System and method for monitoring pipeline leakage based on high-and-low-frequency hybrid detection

A technology of pipeline leakage and monitoring system, applied in pipeline systems, mechanical equipment, gas/liquid distribution and storage, etc., can solve the problems of easy to produce false negatives, low sensitivity of negative pressure wave method, short response time and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0160] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

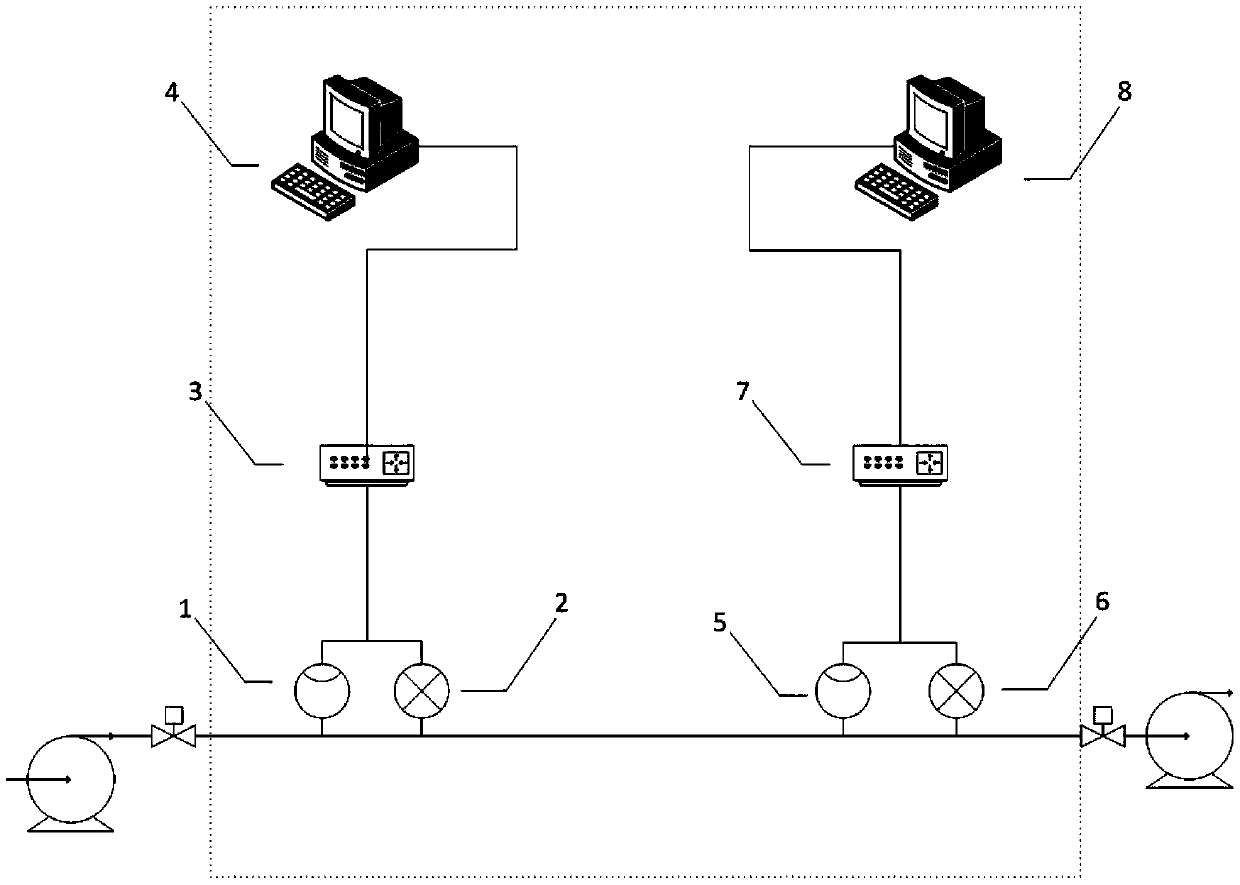

[0161] A pipeline leakage monitoring system based on high and low frequency mixed detection, including a head-end UHF sensor 1, a head-end acceleration sensor 2, a head-end lower computer 3, a head-end upper computer 4, an end UHF sensor 5, and an end acceleration sensor 6. The terminal lower computer 7 and the terminal upper computer 8, such as figure 1 shown;

[0162] The head-end UHF sensor 1 and the head-end acceleration sensor 2 are respectively installed at the head end of the pipeline to be tested. The head-end UHF sensor 1 and the head-end acceleration sensor 2 are connected to the head-end lower computer 3 through wires. The end lower computer 3 is connected to the head end upper computer 4 through a network cable;

[0163] The terminal ultra-high frequency sensor 5 and the terminal acceleratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com