An automotive electric vacuum pump test system

An electric vacuum pump and testing system technology, applied in pump testing, pump control, machine/engine, etc., can solve the problems of cumbersome matching and fixing process of different electric vacuum pumps, inability to apply different torque loading forces on pedals, etc., to reduce cumbersome steps. and material waste, saving human and material resources, and accurate data collection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing, the present invention is described in detail:

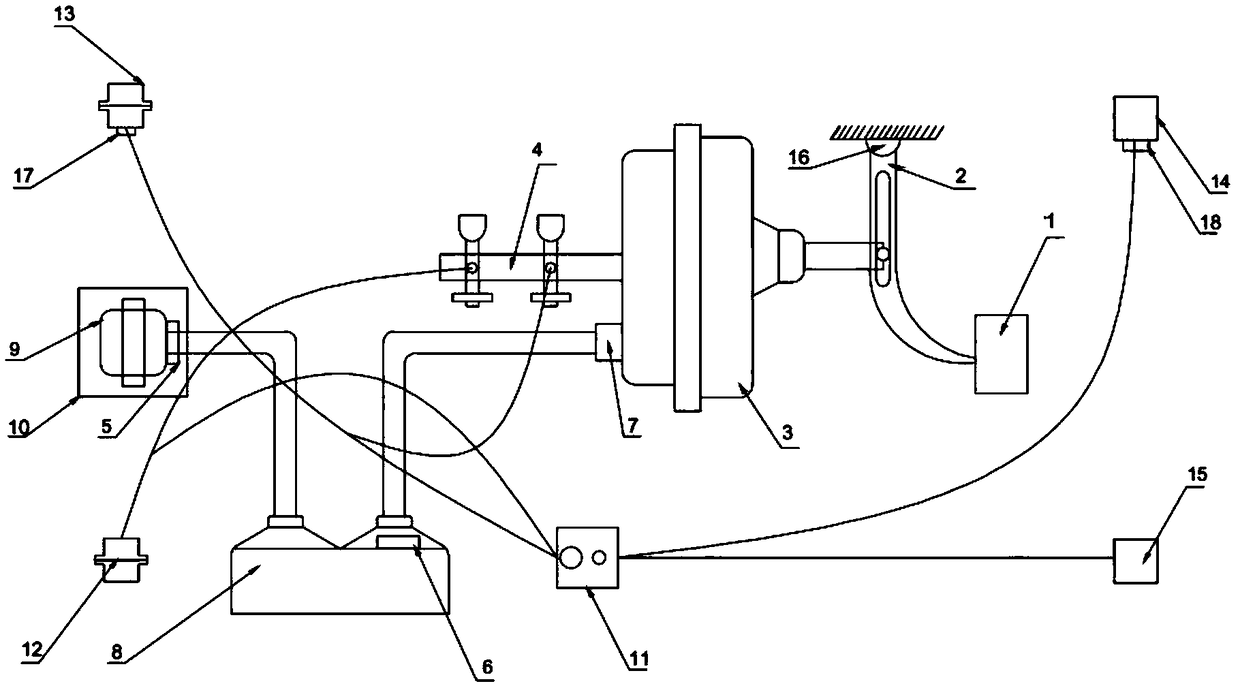

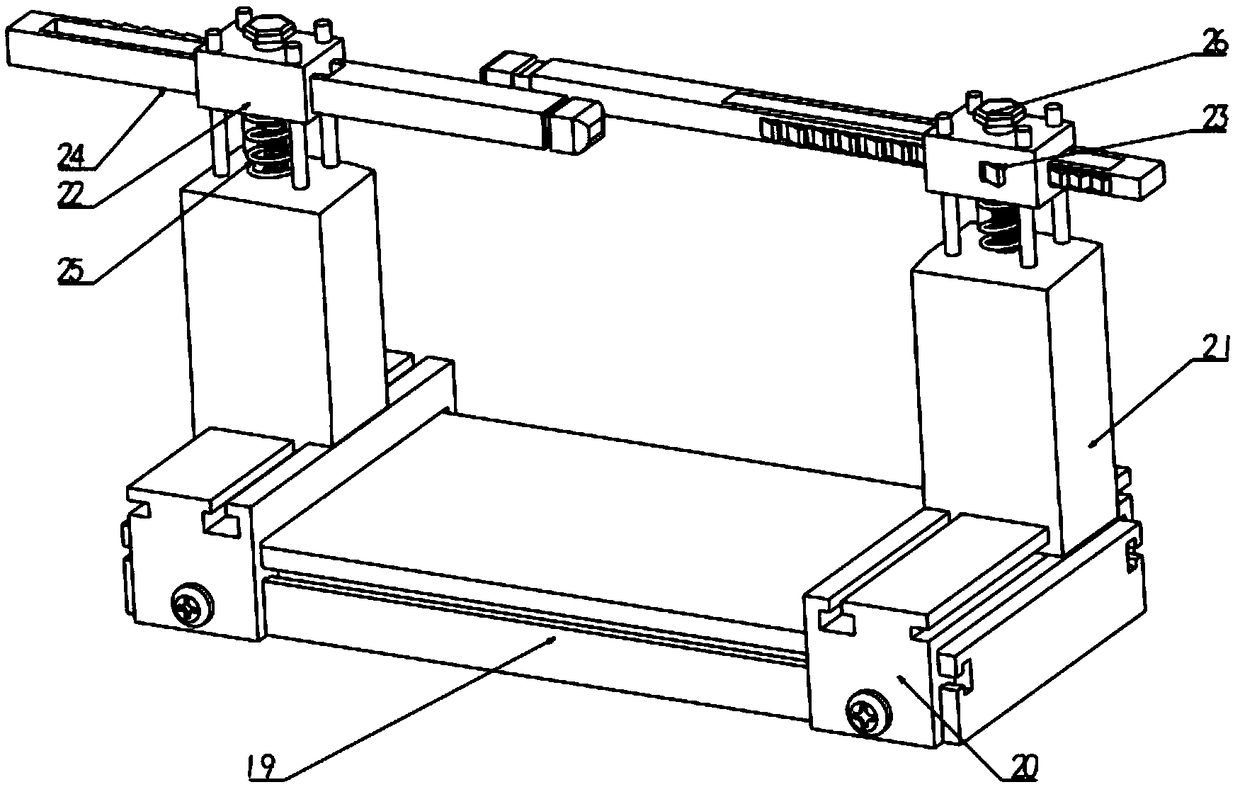

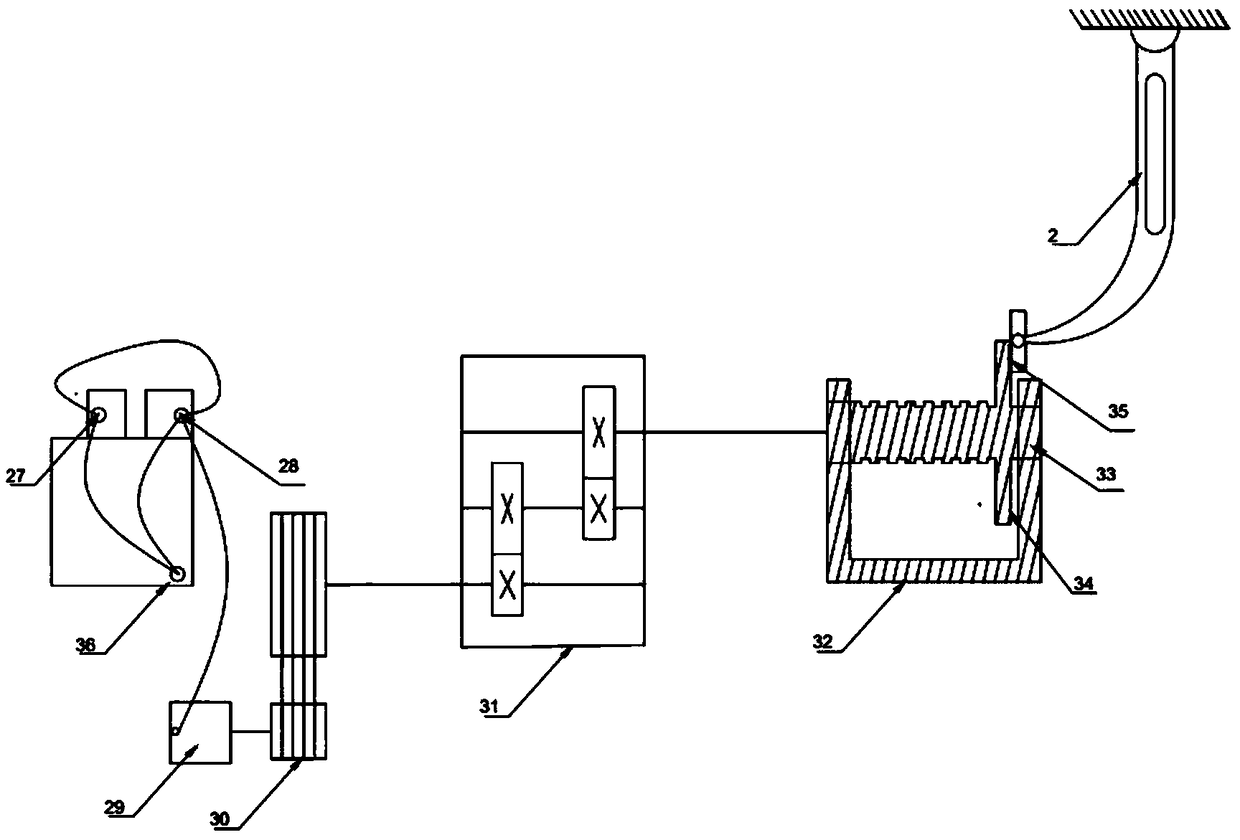

[0020] see figure 1 , An automobile electric vacuum pump test system consists of pedal force loading system 1, pedal 2, vacuum booster 3, brake master cylinder 4, infrared temperature sensor 5, vacuum degree sensor 6, vacuum check valve 7, vacuum tank 8, Electric vacuum pump 9, vacuum pump fixing device 10, load sensing proportional valve 11, left front wheel cylinder 12, right front wheel cylinder 13, left rear wheel cylinder 14, right rear wheel cylinder 15, pedal degree sensor 16, right front wheel cylinder pressure sensor 17. The right rear wheel cylinder pressure sensor 18 is composed. The braking function is realized by the following method. The movable plate 34 in the pedal force loading system 1 is connected to the board surface of the pedal 2 through a pressure sensor 35, and the pedal force loading system 1 completes the loading of the pedal 2 through the board sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com