twin turbo internal combustion engine

A technology of internal combustion engines and twin turbines, applied in the direction of machines/engines, non-variable engines, mechanical equipment, etc., can solve problems such as polluting the environment, complex structures, and difficult expansion of structural and space restrictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

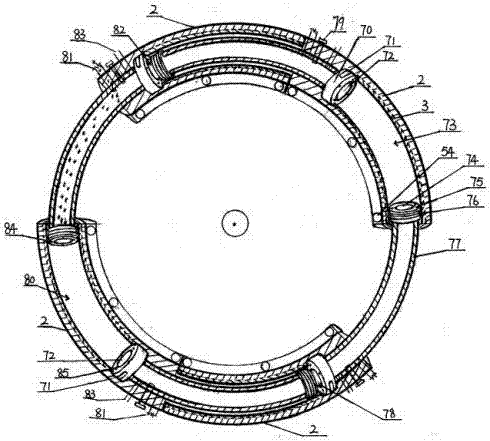

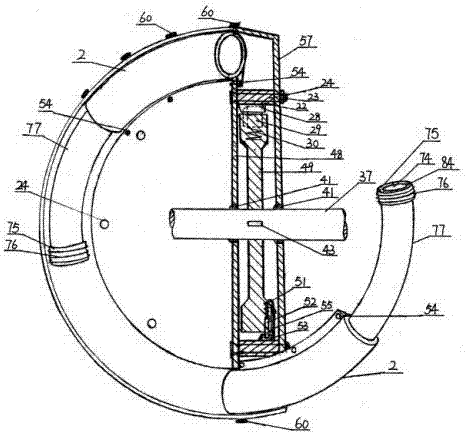

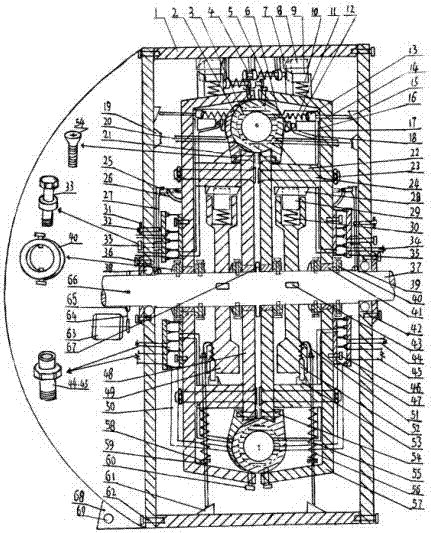

[0008] Such as figure 1 , 2 , shown in 3, the present invention comprises piston, transmission member, connecting member, oil-water-gas supply device and exhaust pipeline, adjustment control member, starter motor 63, clutch wheel 65, clutch wheel key 66, V-belt pulley 64, body circular shell 1. It is composed of several arc-shaped plates connected into one body through shell screws 62. The shell is fixedly connected with the machine base 68. There are fixed screw holes 69 on the machine base. The turbine frame is composed of a turbine disc 57 and a circular steel plate 48. The cylinder The body 2 is arc-shaped, and the cylinder body is provided with an air inlet 81 and an oil inlet 83. The inner ring of the cylinder is connected with the inner circular steel plate through the torx screw 54, and the back is connected with the edge of the turbine disk with the flat head screw 60. The arc cylinder The body is equipped with an arc-shaped inner cylinder liner 3, and each cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com