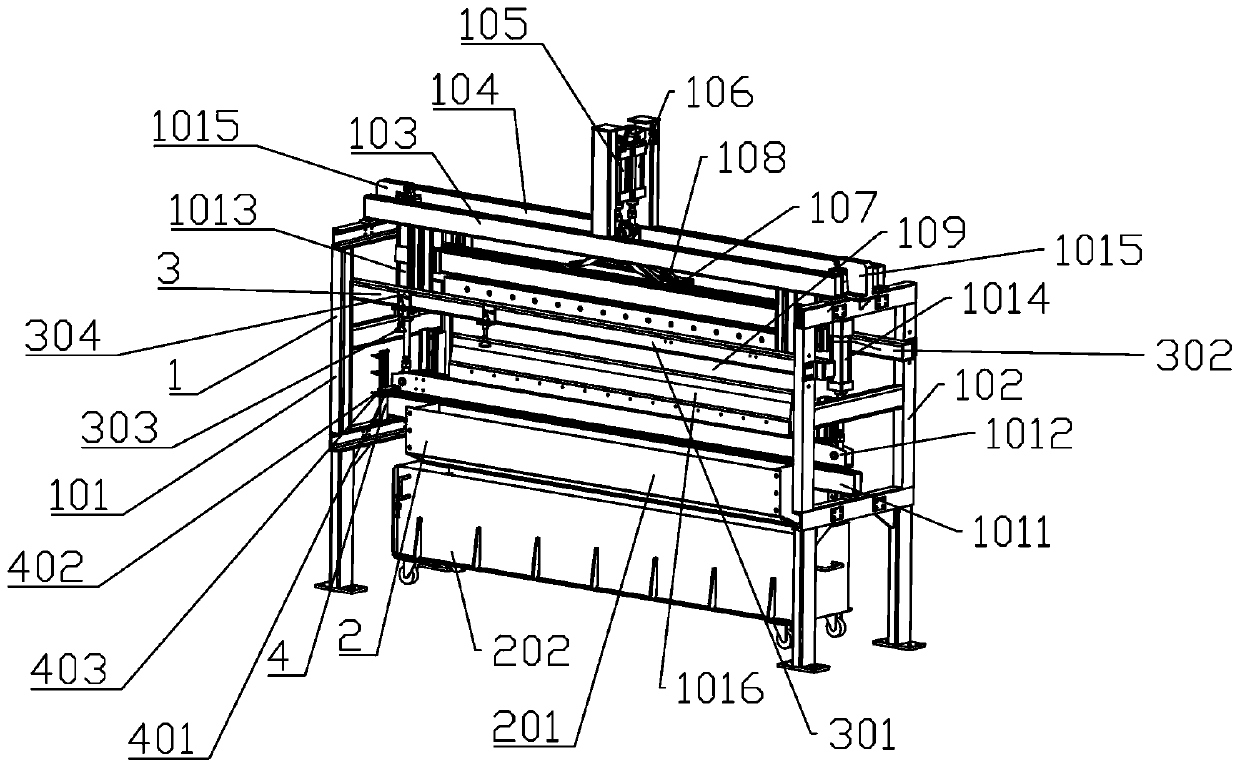

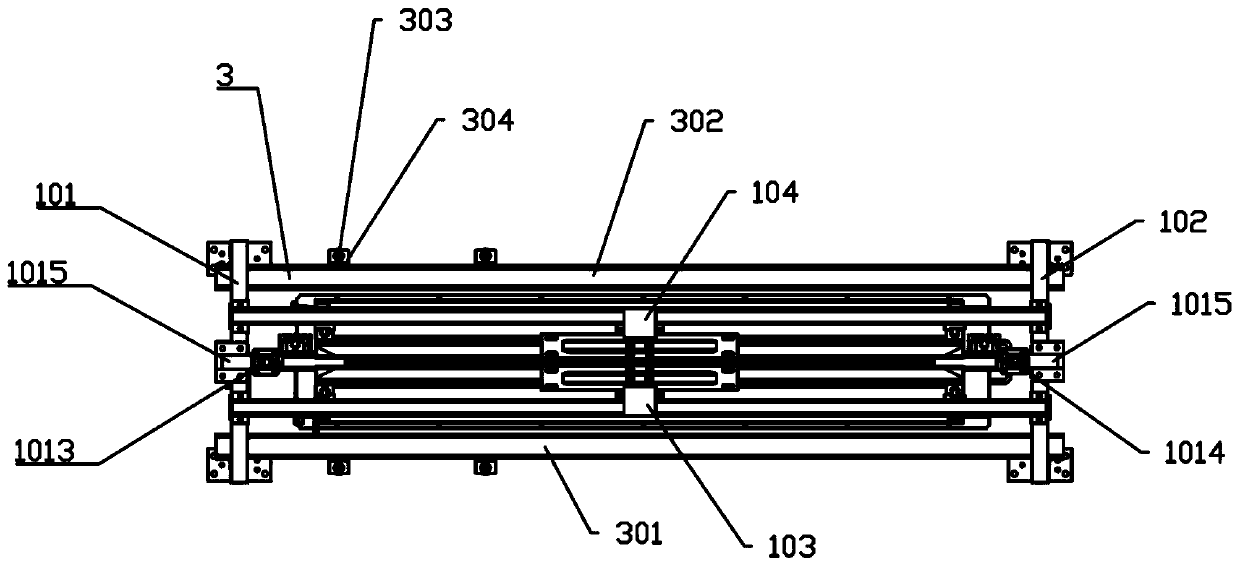

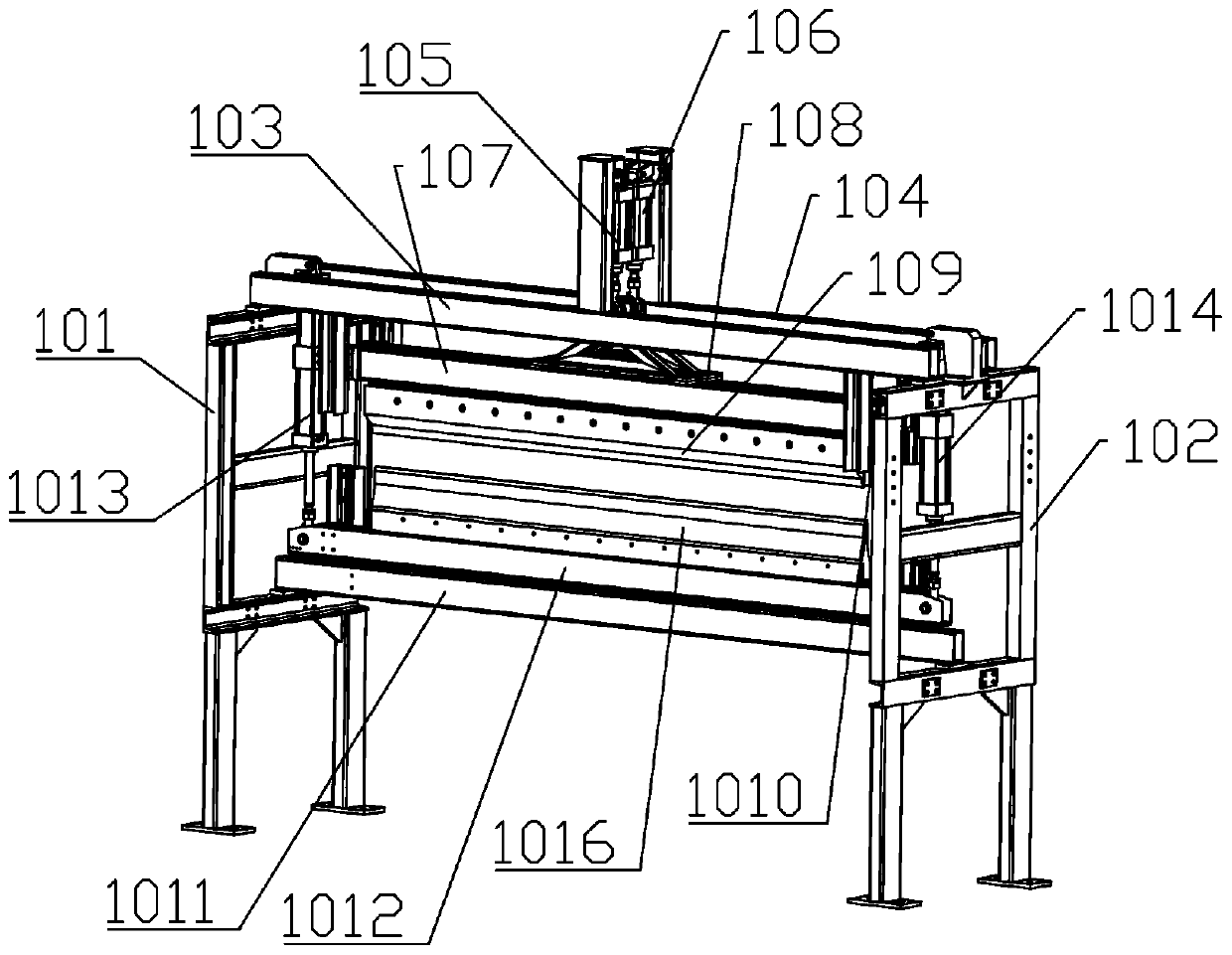

Fully-automatic glass breaking-off device

ActiveCN107739150ARealize the process requirements of productionFulfill process requirementsGlass severing apparatusOperabilityEngineering

The invention relates to a fully-automatic glass breaking-off device. The fully-automatic glass breaking-off device comprises a breaking-off mechanism, a scrap guiding mechanism, a glass supporting mechanism and a limiting induction mechanism. According to the fully-automatic glass breaking-off device, a whole sheet of glass can be subjected to edge and sheet breaking-off operation, and thus, theprocess requirements on production of glass of small sheets of certain specifications are met; when one edge of the whole sheet of glass is subjected to vertical downward edge breaking-off action, a single edge breaking-off cylinder is used for providing a downward acting force, output power is stable, a cylinder output speed can be rapidly and conveniently regulated, and the edge breaking-off action is reliable; a proximity switch is adopted as a control element for the edge and sheet breaking-off operation, thus, positions, relative to the whole sheet of glass, of cutter blades can be accurately controlled, the glass is subjected to the edge and sheet breaking-off operation after the cutter blades move to proper positions, and thus, the operability is good while the locating accuracy ishigh; glass scraps generated during the edge and sheet breaking-off operation of the glass are subjected to timely collecting treatment through the scrap guiding mechanism, meanwhile, a glass trolleyis ingenious in structural design, and thus, the operability of pouring of the glass scraps by working personnel is improved.

Owner:CNBM TRIUMPH ROBOTICS SHANGHAI CO LTD

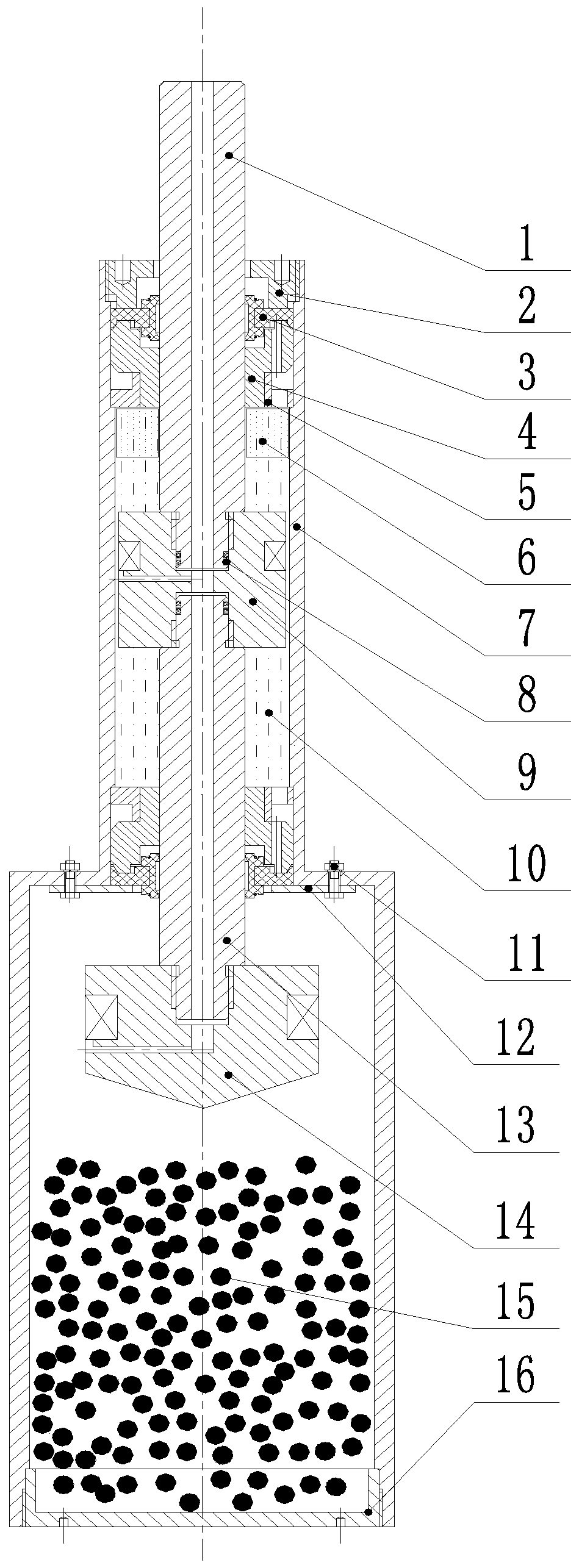

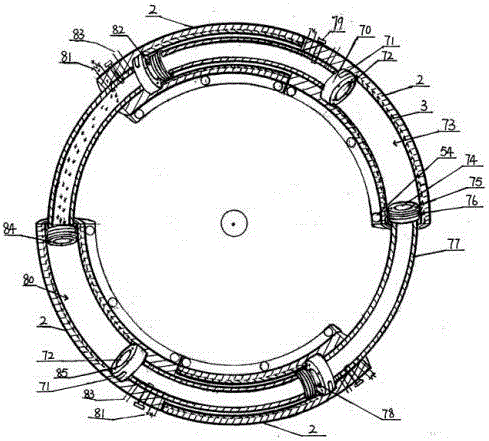

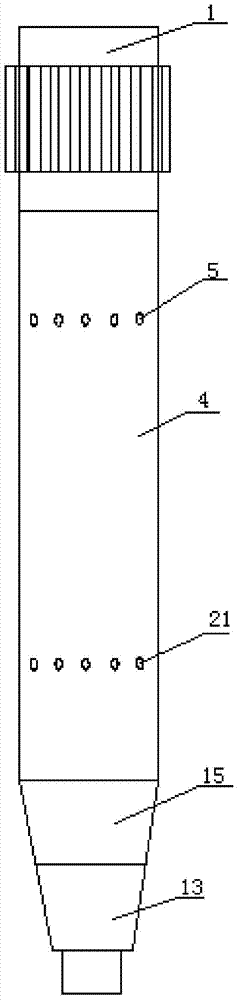

A pneumatic vibration device

InactiveCN105032751BSimple structureStrong vibrationMechanical vibrations separationContact freeReciprocating motion

The invention relates to a vibration device, in particular to a novel pneumatic vibration device. Collision contact-free reciprocating motion of a piston, an end cover and a transition connector in a cylinder is achieved by filling the novel pneumatic vibration device with compressed air, and a vibration effect is generated. The novel pneumatic vibration device has the advantages of being simple in structure, large in vibration force, high in frequency, low in noise, small in size, long in service life, stable in operating and stable in output force.

Owner:王洪波

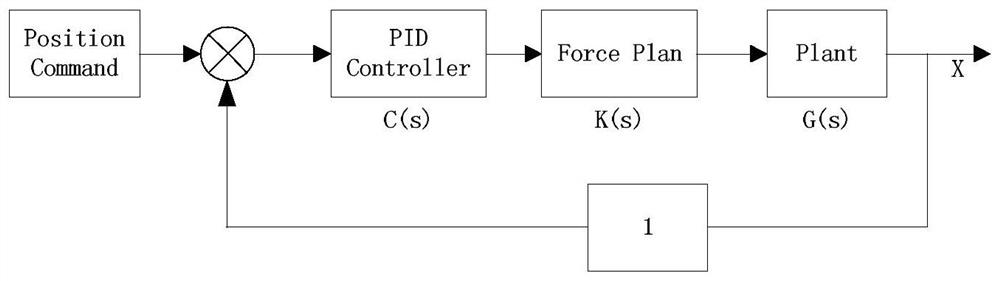

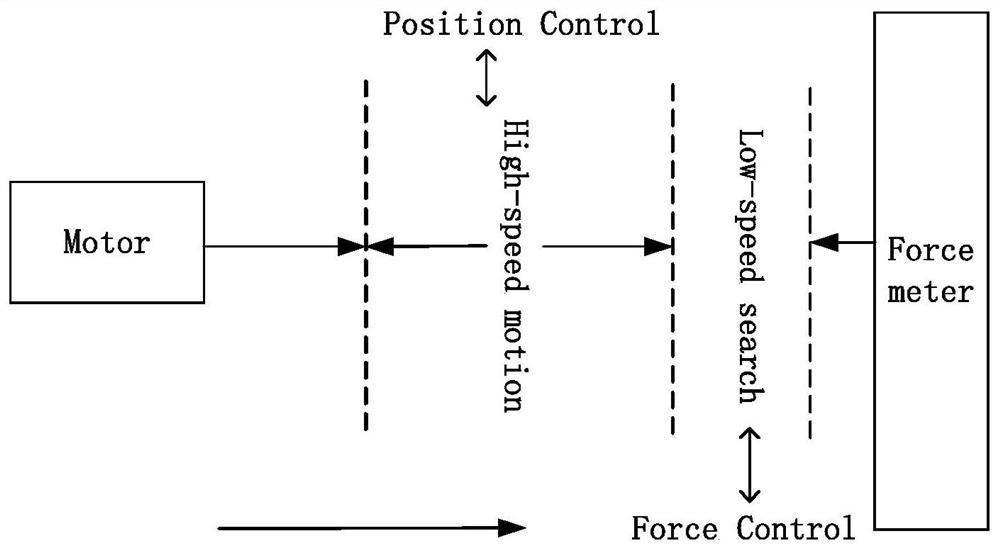

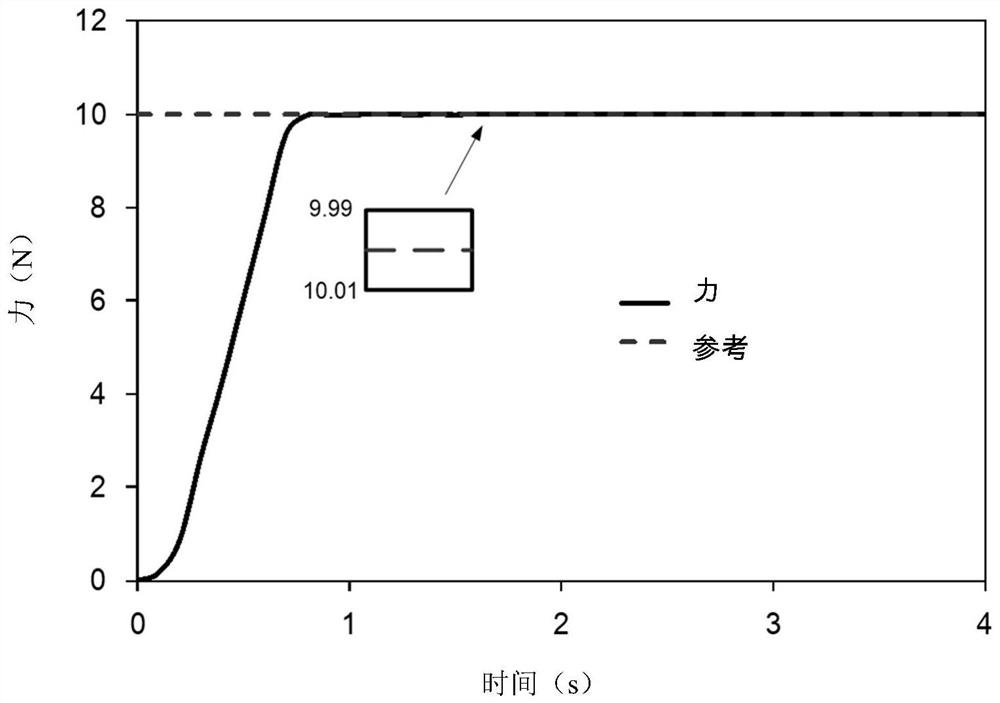

Force control method and force control system of linear switched reluctance motor

PendingCN113824381AStable output forceTo achieve the effect of force controlGeneral control strategiesElectric machineryControl mode

The invention relates to the technical field of linear switched reluctance motor control, in particular to a force control method and a force control system of a linear switched reluctance motor. The method comprises the steps that in the process that the linear switched reluctance motor approaches a machining target, obtaining the actual position, speed and current of the linear switched reluctance motor; judging whether the linear switched reluctance motor reaches or exceeds a preset contact condition according to the actual position and the speed condition; when the judgment result is yes, indicating that the linear switched reluctance motor is in contact with the target; and after the linear switched reluctance motor is in contact with the target, limiting the output force of the linear switched reluctance motor according to the output strategy, and then controlling the output of the force. According to the force control method and system of the linear switched reluctance motor, after the linear switched reluctance motor reaches the contact condition, the linear switched reluctance motor enters the force control mode, and the output force is limited by limiting the output current of the motor, so that the output force of the motor and the target is stable, and the force control effect is achieved.

Owner:CREATING CHANGE THROUGH TECH

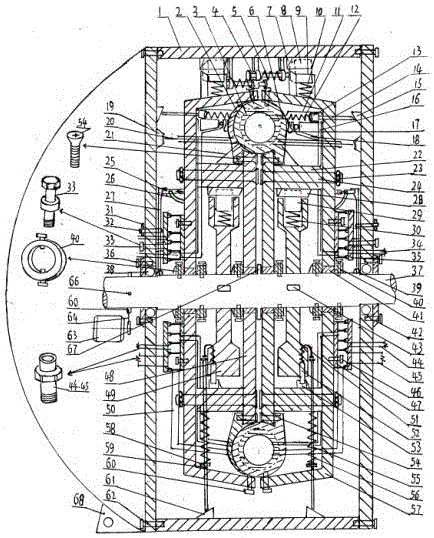

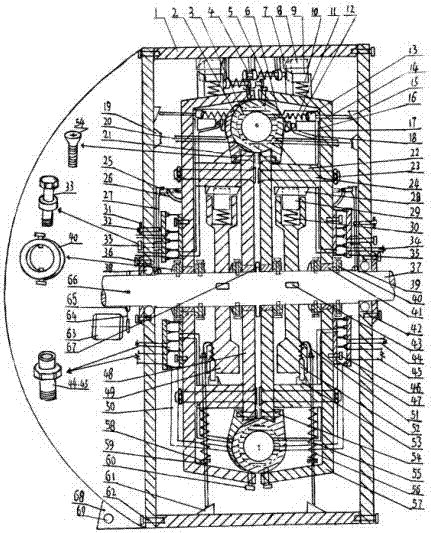

Heavy-duty truck with hand brake

ActiveCN103569153BIncrease braking powerImproving Quick Mitigation Performance FeaturesRail brake actuationDrive shaftEngineering

The invention discloses a hand brake for railway heavy-duty trucks, which comprises a base, a driving shaft, a chain wheel, a hand wheel, a handle, and a box shell. The driving shaft includes a driving shaft, a ratchet, The pinion, the pinion shaft and the key wheel, the hand wheel are connected to the driving shaft, the driving shaft is connected to the ratchet, the key wheel and the pinion in turn, and the handle is composed of a handle, a horizontal shifting frame directly connected to the handle and an action with the horizontal shifting frame With the matching vertical dial frame, when the handle is rotated counterclockwise, the key wheel is dialed to disengage from the pinion. The advantage of the present invention is that the drive shaft of the handbrake is driven by the composition of the rotary handle and the handwheel to complete three functions, including the braking function, the quick relief function and the gradual relief function, which effectively improves the handbraking ability, and at the same time Improved the quick release performance characteristic of the handbrake brake.

Owner:CRRC QINGDAO SIFANG ROLLING STOCK RES INST

Integrated device for vibration reduction and buffering

ActiveCN110701239BChange the size of the currentAchieving semi-active controlSpringsNon-rotating vibration suppressionFrictional coefficientEngineering

The invention discloses a novel vibration reduction and buffering integrated device, which comprises a variable-section cylinder, a first piston arranged in the cylinder, a first piston rod connected with the first piston, and a first piston connected with the first piston. The second piston rod, the second piston arranged at the end of the second piston rod, and the upper end cover and the lower end cover respectively arranged at the end of the cylinder; the cylinder includes a damping section and a buffer section, the first piston and the inner wall of the cylinder There is a gap between them; the second piston is arranged in the buffer section and the second piston can move along the axial direction of the cylinder, and the buffer section is filled with ferromagnetic particle balls. The device of this technical solution utilizes the performance of the magnetorheological damper , can adapt to a variety of external working conditions, and has good vibration damping performance; when buffering, the performance of the particle damper is used, the output force value is stable, and the magnetic field can be changed by adjusting the coil current, and the friction coefficient between the second piston and the particles can be adjusted. It can adapt to various buffer working conditions; and the invention has compact structure and simple installation form.

Owner:CHONGQING UNIV

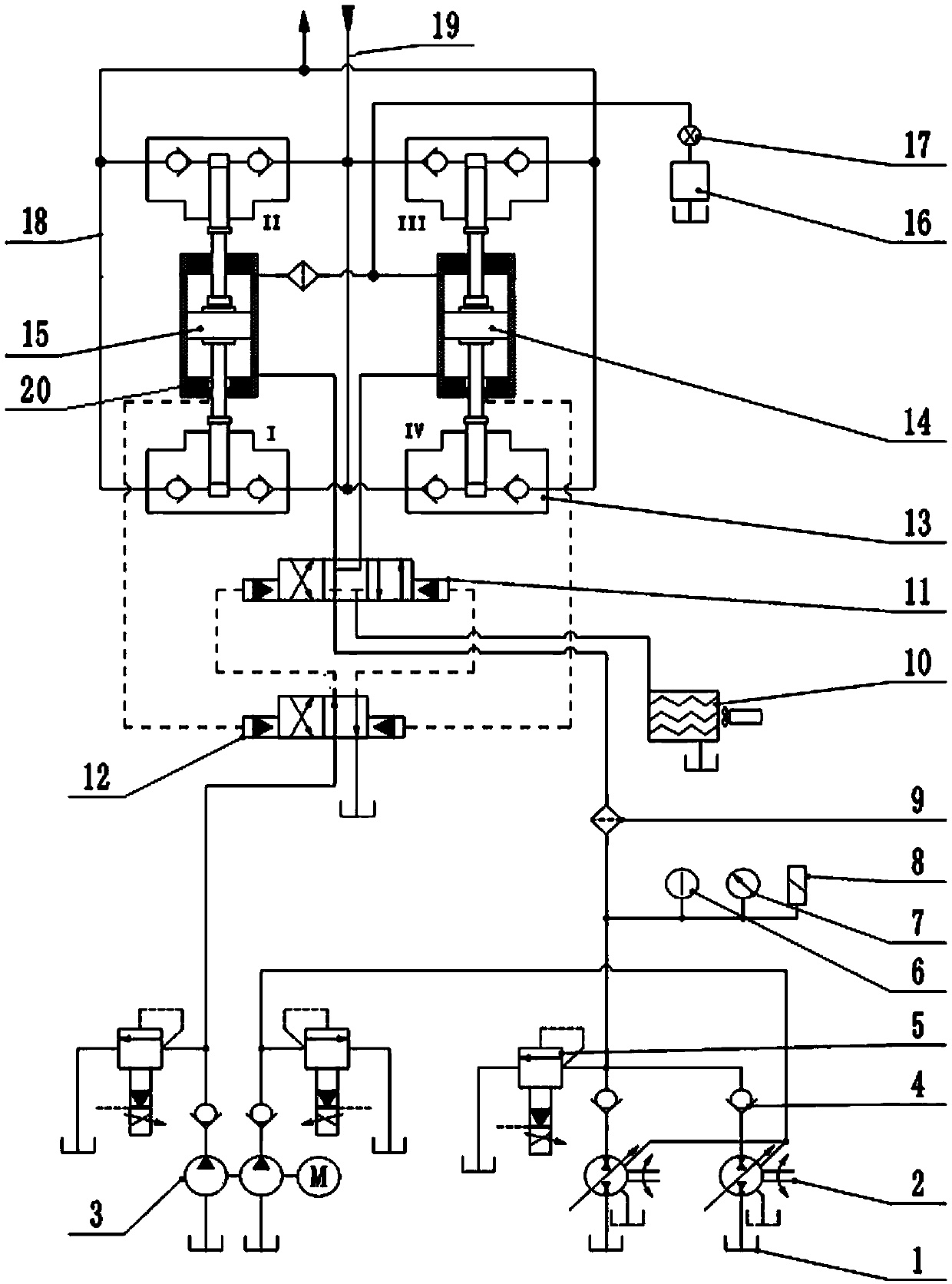

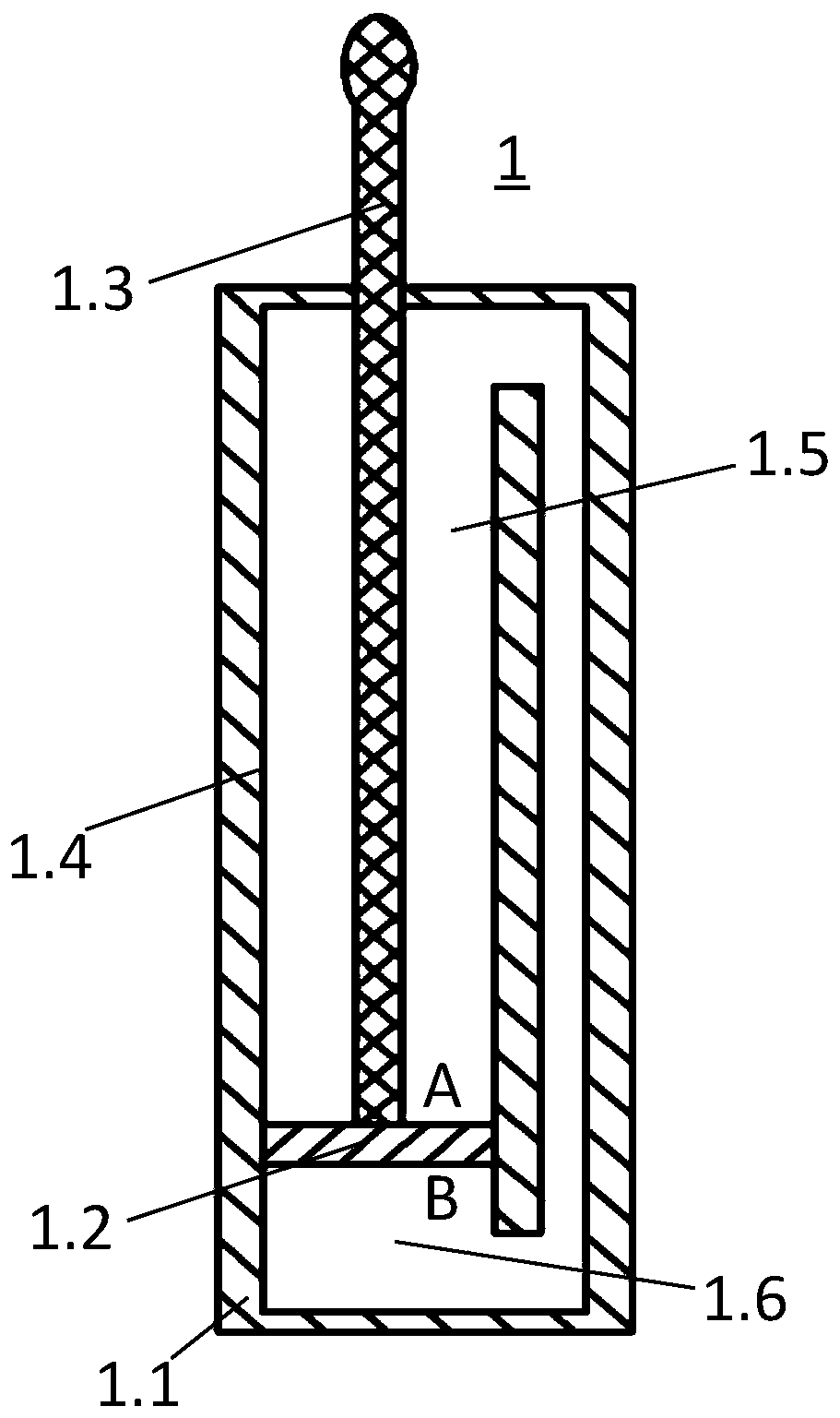

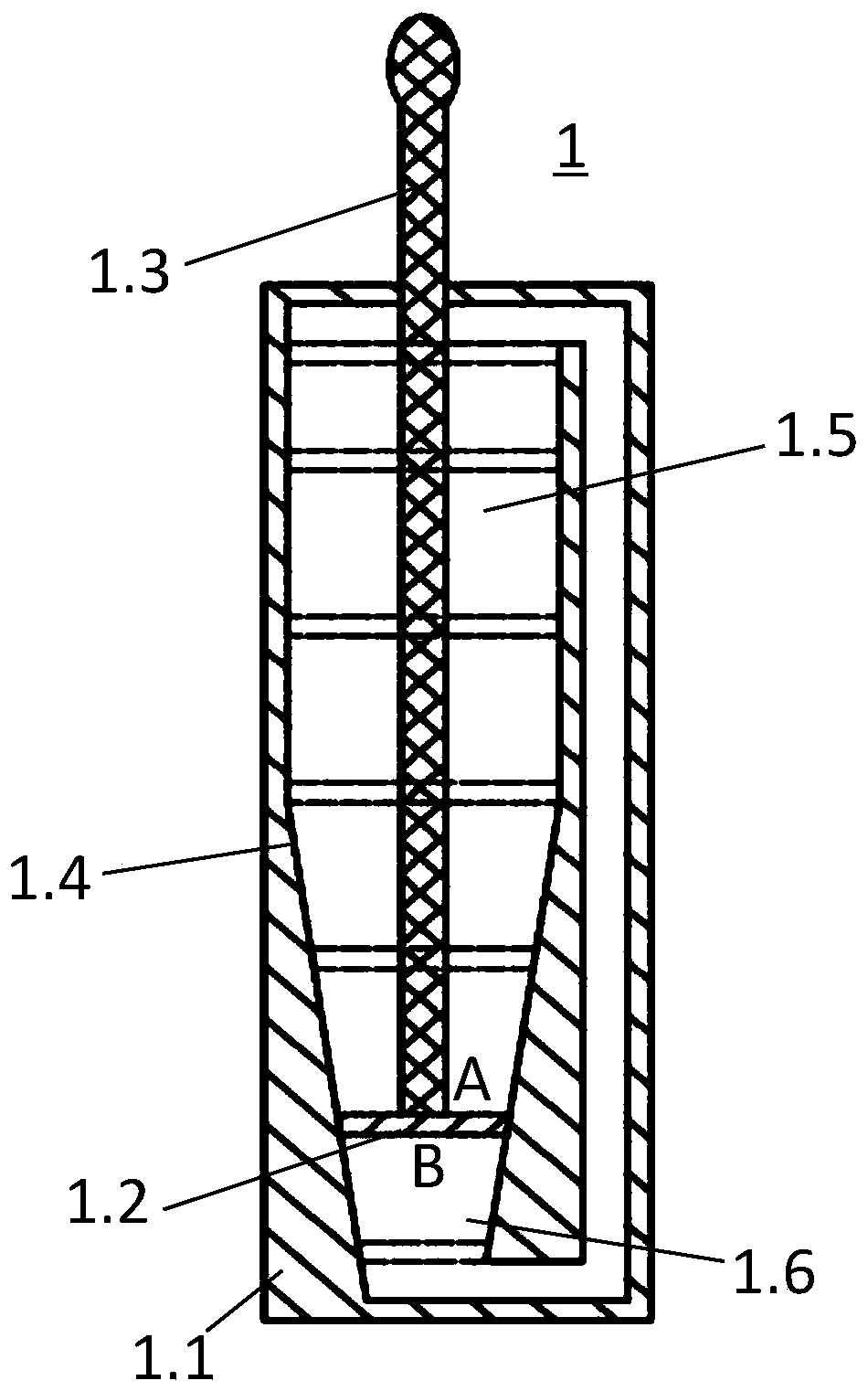

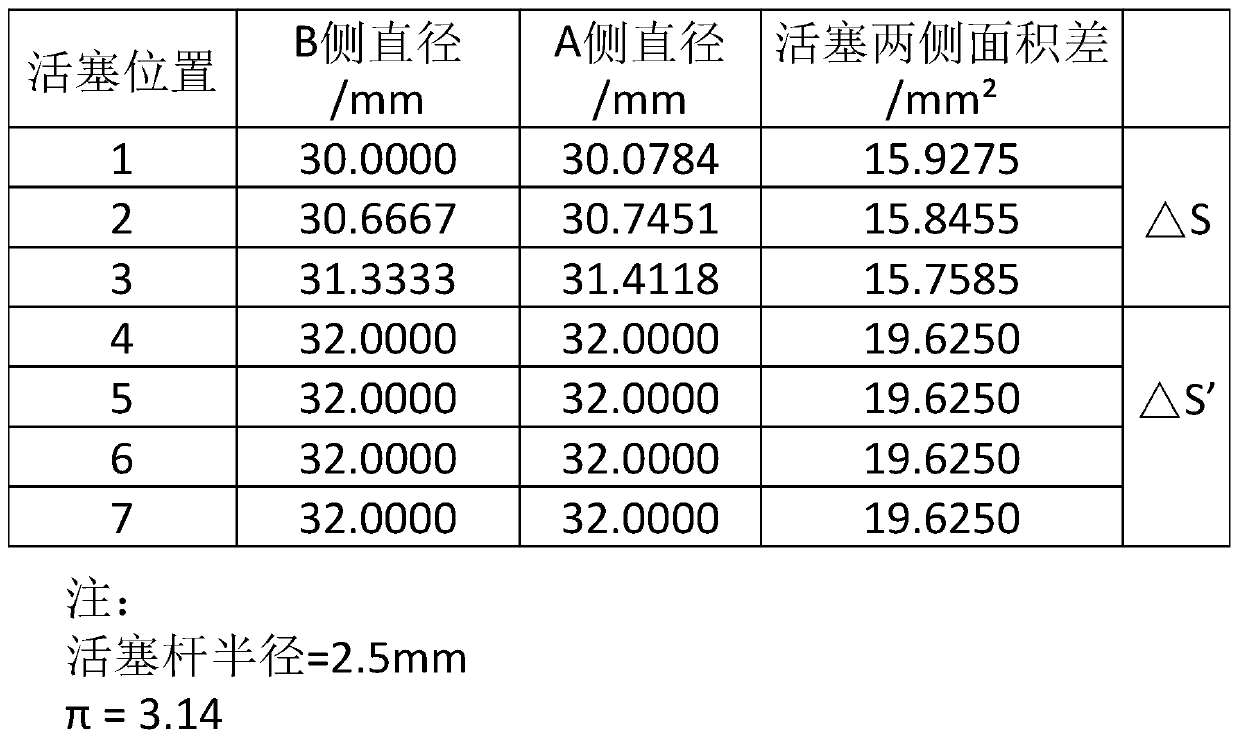

Movable arm energy-saving system adopting variable-diameter balanced hydraulic cylinder

InactiveCN105421510AStable output forceFully absorbedMechanical machines/dredgersEngineeringHydraulic cylinder

The invention discloses a movable arm energy-saving system adopting a variable-diameter balanced hydraulic cylinder. The movable arm energy-saving system comprises the variable-diameter balanced hydraulic cylinder, a first original movable arm hydraulic cylinder and a second original movable arm hydraulic cylinder, wherein a rodless cavity of the first original movable arm hydraulic cylinder is communicated with a rodless cavity of the second original movable arm hydraulic cylinder; a rod cavity of the first original movable arm hydraulic cylinder is communicated with a rod cavity of the second original movable arm hydraulic cylinder; the variable-diameter balanced hydraulic cylinder is connected with a pressure gauge; the variable-diameter balanced hydraulic cylinder comprises a shell, an elastic diaphragm is arranged in the shell, a push rod with an inclined surface is arranged below the elastic diaphragm, and the push rod is connected with a piston; the piston is connected with a piston rod; an energy accumulation cavity is arranged above the elastic diaphragm, and a first adjustment cavity is arranged between the elastic diaphragm and the piston; a second adjustment cavity is arranged below the piston; and the first adjustment cavity is communicated with the second adjustment cavity. The movable arm energy-saving system disclosed by the invention is capable of providing a stable additional force for a movable arm, thus realizing efficient reutilization for the recovered energy.

Owner:FUJIAN UNIV OF TECH

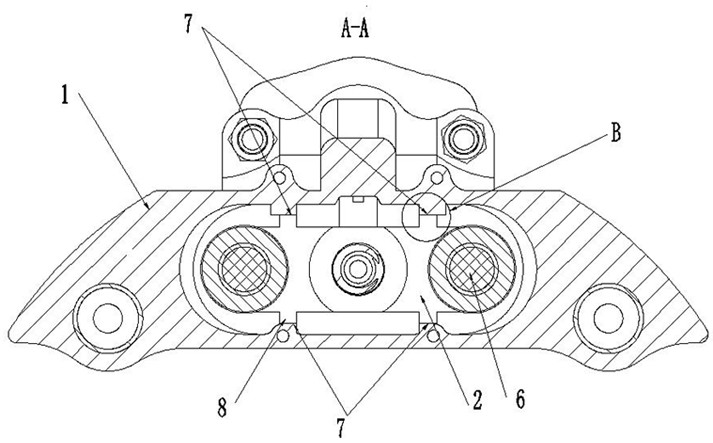

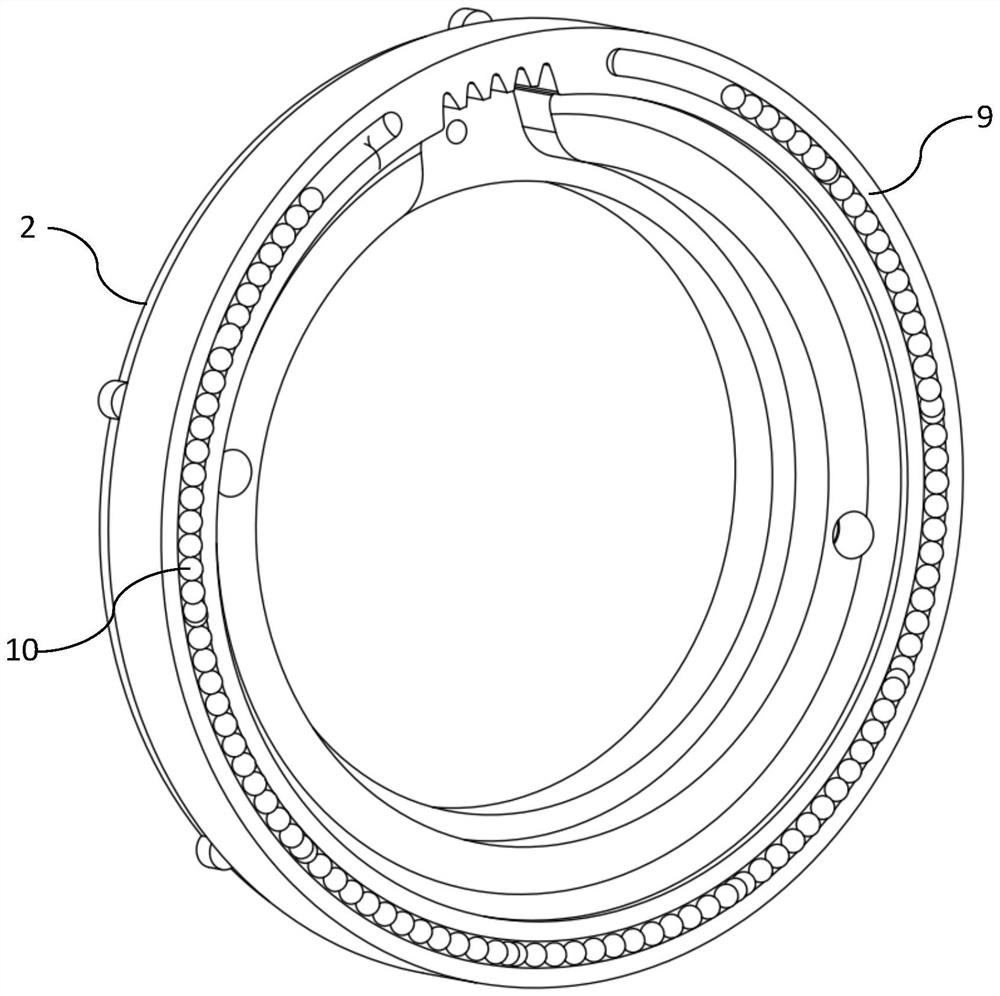

Disc brake of anti-deflection double-push-rod thrust mechanism

PendingCN112145584AStable output forceImprove reliabilityAxially engaging brakesBrake actuating mechanismsDisc brakeEngineering

The invention provides a disc brake of an anti-deflection double-push-rod thrust mechanism. The disc brake of the anti-deflection double-push-rod thrust mechanism comprises a caliper body and the double-push-rod thrust mechanism, the double-push-rod thrust mechanism comprises a thrust seat, and first guide bosses are arranged on the upper portion and the lower portion of an inner cavity of the caliper body correspondingly; and second guide bosses are also arranged at the position corresponding to the installation of the thrust seat, the thrust seat is supported on the first guide bosses of theinner cavity of the caliper body through the second guide bosses to achieve guide, the thrust seat can only slide in the cavity of the caliper body in the thrust direction, and the thrust seat cannotdeflect and rotate, and deflection force borne by the thrust mechanism is transmitted to the inner cavity of the caliper body through the thrust seat and borne by the caliper body, so that output force of the thrust mechanism is stable, and reliability of parts is improved.

Owner:湖北华阳汽车制动器股份有限公司

Proportional solenoid for controlling hydraulic valve spool position

ActiveCN102788186BEliminate hydraulic disturbancesOrderly control flow rateOperating means/releasing devices for valvesSolenoid valveHydraulic circuit

Owner:宁波市鄞州通力液压电器厂

An automotive electric vacuum pump test system

ActiveCN106939884BAccurate data collectionEasy to assemble and disassemblePump testingPump controlLoad sensingWheel cylinder

Owner:JILIN UNIV

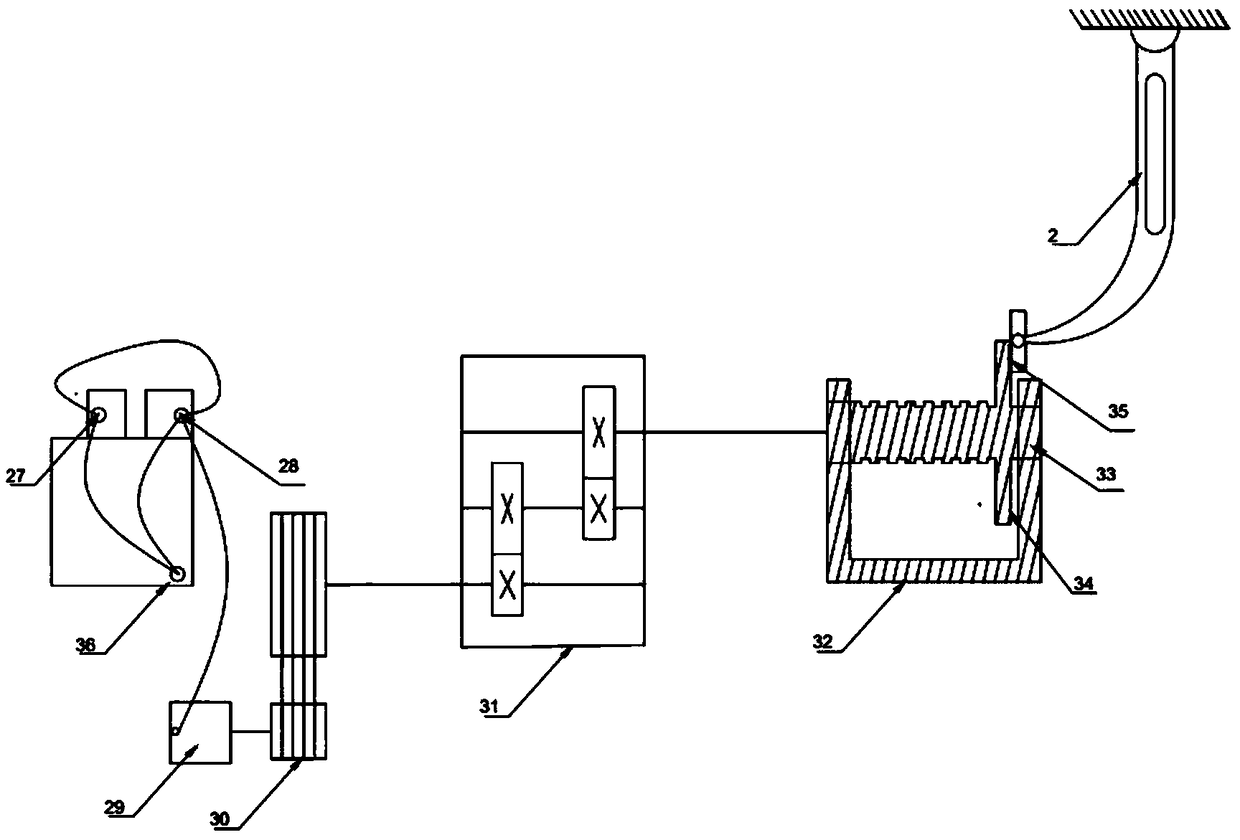

A hydraulically driven double-acting mud pump

ActiveCN106870317BRunning speed is stableStable output forcePositive displacement pump componentsPiston pumpsFuel tankEngineering

The invention discloses a hydraulically driven double-acting mud pump, which includes a power motor, a pressure oil pump, a three-position four-way hydraulic reversing valve, a hydraulic power end and a mud pump head. The power motor is traditionally connected to the pressure oil pump, and the pressure oil pump passes through a pipeline. It is connected to the P port of the three-position four-way hydraulic directional valve, the T port of the three-position four-way hydraulic directional valve is connected to the oil tank through the pipeline, and the A port and B port of the three-position four-way hydraulic directional valve are connected to the hydraulic power end , The hydraulic power end is traditionally connected to the mud pump head, the lower end of the mud pump head is connected to the low-pressure manifold, and the two sides of the mud pump head are respectively connected to the high-pressure manifold. The hydraulically driven double-acting mud pump of the present invention can make the instantaneous flow and pressure of the liquid discharged from the mud pump more stable and reduce fluctuations.

Owner:HUANGSHAN HUIRUN MACHINERY CO LTD

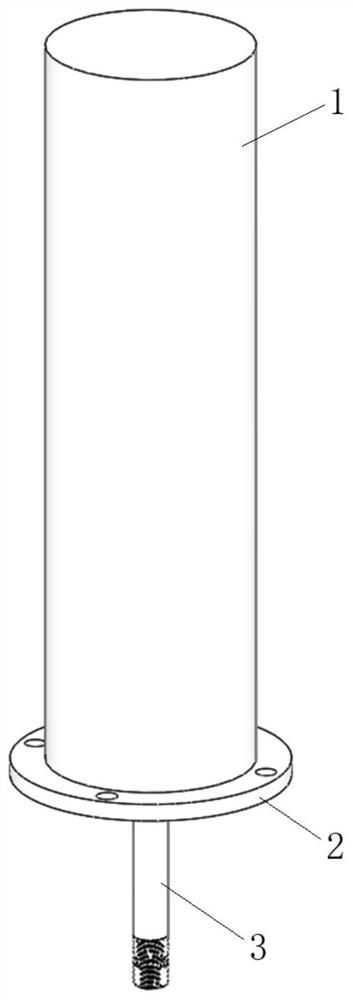

Pressure cylinder and lifting table with the pressure cylinder

ActiveCN108119430BSmooth liftRealize lifting actionServometer circuitsLifting framesEngineeringCylinder block

Owner:区赞勋

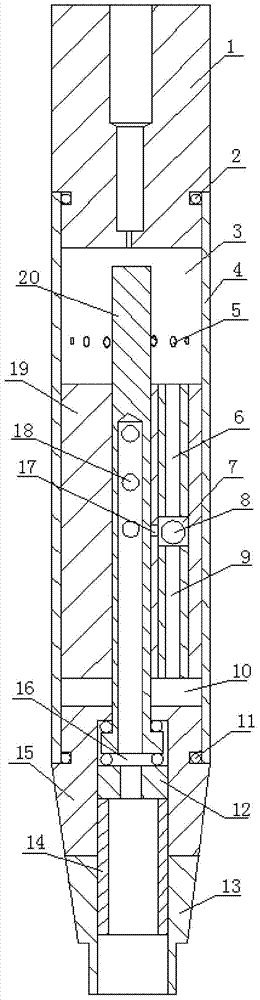

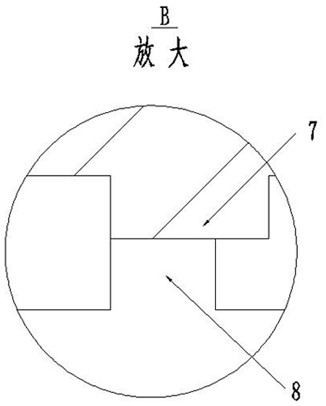

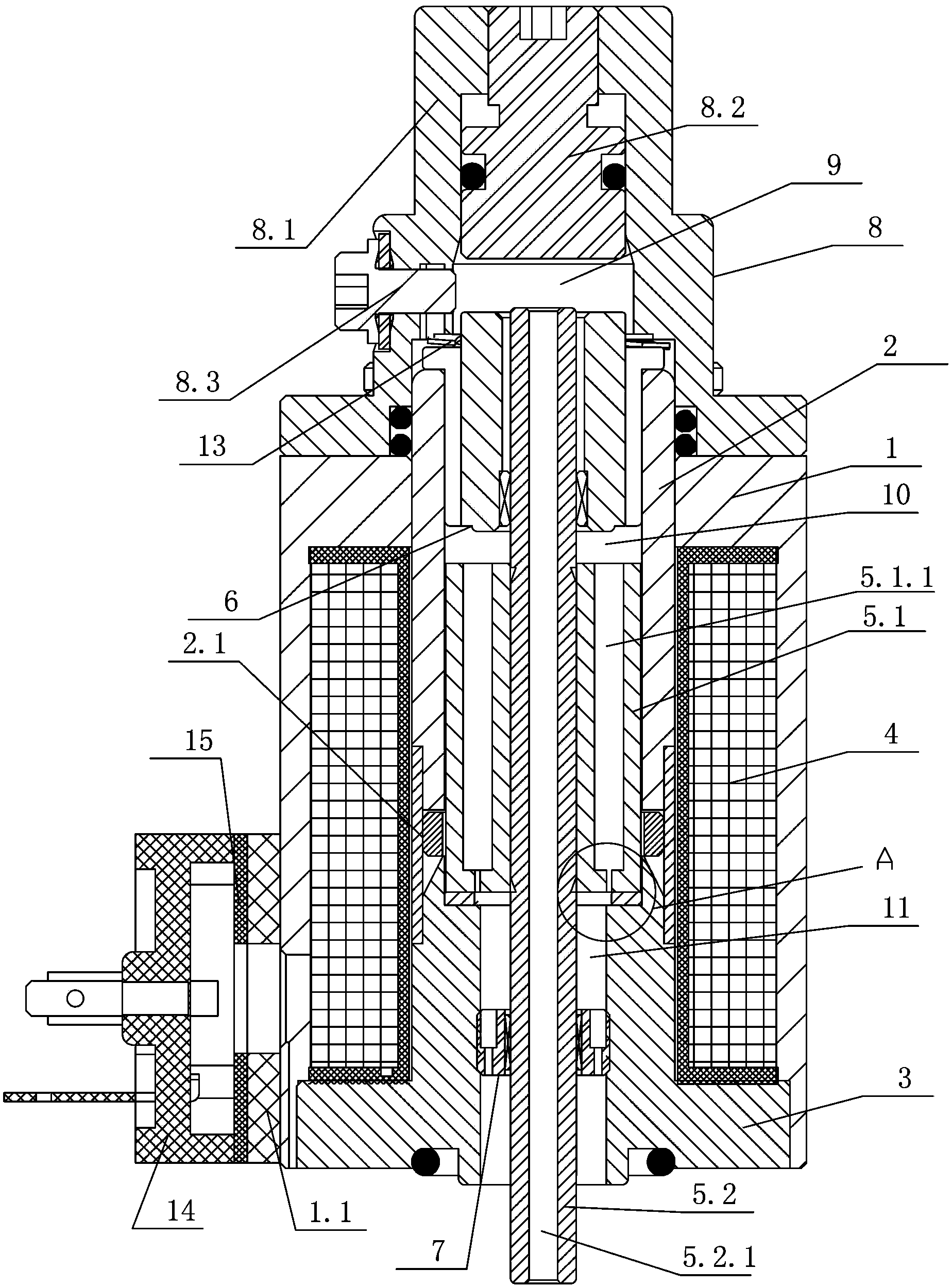

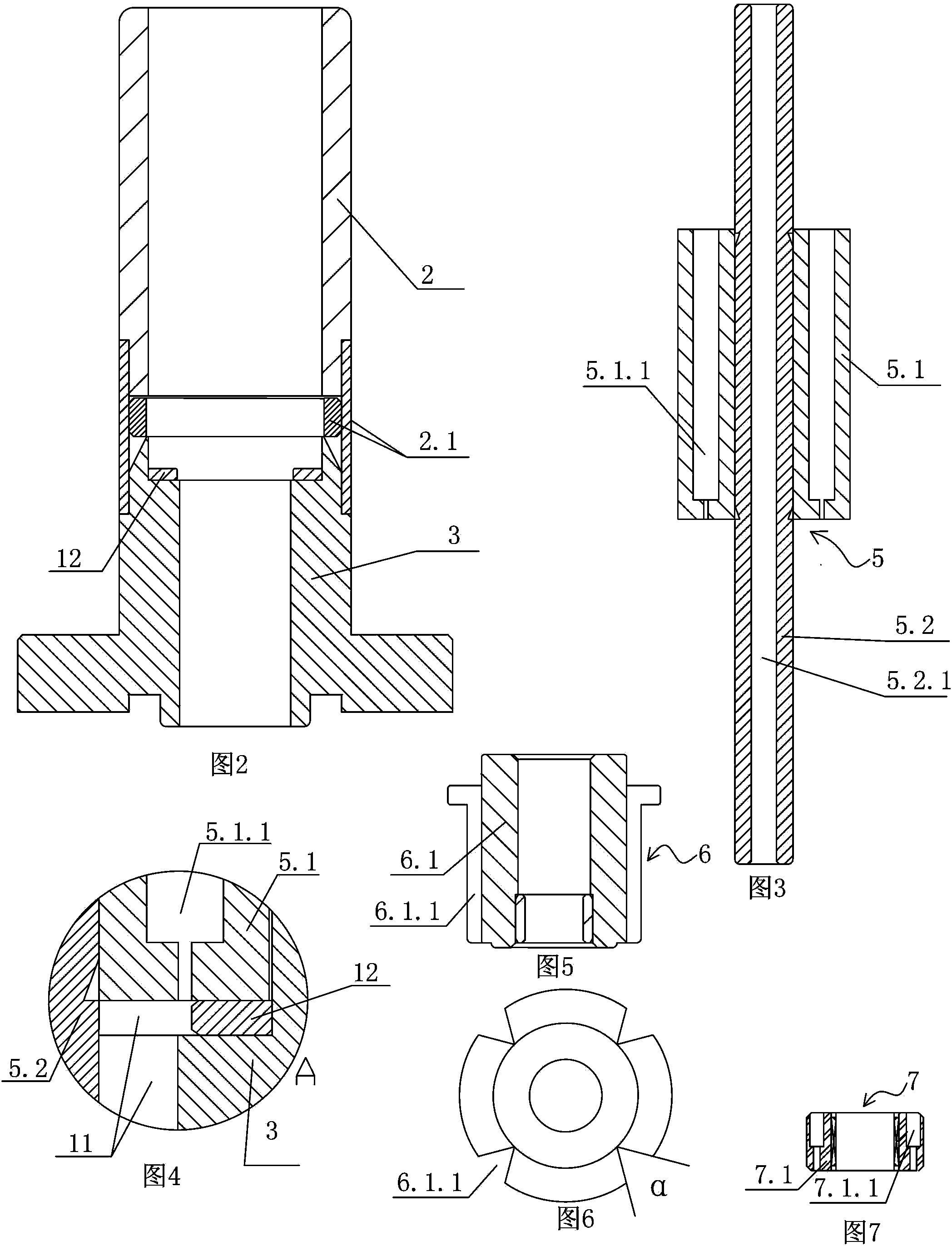

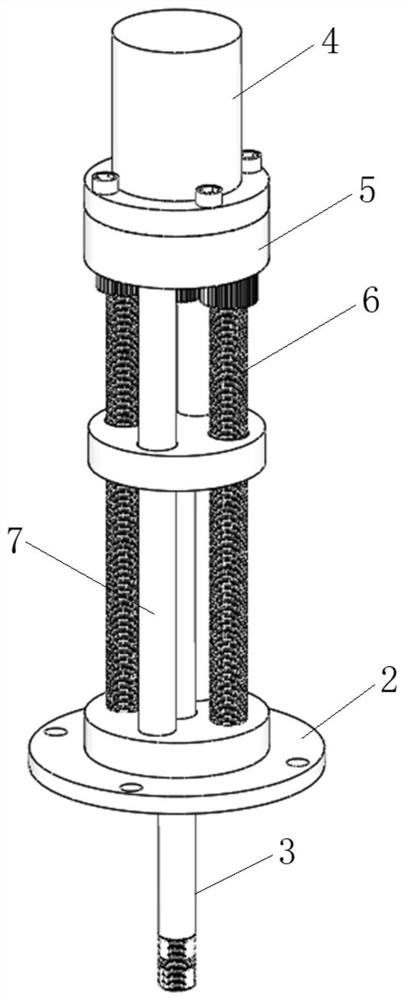

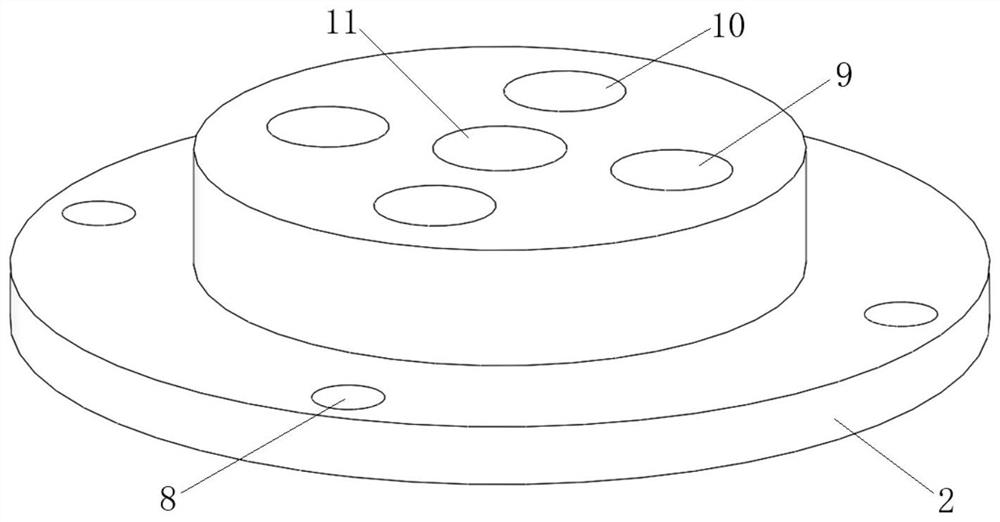

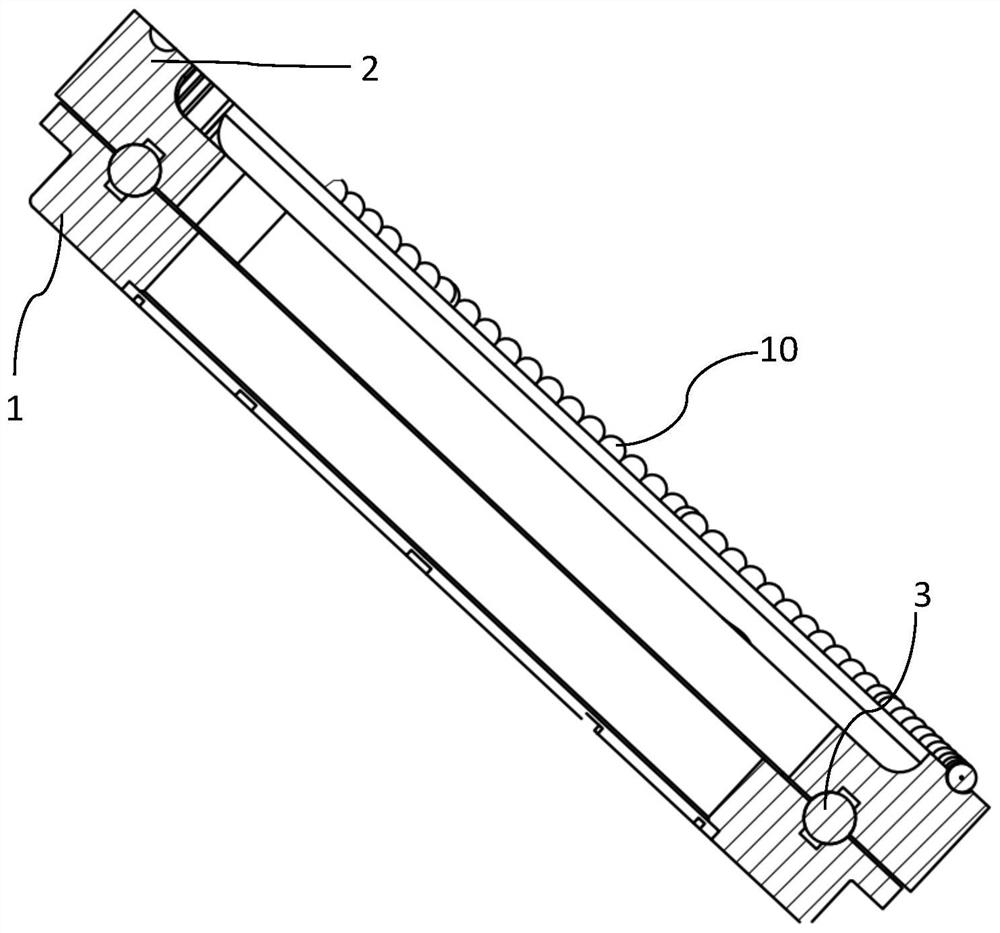

Telescopic motor capable of accurately controlling extension length of main shaft and application thereof

PendingCN113572303APrecise control of axial movementPrecisely control the extension lengthMechanical energy handlingGear wheelElectric machinery

The invention relates to a telescopic motor capable of accurately controlling the extension length of a main shaft and application of the telescopic motor. The telescopic motor comprises a machine shell, a motor body, a top disc, a bottom disc, a lead screw, the main shaft and a piston, wherein the motor body, the top disc, the bottom disc, the lead screw, the main shaft and the piston are arranged in the shell. The motor is fixedly connected with the top disc, and lead screw penetrates through the piston and is in threaded connection with the piston; the upper end and the lower end of the lead screw are connected with the top disc and the bottom disc respectively, an output shaft of the motor is in transmission connection with the upper end of the lead screw, the top end of the main shaft is fixedly connected with the bottom face of the piston, and the bottom end of the main shaft penetrates through the bottom disc and then extends out of the machine shell. According to the invention, a servo motor is matched with a gear reducing mechanism and the lead screw, so that the axial action of the motor spindle can be accurately controlled, namely the extension length of the spindle can be accurately controlled. According to the servo motor, the gear reducing mechanism is matched with the lead screw, so that the motor has large rated load; meanwhile, the gear reducing mechanism is matched with the lead screw, so that the motor has stable output force; and the gear reducing mechanism is matched with the lead screw, so that the motor has a large main shaft stroke and a long telescopic stroke.

Owner:深圳市壹显科技有限公司

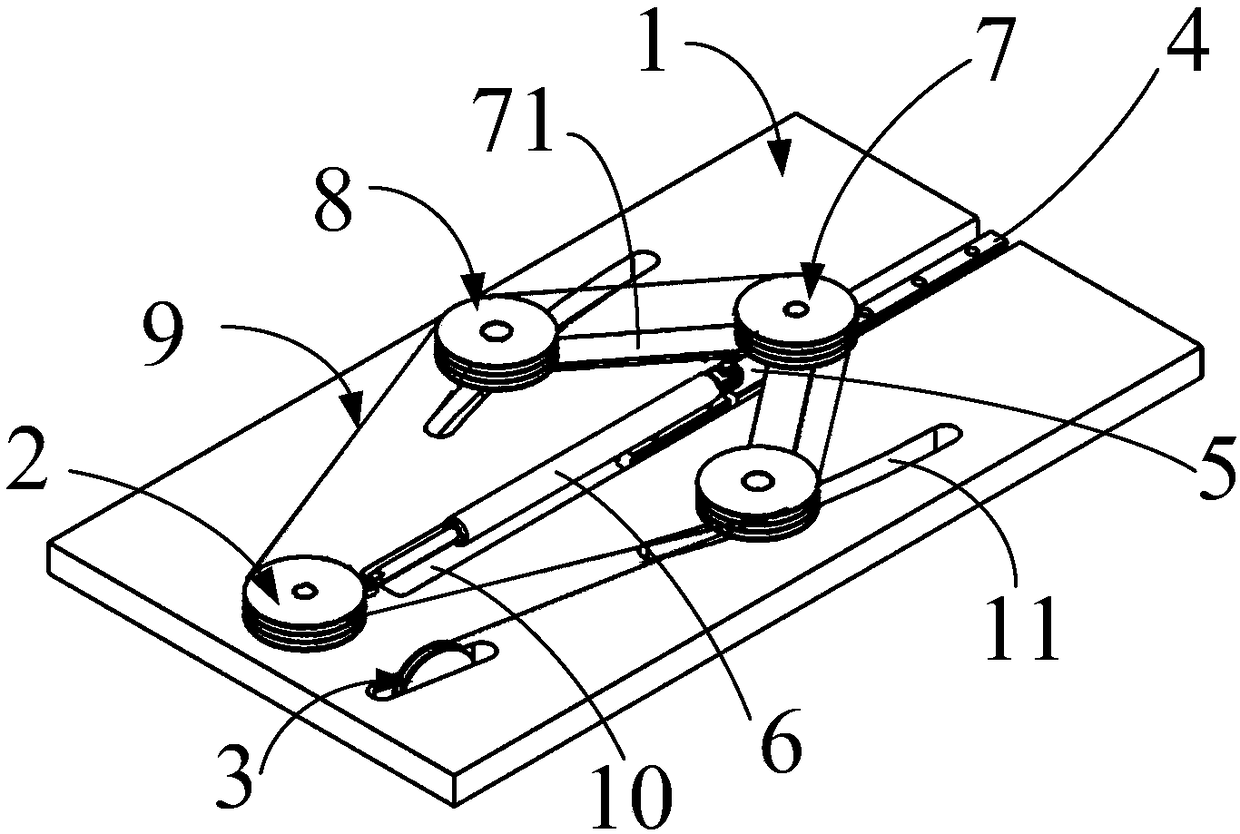

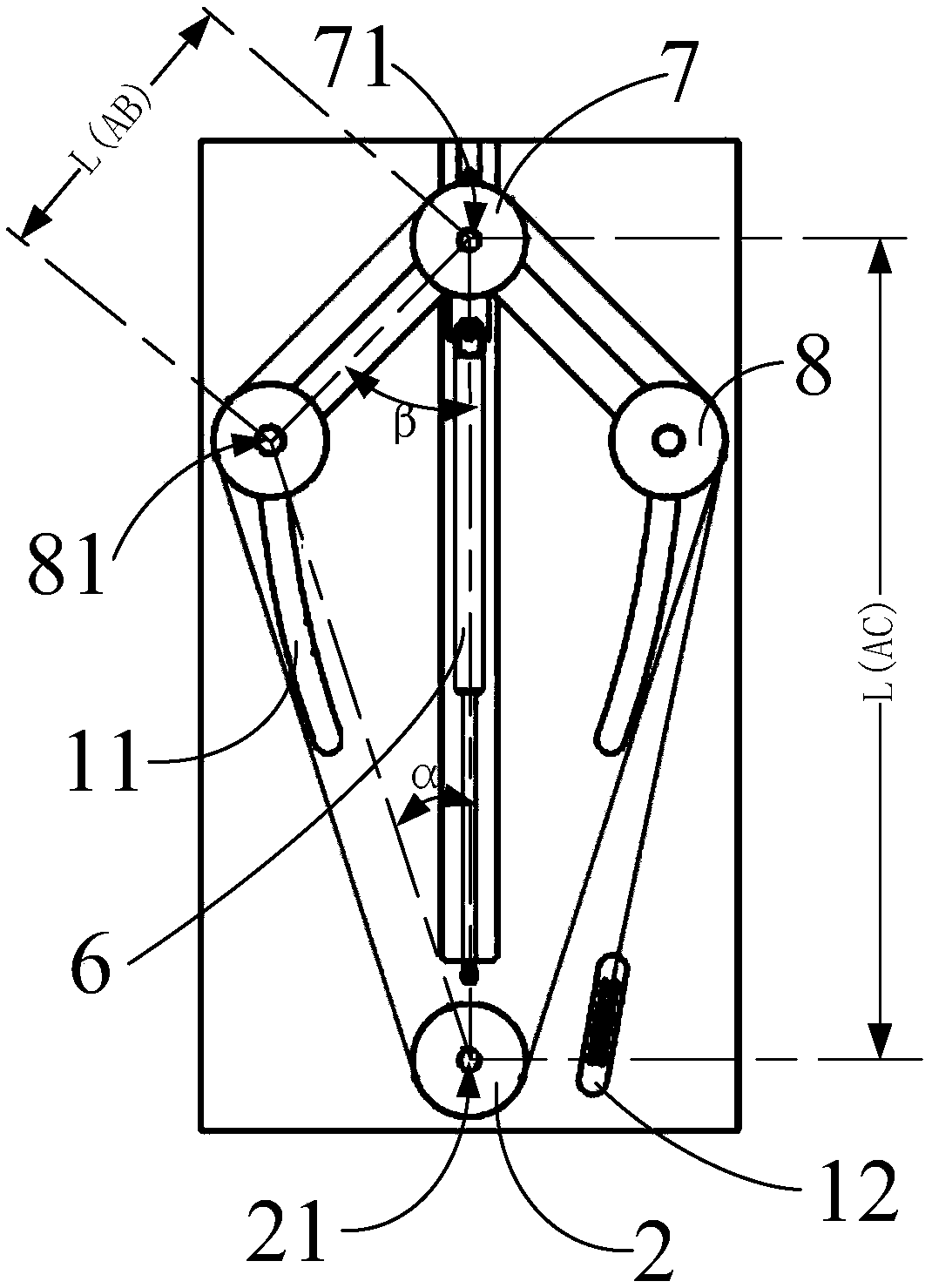

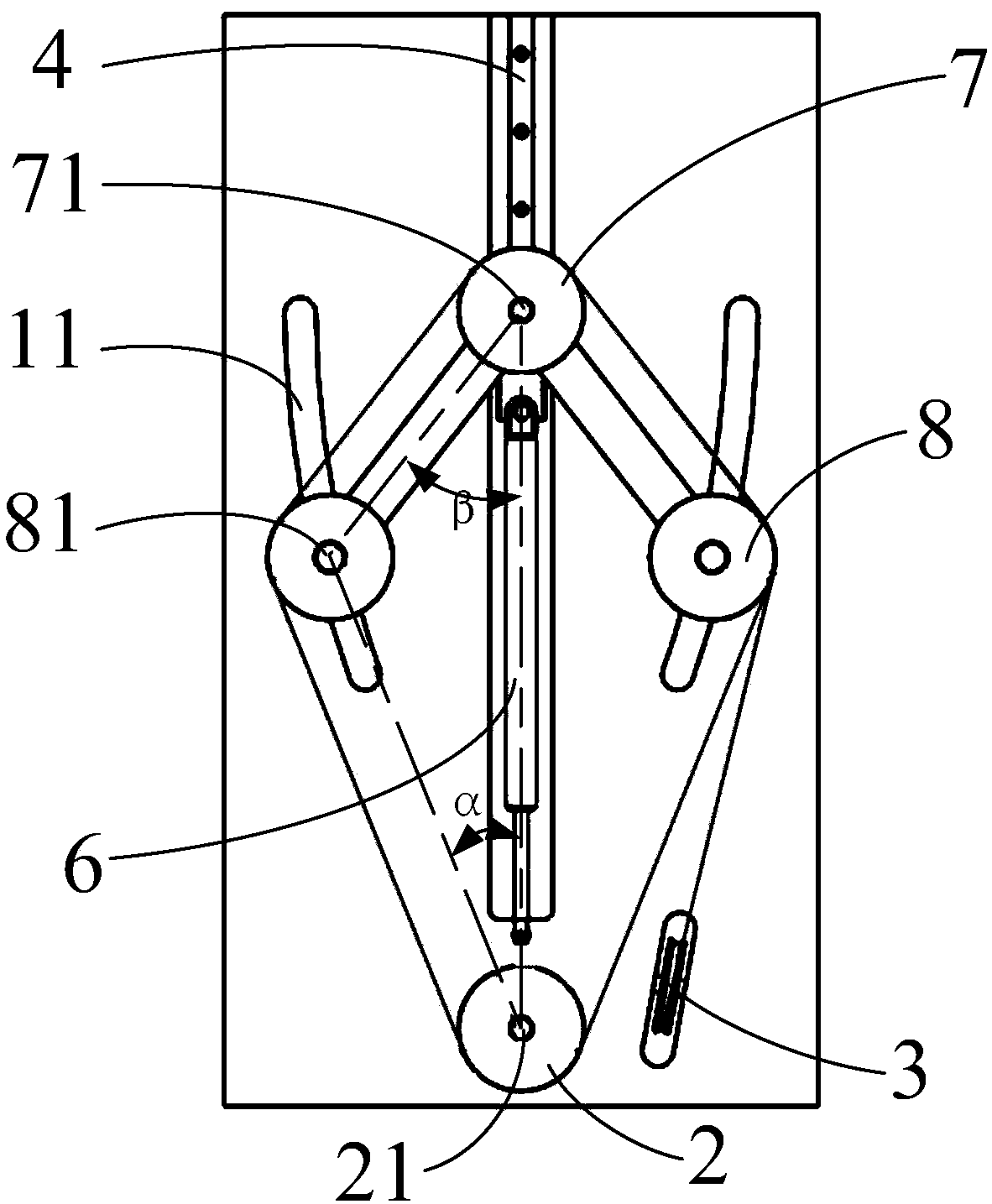

Gravity balancing mechanism

The invention provides a gravity balancing mechanism. The mechanism comprises a pedestal, a fixed pulley, a reversing pulley, a slide block, an elastic component, a moving pulley, one pair of connection rods, one pair of side pulleys and a steel wire rope, wherein the fixed pulley and the reversing pulley are fixed to the pedestal; the slide block slides relative to the pedestal; the elastic component abuts against the slide block; the moving pulley is fixed to the slide block; one pair of connection rods is connected to the moving pulley; one pair of side pulleys is connected to the connection rods; and the steel wire rope winds the reversing pulley, the side pulleys, the moving pulley and the fixed pulley. The fixed pulley, the moving pulley and the side pulleys are fixed through a firstshaft, a second shaft and a third shaft and can be rotated around the first shaft, the second shaft and the third shaft. The pedestal is provided with a pair of guide grooves. The guide grooves are symmetrically arranged relative to the elastic component. The third shaft is in the guide groove and forms rolling contact with an inner wall. The connection rods can be rotated about the second shaftand the third shaft.

Owner:NEUSOFT MEDICAL SYST CO LTD

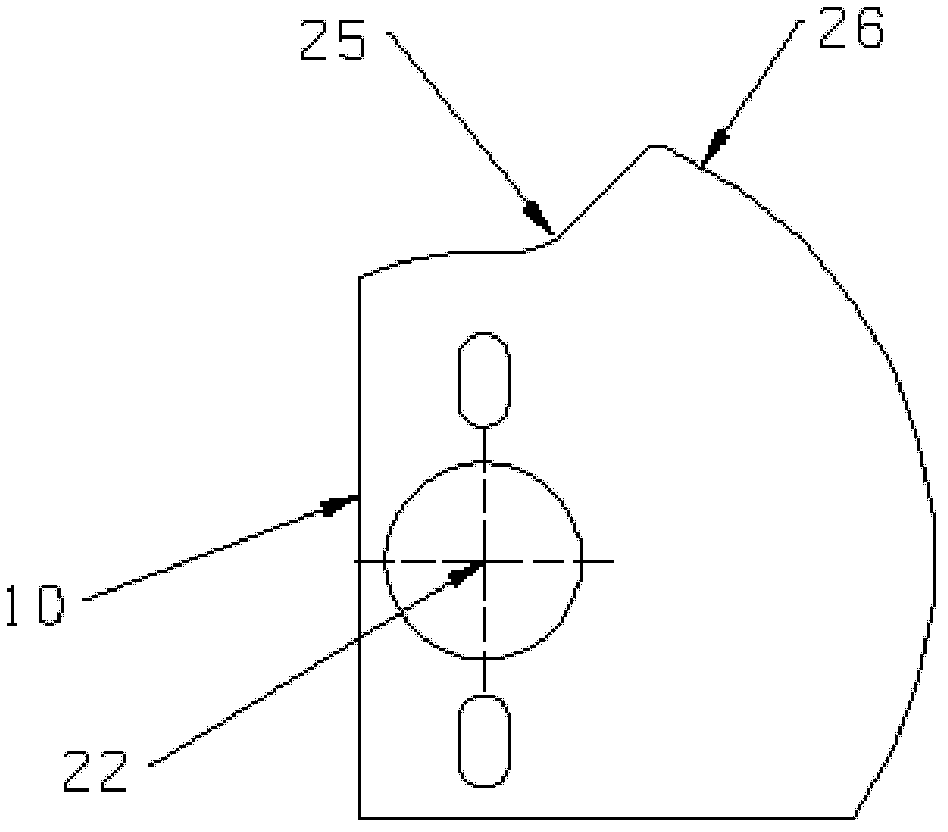

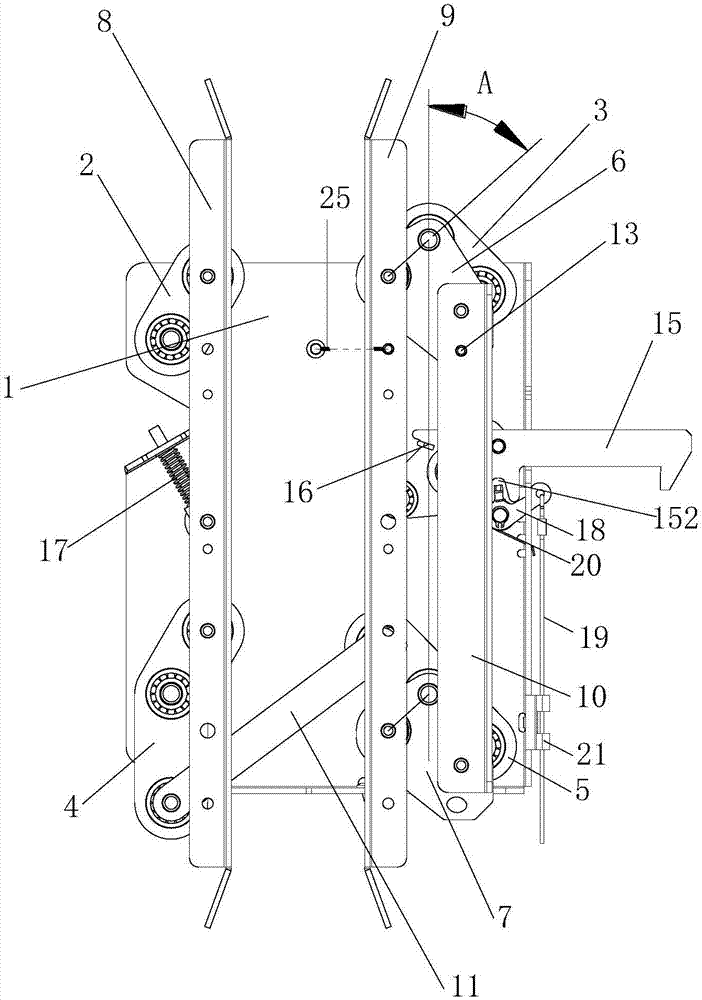

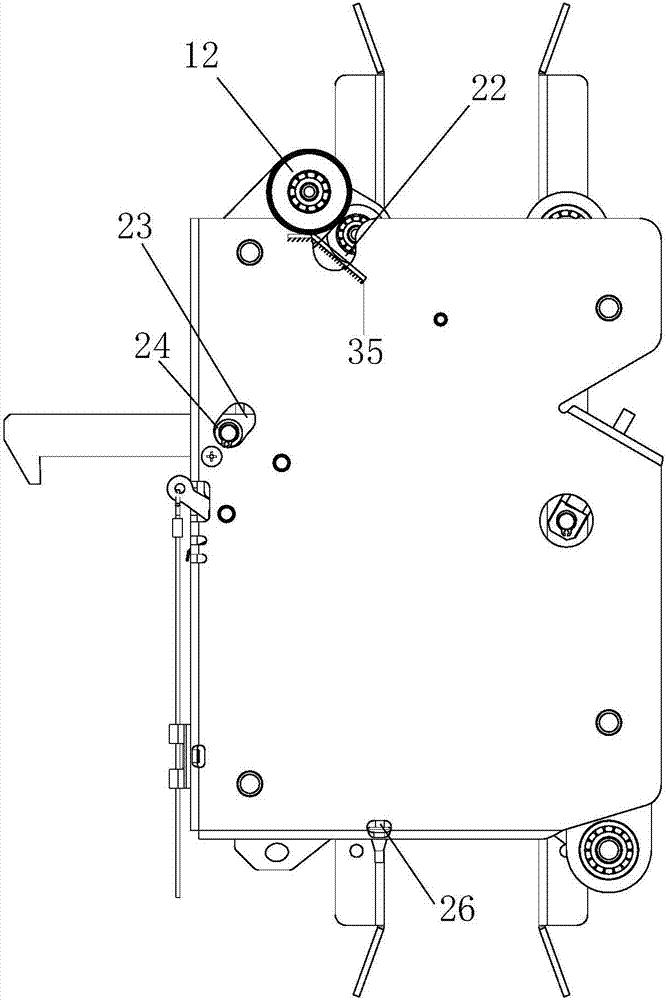

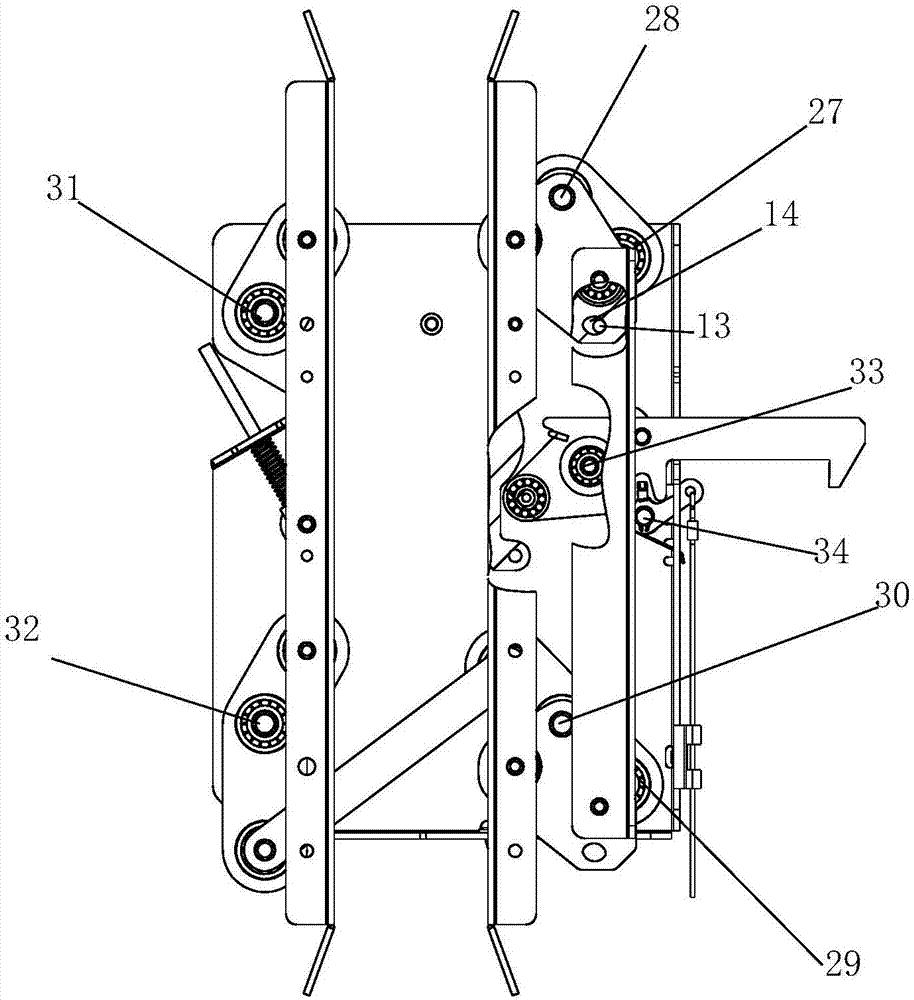

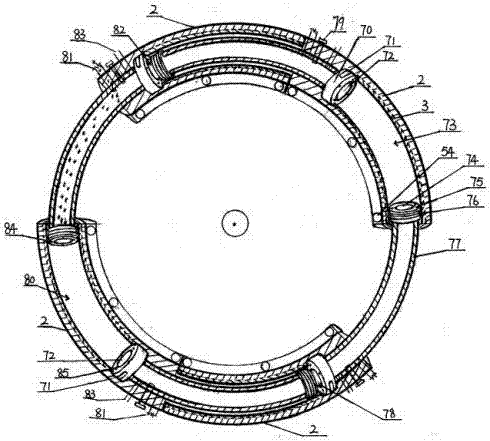

Asynchronous door vane

The invention discloses an asynchronous door vane which comprises a door vane base plate, and further comprises an upper left swing plate, an upper right swing plate, a lower left swing plate, a lower right swing plate, an upper connection rod assembly, a lower connection rod assembly, a left vane, a right vane, a limiting connection rod and a vane arm connection rod, wherein one end of the upper left swing plate is hinged with the front surface of the door vane base plate, and the other end of the upper left swing plate is hinged with the upper part of the left vane; the middle part of the lower left swing plate is hinged with the front surface of the door vane base plate; one end of the lower left swing plate is hinged with the left vane, and the other end of the lower left swing plate is hinged with one end of the vane arm connection rod; the other end of the vane arm connection rod is hinged with the lower right swing plate; a limiting pin shaft is arranged on the door vane base plate; a limiting waist hole is formed in the upper connection rod assembly; the limiting pin hole extends into the limiting waist hole; and the asynchronous door vane further comprises a cage door lock hook. Due to the design of the positions of all the assemblies and the design of the limiting pin shaft and the limiting waist hole, the asynchronous door vane can be self-locked in door opening and closing processes, so that the door vane can always lock a door holder no matter how high the reverse thrust of a landing door is.

Owner:SUZHOU HEYANG METAL PROD

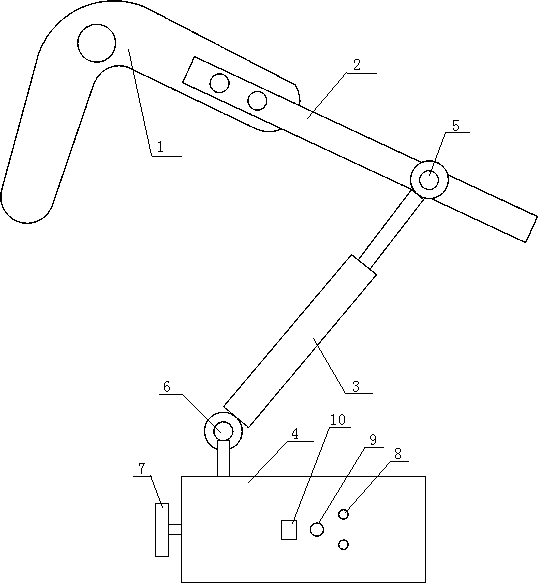

One-button circuit breaker just close point precise positioning debugging device and using method

ActiveCN109166767BPrevent deviationGuaranteed accuracyCalibrating/seeting protective devicesUniversal jointElectric machine

The invention provides a one-key type circuit breaker just-in-place precise positioning and debugging device and a use method thereof, wherein the device comprises a fixed rod, a push rod, a motor andan intermediate relay; The fixing rod is used for fixing with the driving crank arm of the circuit breaker; The push rod and the fixed rod are connected with each other through a universal joint bearing; The motor drives the push rod to rotate; The two lead-out wires of the circuit breaker break are connected in series with the coils of the intermediate relay; The normally closed contact of the intermediate relay is connected in series with the motor. So that that structure of the invention is simplify, low cost, easy to operate, As long as a button switch is use, that precise positioning ofthe rigid joint point of the main body fracture can be realize, The invention avoids the deviation of the rigid point data caused by the difference of the human hand strength, ensures the accuracy ofthe subsequent circuit breaker debugging and test data, does not need to repeatedly pull up or down and insert the skid bar, and greatly improves the production efficiency for the mass production of the production workshop.

Owner:MAINTENANCE BRANCH OF STATE GRID FUJIAN ELECTRIC POWER +1

Force amplifier capable of generating axial displacement and axial thrust through rotation

PendingCN114562527ASimple structureEasy to useBrake actuating mechanismsActuatorsAxial displacementGear wheel

Owner:山东力得汽车科技股份有限公司

twin turbo internal combustion engine

ActiveCN105781621BImprove noiseReduce noiseNon-positive displacement enginesExhaust valveExternal combustion engine

The invention discloses a twin-turbine internal combustion engine. The twin-turbine internal combustion engine is characterized in that a power shaft is in contact with left and right turbine racks for supporting through a sliding bearing, the power shaft is in contact with a housing through a rolling bearing, the power shaft and a ratchet fly wheel are in bonding through a ratchet fly wheel key, a round steel plate and turbine discs are fixedly connected to arc-shaped cylinders of turbines through screws, a cylinder sleeve is arranged in each cylinder, a piston is mounted at one end of an arc-shaped cylinder of the piston, a piston ring is arranged next to the piston, the other end of the arc-shaped cylinder is propped against a cylinder cover, an exhaust valve is arranged on the cylinder cover, oil injection holes are formed in the periphery of the exhaust valve, an inlet valve is arranged on the piston, and water spray holes are formed in the periphery of the inlet valve. The twin-turbine internal combustion engine disclosed by the invention solves the problem of high internal combustion waste heat and severe pollution. The twin-turbine internal combustion engine is small in noise, small in vibration and long in service life. The power shaft is straight, the output force is steady, the weight of the twin-turbine internal combustion engine is half of that of a crankshaft internal combustion engine, and the effective work can reach 90%.

Owner:陈名碧

Automatic glass breaking device

ActiveCN107739150BRealize the process requirements of productionFulfill process requirementsGlass severing apparatusStructural engineeringMechanical engineering

The invention relates to a fully-automatic glass breaking-off device. The fully-automatic glass breaking-off device comprises a breaking-off mechanism, a scrap guiding mechanism, a glass supporting mechanism and a limiting induction mechanism. According to the fully-automatic glass breaking-off device, a whole sheet of glass can be subjected to edge and sheet breaking-off operation, and thus, theprocess requirements on production of glass of small sheets of certain specifications are met; when one edge of the whole sheet of glass is subjected to vertical downward edge breaking-off action, a single edge breaking-off cylinder is used for providing a downward acting force, output power is stable, a cylinder output speed can be rapidly and conveniently regulated, and the edge breaking-off action is reliable; a proximity switch is adopted as a control element for the edge and sheet breaking-off operation, thus, positions, relative to the whole sheet of glass, of cutter blades can be accurately controlled, the glass is subjected to the edge and sheet breaking-off operation after the cutter blades move to proper positions, and thus, the operability is good while the locating accuracy ishigh; glass scraps generated during the edge and sheet breaking-off operation of the glass are subjected to timely collecting treatment through the scrap guiding mechanism, meanwhile, a glass trolleyis ingenious in structural design, and thus, the operability of pouring of the glass scraps by working personnel is improved.

Owner:CNBM TRIUMPH ROBOTICS SHANGHAI CO LTD

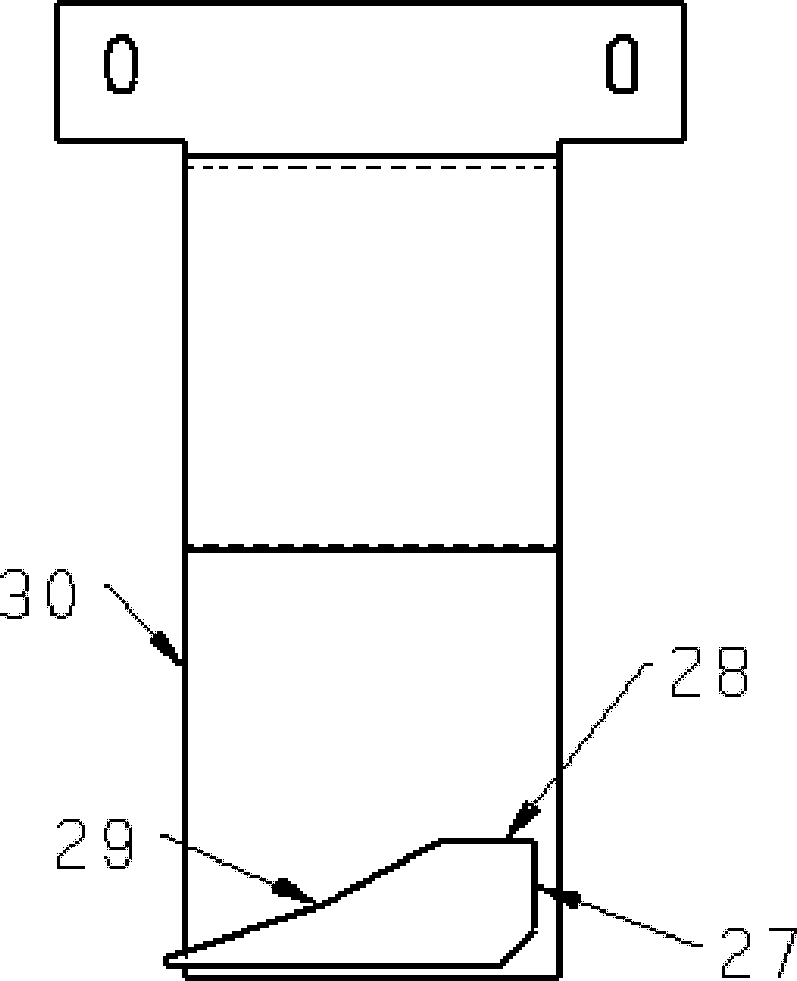

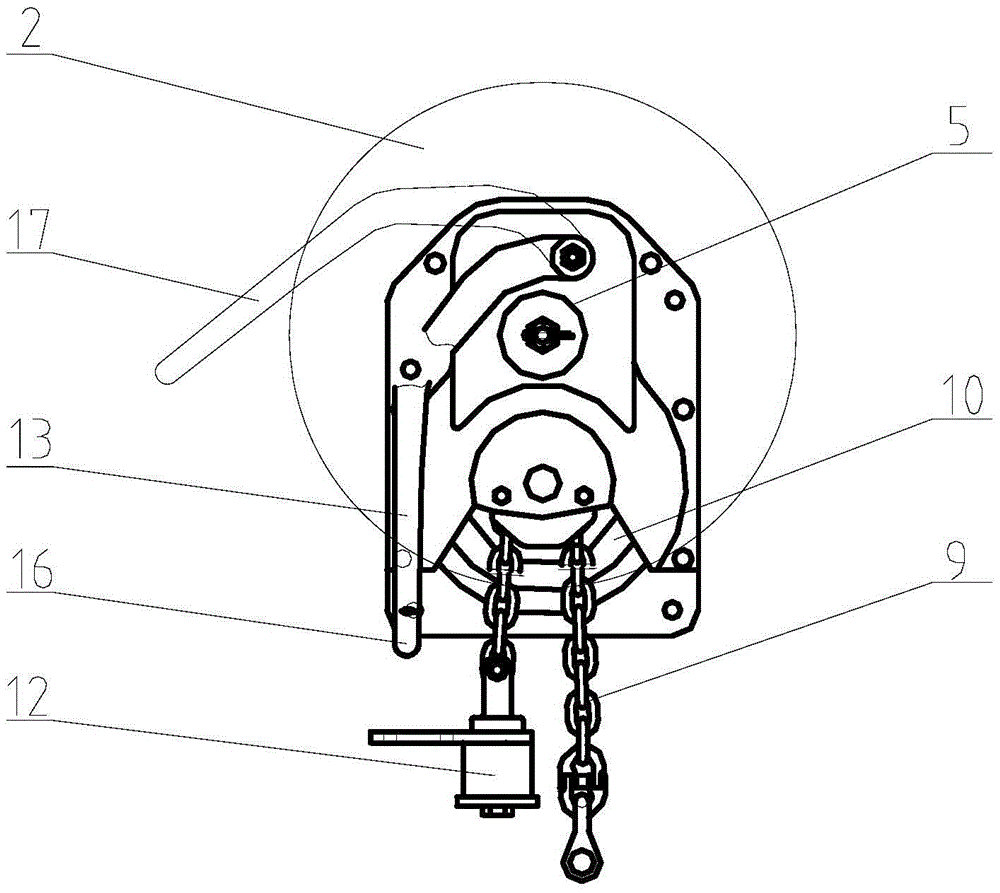

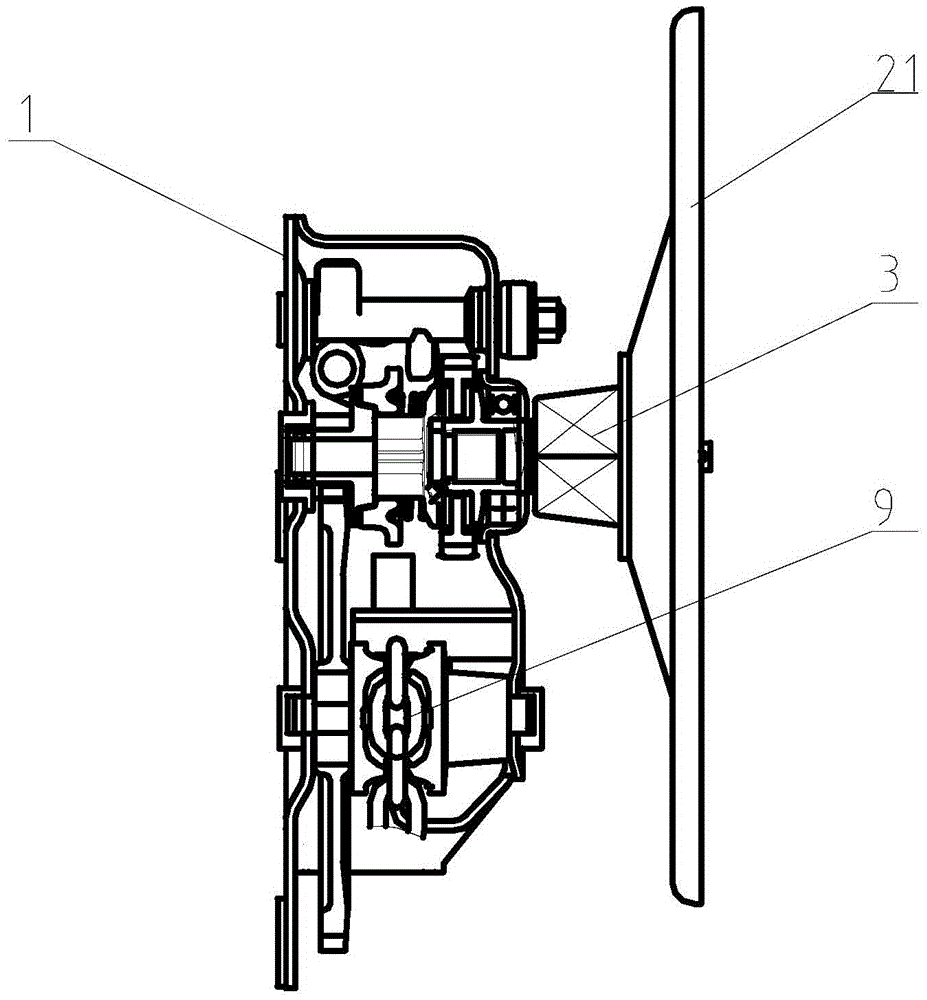

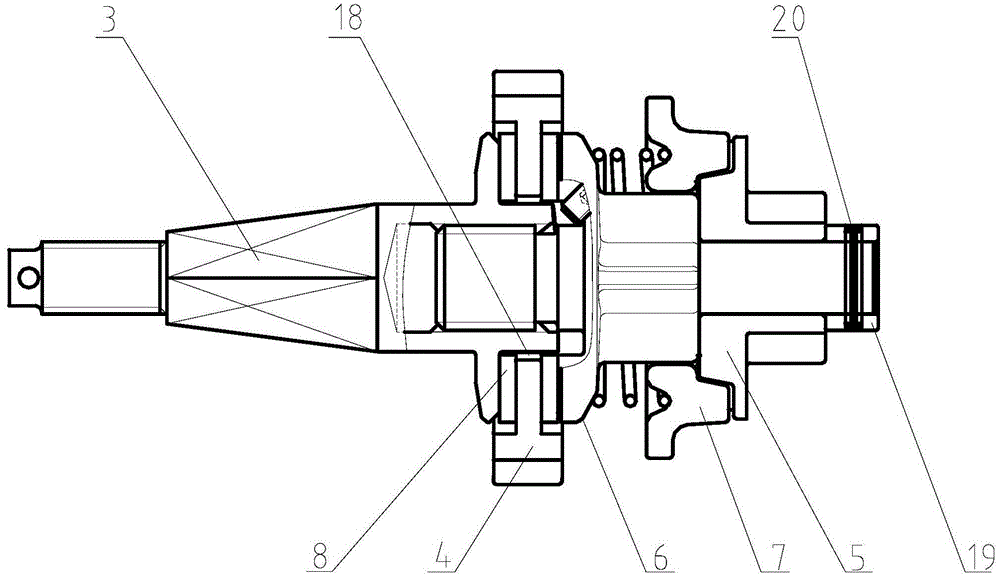

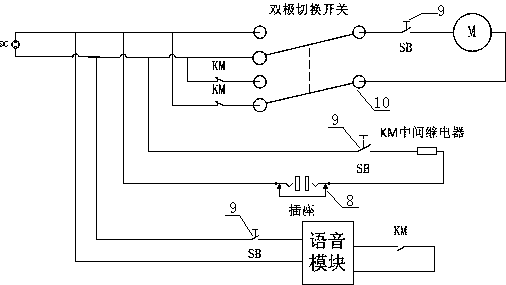

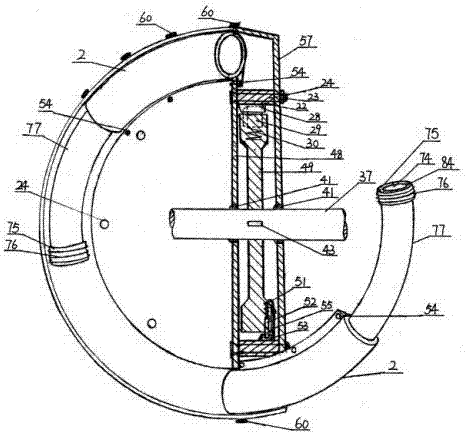

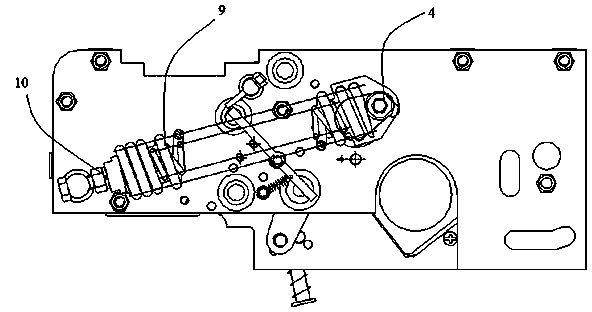

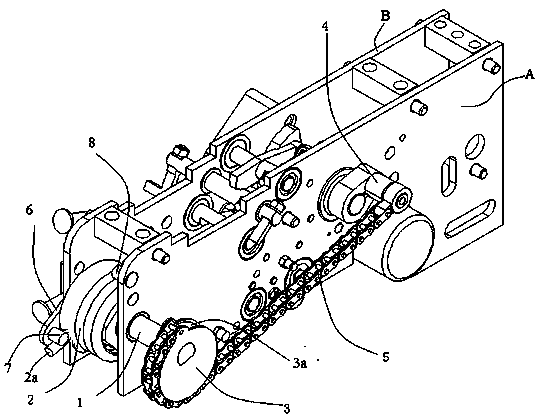

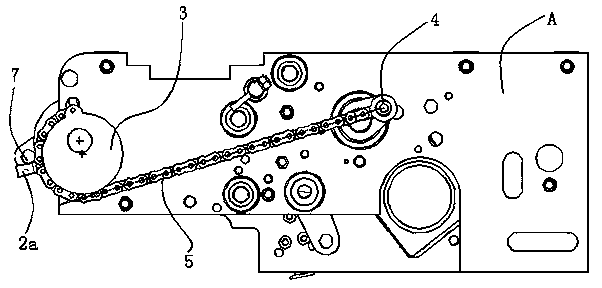

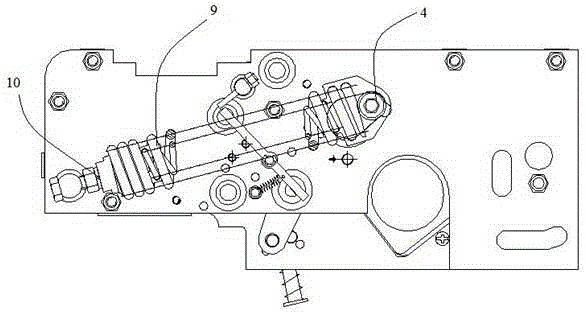

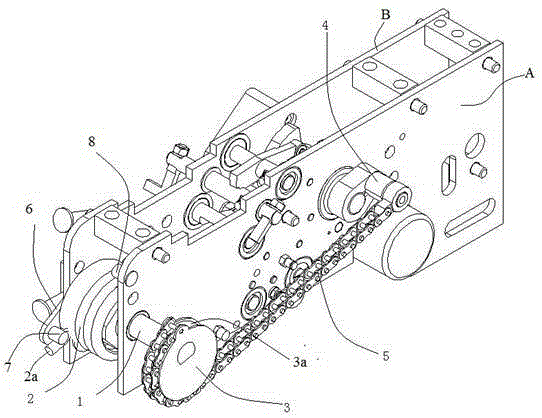

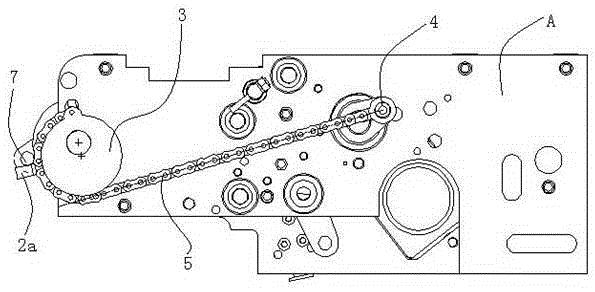

Energy storing outputting mechanism applied to spring operating mechanism

ActiveCN104217887AReliable closingSimple structureHigh-tension/heavy-dress switchesAir-break switchesMechanical engineeringControl theory

The invention provides an energy storing outputting mechanism applied to a spring operating mechanism. The energy storing outputting mechanism comprises a frame body, a rotating shaft which is arranged at one end of the frame body, and an output connecting lever which is arranged at the other end of the frame body; an energy storing biasing part sleeves the rotating shaft; a reducing structure of which the radius is gradually varied from long to short is also arranged on the rotating shaft and integrally rotated with the rotating shaft. The energy storing outputting mechanism further comprises a transmission chain or rope, wherein the transmission chain or rope is arranged about the sidewall of the outer edge of the reducing structure; one end of the transmission chain or rope is connected with the reducing structure, and while the other end is connected to the output connecting lever. With the adoption of the energy storing outputting mechanism with such structure applied to the spring operating mechanism, the problem that the output force of the outputting mechanism of the spring energy storing mechanism in the prior art is reduced to cause unreliable closing and enable an energy storing spring to be easily fatigued when the spring releases energy can be solved; the energy storing outputting mechanism meets the closing curve of a switch when closing the switch, the service life of the energy storing spring is prolonged, and reliable closing is ensured.

Owner:ZHEJIANG HUAYI ELECTRIC APPLIANCE TECH

An energy storage output mechanism for a spring operating mechanism

ActiveCN104217887BClose reliableExtended service lifeHigh-tension/heavy-dress switchesAir-break switchesEngineeringActuator

The invention provides an energy storing outputting mechanism applied to a spring operating mechanism. The energy storing outputting mechanism comprises a frame body, a rotating shaft which is arranged at one end of the frame body, and an output connecting lever which is arranged at the other end of the frame body; an energy storing biasing part sleeves the rotating shaft; a reducing structure of which the radius is gradually varied from long to short is also arranged on the rotating shaft and integrally rotated with the rotating shaft. The energy storing outputting mechanism further comprises a transmission chain or rope, wherein the transmission chain or rope is arranged about the sidewall of the outer edge of the reducing structure; one end of the transmission chain or rope is connected with the reducing structure, and while the other end is connected to the output connecting lever. With the adoption of the energy storing outputting mechanism with such structure applied to the spring operating mechanism, the problem that the output force of the outputting mechanism of the spring energy storing mechanism in the prior art is reduced to cause unreliable closing and enable an energy storing spring to be easily fatigued when the spring releases energy can be solved; the energy storing outputting mechanism meets the closing curve of a switch when closing the switch, the service life of the energy storing spring is prolonged, and reliable closing is ensured.

Owner:ZHEJIANG HUAYI ELECTRIC APPLIANCE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com