Patents

Literature

105 results about "Negative pressure wave" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

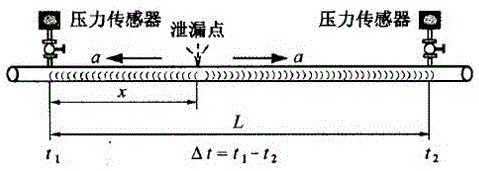

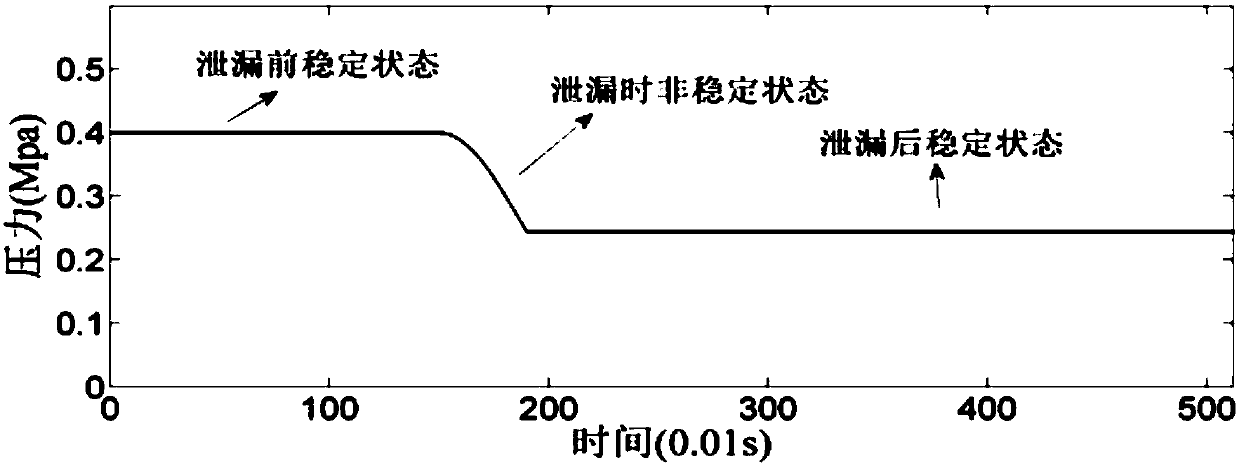

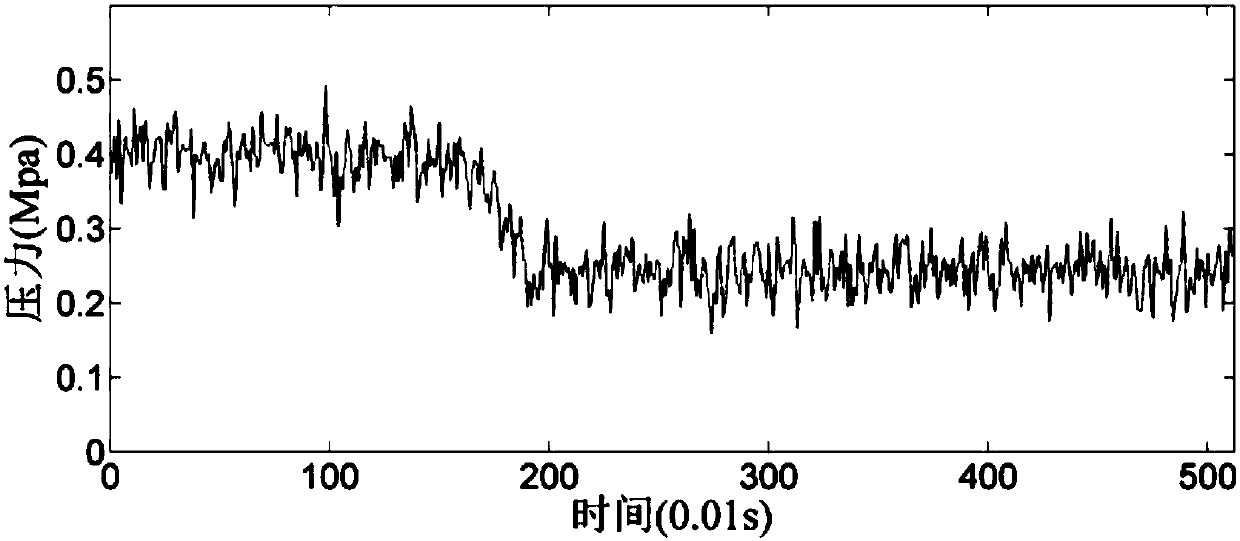

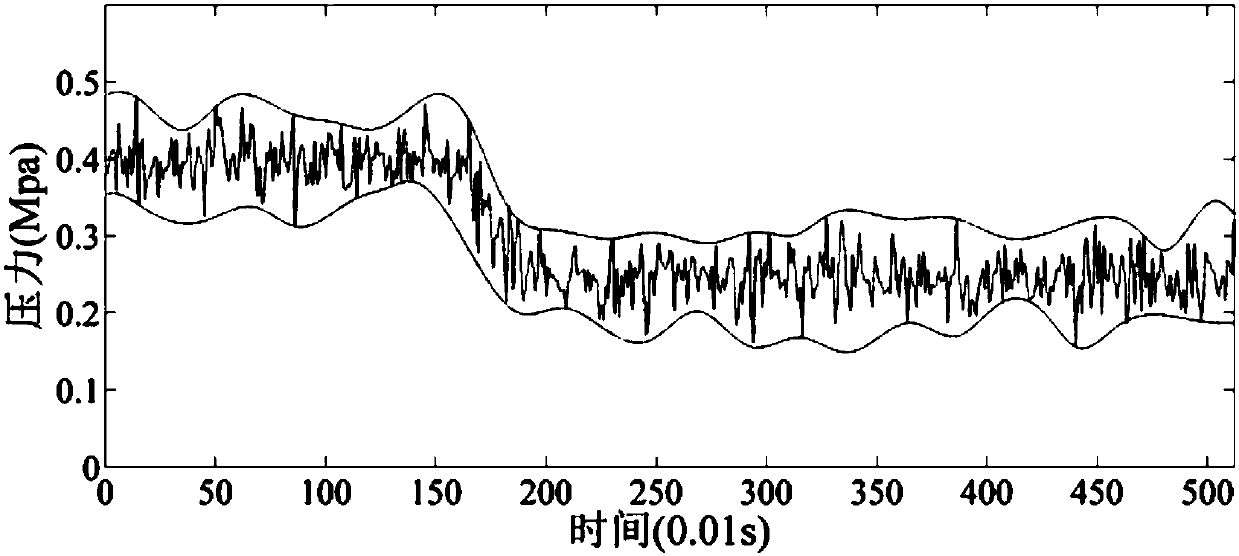

Negative pressure wave description. The system is based on the energy conservation law. The onset of a leak creates a flow of liquid or gas into to the environment, which in its turn releases the pressure inside the pipeline, generating a negative pressure wave (NPW).

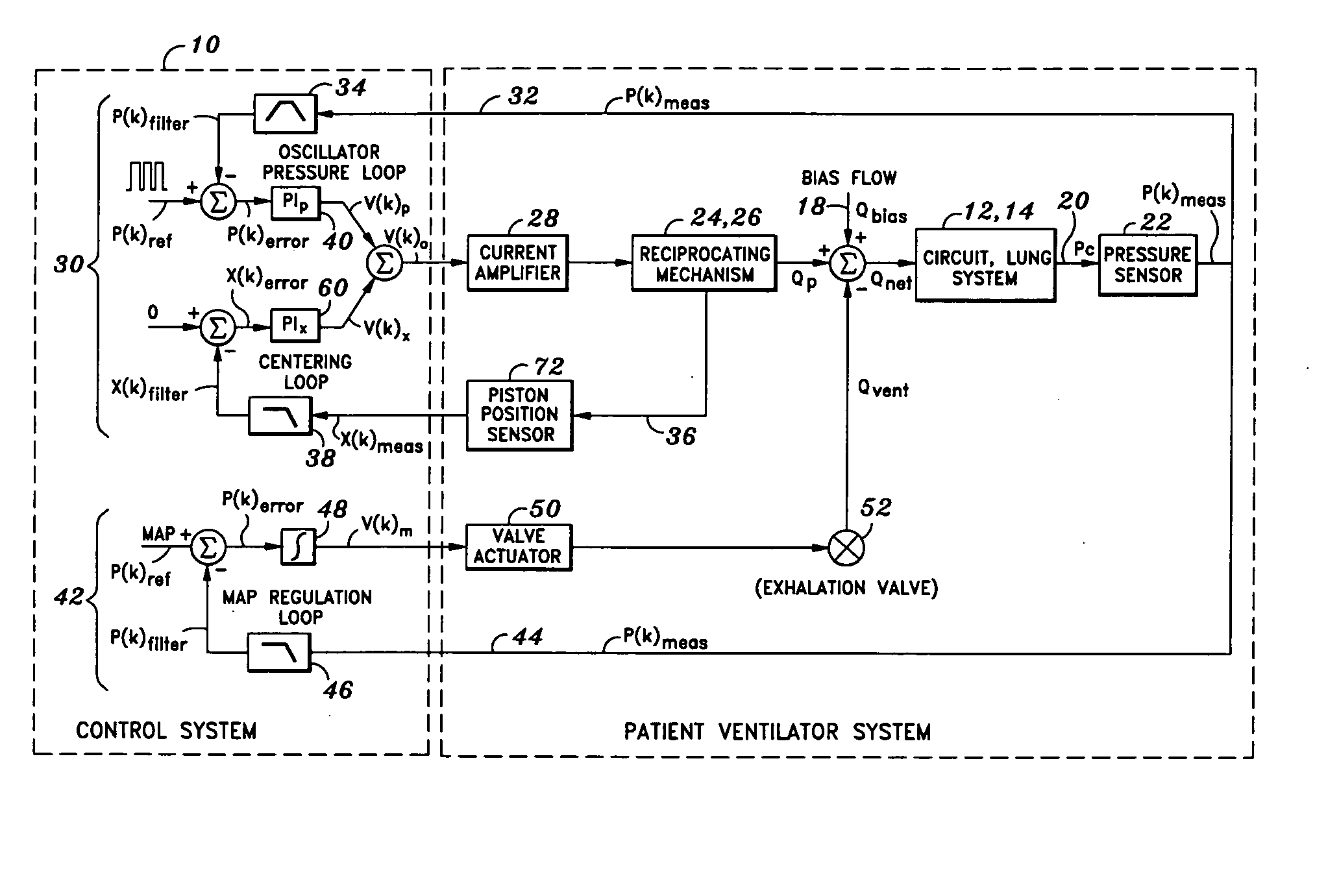

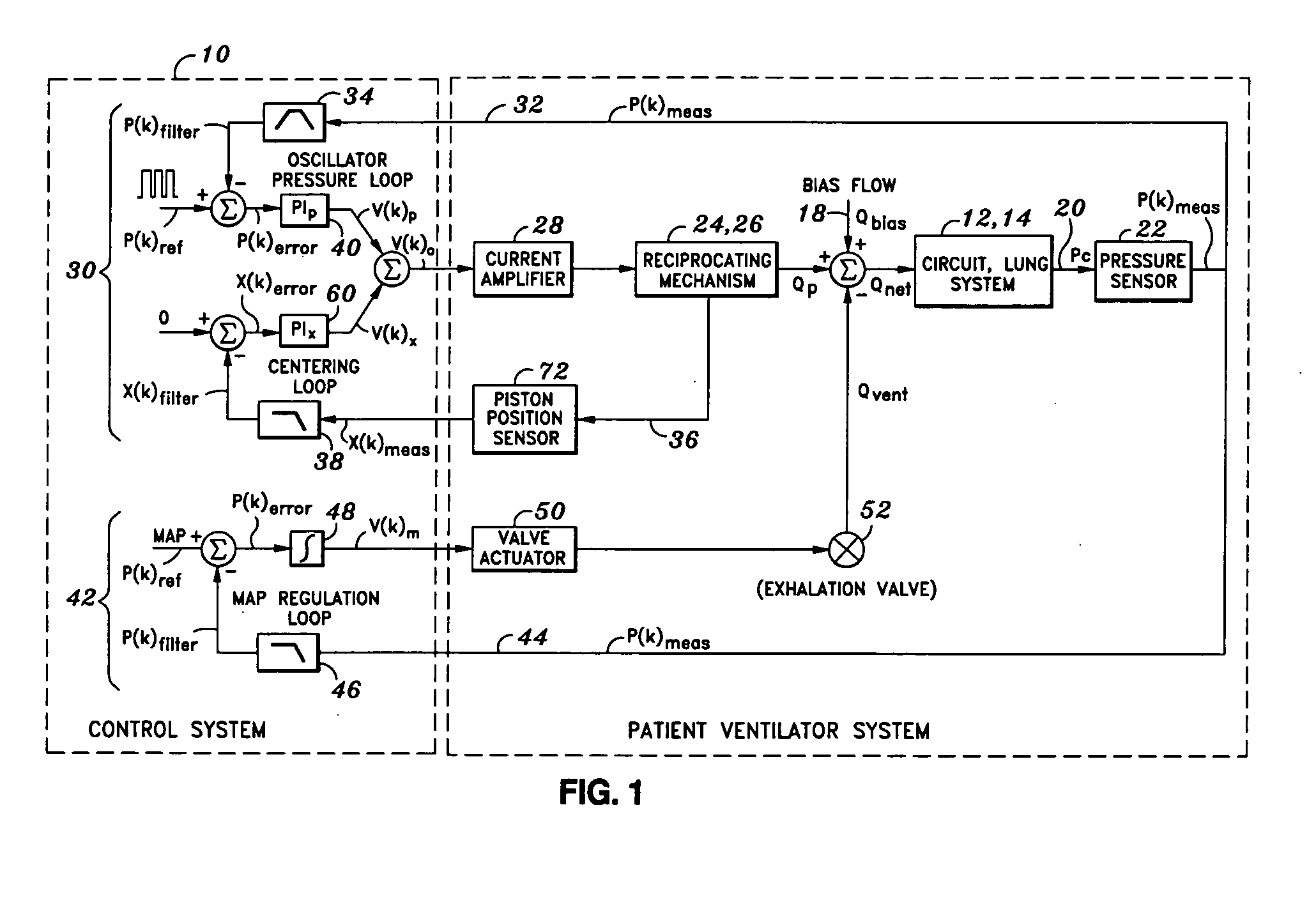

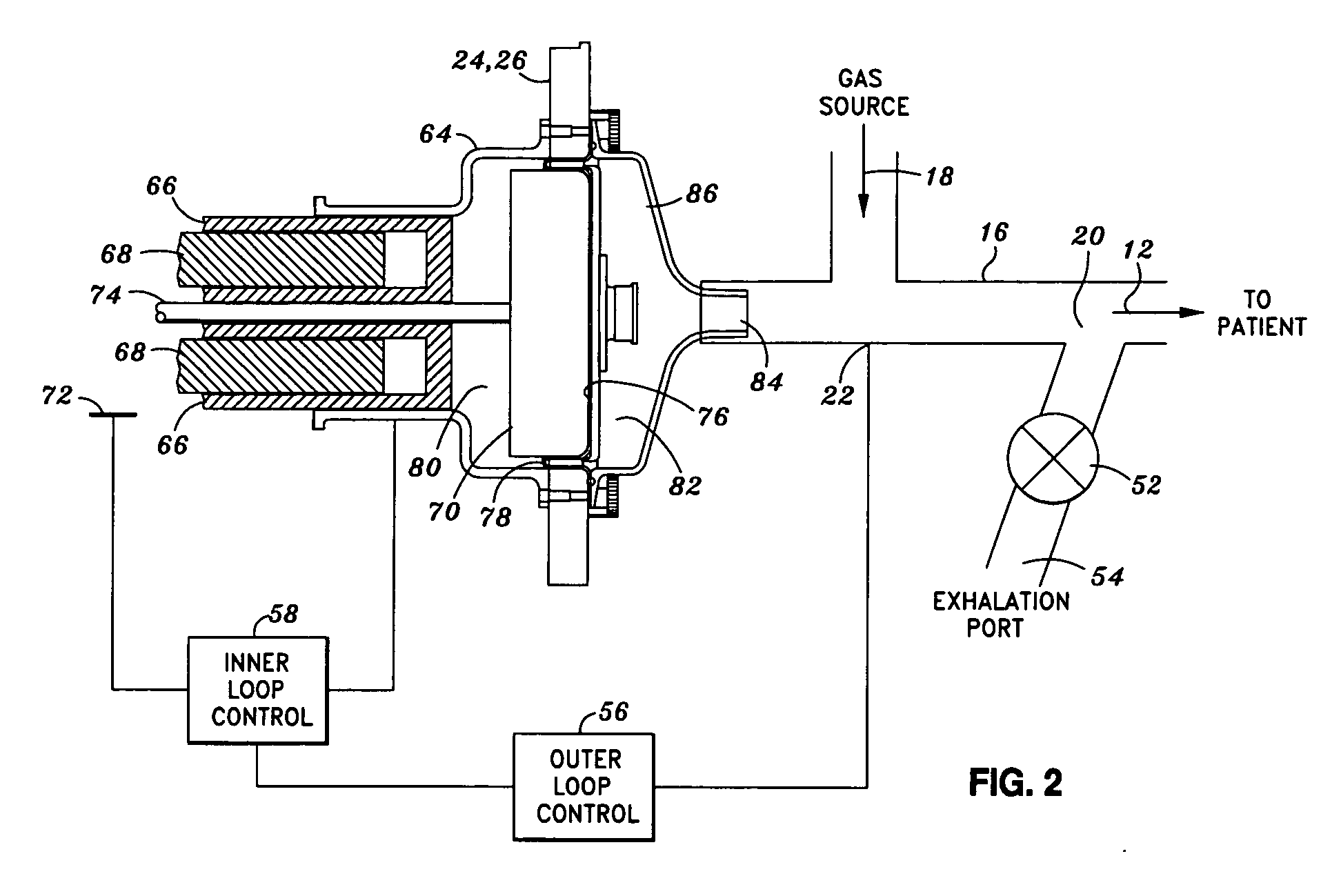

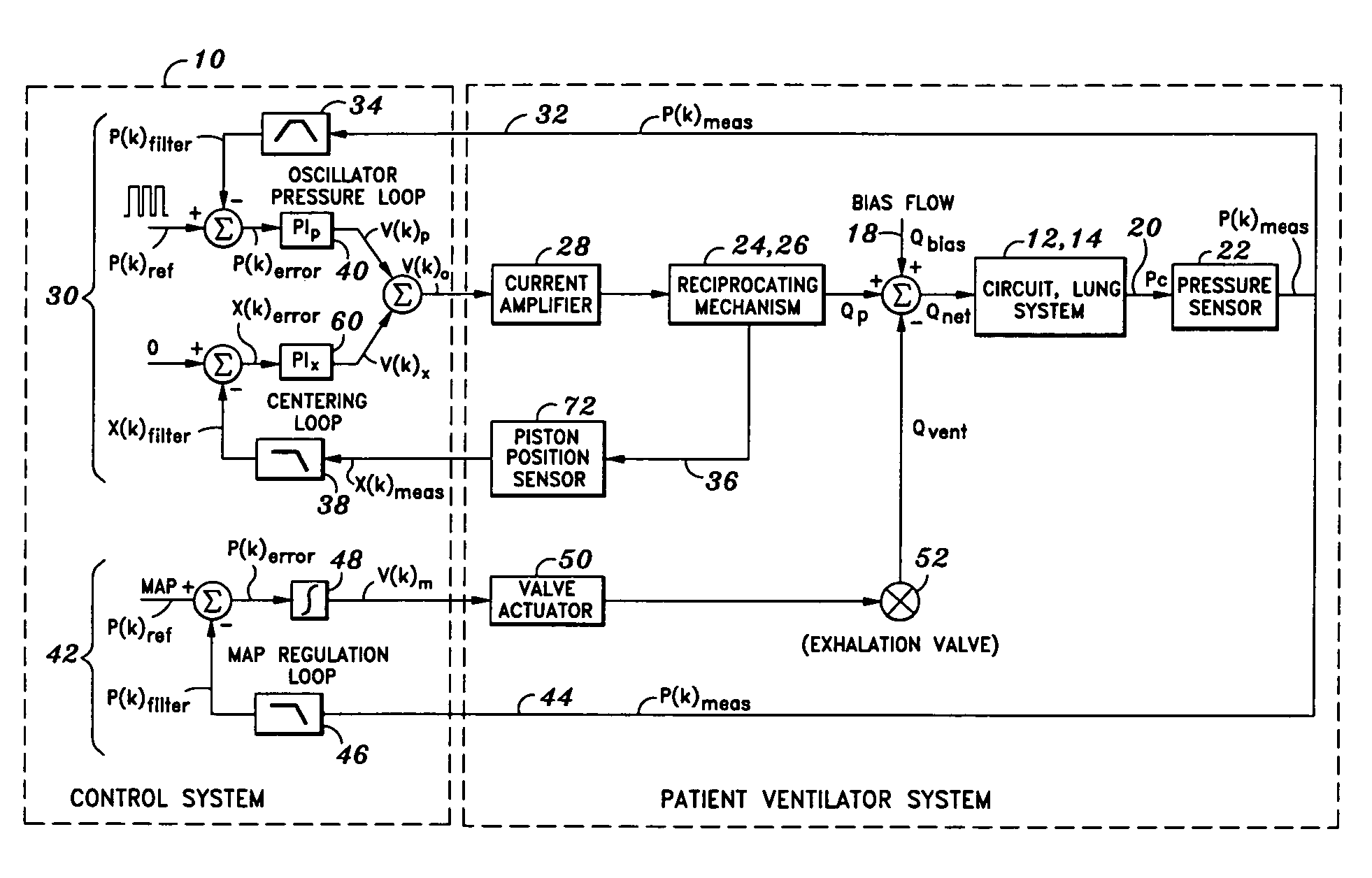

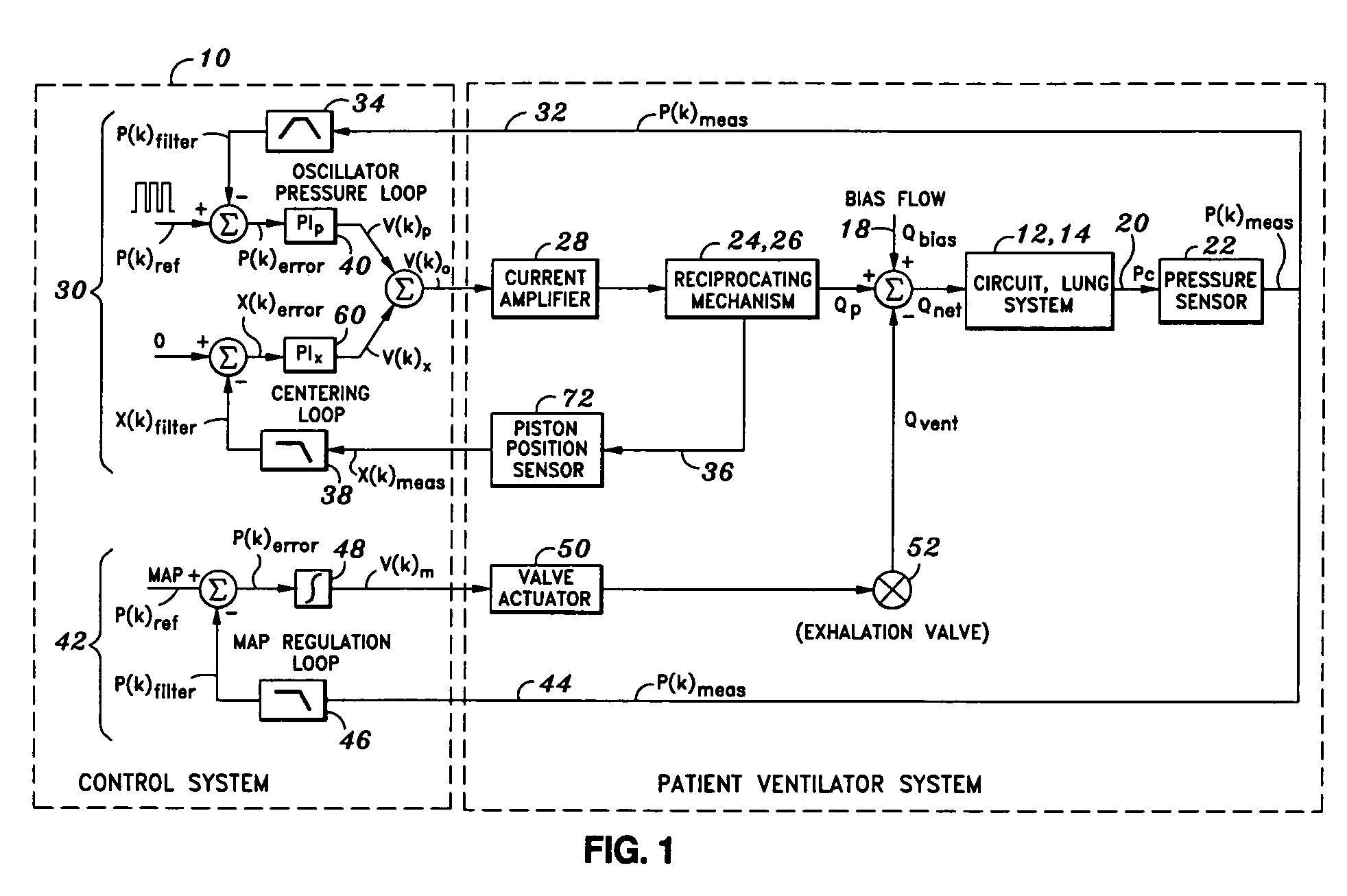

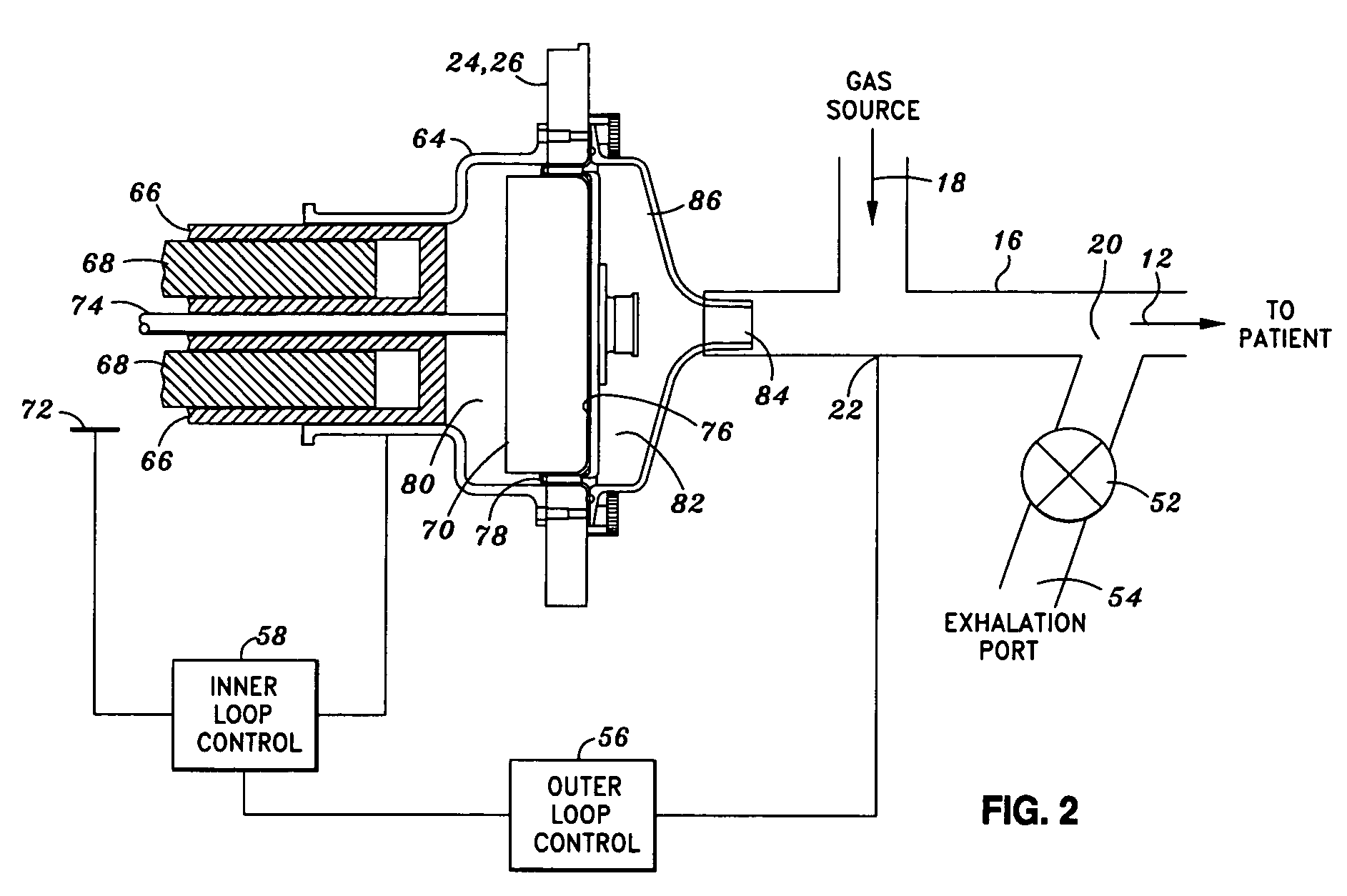

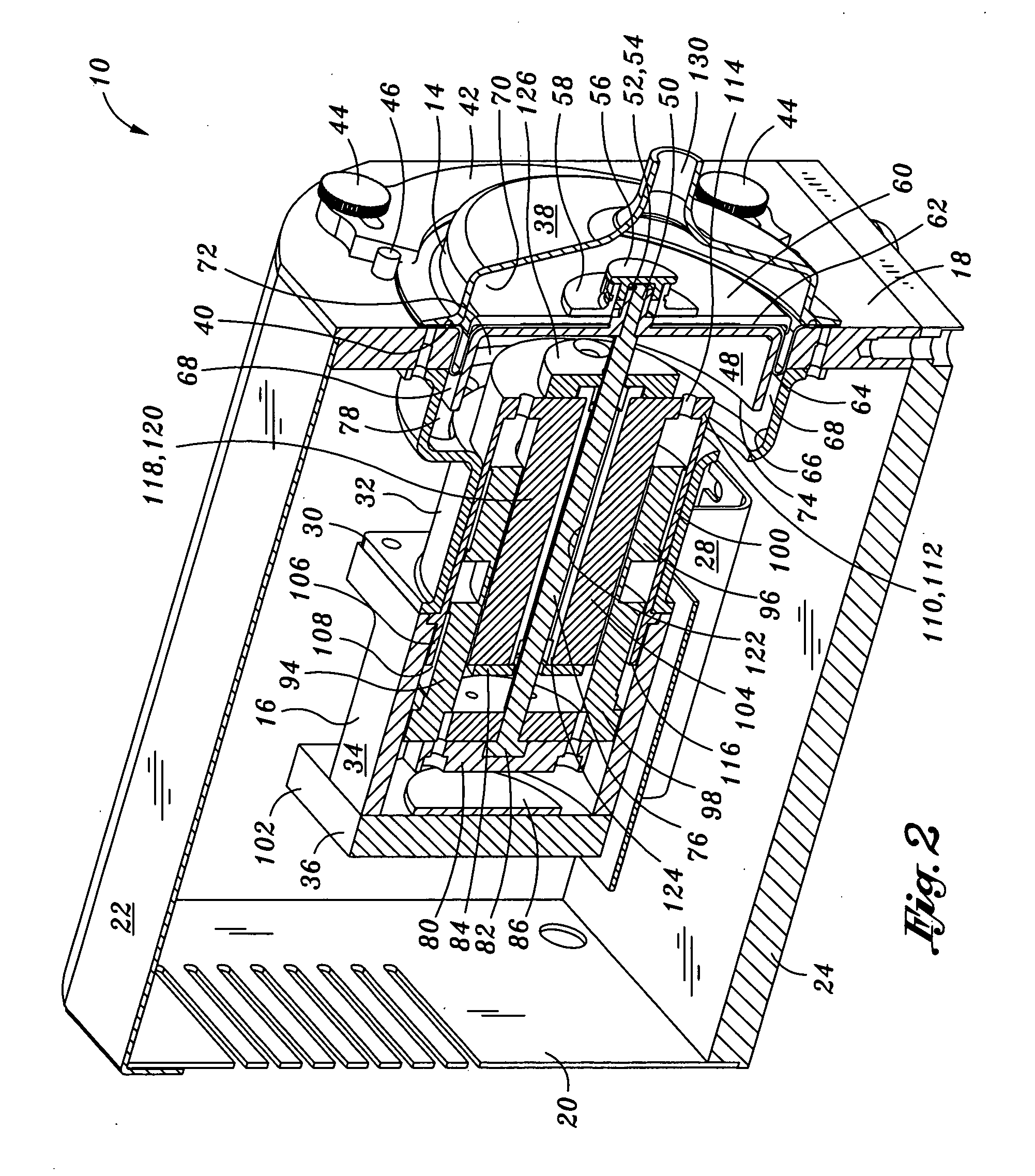

Closed loop control system for a high frequency oscillation ventilator

ActiveUS20070215154A1Smooth and precise controlRespiratorsOperating means/releasing devices for valvesControl systemClosed loop

A control system for a high frequency oscillating ventilator (HFOV) includes and oscillator controller and a mean airway pressure (MAP) controller. The HFOV includes a reciprocating piston which is adapted to generate positive and negative pressure waves for delivery to a patient airway. The oscillator controller comprises a pair of closed loop control circuits including an oscillator pressure loop and a centering loop which are collectively adapted to regulate frequency and amplitude of piston reciprocations and centering of the piston. The MAP controller comprises a closed loop control circuit that is adapted for regulating MAP at the patient utilizing feedback in the form of patient circuit pressure. Likewise, the oscillator controller utilizes patient circuit pressure as well as piston displacement feedback in order to regulate movement of the piston.

Owner:VYAIRE MEDICAL 211 INC

Closed loop control system for a high frequency oscillation ventilator

A control system for a high frequency oscillating ventilator (HFOV) includes and oscillator controller and a mean airway pressure (MAP) controller. The HFOV includes a reciprocating piston which is adapted to generate positive and negative pressure waves for delivery to a patient airway. The oscillator controller comprises a pair of closed loop control circuits including an oscillator pressure loop and a centering loop which are collectively adapted to regulate frequency and amplitude of piston reciprocations and centering of the piston. The MAP controller comprises a closed loop control circuit that is adapted for regulating MAP at the patient utilizing feedback in the form of patient circuit pressure. Likewise, the oscillator controller utilizes patient circuit pressure as well as piston displacement feedback in order to regulate movement of the piston.

Owner:VYAIRE MEDICAL 211 INC

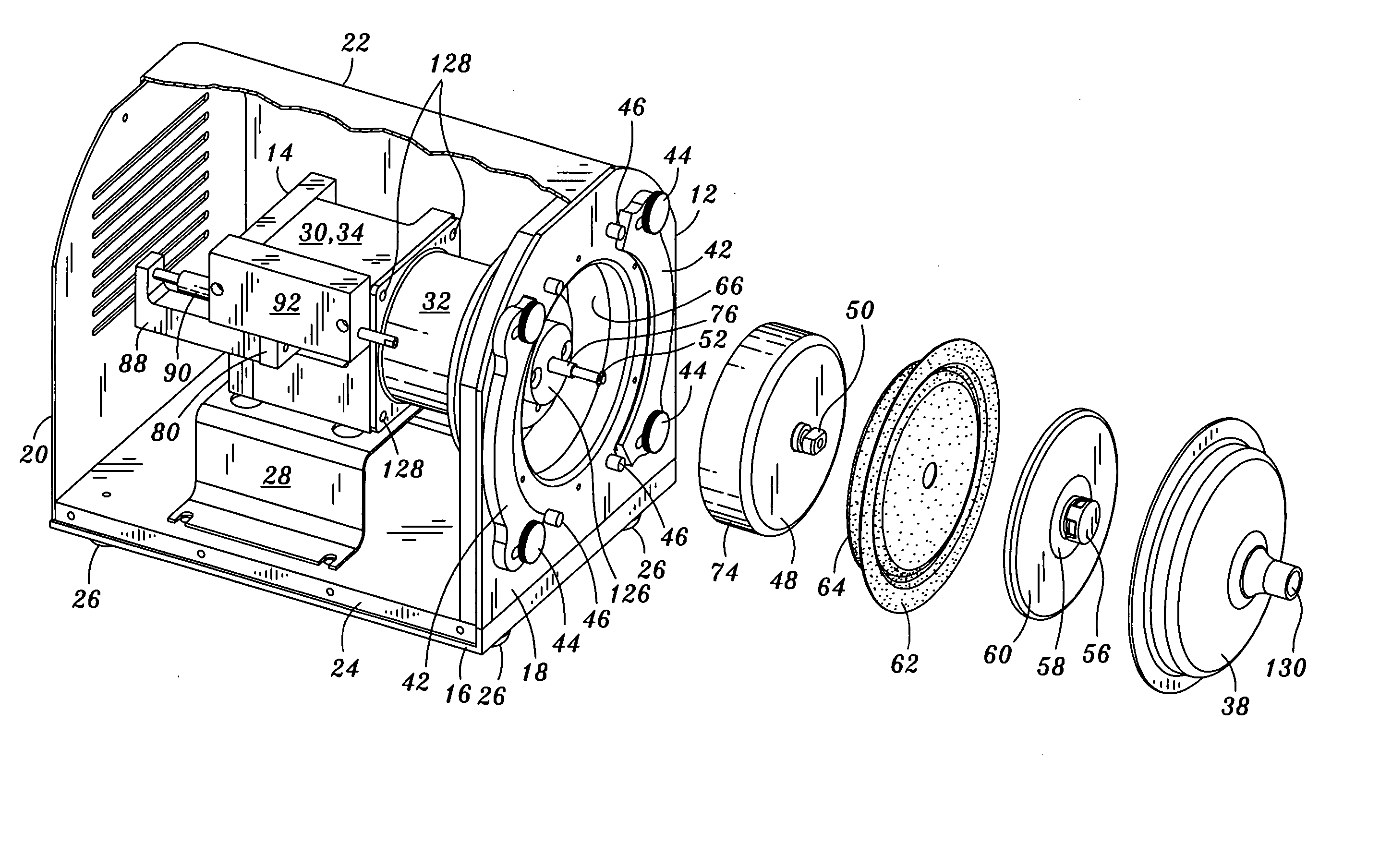

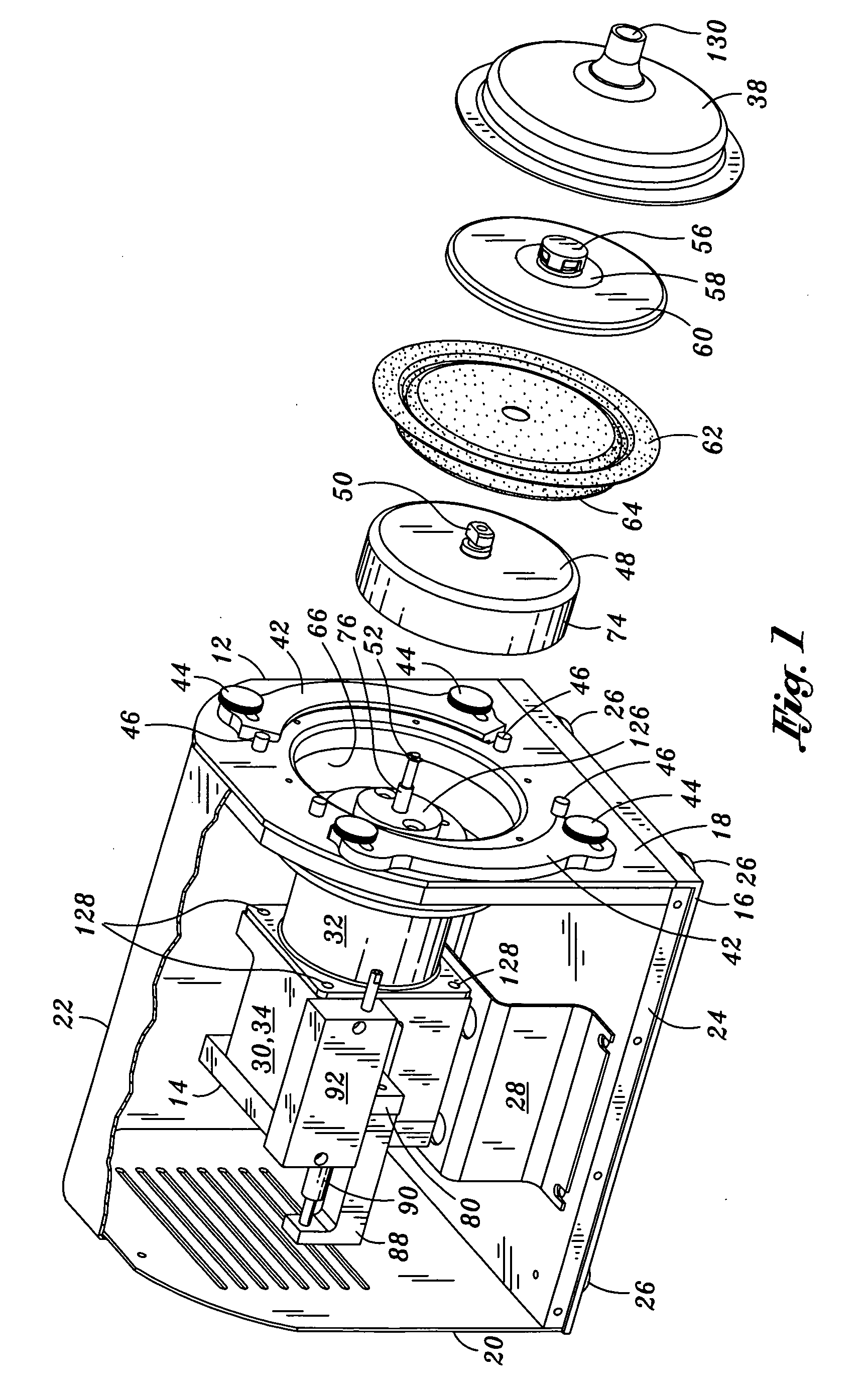

High frequency oscillator ventilator

ActiveUS20070101999A1Great noise can be producedReduce noiseTracheal tubesFlexible member pumpsReciprocating motionControl theory

Provided is a high frequency oscillating ventilator comprising a housing assembly, a linear actuator, a linear coil, a piston mounted on a pushrod, a diaphragm dividing a housing into a first and second side and having an opening formed on the second side that is fluidly connected to the patient's airway for delivering gas thereto. The linear actuator is fixedly mounted to the housing assembly and has a linear coil coaxially disposed therewithin. A pushrod supports the linear coil on the linear actuator to allow relative axially sliding therebetween. The piston is directly mounted to the diaphragm such that reciprocation thereof as effectuated by the linear coil cooperating with the linear actuator alternately produces positive and negative pressure waves in the gas in the patient's airway.

Owner:VYAIRE MEDICAL 211 INC

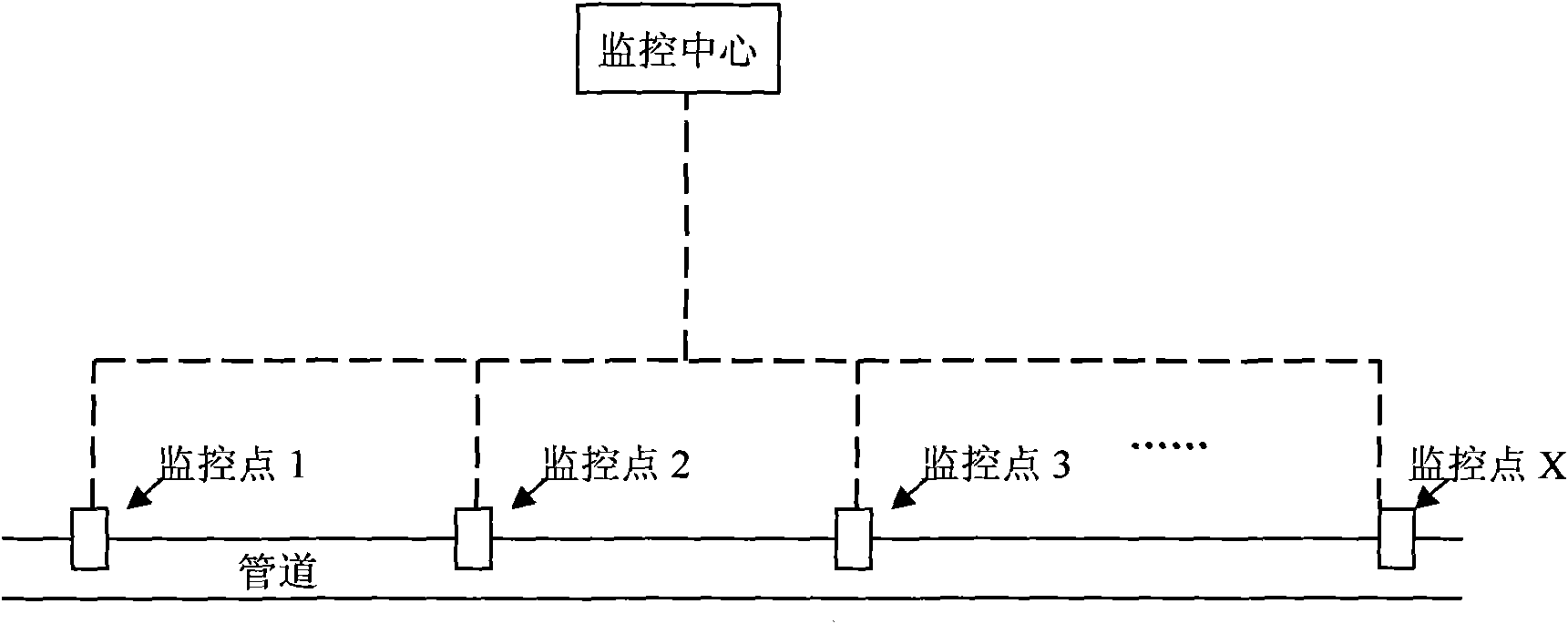

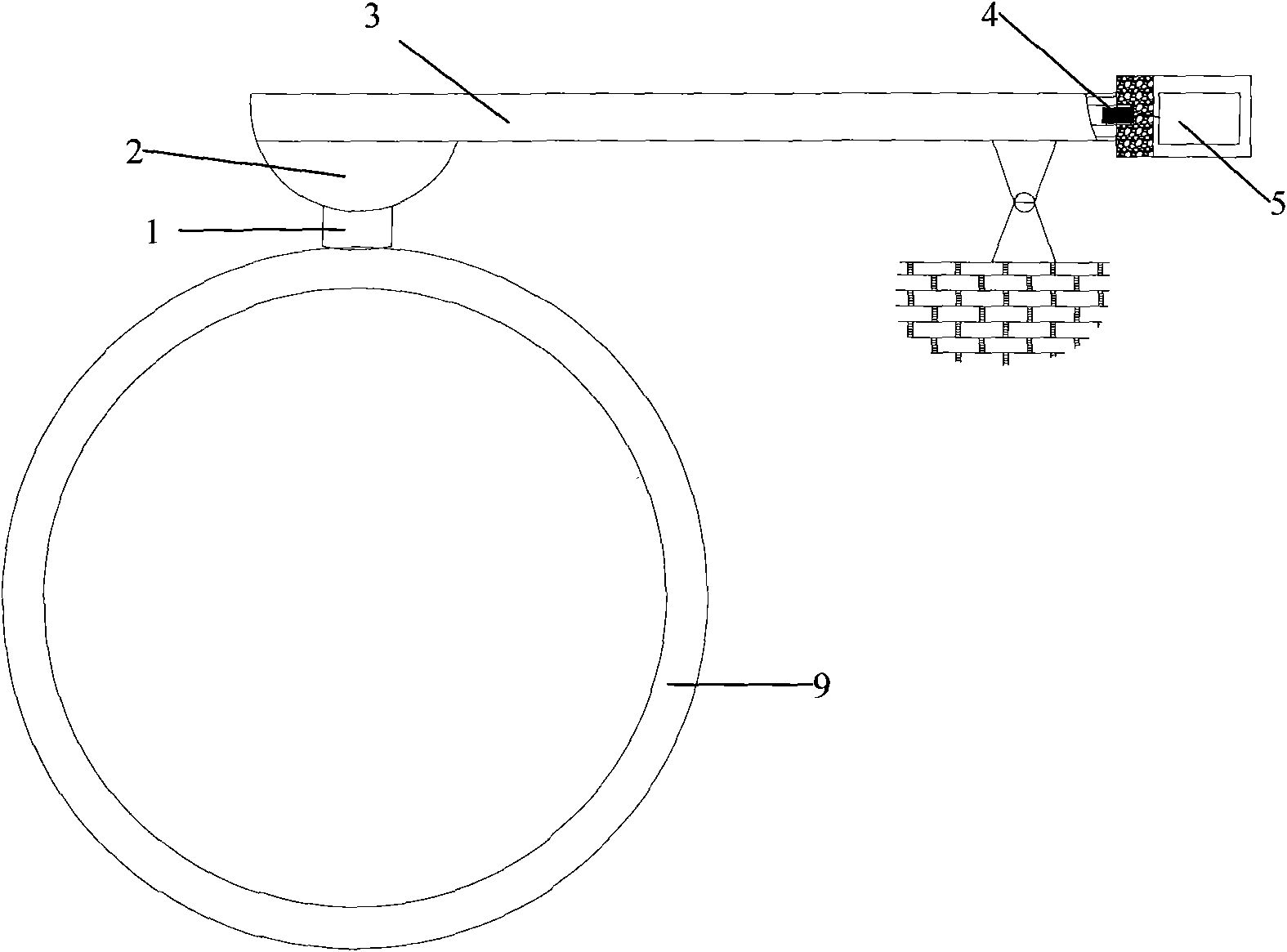

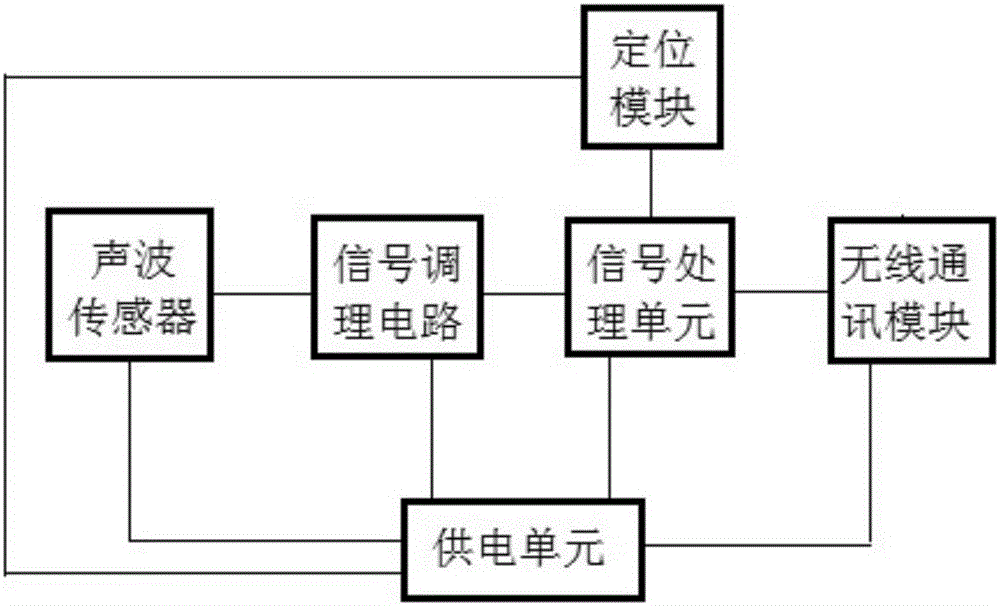

Non-intrusive pipeline real-time monitoring, prewarning and fault locating system

InactiveCN103245454AReflect real-timeEasy to usePipeline systemsFluid pressure measurement by acoustic meansEngineeringTemperature monitoring

The invention discloses a non-intrusive pipeline real-time monitoring, prewarning and fault locating system, and belongs to the technical field of pipeline system temperature and pressure monitoring, and pipeline system fault diagnosis. The method adopted by the invention comprises the following three aspects: temperature and pressure real-time monitoring, prewarning, and fault locating; the pressure monitoring and the temperature monitoring adopt non-intrusive measuring methods, the pressure is monitored by adopting an ultrasonic non-invasive measuring method, the temperature is monitored by adopting a traditional temperature sensor non-invasive measuring method, and sensors for pressure monitoring and temperature monitoring are mounted on the outer wall of a pipeline; a design database is used for prewarning a fault signal; and a negative-pressure wave leak detection method is adopted for locating a fault in a pipeline system.

Owner:SOUTHWEST PETROLEUM UNIV

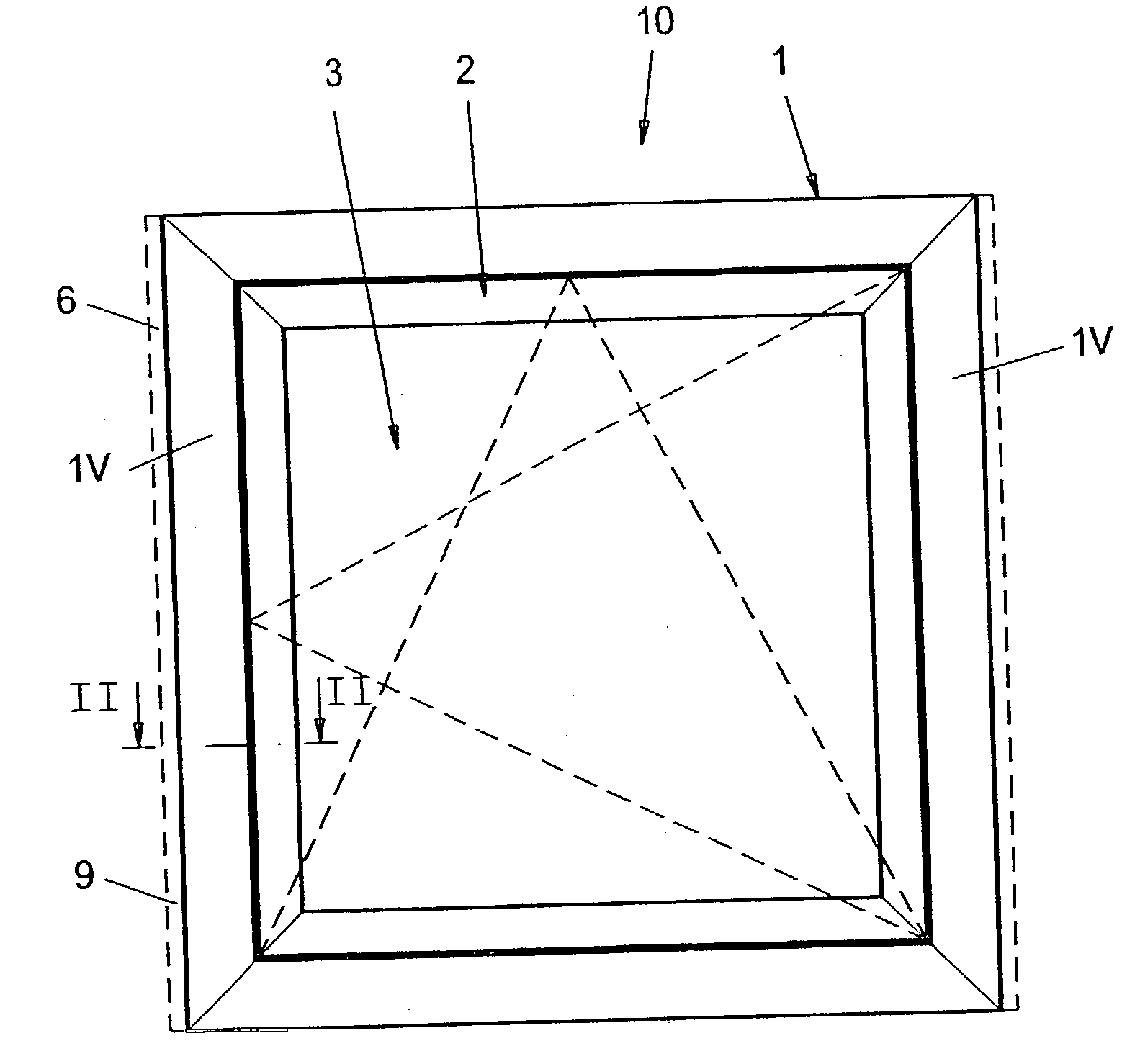

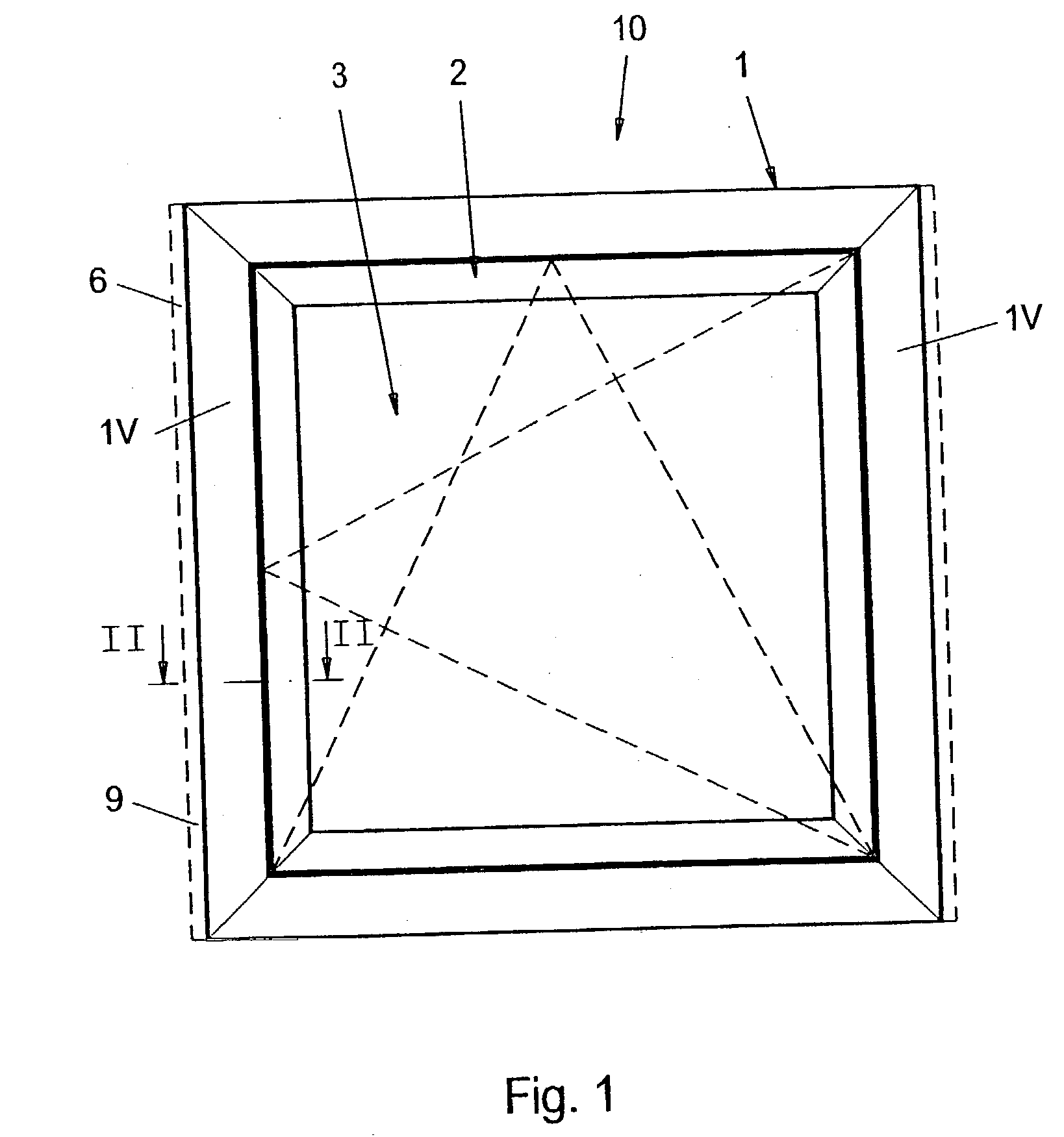

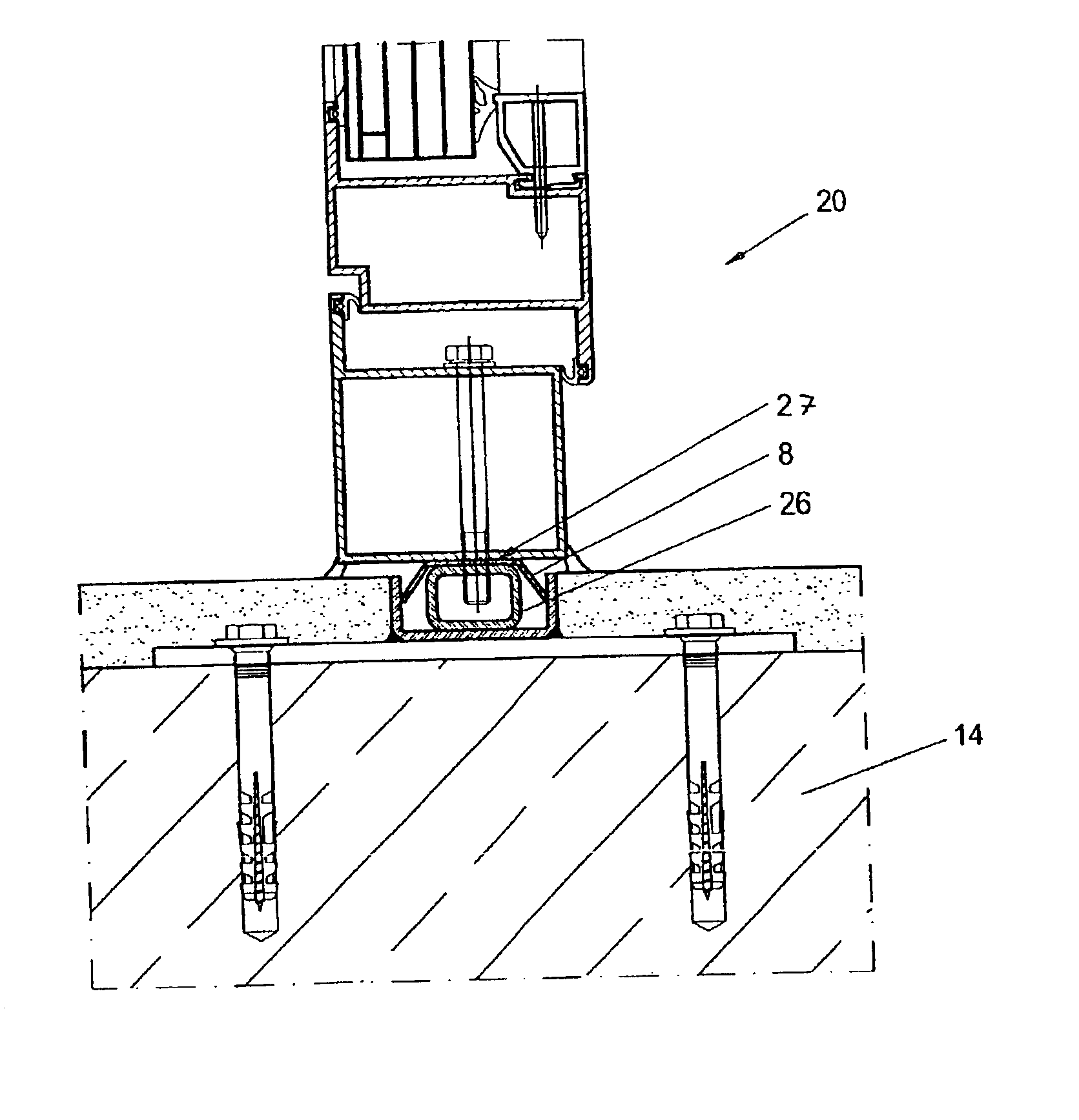

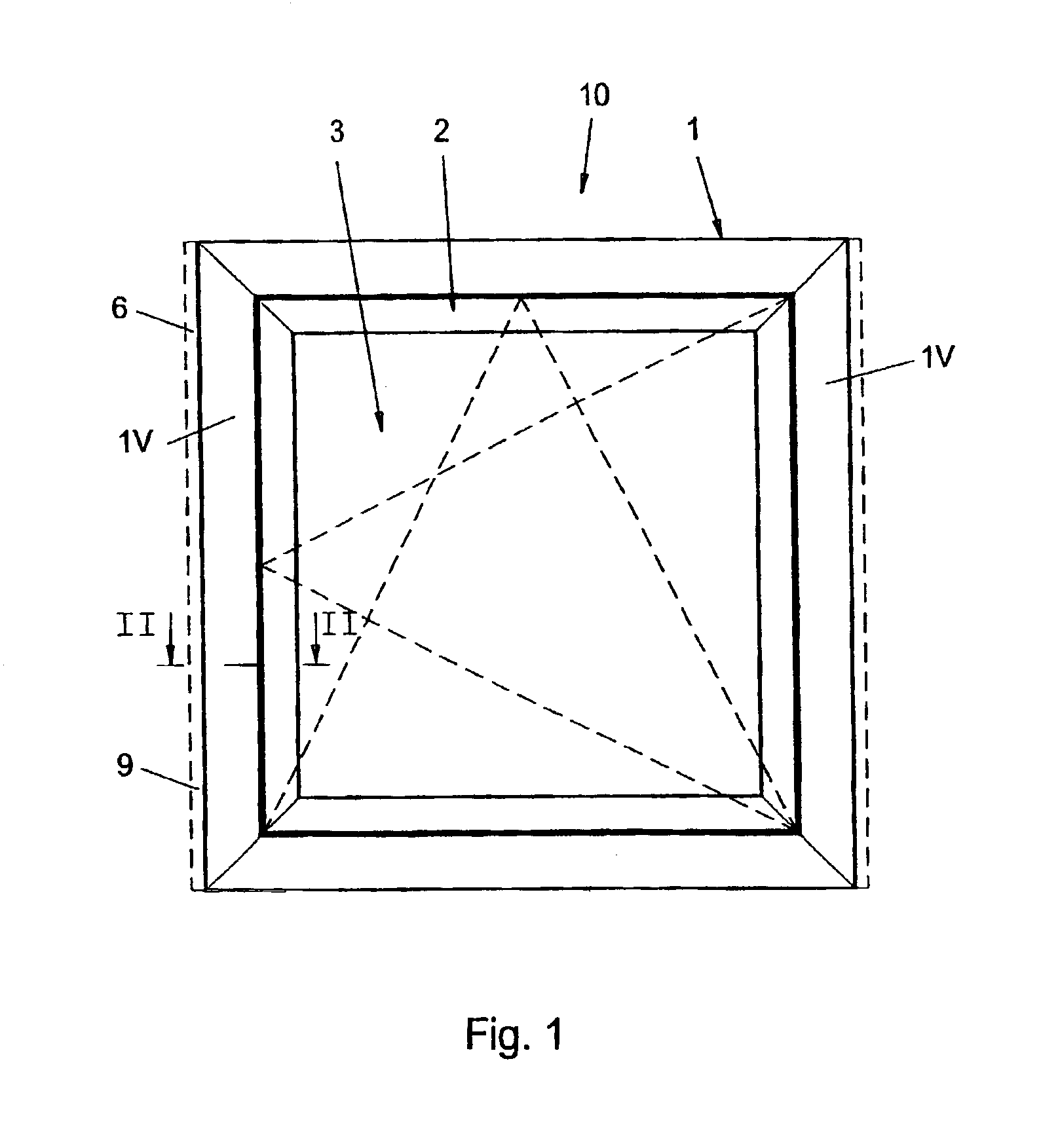

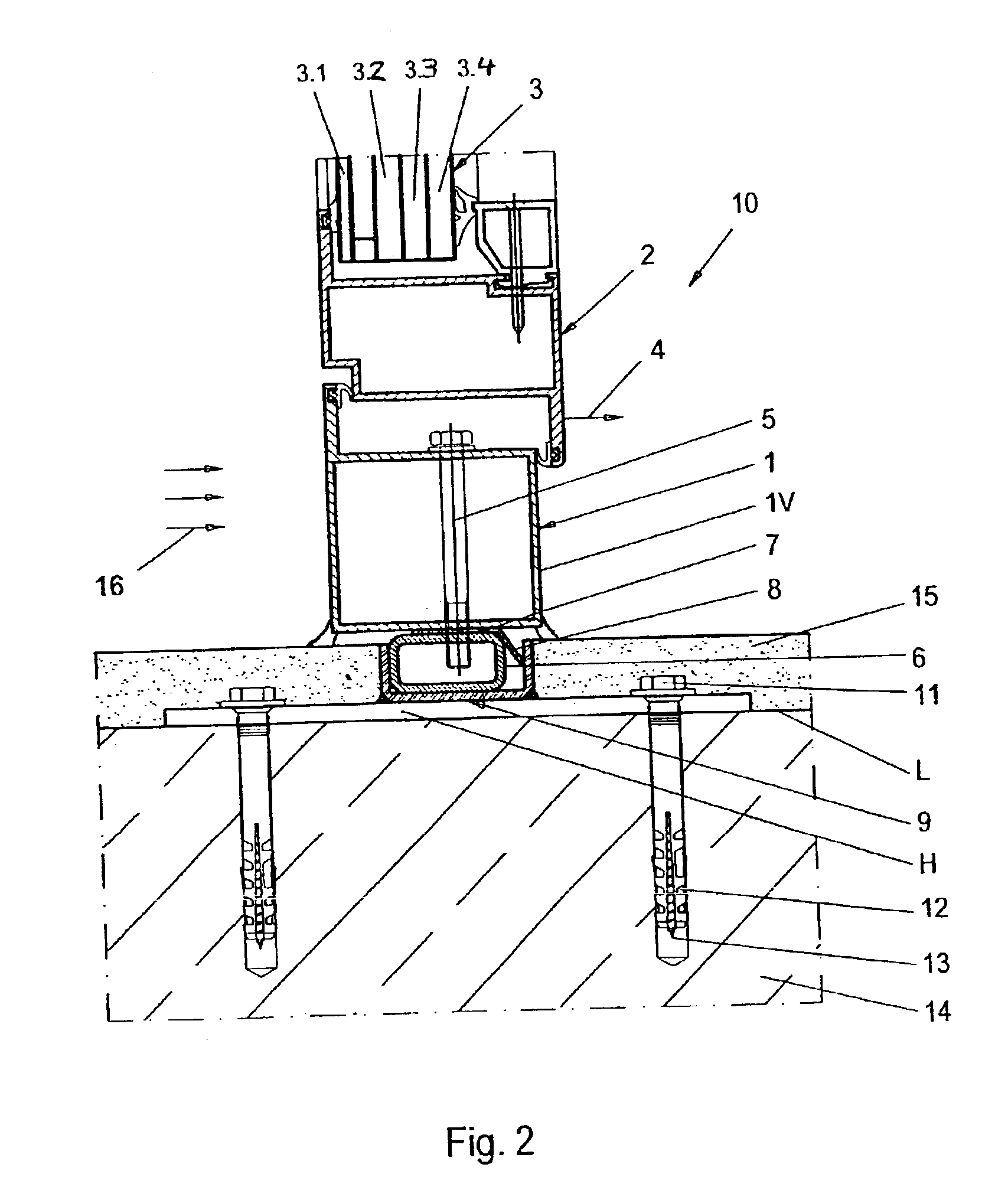

Building closure, such as a door or window, constructed to resist an explosive blast

InactiveUS20030208970A1Improved resistance characteristicsReduce complexityArtificial islandsFrame fasteningMetal stripsAbsorbed energy

An opening in a building wall is closed by a building closure such as a window or door. A mounting part of the closure arrangement is received in a space between two countersupport surfaces formed by a U-channel or opposite L-members that protrude perpendicularly from the sill or jamb surface of the wall bounding the opening. Mounting brackets secure the U-channel or L-members to the wall. On one or both sides, a respective damping element is interposed between the mounting part and the respective adjacent countersupport surface. The damping element may be a plastically deformable metal strip. When an explosion force acts on the closure arrangement, the damping element is first plastically deformed to absorb energy, before the remaining force is transmitted into the building wall. The two damping elements on opposite sides damp forces from the positive and negative pressure waves of the explosion.

Owner:SALZER SICHERHEITSTECHN

System and method for monitoring pipeline vibration

InactiveCN101603630AOvercoming technical deficienciesReduce distractionsPipeline systemsFrequency spectrumEngineering

The invention provides a system and a method for monitoring pipeline vibration. The system comprises a plurality of pipeline vibration monitoring devices arranged on pipeline monitoring points and a central control device connected with each pipeline vibration monitoring device, wherein each pipeline vibration monitoring device comprises a detection device, a conversion device, a connection device, an acquisition device and an analysis processing device which are connected in turn. The method comprises the following steps: establishing a background frequency spectrum; acquiring and processing signals; determining event attribute; determining a fault point and giving an alarm. The method has the advantages that the method detects pipeline state by acquiring pipeline noises, and does not have the disadvantages of a negative pressure wave detection method which is susceptible to low pressure, temperature change and transported substance density; moreover, as for noise influence, the method is only sensitive to noises with the intensity and frequency equivalent to those of an occurring event, and noises at other frequency do not generate greater influence on the method.

Owner:SHANGHAI NENGXIN GASOLINEEUM TECH SERVICE

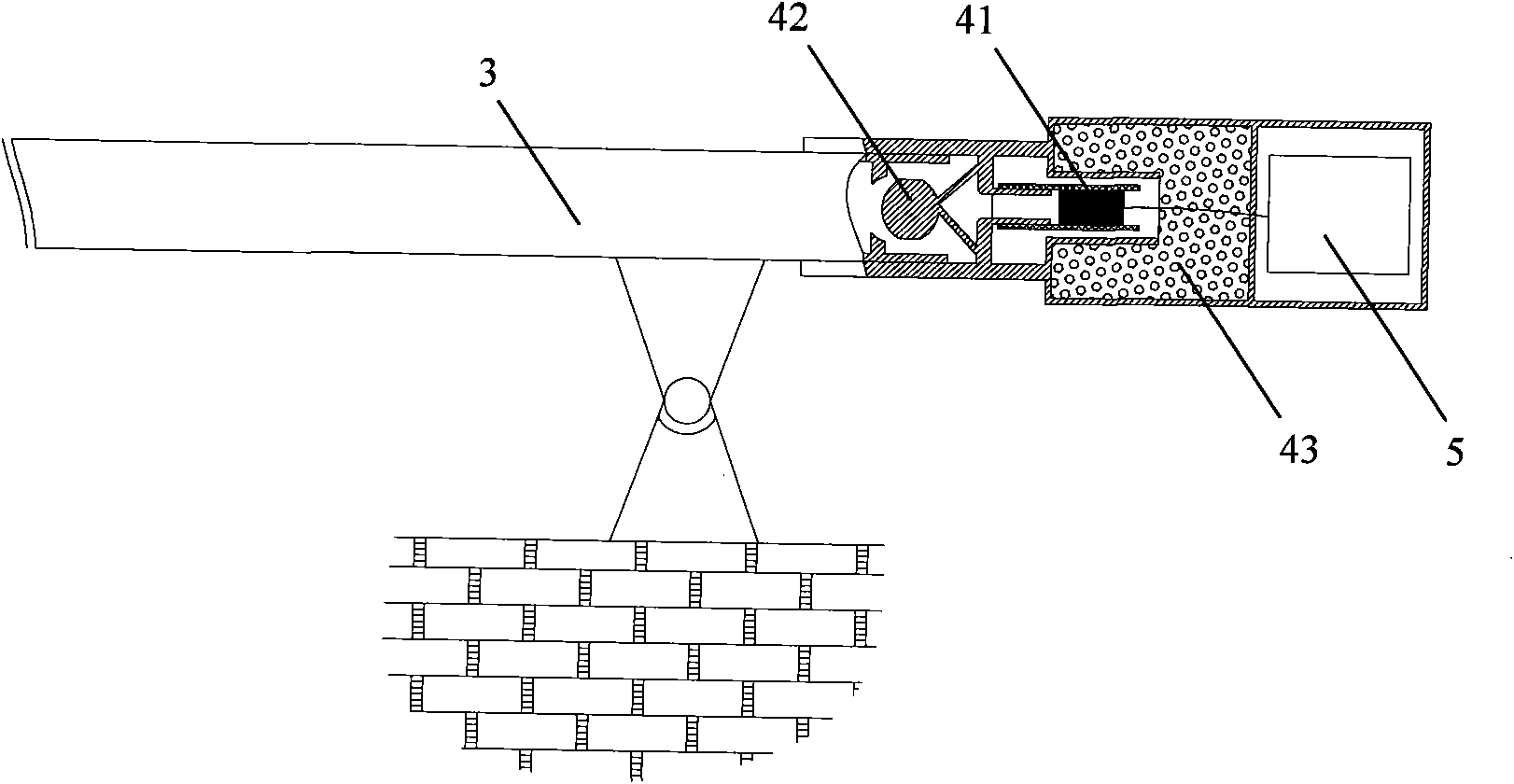

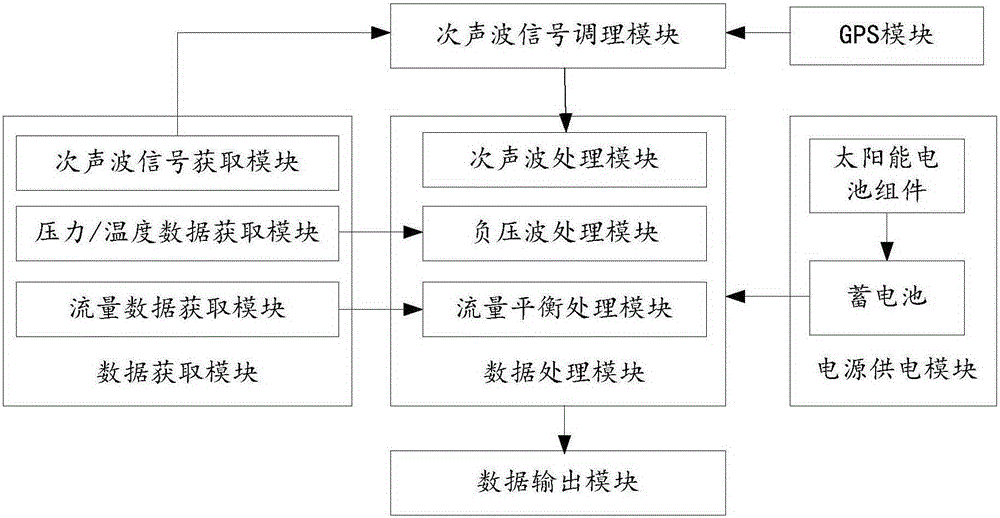

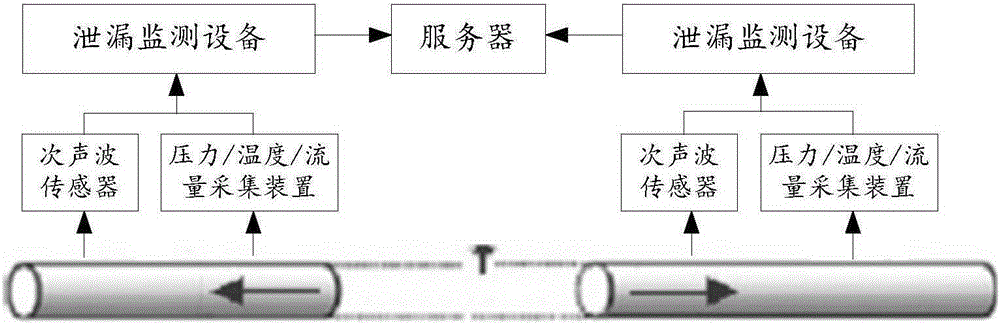

Leakage monitoring system, method and device for pipeline and server

InactiveCN105156905ATimely, fast and accurate positioningImprove leak alarm ratePipeline systemsTraffic capacityInfrasonic waves

The invention relates to a leakage monitoring system, method and device for a pipeline and a server. The method includes the steps that infrasonic signal, pressure, temperature and flow data in the pipeline are obtained; infrasonic leakage detection is performed according to an infrasonic signal so that the leakage state and the leakage occurrence time of the pipeline can be obtained; negative pressure wave leakage detection is performed according the pressure and temperature data so that the leakage state and the leakage occurrence time of the pipeline can be obtained; flow balance leakage detection is performed according to the flow data so that the leakage state of the pipeline can be obtained; the leakage occurrence time obtained according to infrasonic leakage detection and / or leakage occurrence time obtained according to negative pressure wave leakage detection are / is output to the server. The leakage monitoring device integrating the three leakage monitoring methods achieved through infrasonic waves, negative pressure waves and flow balance can achieve the effects that the methods are complementary, the leakage alarming rate is increased, and the error alarming rate and the missing alarming rate are reduced.

Owner:NANJING SHENGHONG YITING NETWORK TECH CO LTD

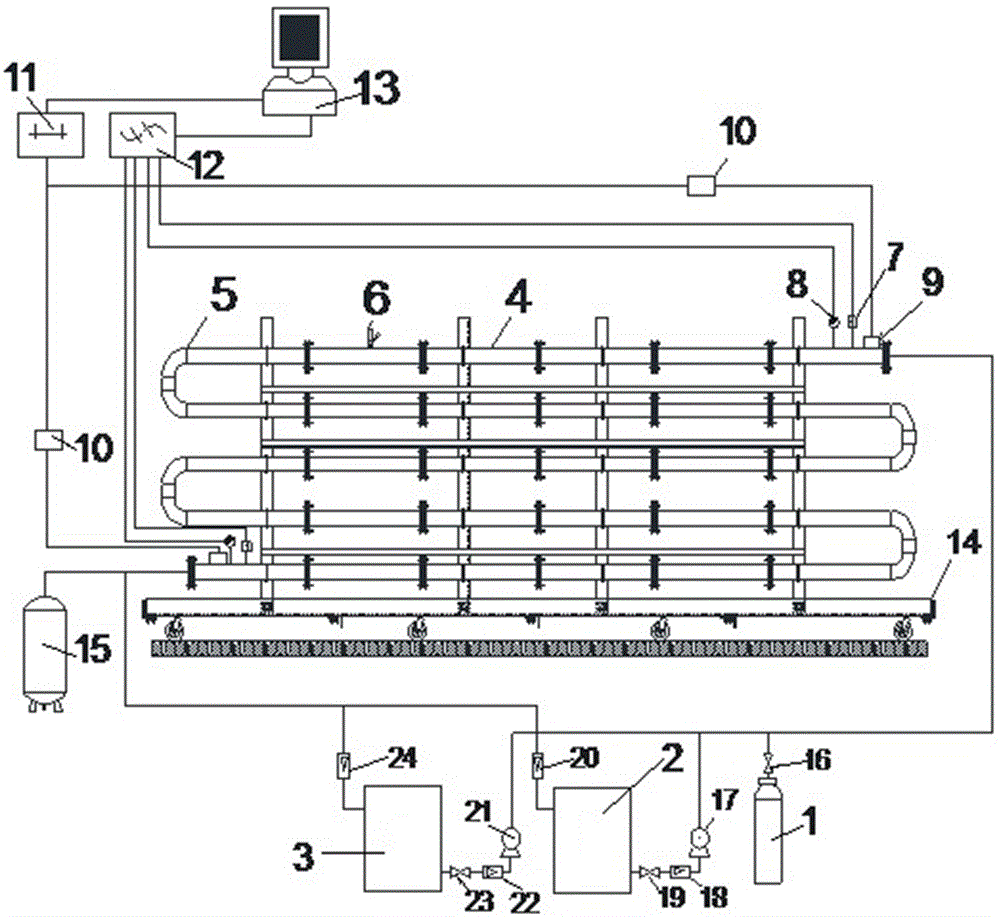

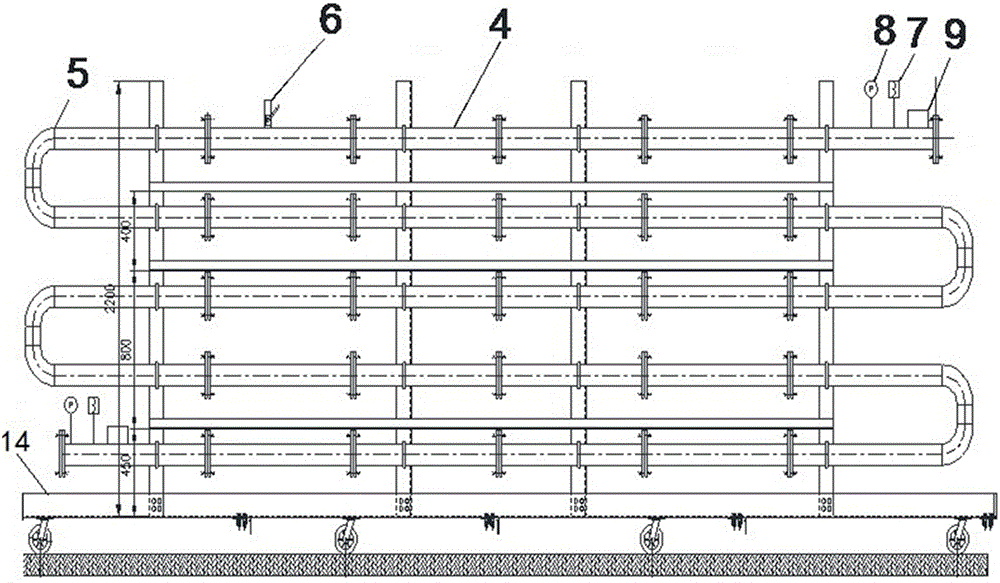

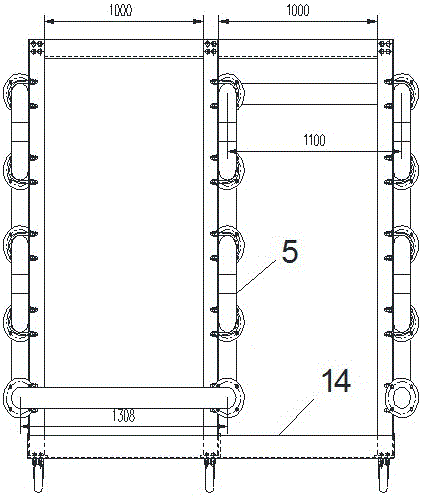

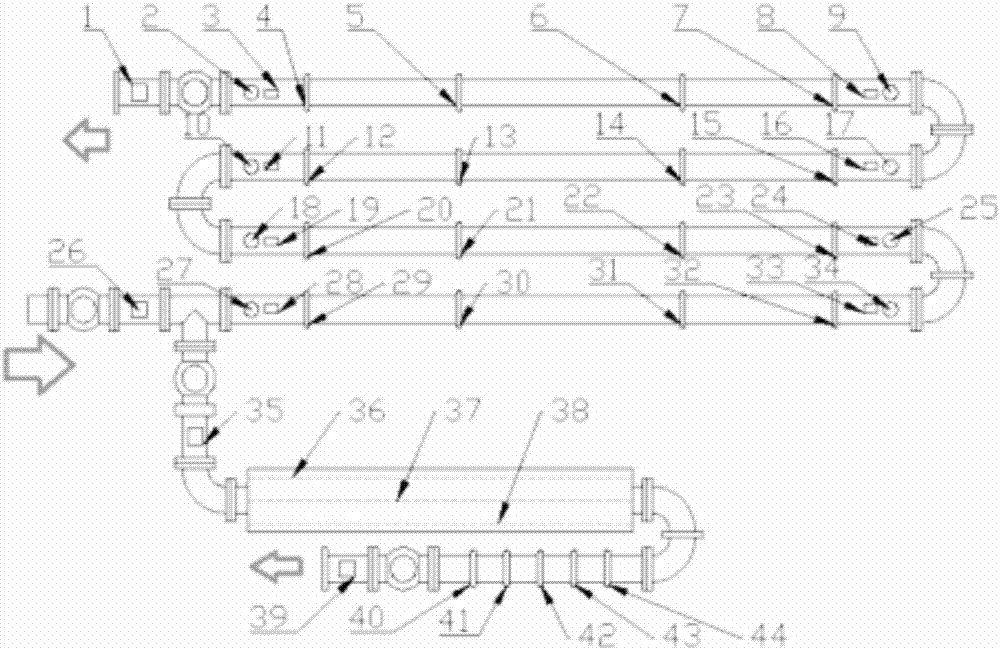

Pipeline leakage detecting and positioning experimental system and detection method thereof

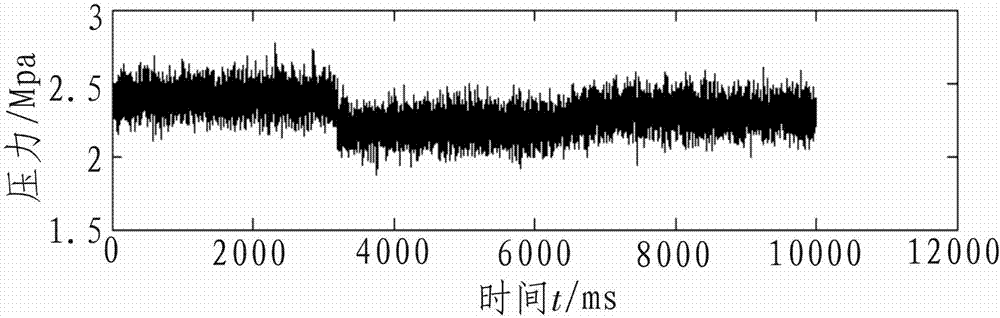

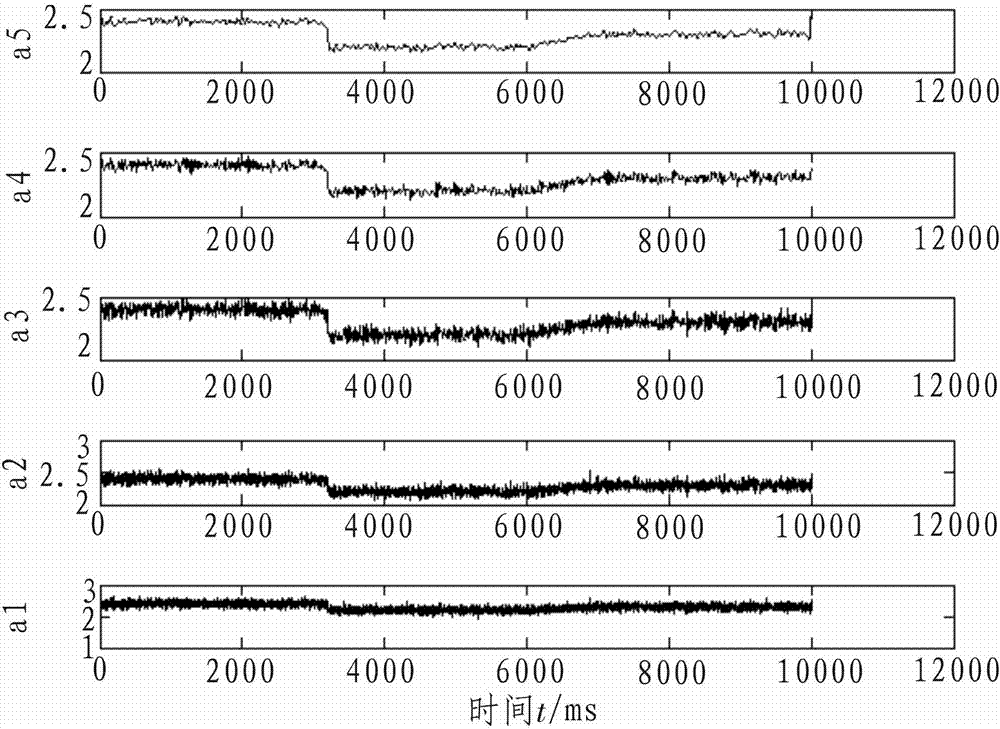

The invention relates to a experimental system for scientific research, in particular to a pipeline leakage detecting and positioning experimental system and a detection method thereof, and the system is used for realizing detection and positioning experiments on leakage of long-distance gas conveying pipelines and long-distance liquid conveying pipelines by virtue of different leakage detection methods. The pipeline leakage detecting and positioning experimental system comprises a conveying pipeline, a medium conveying device, a negative-pressure wave detection device and an acoustic emission detection device; the medium conveying device comprises a conveying pipeline, a medium container, a surge tank, a water pump, an oil pump, a water tank outlet flowmeter, a water tank inlet flowmeter, an oil tank outlet flowmeter, an oil tank inlet flowmeter, a nitrogen cylinder outlet valve, a water tank outlet valve and an oil tank outlet valve; a bent part of the conveying pipeline is of a U-shaped pipeline, and the rest part of the conveying pipeline is a straight pipeline section; the negative-pressure detection device comprises a pressure sensor, an electromagnetic flowmeter, a data acquisition card and a computer; the acoustic emission detection device comprises an acoustic emission sensor, a signal preamplifier, an acoustic emission detection instrument and a computer; the acoustic emission detection instrument is used for processing signals, and transmitting the signals to the computer of the acoustic emission detection instrument so as to analyze the signals.

Owner:NANJING TECH UNIV

Building closure, such as a door or window, constructed to resist an explosive blast

InactiveUS6922957B2Improved resistance characteristicsReduce complexityFrame fasteningWindow/door framesMetal stripsAbsorbed energy

An opening in a building wall is closed by a building closure such as a window or door. A mounting part of the closure arrangement is received in a space between two countersupport surfaces formed by a U-channel or opposite L-members that protrude perpendicularly from the sill or jamb surface of the wall bounding the opening. Mounting brackets secure the U-channel or L-members to the wall. On one or both sides, a respective damping element is interposed between the mounting part and the respective adjacent countersupport surface. The damping element may be a plastically deformable metal strip. When an explosion force acts on the closure arrangement, the damping element is first plastically deformed to absorb energy, before the remaining force is transmitted into the building wall. The two damping elements on opposite sides damp forces from the positive and negative pressure waves of the explosion.

Owner:SALZER SICHERHEITSTECHN

Method for locating leakage position of ore pulp conveying pipe

InactiveCN105135216ARealize real-time online monitoringReduce workloadPipeline systemsInternal pressurePressure difference

The invention provides a method for locating the leakage position of an ore pulp conveying pipe, relates to a conveying control method, in particular to the method for determining the leakage position when the conveying pipe is blocked in the long-distance iron concentrate ore pulp conveying process. According to the method, by the adoption of a negative-pressure wave method, when the iron concentrate pulp pipe generates leakage, concentrate pulp at a leakage point flows away rapidly due to the difference between the internal pressure and the external pressure of the pipe, and pressure drops down; liquid on both sides of the leakage point is supplemented to the leakage point due to the pressure difference; the above processes are sequentially passed to an upstream pump station and a downstream pump station through the concentrate pulp pipe, that is, negative-pressure waves propagating at a certain speed are generated at the leakage point; and the position of the leakage point can be worked out according to the time difference generated when negative-pressure weaves generated at the leakage point are propagated to the upstream pump station and the downstream pump station and the propagation speed of the negative pressure waves in the pipe. The method has the beneficial effects of being less in required devices, low in operation cost, simple in operation and the like and is superior to an existing method for determining the leakage position of the pipe.

Owner:YUNNAN DAHONGSHAN PIPELINE

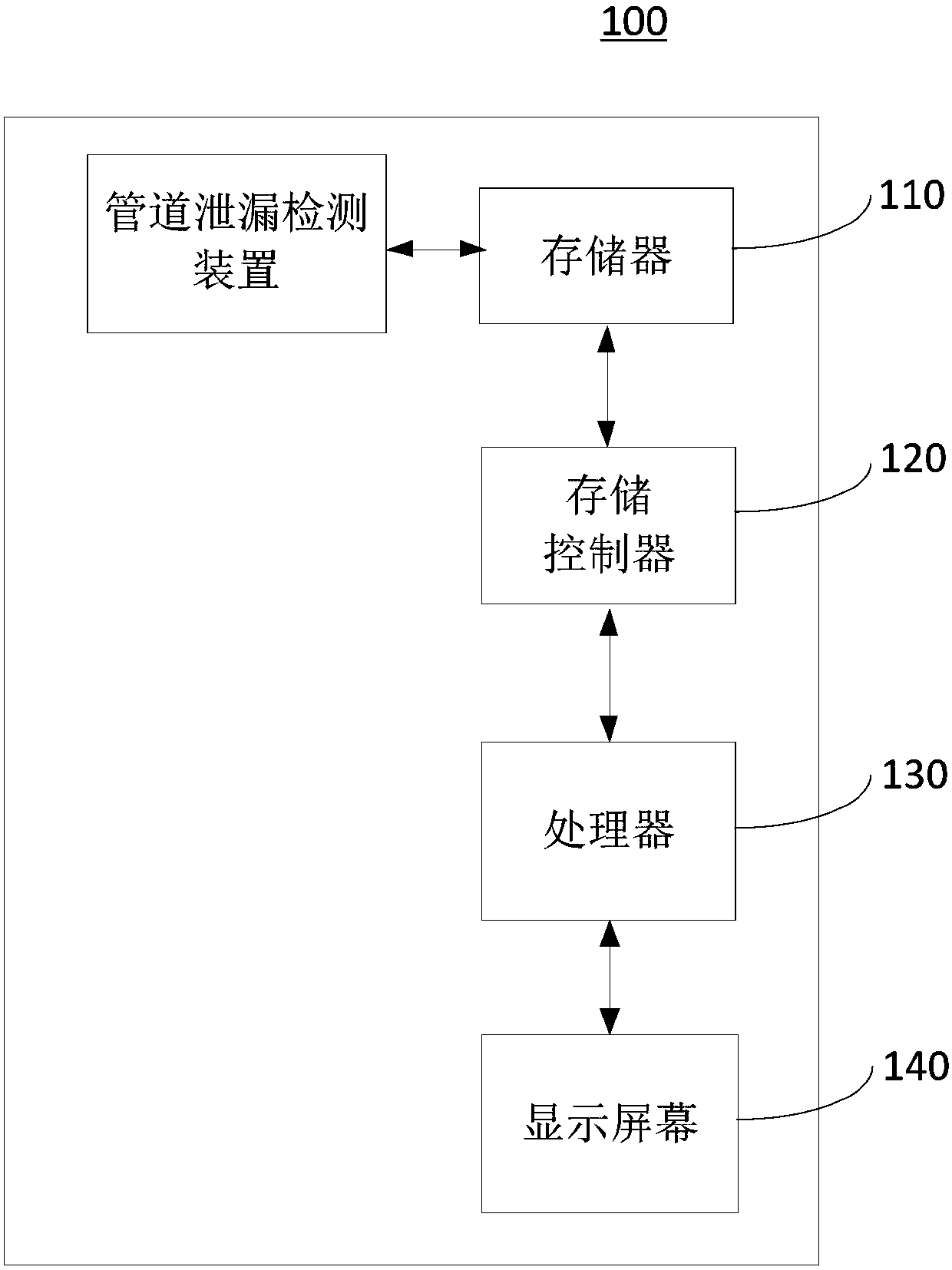

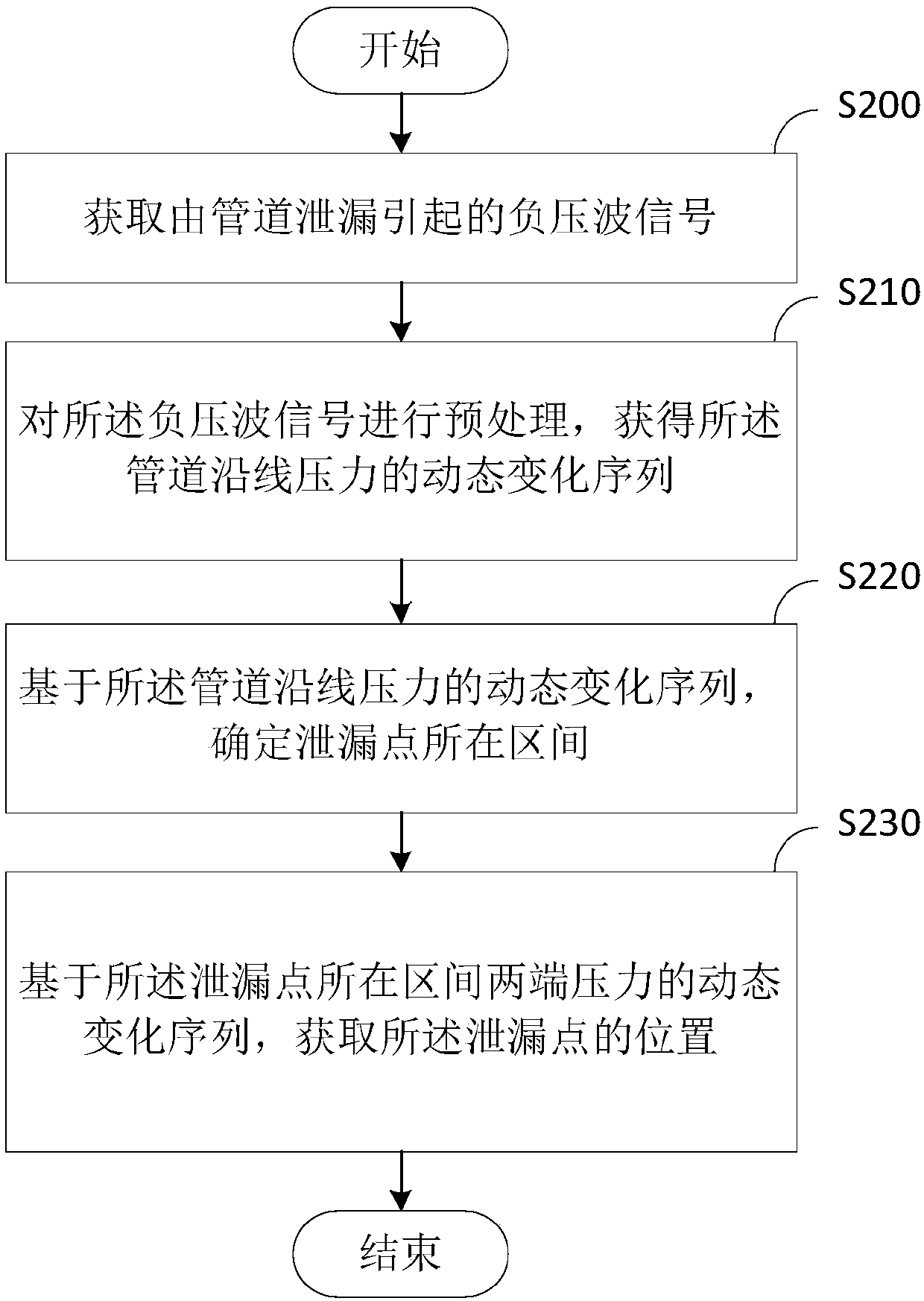

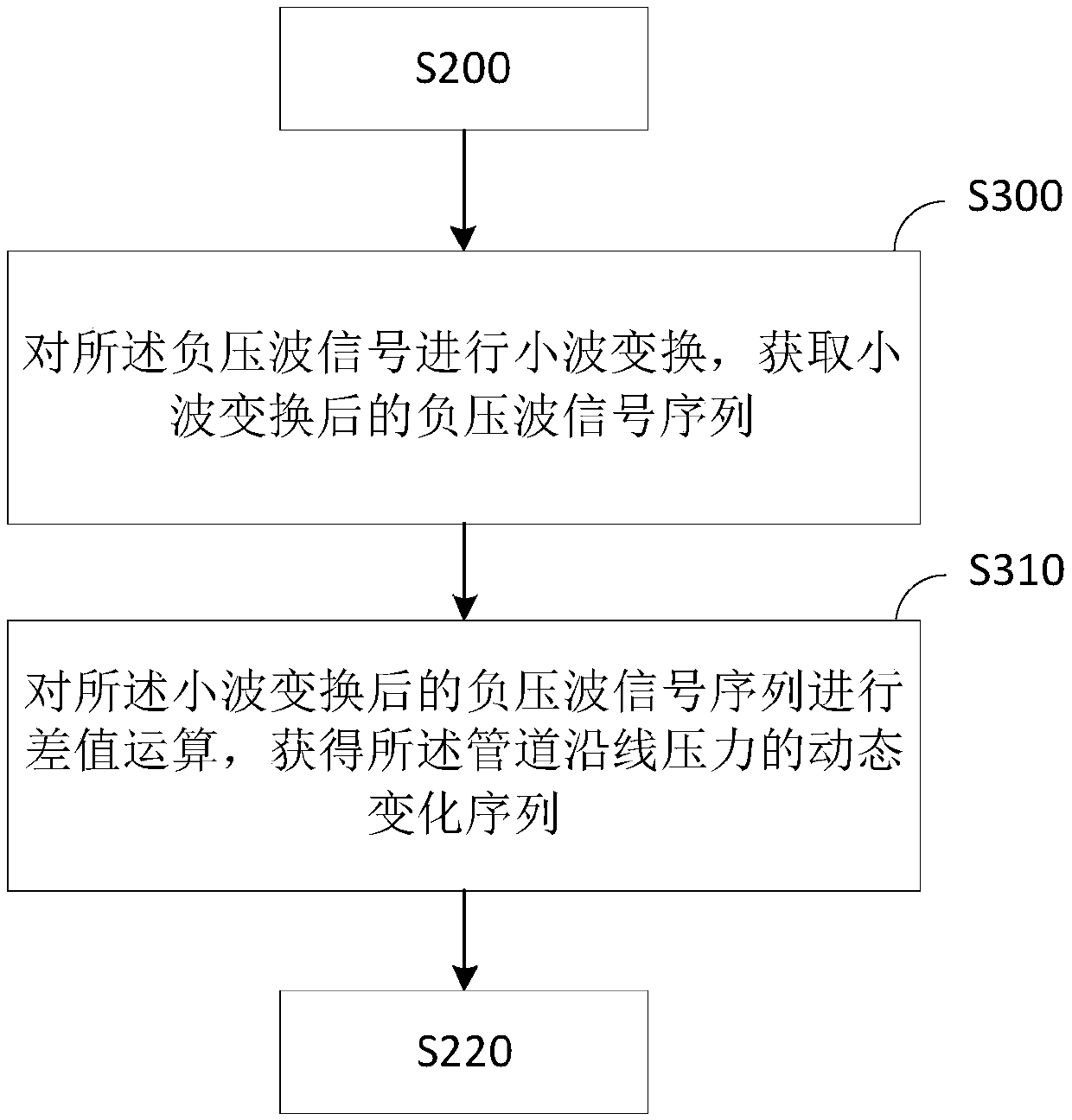

Pipeline leakage detection method and device

The invention provides a pipeline leakage detection method and device and relates to the field of pipeline leakage monitoring. The pipeline leakage detection method comprises the steps of obtaining anegative pressure wave signal caused by pipeline leakage; preprocessing the negative pressure wave signal to obtain the dynamic change sequence of pressure along a pipeline; determining the interval of a leakage point on the basis of the dynamic change sequence of pressure along the pipeline; and obtaining the position of the leakage point on the basis of dynamic change sequences of pressure at the two ends of the interval of the leakage point. According to the method and the device, the pipeline is detected in a segmented manner by multiple sensors arranged in the pipeline so as to determinethe interval of the leakage point, then the leakage point is positioned on the basis of the interval of the leakage point, the positioning precision is high, the site operability is high, and the method and the device can be widely applied to leakage detection of long oil and gas transmission pipelines and city water supply and heat supply pipelines.

Owner:LASER RES INST OF SHANDONG ACAD OF SCI

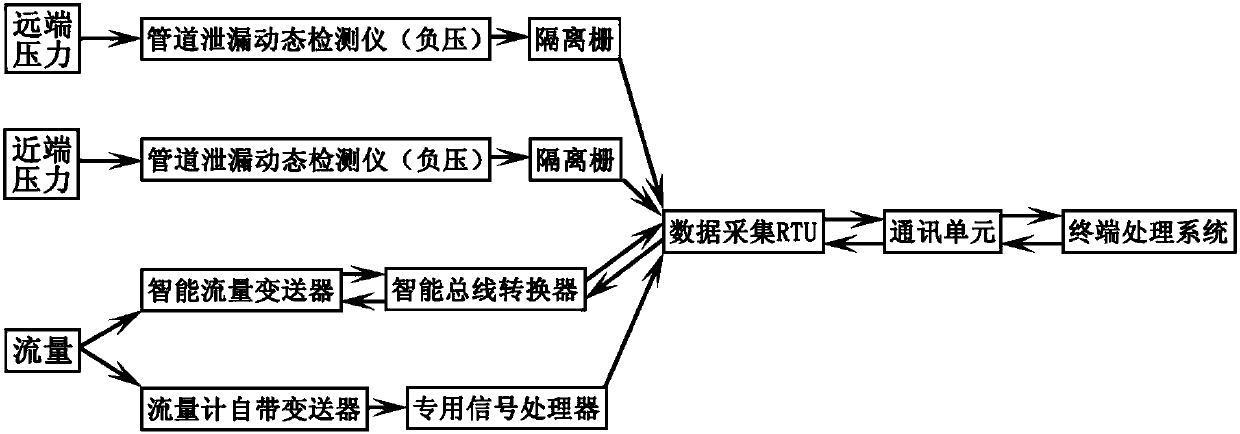

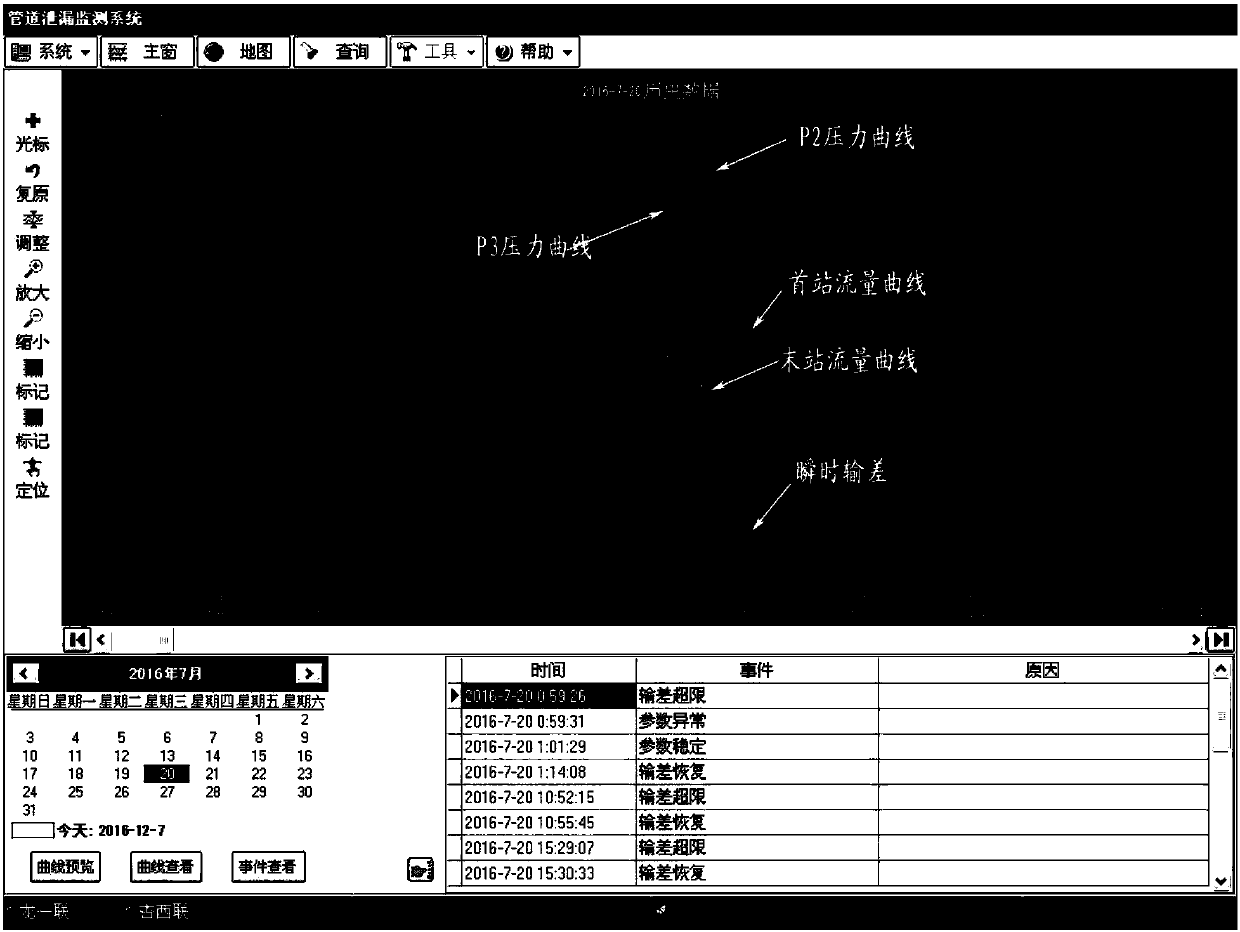

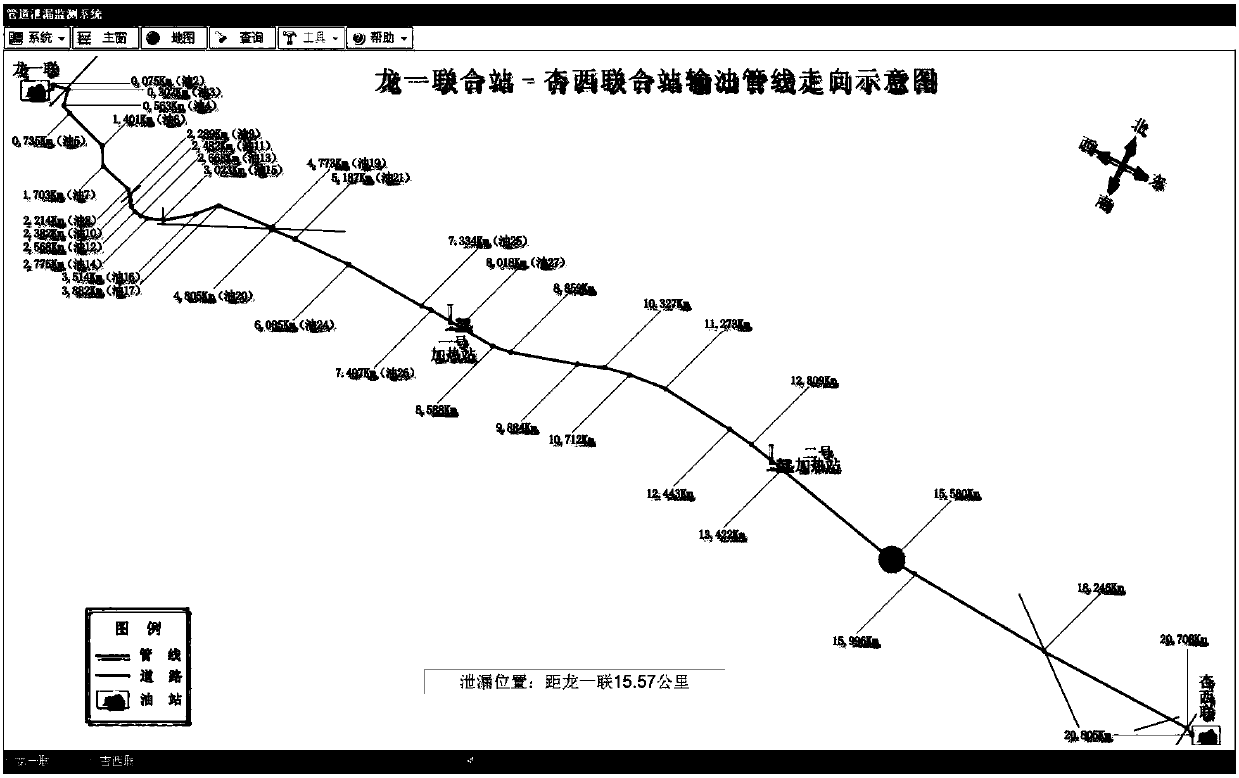

Oil conveying pipeline leakage monitoring method based on negative pressure wave method and flow trend method

ActiveCN108036201AHigh sampling processing speedHigh precisionPipeline systemsTraffic capacityCommunication unit

The invention discloses an oil conveying pipeline leakage monitoring method based on a negative pressure wave method and a flow trend method. The monitoring method is characterized in that a system monitoring terminal, data acquiring units, communication units, a field instrument and monitoring system software are arranged, wherein the field instrument comprises flow meters and pressure transmitters; the pressure transmitters are mounted at an outlet pipeline of the flow meter in an exit, and the pipeline between the pressure transmitters is not less than 20m; another two pressure transmittersare mounted at an inlet pipeline of the flow meter in an entrance, and the pipeline between the pressure transmitters is not less than 20m; the data acquiring units are mounted at the exit and the entrance and used for acquiring the station double pressure and flow data in real time and preprocessing the data; the communication units are mounted at the exit and the entrance and used for encapsulating the data processed by the data acquiring units and then transmitting to the system monitoring terminal. With the adoption of the method, the operation variation of a station can be accurately determined, thus the alarm caused by the operation in the station can be shielded or accurately promoted, so that the stability and the accuracy of a leakage monitoring system can be improved.

Owner:廊坊市蓝德采油技术开发有限公司

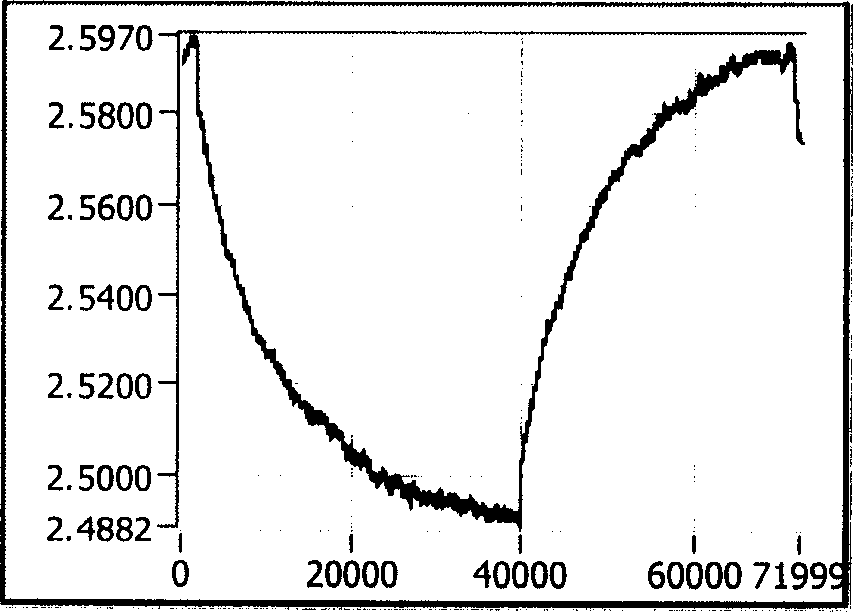

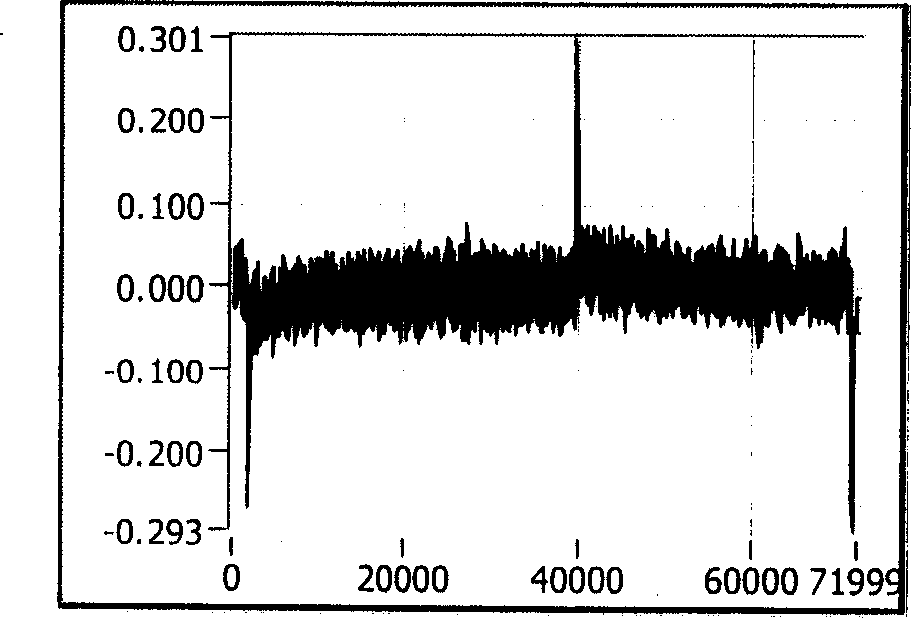

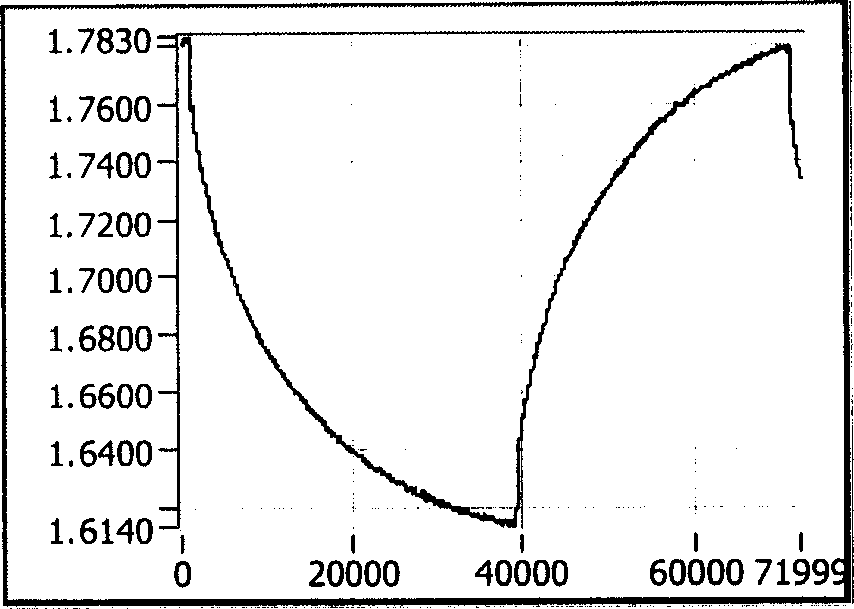

Method for detecting leakage of oil gas pipe based on pressure signal knee

InactiveCN1693865AFully automatedReduce false alarm rateMeasurement of fluid loss/gain rateSignal waveMeasurement point

The invention discloses an oil gas pipeline leakage detecting method based on pressure signal inflexion that belongs to pipeline monitoring technology. It includes the following steps: collecting the output value list of the entrance and exit of the pipeline from the pumping station pressure transmitter; sending to computer; taking conversion process to make the pressure signal wave mutation inflexion obvious; identifying the moment of the inflexion happening, and gaining time table; then, judging whether the pipeline is leakage. The advantage of the invention are simple, practical, and can effectively decreases the miss alarming rate, increases the location accuracy of leakage. It is suited for detecting the oil gas pipe in normal transferring condition.

Owner:TIANJIN UNIV

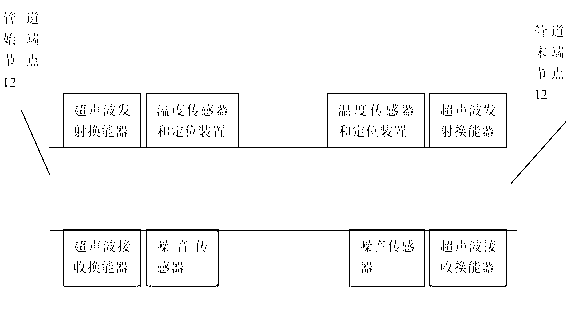

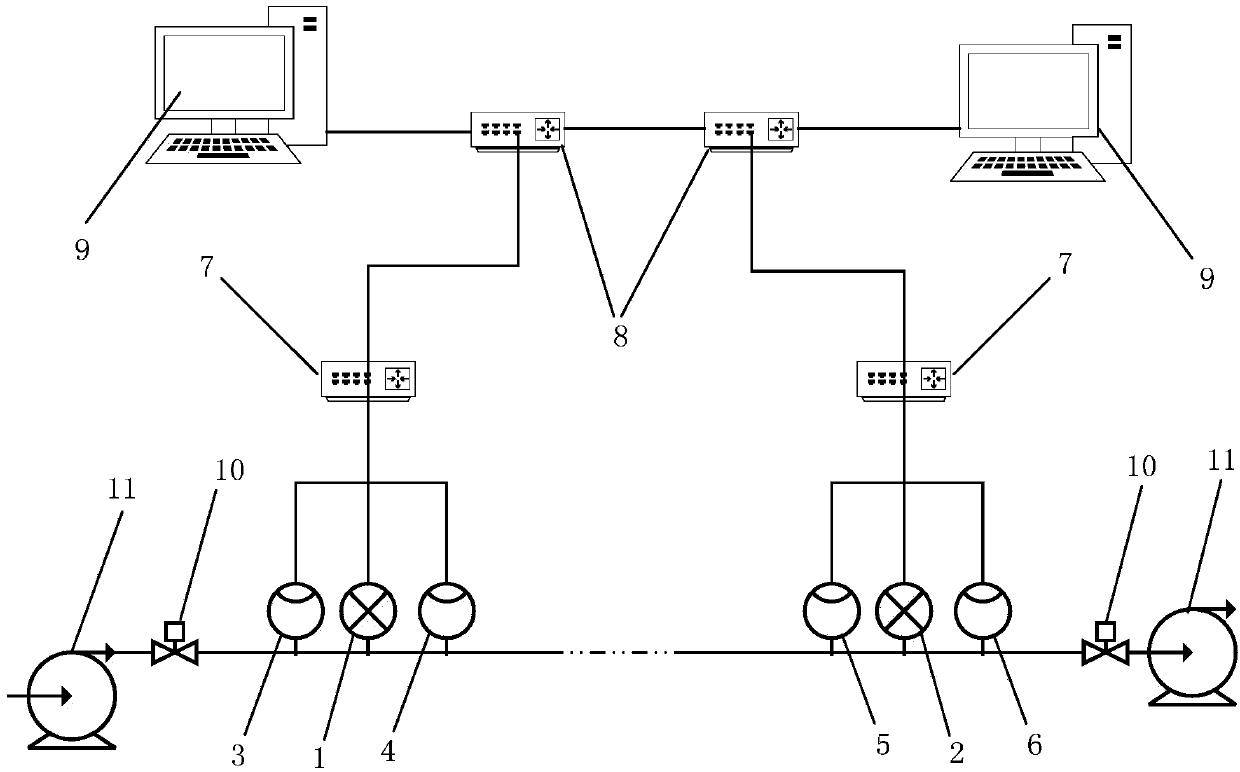

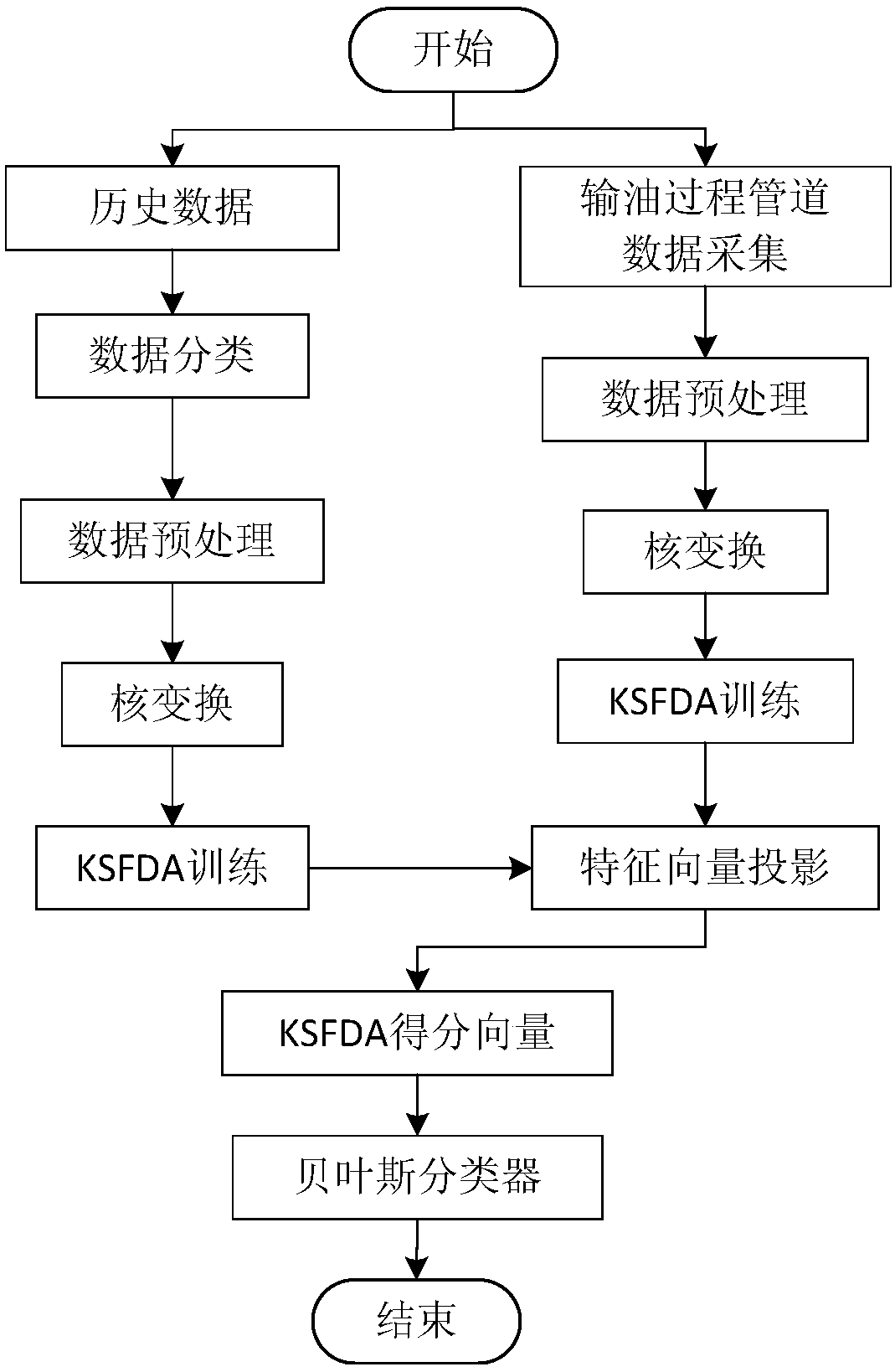

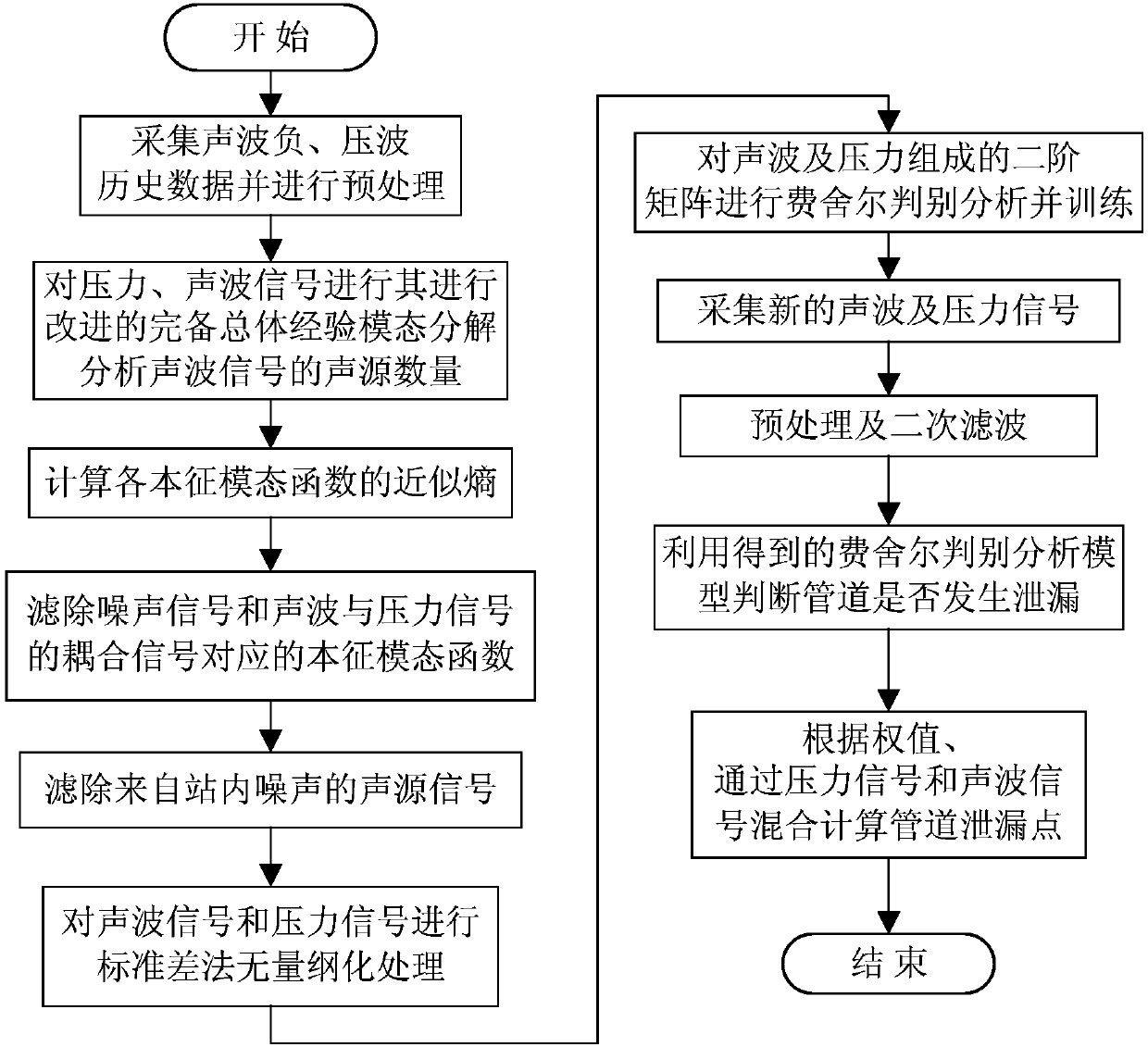

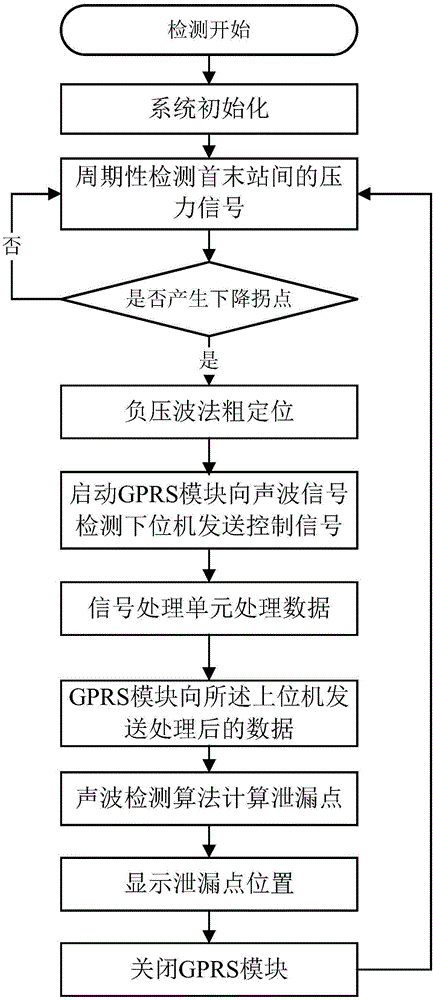

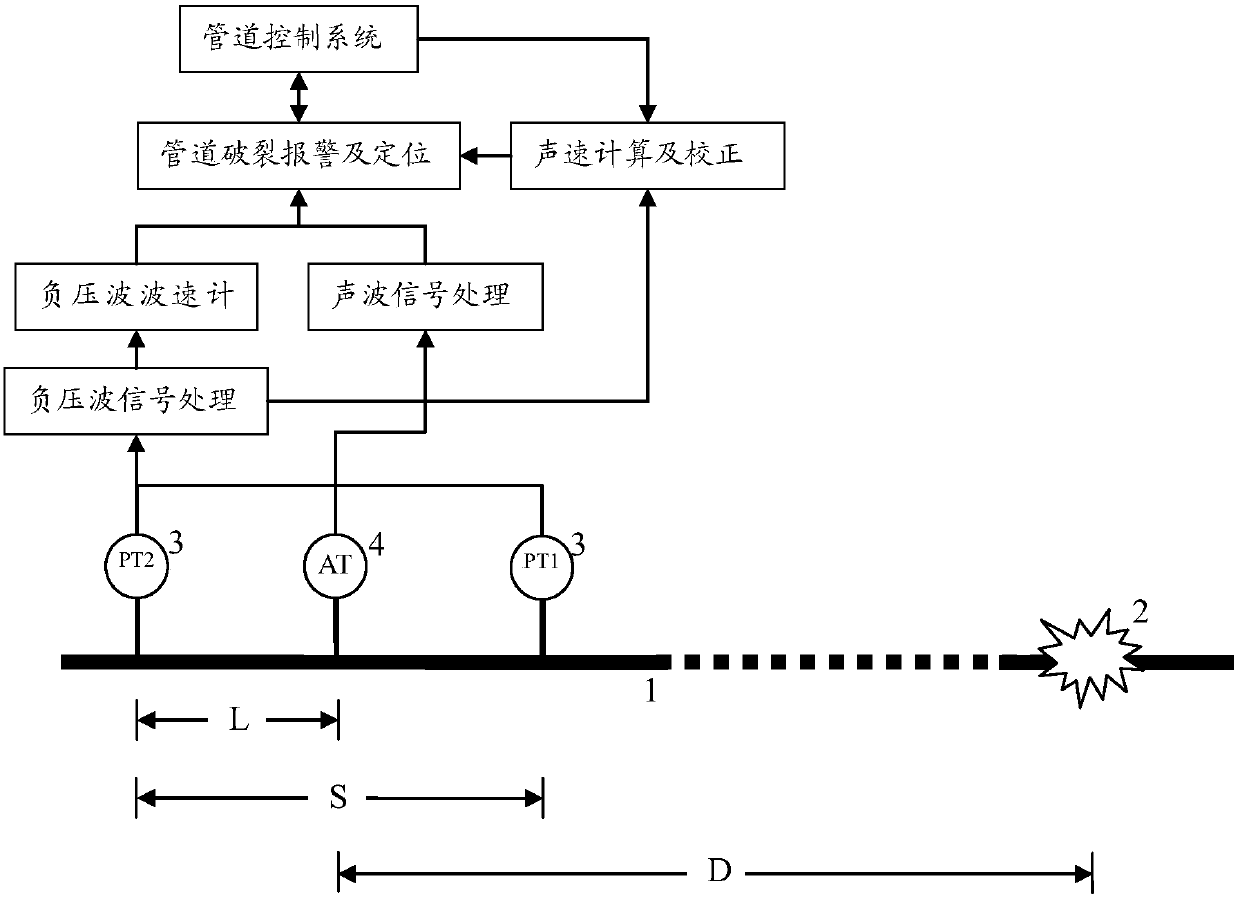

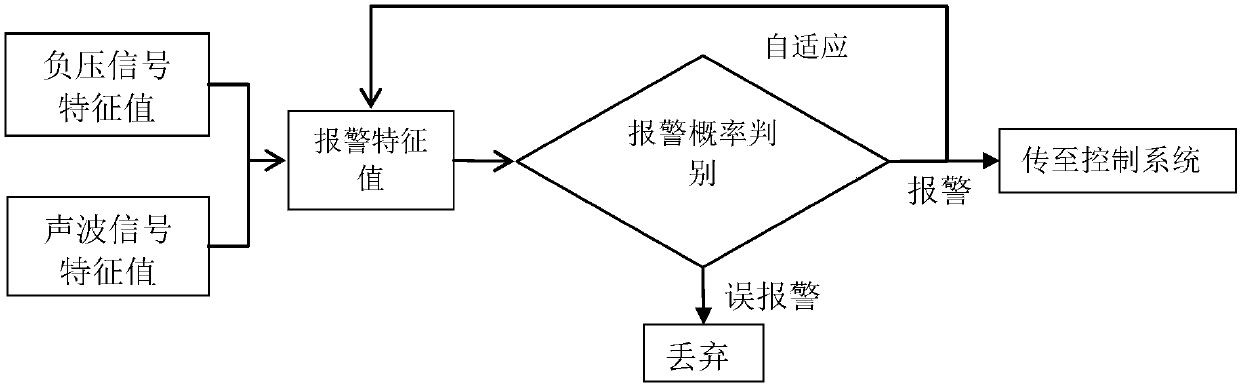

Pipeline leakage monitoring system and method based on sound wave and negative pressure wave hybrid monitoring

ActiveCN108488638ALow costShield interferenceDetection of fluid at leakage pointMeasurement of fluid loss/gain rateMonitoring systemComputer module

The invention provides a pipeline leakage monitoring system and method based on sound wave and negative pressure wave hybrid monitoring, and relates to the technical field of pipeline risk prediction.The system comprises pressure sensors, sound wave sensors, lower computers, exchangers and upper computers which are located at the head end and the tail end of a pipeline, wherein the lower computers control the pressure sensors and the sound wave sensors to acquire pressure and sound wave data, preprocess the pressure and sound wave data and then send the pressure and sound wave data to the upper computers through the exchangers, and the upper computers execute leakage monitoring programs in the upper computers, receive and analyze the pressure and sound wave data transmitted by the lower computers through pressure and sound wave data integration and storage modules, carry out secondary filtering, dimensionless processing and semi-supervised Fisher discriminant analysis processing on the acquired data through data processing module, judge whether the pipeline leaks or not through pipeline leakage monitoring modules, and carry out hybrid positioning on the pressure signals and the sound wave signals. According to the pipeline leakage monitoring system and method, noise interference can be better shielded, when a signal source is changed, the accuracy of the restored signals afterfiltering can be guaranteed, and positioning of leakage points can be more accurate.

Owner:NORTHEASTERN UNIV

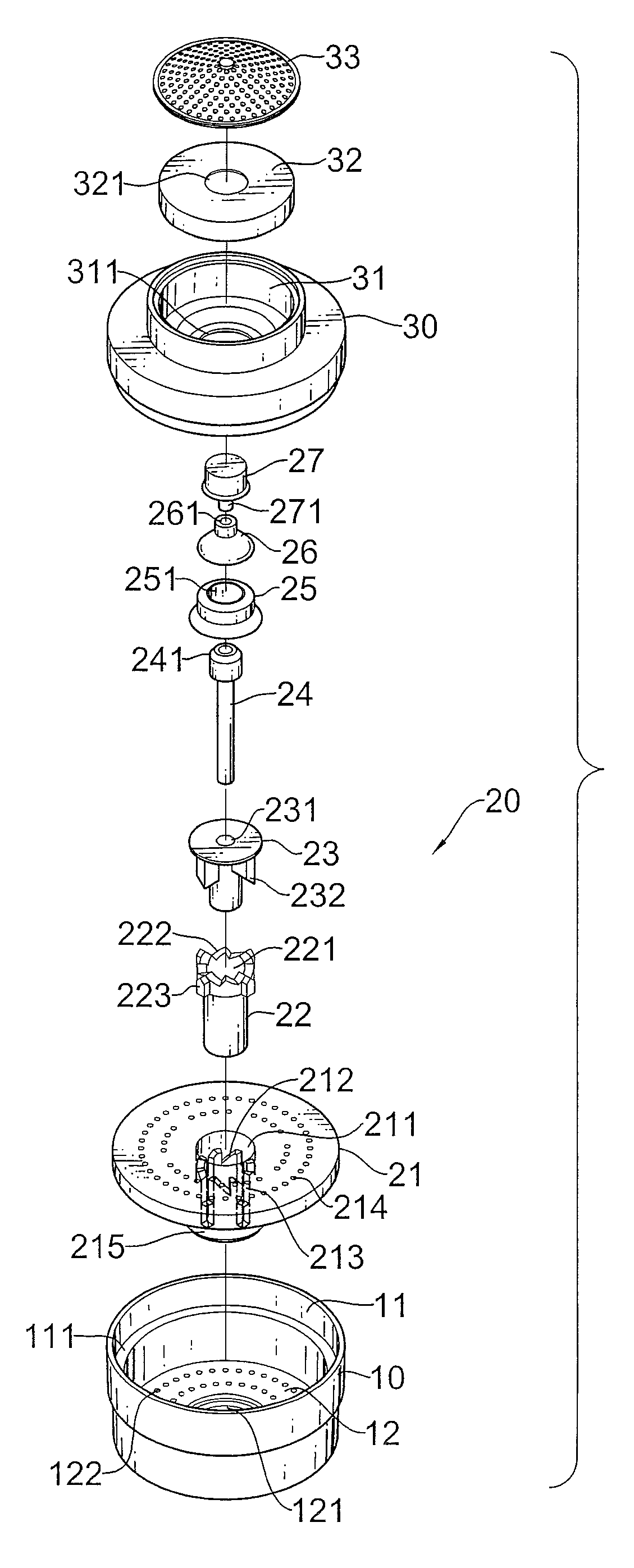

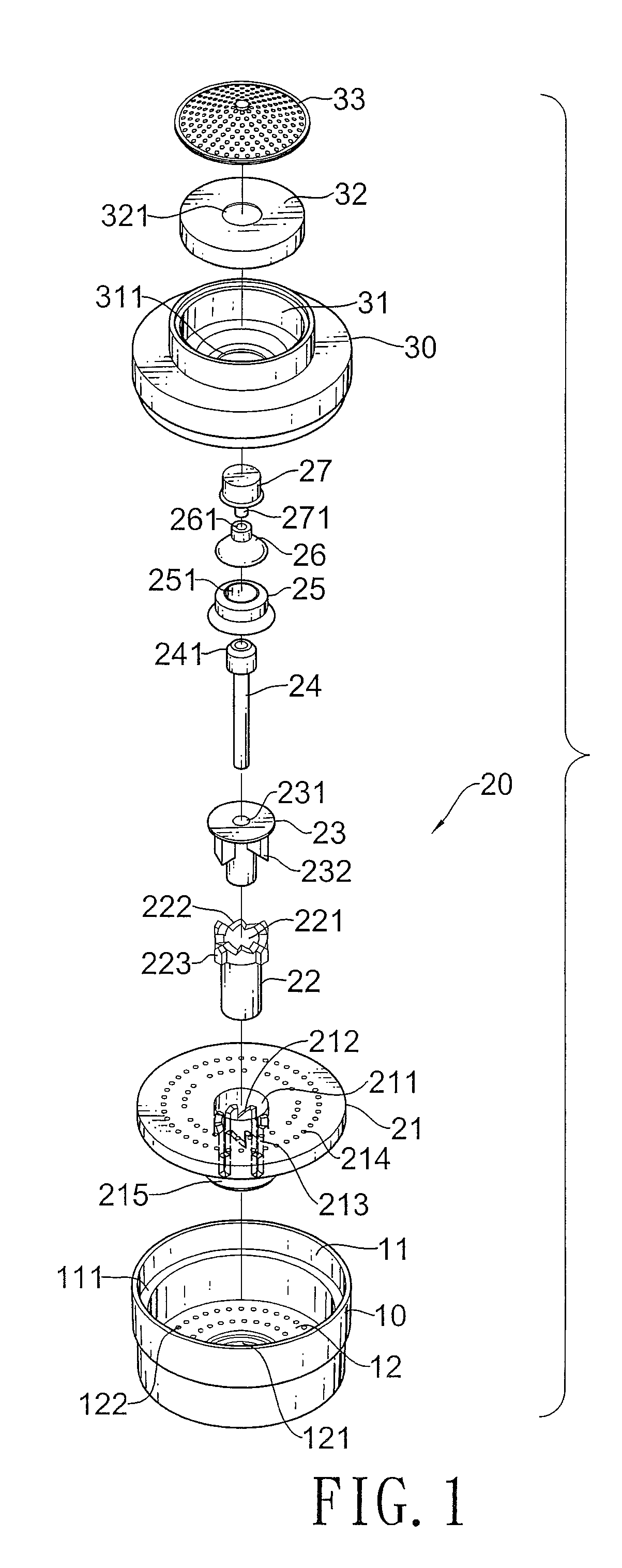

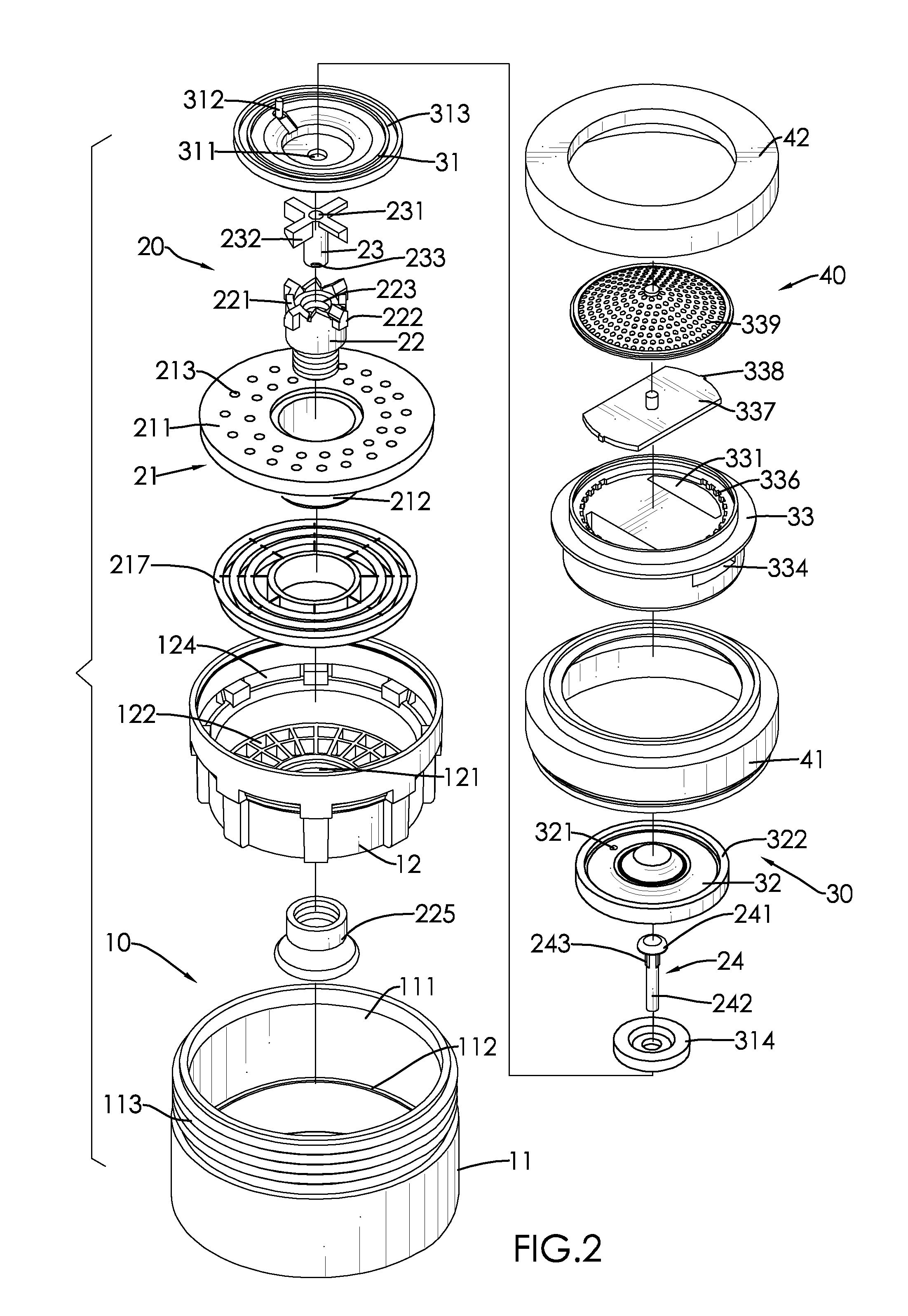

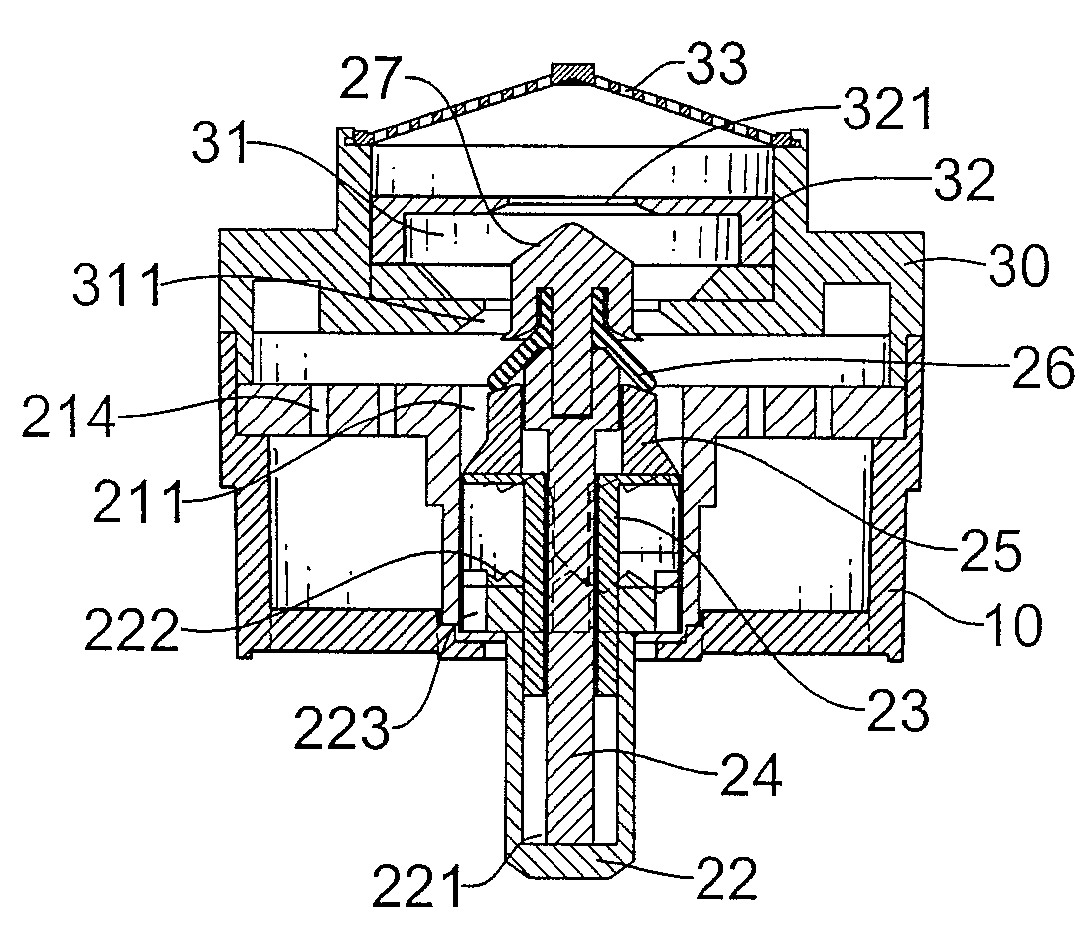

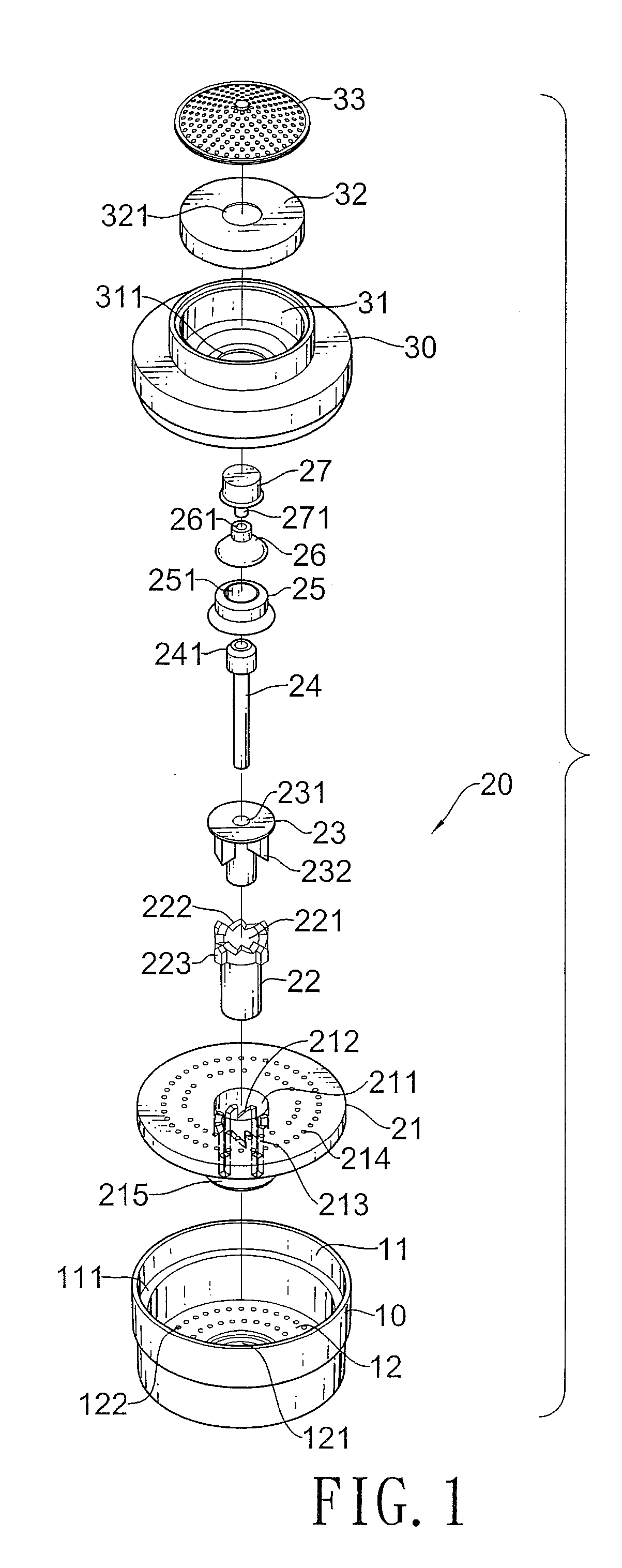

Water controlling valve

InactiveUS8028356B2Reduce pressureServomotor componentsAnimal watering devicesEngineeringControl valves

Owner:HIGHPLUS INT

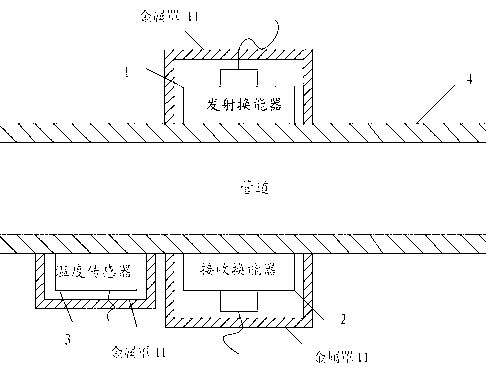

Detecting system and method for leakage of water supply pipeline of urban underground pipe gallery

The invention provides a detecting system and method for leakage of a water supply pipeline of an urban underground pipe gallery. The detecting system comprises a head end pressure detection module, a tail end pressure detection module, acoustic detection modules and an upper computer, wherein the head end pressure detection module and the tail end pressure detection module are located at the head end and the tail end of the water supply pipeline correspondingly, are of the same structure and are each provided with a pressure sensor and a real-time data acquisition device in sequence; and the acoustic detection modules and the upper computer are distributed between the head end and the tail end of the water supply pipeline. The acoustic detection modules are used for detecting acoustic waves of water current in the water supply pipeline; the upper computer is used for conducting rough positioning according to declining inflection points generated by negative pressure waves in the water supply pipeline and obtained through the head end pressure detection module and the tail end pressure detection module, and for conducting accurate positioning through the acoustic waves detected by the acoustic detection modules. According to the detecting system and method for leakage of the water supply pipeline of the urban underground pipe gallery, the pressure sensors are firstly utilized for rough positioning for leakage points, then acoustic sensors are utilized for conducting accurate positioning, and fast positioning and accurate alarming for leakage of the water supply pipeline of the urban underground pipe gallery are achieved accordingly.

Owner:WISDRI ENG & RES INC LTD

Pipeline leakage location calculation method based on pressure difference

InactiveCN108019622AIncrease sampling rateImprove denoising effectPipeline systemsComplex mathematical operationsUltrasound attenuationTime domain

Owner:JILIN UNIV

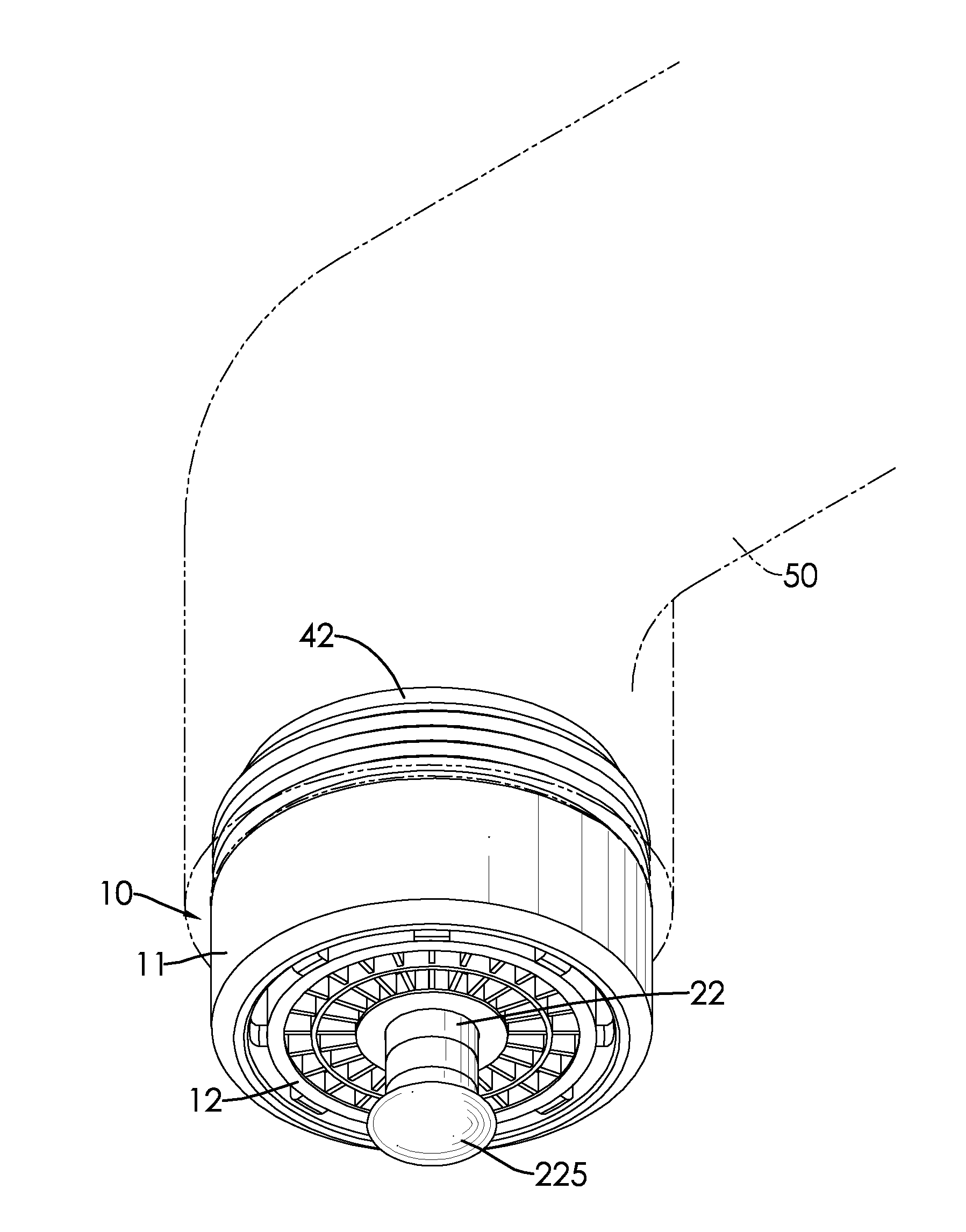

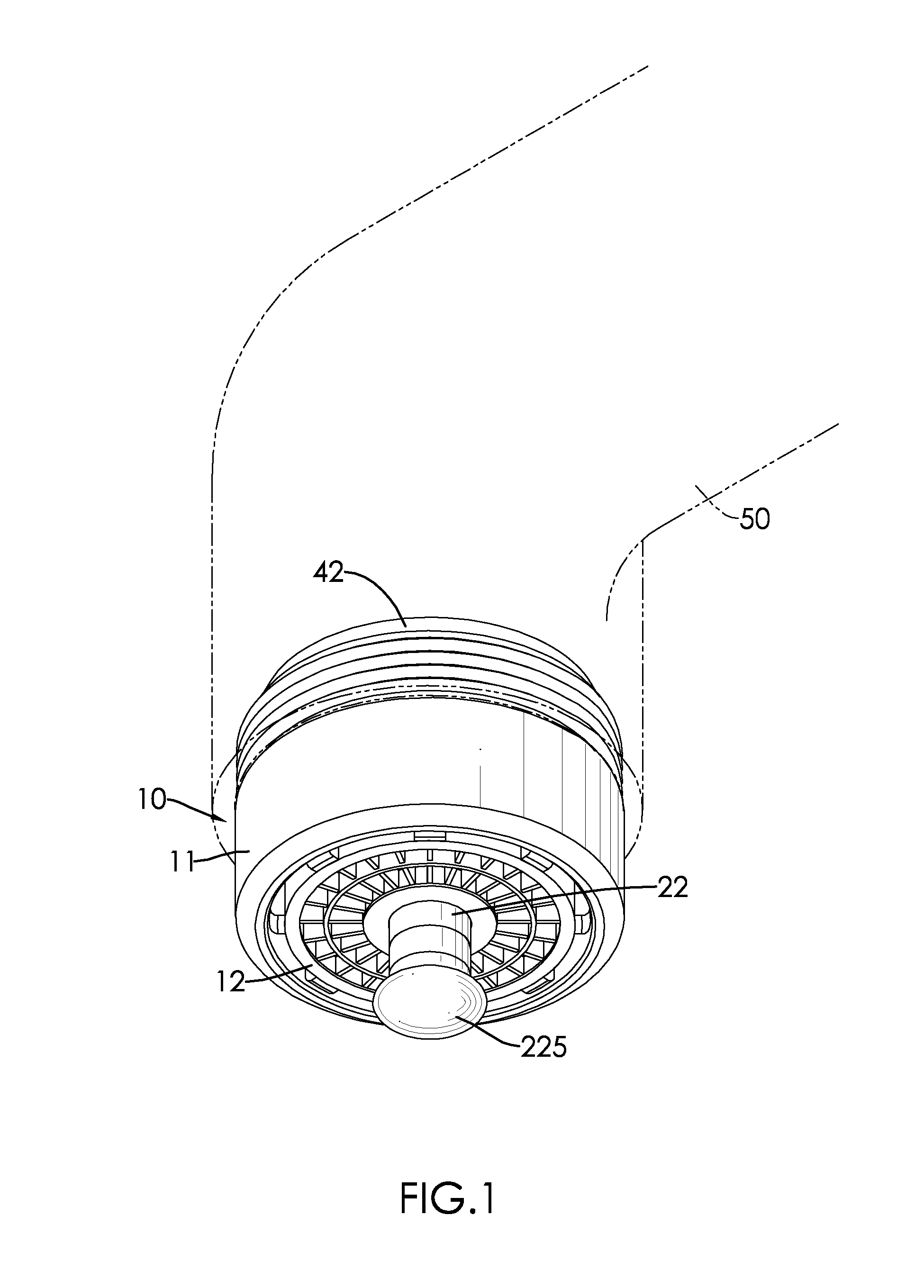

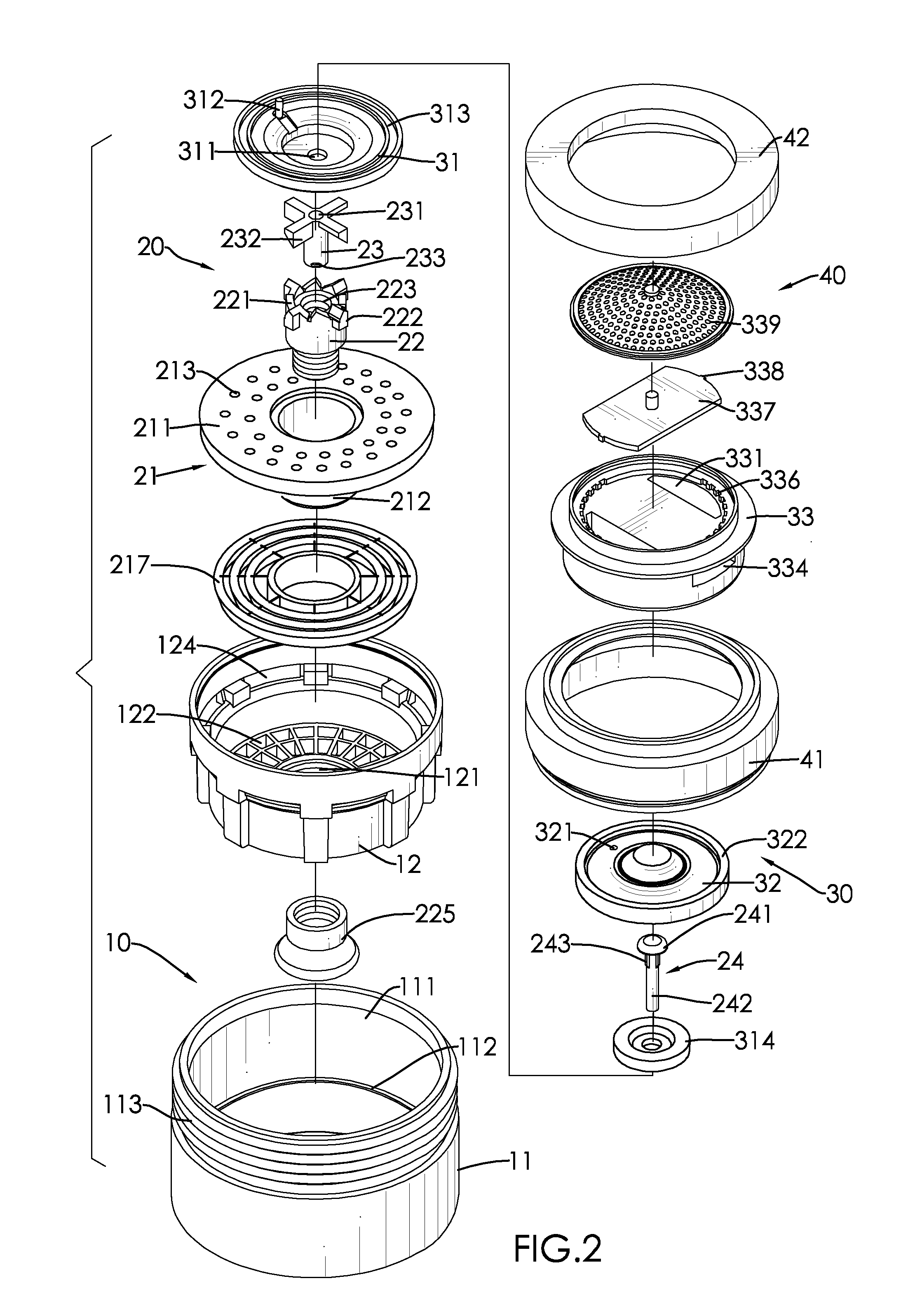

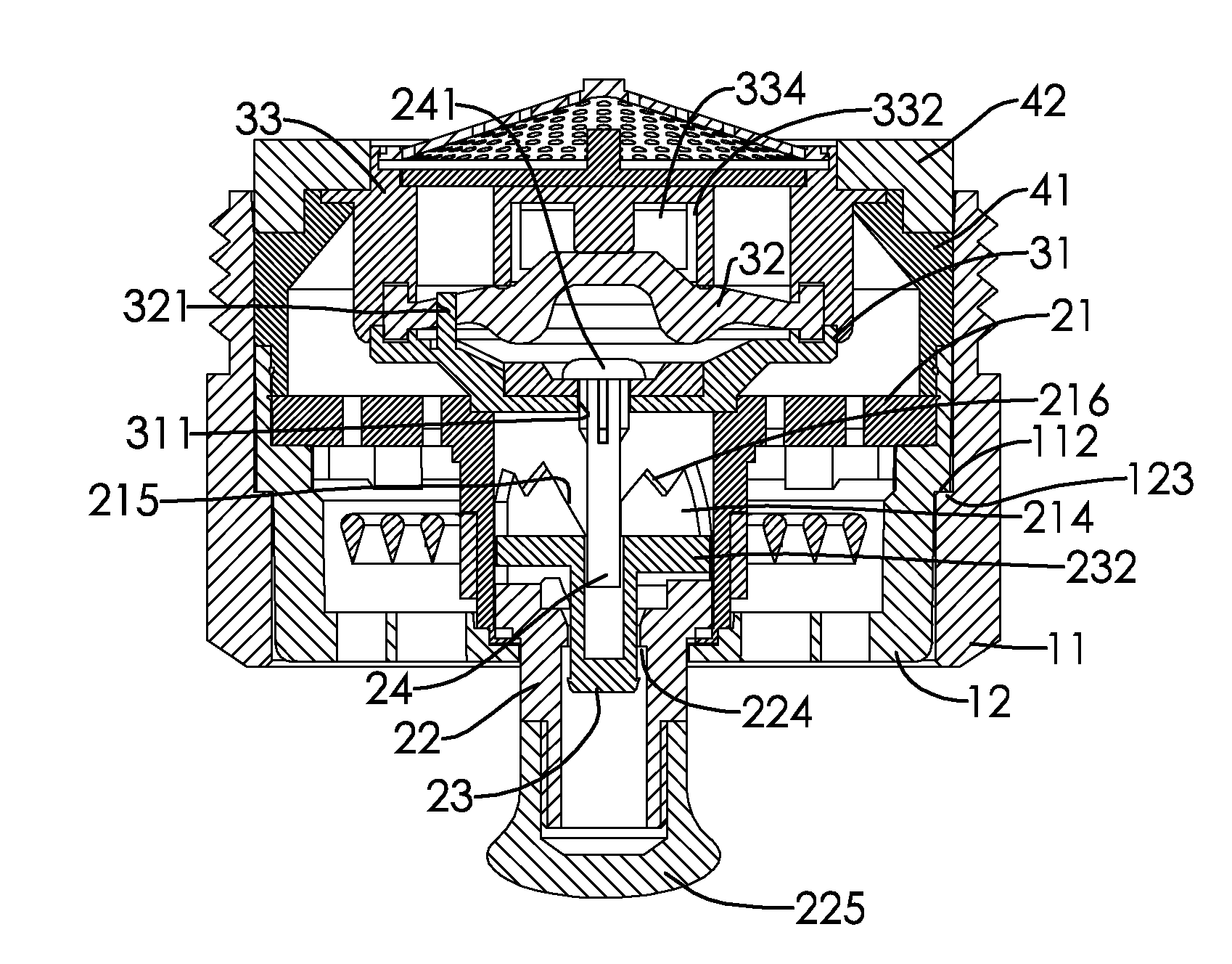

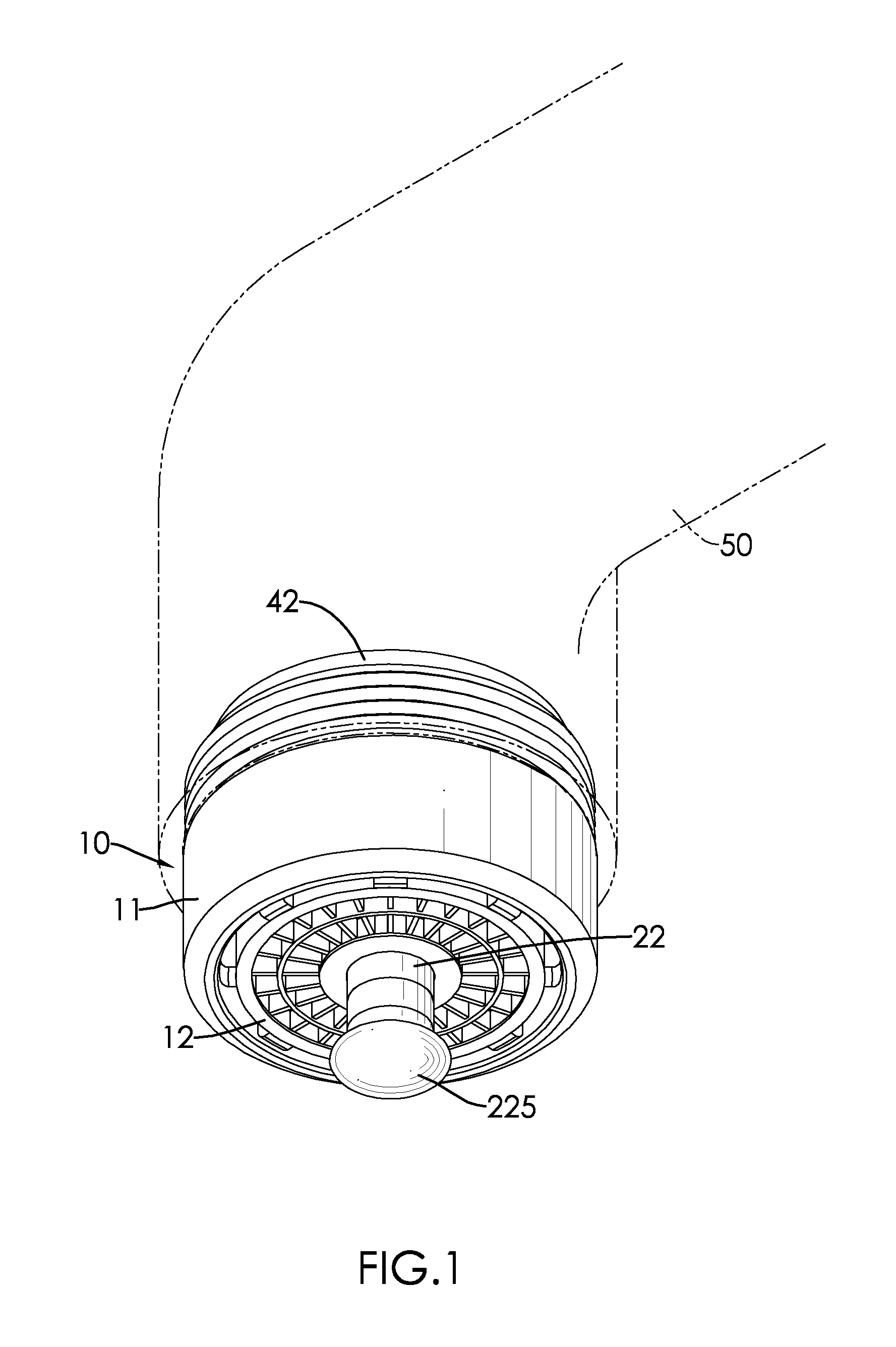

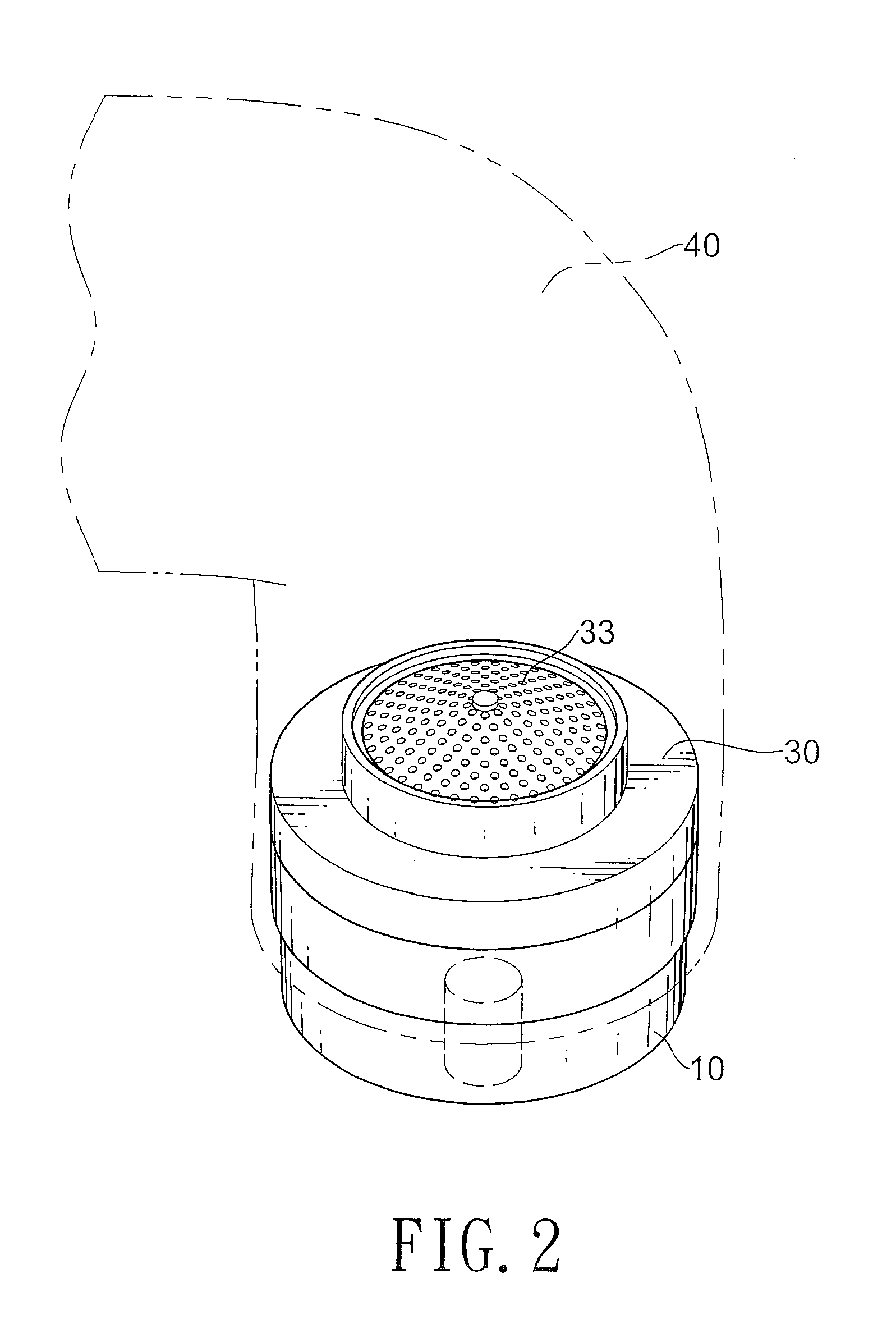

Water-saving valve assembly

ActiveUS20120018661A1Reduce pressure waveAvoid damageValve members for absorbing fluid energyDomestic plumbingWater savingEngineering

A water-saving valve assembly has a base, a control valve device and a buffer device. The control valve device is mounted in the base. The water-saving valve assembly is mounted on an exit of a water pipe. Users can control the flowing out or stopping of water in the water pipe via the control valve device. The buffer device provides a gradual effect of switching off and can effectively reduce positive and negative pressure waves generated in the water pipe. Noises and damage to the water pipe are also prevented.

Owner:NEOPERL

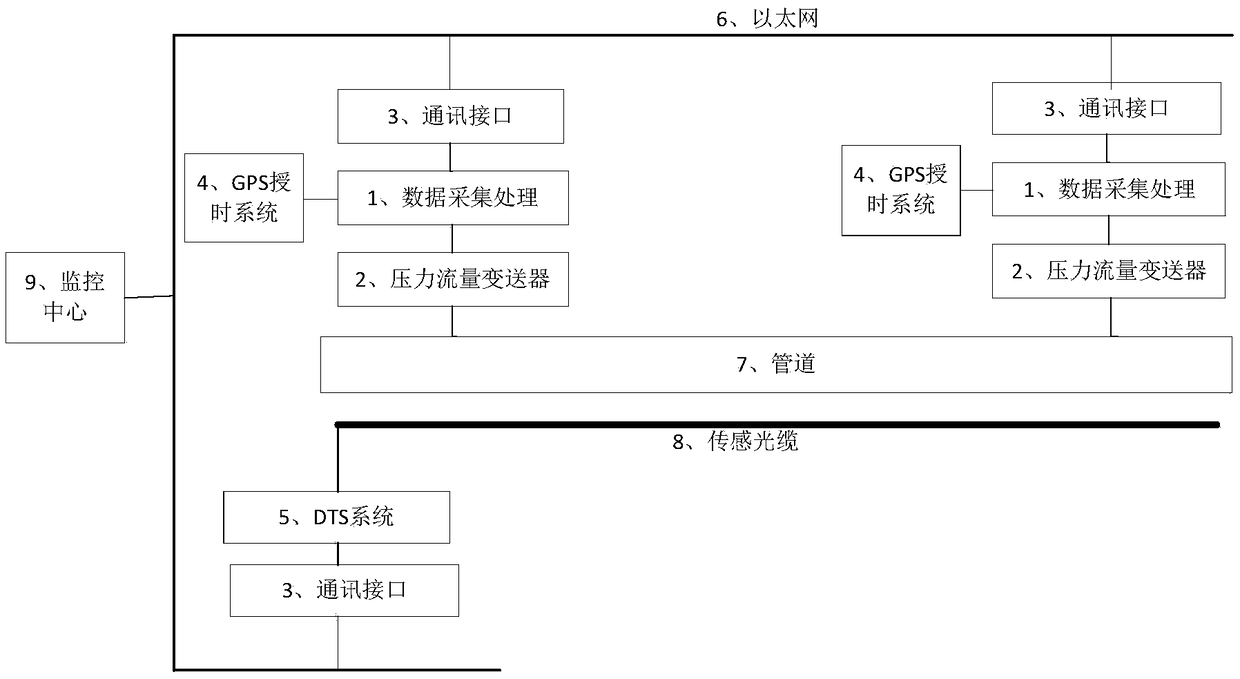

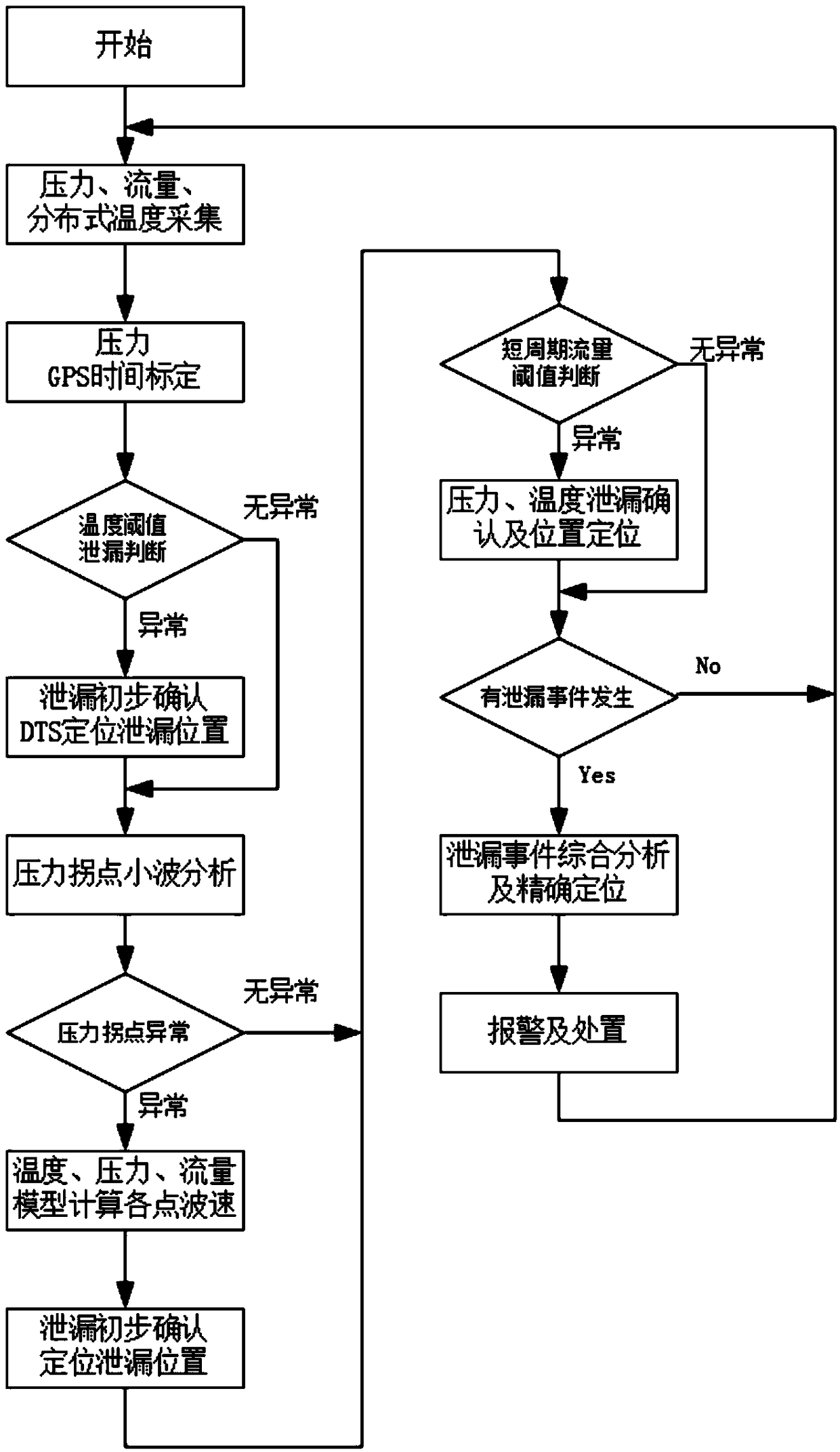

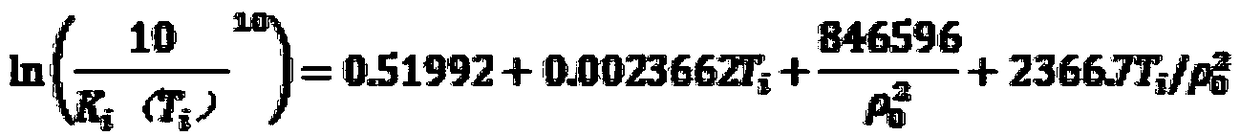

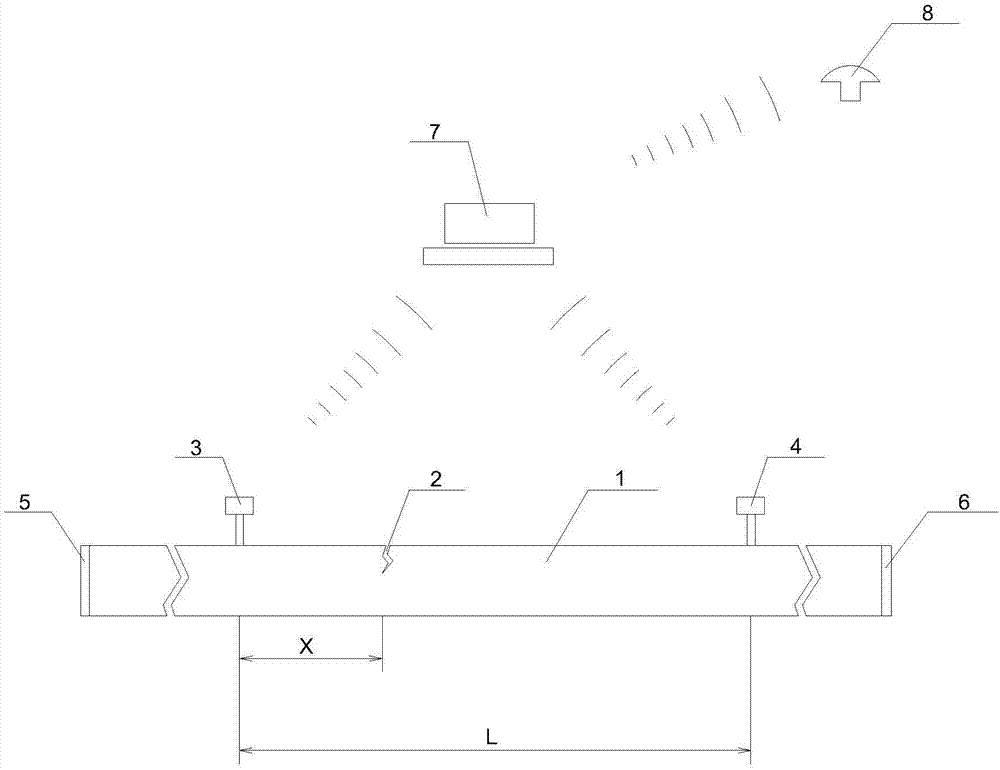

Distributed optical fiber multi-parameter pipeline leakage positioning and warning system and leakage positioning method

InactiveCN108758353AImprove accuracyReduce false alarm ratePipeline systemsData acquisitionEngineering

The invention relates to a distributed optical fiber multi-parameter pipeline leakage positioning and warning system and a leakage positioning method. The distributed optical fiber multi-parameter pipeline leakage positioning and warning system comprises a sensing optical fiber laid in the same ditch as a pipeline and a DTS system connected with the sensing optical fiber. At least two negative-pressure wave monitoring devices are arranged on the pipeline. A negative-pressure wave monitoring system and the DTS system are both connected with a monitoring center through communication interfaces and the Ethernet network. Each negative-pressure wave monitoring device comprises a pressure flow transmitter connected with the pipeline, and the pressure flow transmitter is connected with a data acquisition unit. The data acquisition units are connected with GPS timing antennas. The distributed optical fiber multi-parameter pipeline leakage positioning and warning system has the beneficial effects that the defects that a negative-pressure wave monitoring and infrasonic wave leakage monitoring system cannot conduct monitoring and cannot conduct accurate positioning due to small leakage and adistributed optical fiber temperature leakage monitoring system cannot monitor leakage due to a low-temperature difference are overcome; based on the temperatures, obtained by a distributed optical fiber temperature measuring system, of all points, the wave velocity is calculated and corrected accurately, and accurate positioning of the leakage position is achieved.

Owner:青岛汇安谷科技发展有限公司

Positioning and alarming system and method for ore pulp pipeline leakage

InactiveCN107084313ADetect singularitiesSuppress Noisy WaveformsPipeline systemsEngineeringTime difference

The invention relates to the field of ore pulp pipeline safety maintenance, in particular to a positioning and alarming system and method for ore pulp pipeline leakage. According to the technical key points of the positioning and alarming system and method, the positioning and alarming system comprises two or more pressure sensors, a first flow sensor, a second flow sensor, a datum processor and an alarming device; the two or more pressure sensors are connected with the outer wall of an ore pulp pipeline along the flow direction of the ore pulp pipeline, and the space between the adjacent pressure sensors is the same; the first flow sensor is arranged at the beginning end of the ore pulp pipeline; the second flow sensor is arranged at the tail end of the ore pulp pipeline; and the datum processor is connected with the pressure sensors, the first flow sensor, the second flow sensor and the alarming device. The negative pressure wave method and the flow balance method are combined, the problem that leakage positioning of an existing ore pulp pipeline is inaccurate is solved, and the problems that in practical application, the negative pressure wave method cannot accurately determine the time difference of an upstream pressure sensor and a downstream pressure sensor to receive the pressure wave, and thus false judging of the leakage point position is caused are solved.

Owner:YUNNAN DAHONGSHAN PIPELINE

Water-saving valve

ActiveUS8757518B2Reduce pressureAvoid damageServomotor componentsValve members for absorbing fluid energyWater savingEngineering

Owner:NEOPERL

Oil gas pipe network leak detection method based on two-dimensional information fusion

The invention provides an oil gas pipe network leak detection method based on the two-dimensional information fusion. The oil gas pipe network leak detection method includes the steps of obtaining the pressure, the flow, the density, the throttling valve opening degree, the download valve opening degree, water attack decompression valve switching signals and main delivery pump starting-stopping signals collected by monitoring stations of an oil gas pipe network in real time, judging whether oil gas pipe sections are abnormal or not, inquiring working condition adjustment information for enabling the oil gas pipe sections to be abnormal, starting to track negative pressure waves from the monitoring station where the working condition information is inquired, identifying the state of the oil gas pipe network, and positioning leak points of the oil gas pipe network. According to the complex working condition and the uncertainty of an oil gas pipe network system, in order to effectively lower the leak detection false alarm rate and improve the leak positioning accuracy, the two-dimensional fusion is adopted for the oil gas pipe network leak detection method to analyze the working state of the oil gas pipe network, and the accuracy of the leak detection of the oil gas pipe network can be improved; real-time change information of pipe parameters such as the pressure and the flow in the system and the working condition adjustment information of valves and the like are synchronously analyzed, and the leak detection false alarm rate is effectively lowered.

Owner:NORTHEASTERN UNIV

Pipe leakage diagnosis system, device and method

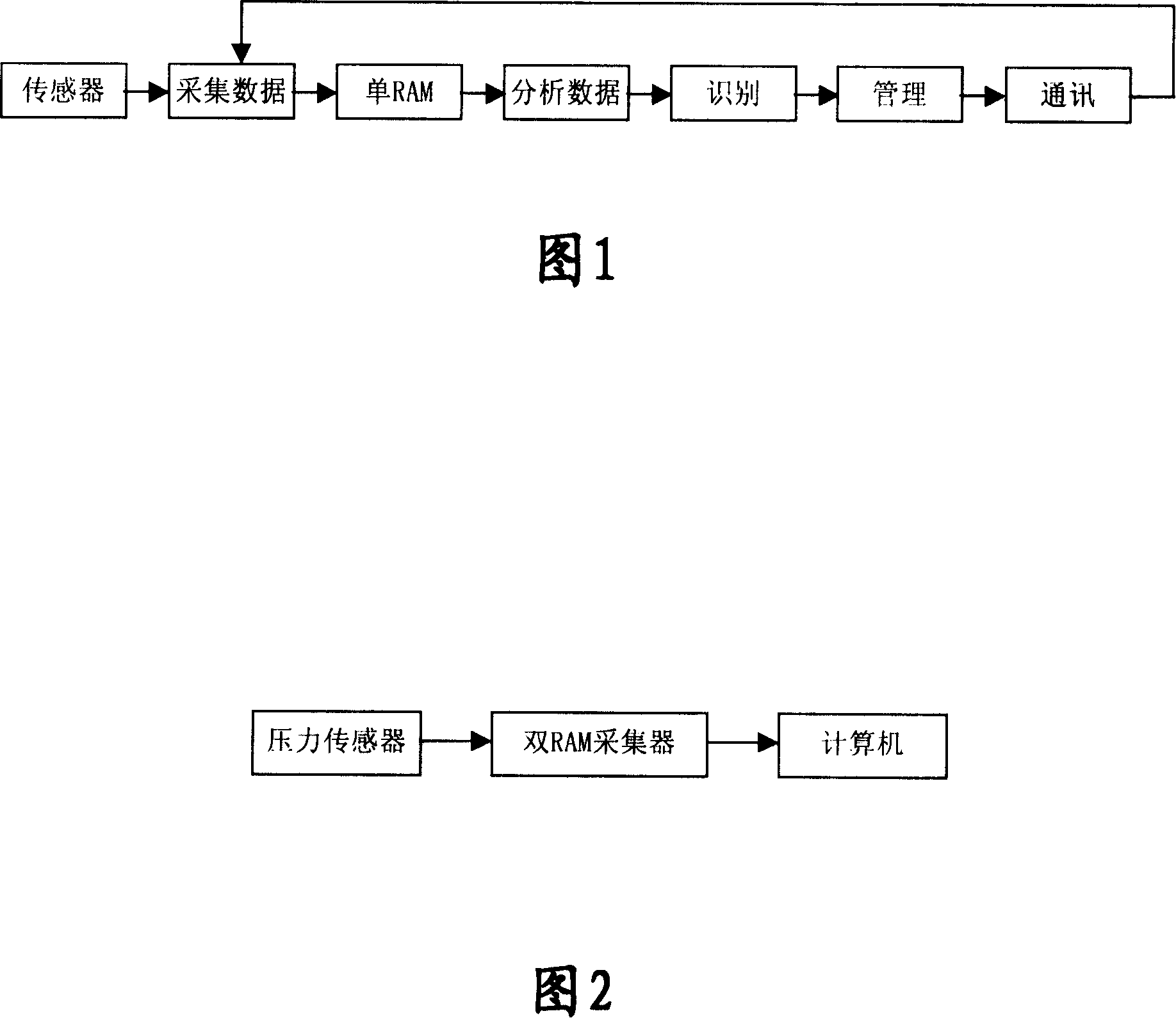

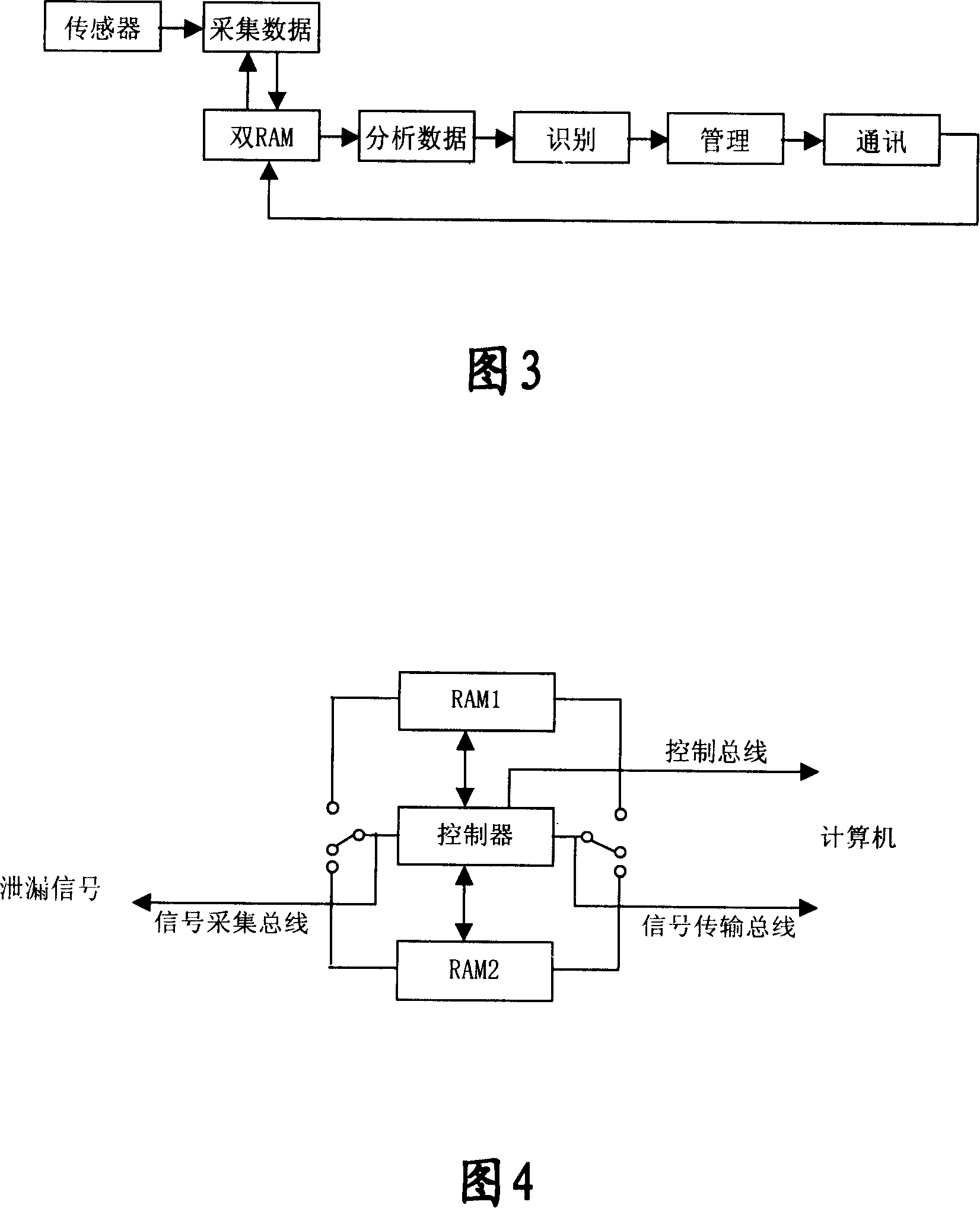

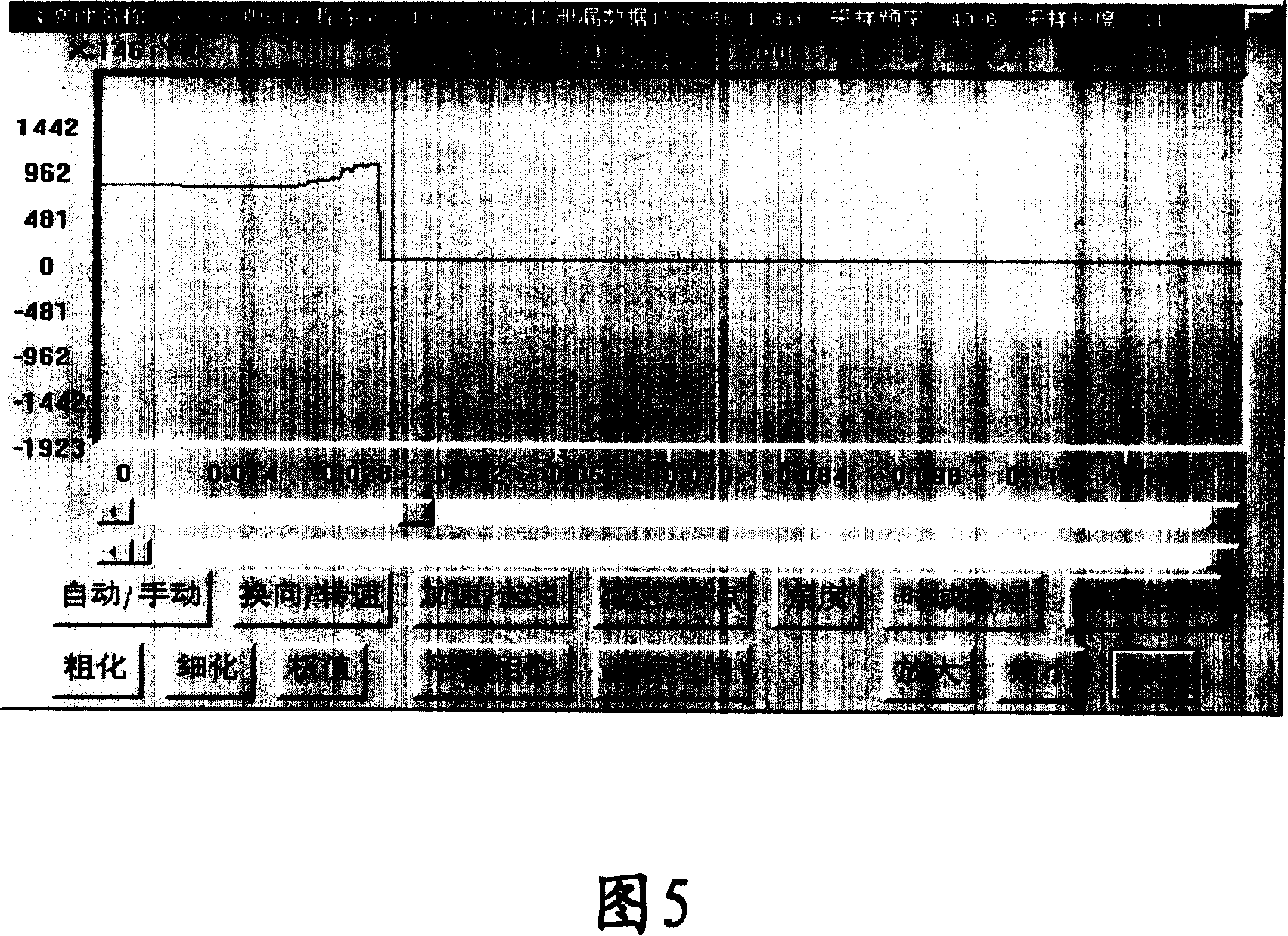

InactiveCN101122367AImplement diagnosticsSolving recognition problemsPipeline systemsDiagnosis methodsData acquisition

The invention provides a diagnosis system, a diagnosis device and a diagnosis method for pipe leaking. The system comprises a pressure sensing device, which is arranged on a pipe to be diagnosed and used to pick up a negative pressure wave signal of leaking in the pipe, a multi-task data acquisition device, at least two RAM of which are controlled by a control circuit to acquire the negative pressure signal and transmit the data acquired alternately, and a data processing device, which receives the data transmitted by the multi-task data acquisition device, analyzes the data and identifies the leaking. The invention settles the issue of identifying a signal of a small leakage with a pipe.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

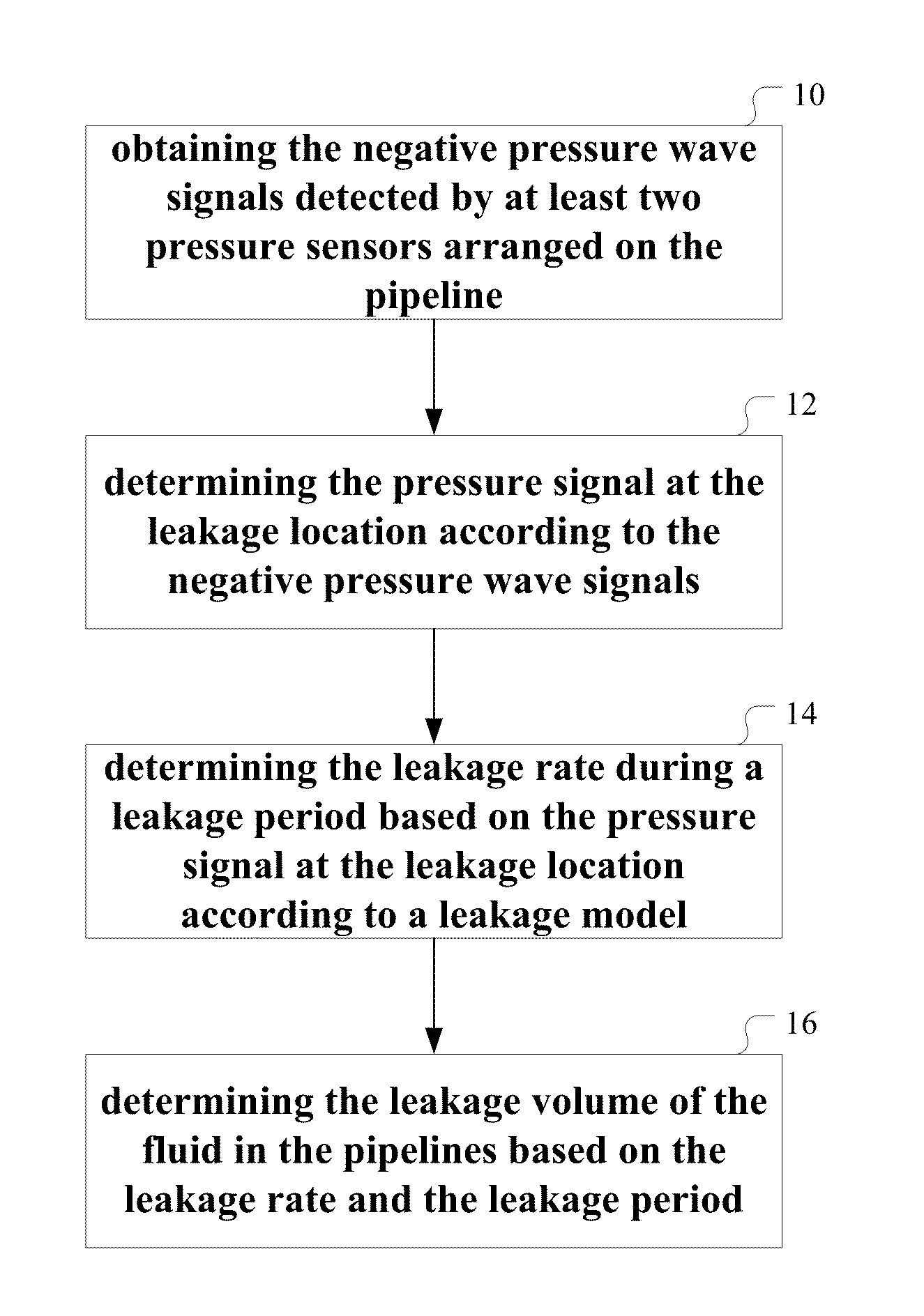

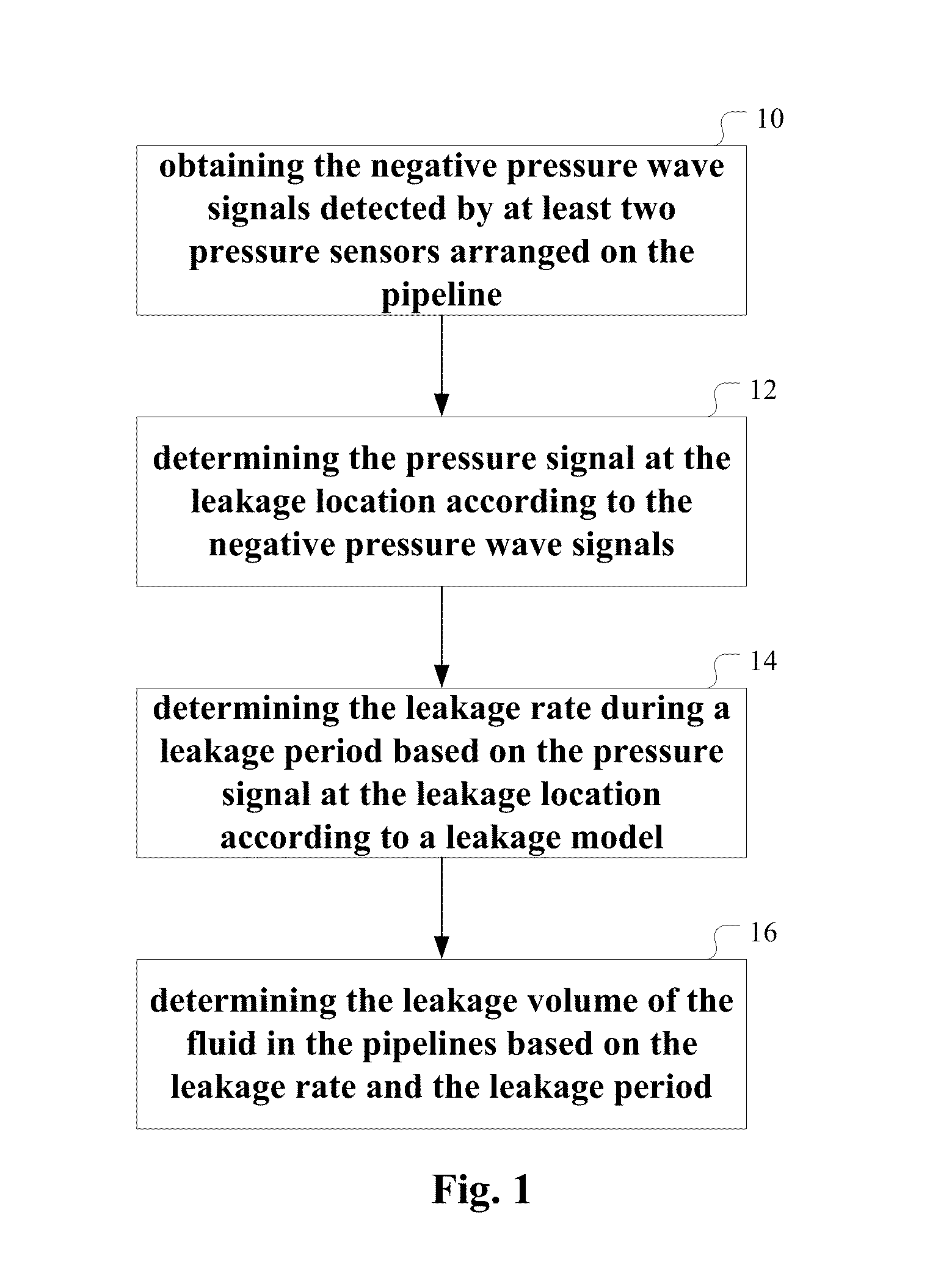

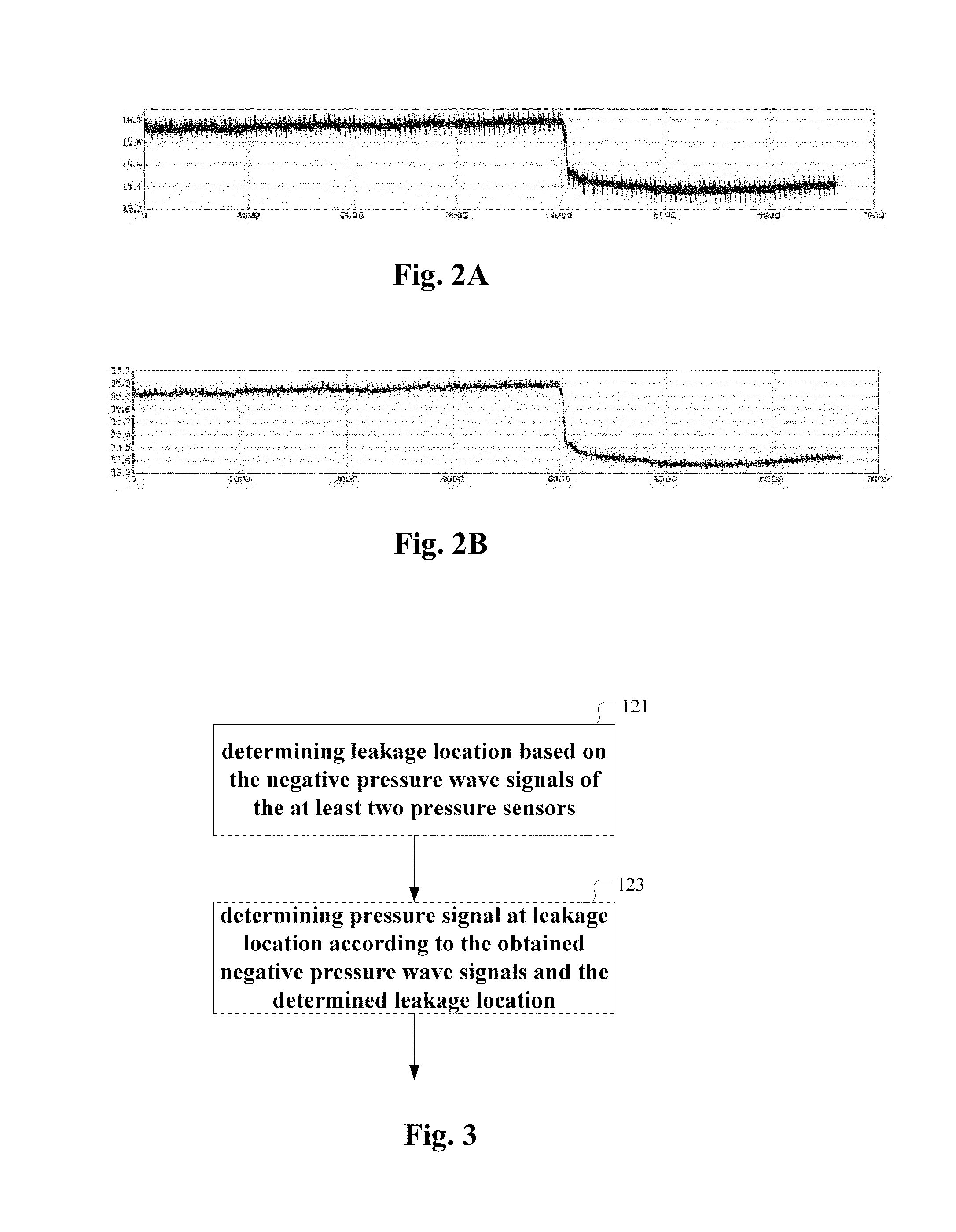

Determining fluid leakage volume in pipelines

ActiveUS20140229124A1Low costEfficiently obtainedVolume measurement apparatus/methodsFluid-tightness measurementEngineeringPressure sensor

A method and an apparatus for determining leakage volume of fluid in transportation pipelines are provided. The method comprises: obtaining the negative pressure wave signals detected by at least two pressure sensors arranged on the pipeline; determining the pressure signal at the leakage location based on the negative pressure wave signals; determining the leakage rate during a leakage period based on the pressure signal at the leakage location according to a leakage model; and determining the leakage volume of the fluid in the pipeline based on the leakage rate and the leakage period. The apparatus provided corresponds to the method described above. By using the method and apparatus described above, the leakage volume of the transportation pipelines can be obtained to help understand the leakage profile of the pipelines and thus reduce losses.

Owner:IBM CORP

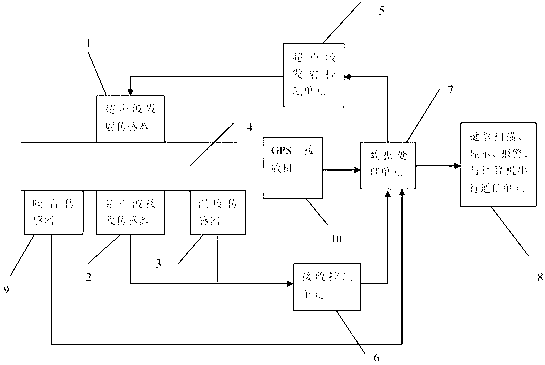

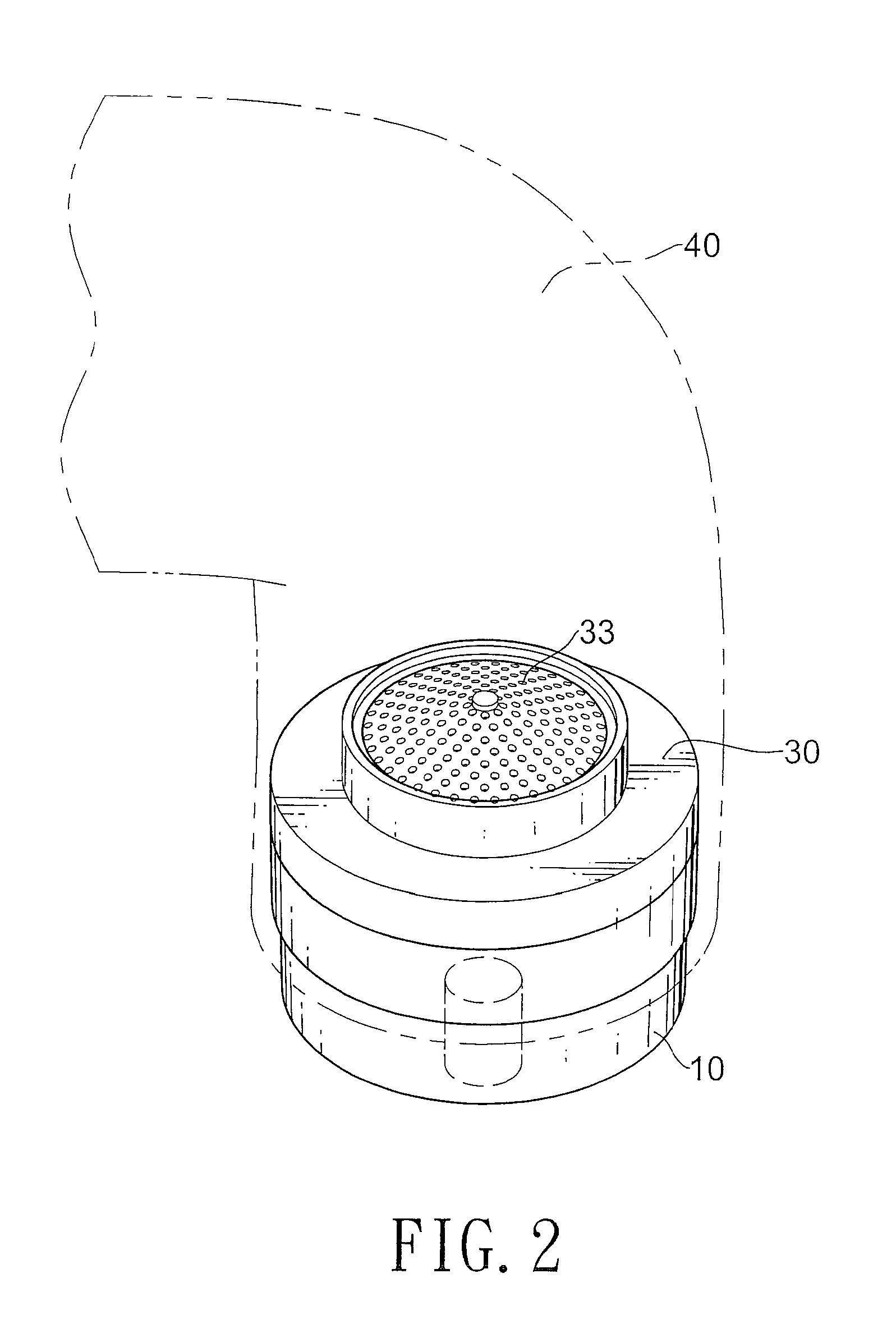

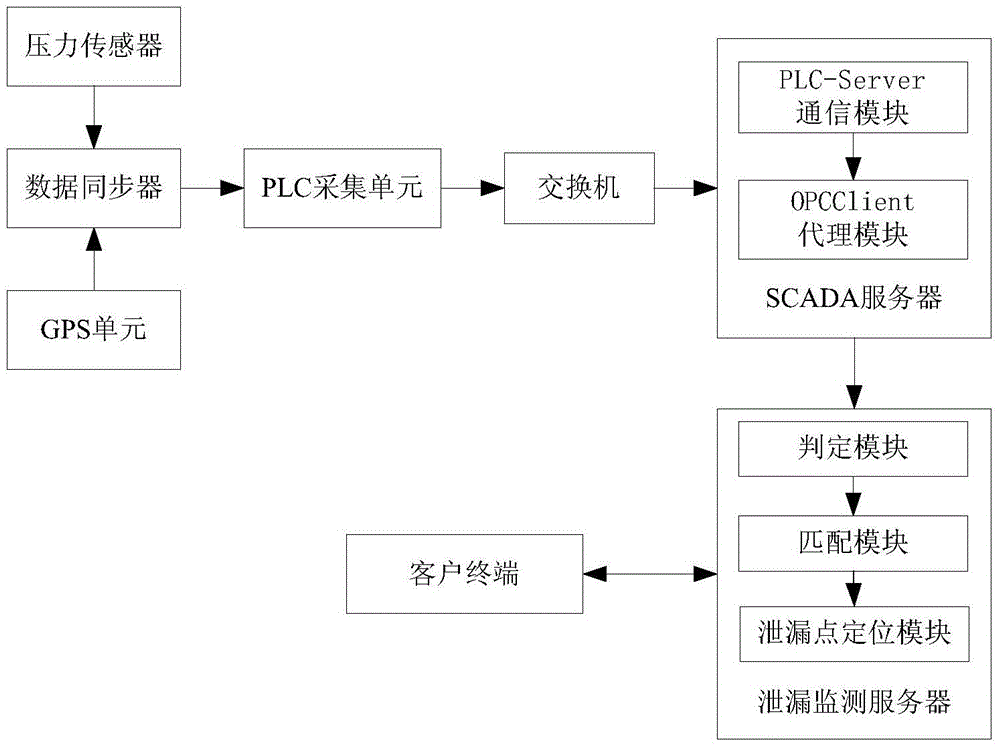

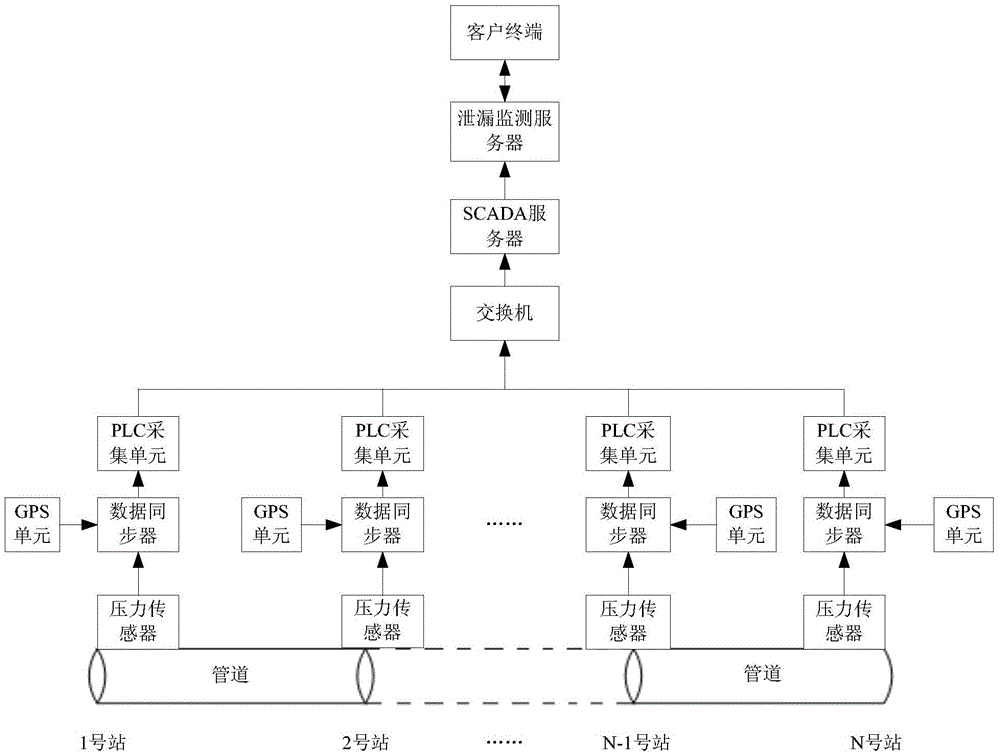

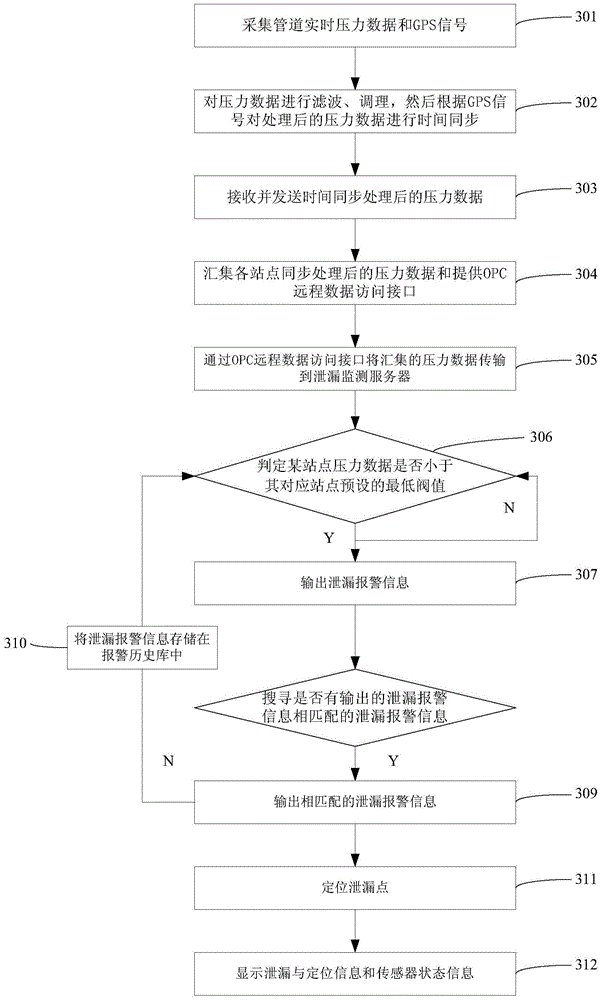

Pipeline leakage detection system and method using negative pressure waves

ActiveCN105485524AGuaranteed stabilityEnable leak detectionPipeline systemsData synchronizationSCADA

The invention provides a pipeline leakage detection system and method using negative pressure waves, and relates to the field of oil pipeline leakage detection. According to the system and method, time synchronization of pressure data is achieved accurately through pressure sensors, GPS units and data synchronizers which are arranged at all stations of pipelines; a PLC collecting unit transmits pressure data subjected to time synchronization to an SCADA server; the SCADA server assembles the pressure data of all the stations and provides a remote access interface; the data is uploaded to a leakage detection server through the access interface, so that the stability of data transmission is guaranteed, sending of a pressure data read failure is avoided, and the reliability and the accuracy of the pressure data are guaranteed; and finally the leakage detection server finishes judging and matching of the pressure data as well as the detection positioning, leakage detection among multi-station pipelines is achieved, and the accuracy of the final computed result is improved.

Owner:江苏中海达海洋信息技术有限公司

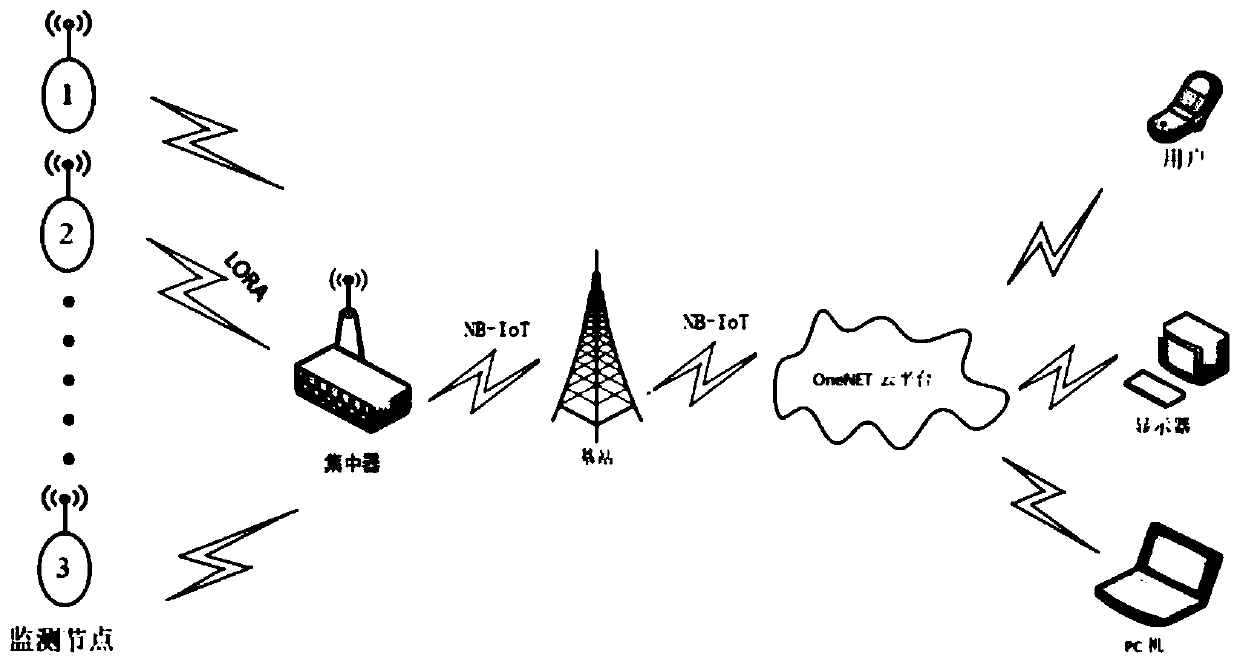

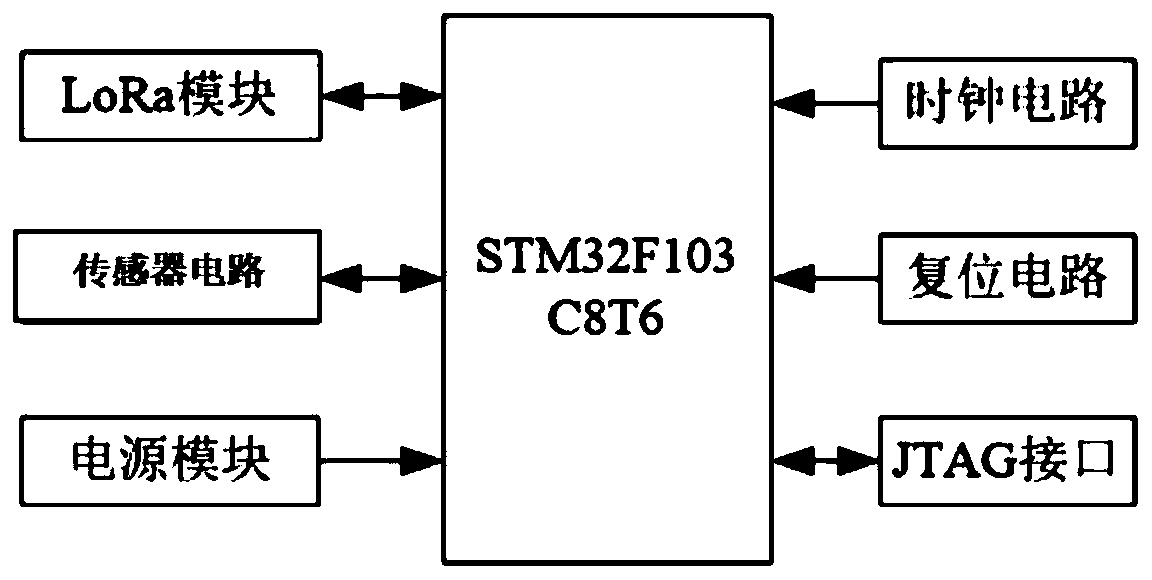

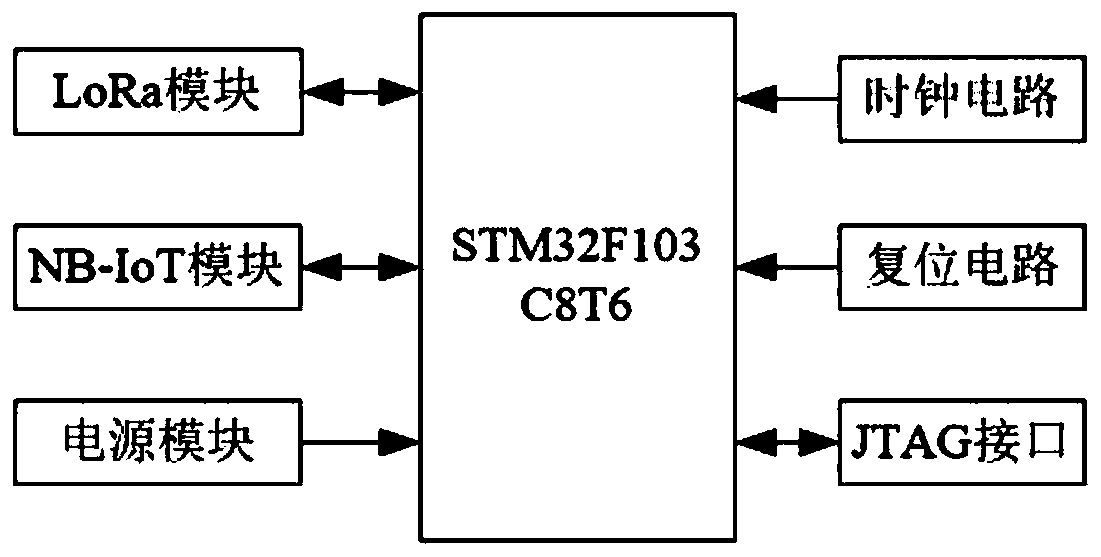

Urban underground gas pipeline monitoring system

InactiveCN110230779AImprove transmission efficiencyHigh transmission accuracyPipeline systemsTransmissionEngineeringCLOUD experiment

The invention provides an urban underground gas pipeline monitoring system. The urban underground gas pipeline monitoring system comprises a monitoring terminal, a wireless transmission module and real-time communication monitoring equipment. Gas concentration and negative pressure wave signal data are collected through sensors; data fusion is conducted through a STM32C8T6 processor; leakage sources are located by adopting an improvement cross-correlation analysis method; processed data are transmitted to a ground concentrator module through a LoRa wireless module; and data detected by different detection nodes are fused by a concentrator, and then the data are transmitted to a OneNET cloud platform and terminal equipment for display through a narrow band Internet of things (NB-IoT) wireless communication module. When gas leakage occurs, the working staff in a monitoring center are notified in time to deal with the situation through alarm display and sending of alarm text messages. According to design principles, outstanding anti-interference and signal penetrating capacities of the LoRa wireless module are utilized under the ground to conduct communication so that stability of signals can be guaranteed; on the ground, through the NB-IoT module, uploading of data and intercommunication between users are achieved; and by means of the platform of Internet of things, updating, adjustment and pre-overhaul of products are convenient.

Owner:ANHUI UNIV OF SCI & TECH

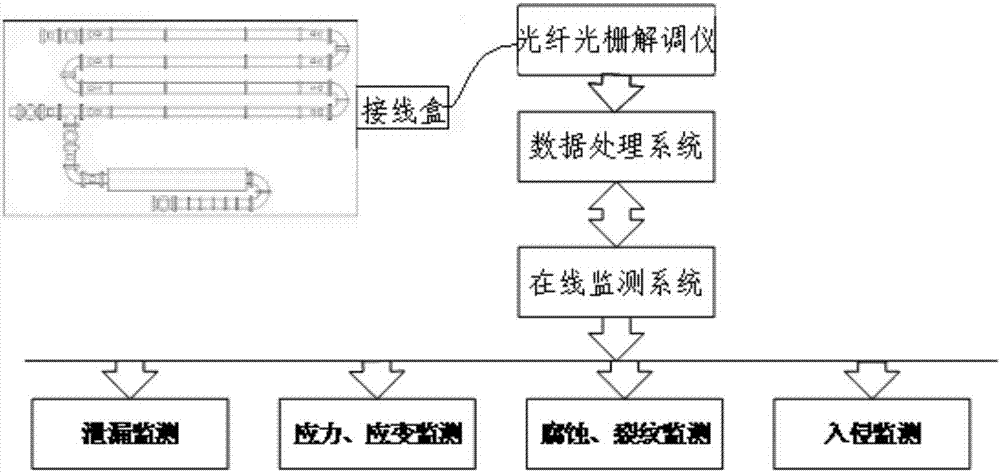

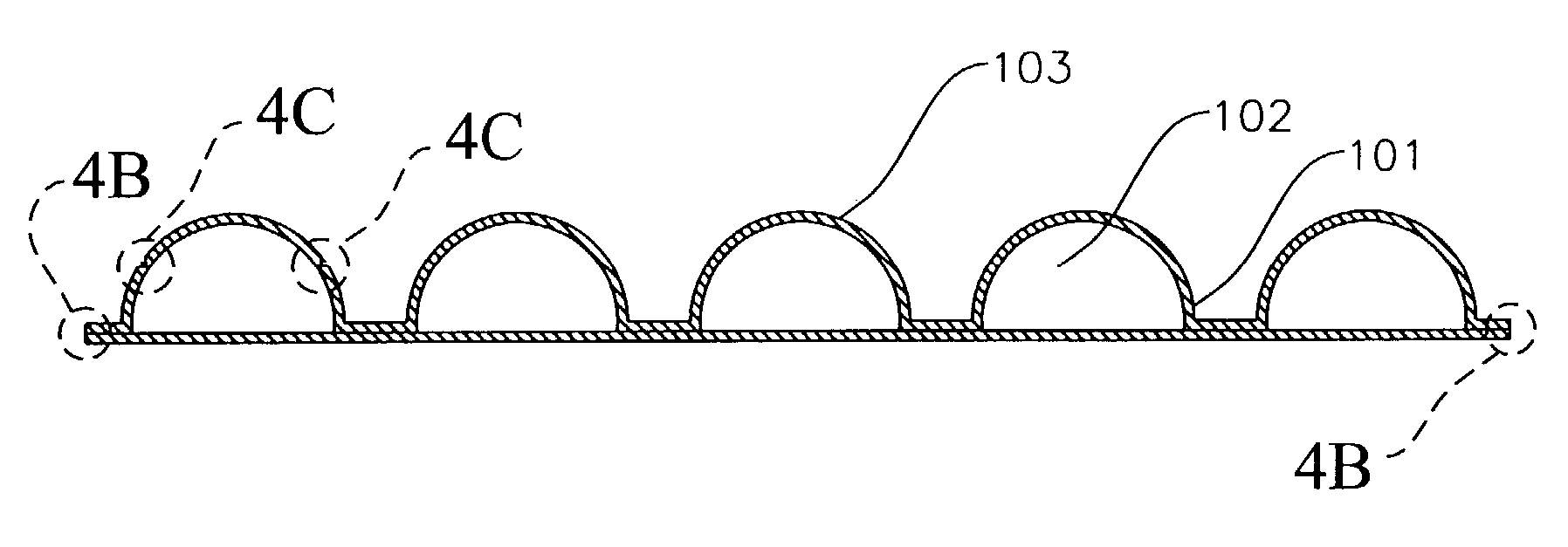

Multi-parameter fiber bragg grating sensing pipe health monitoring system

InactiveCN106958742AHigh measurement accuracyImprove accuracyMeasurement devicesPipeline systemsFiberGrating

The invention relates to a multi-parameter fiber grating sensing pipeline health monitoring system, which includes a fiber grating sensor, a junction box, a grating fiber optic demodulator, a data processing system and an online monitoring system, and optical fibers are installed at key nodes of pipeline main lines and branch lines Grating flow sensor, fiber grating pressure sensor installed near the valve and elbow of the pipeline, for the unburied pipeline, install the fiber grating acoustic emission sensor on the outer wall of the pipeline near the valve and elbow, and install the fiber grating acoustic emission sensor on the outer wall of the pipeline in the axial direction Fiber Bragg grating strain sensors arranged around the circumference are installed at intervals to monitor the stress distribution of the outer wall of the pipeline when there is no leakage and the strain on the outer wall of the pipeline caused by negative pressure waves when there is leakage. For buried pipelines, fiber gratings are arranged around the pipeline to measure temperature For optical cables, fiber grating anti-intrusion optical cables are laid above the pipeline. The system can monitor various parameters and judge various health states of the pipeline, and the accuracy of leakage judgment is high.

Owner:WUHAN UNIV OF TECH

Blast compression wave absorbing device

InactiveUS20060027419A1Reduction of peak overpressureReduce impulseNoise reduction installationsFuel tank safety measuresMilitary installationAmbient pressure

A blast compression wave absorbing device comprises a container filled with gas or air under pressure below ambient pressure (under vacuum). The device is positioned close to the facility or structure being protected, in atmosphere or under water. When a blast compression wave reaches the device, in accordance with various embodiments of the invention, the container collapses, ruptures, or its interior is being connected to the environment through rupturable diaphragm or fast-actuating valve. The ambient air starts to fill the internals of the container generating a negative pressure wave, which interferes with blast compression wave and produces a resulting pressure wave with reduced pressure and impulse affecting the facility or structure to be protected. The device can be used in a counter-terrorism operations, to protect high-risk facilities (nuclear and military installations, petrochemical plants, embassies), submerged structures, or to protect personnel in tunnels and bunkers from shock waves of fuel-air explosives.

Owner:PONOMAREV VLADIMIR +1

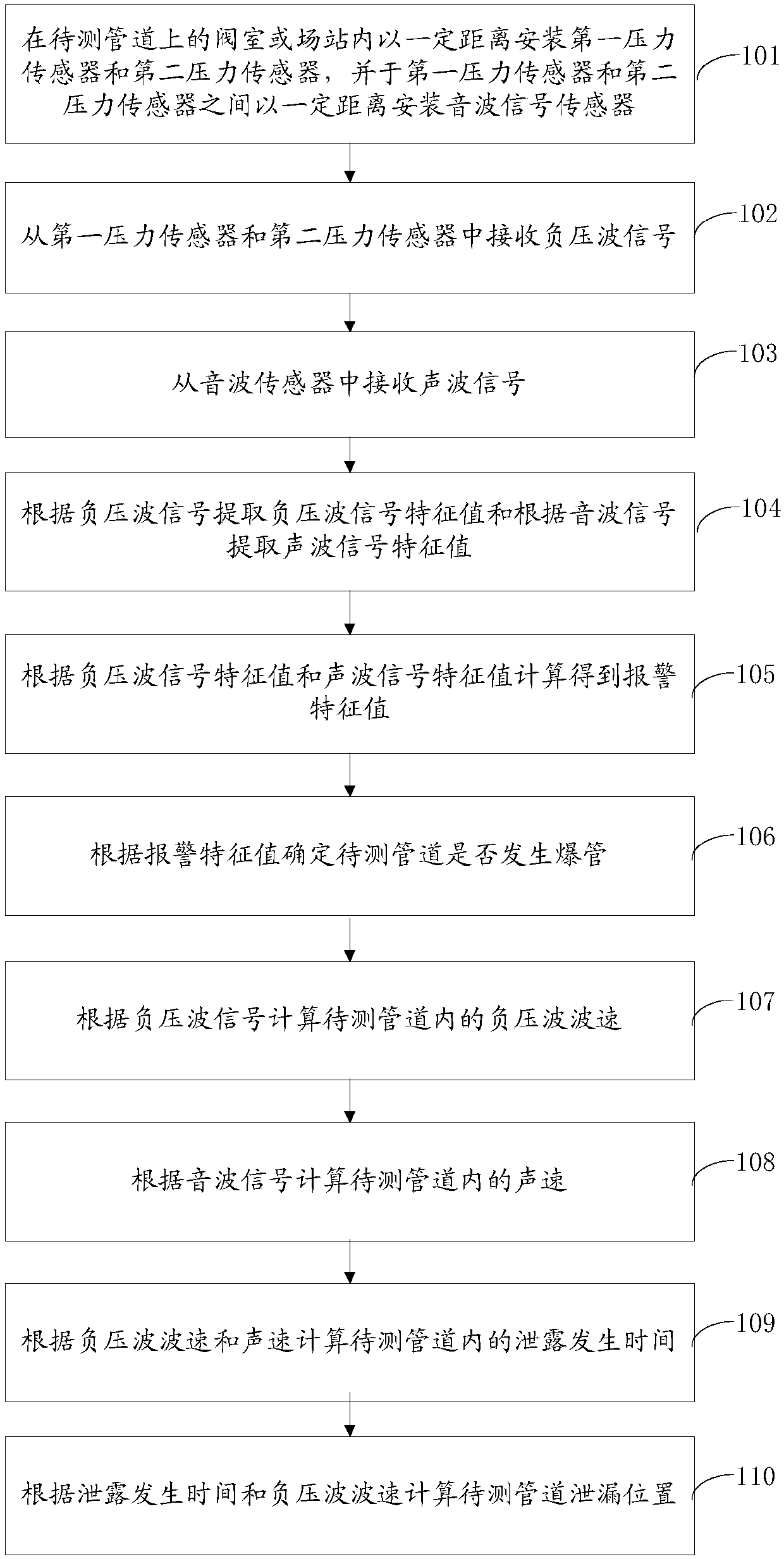

Oil and gas pipeline burst detecting and positioning method

ActiveCN107869654ADiscovered in timeReduce false alarm rateDetection of fluid at leakage pointPipeline systemsAcoustic waveFalse alarm

The invention discloses an oil and gas pipeline burst detecting and positioning method, and belongs to the technical field of oil and gas storage and transportation. The method comprises the steps that a first pressure sensor, a second pressure sensor and a sound wave signal sensor are arranged in a valve chamber or a field station on a pipeline to be detected at a certain distance, a negative pressure wave signal and a sound wave signal are received, negative pressure wave signal characteristic value and sound wave signal characteristic value are extracted to calculate alarm characteristic value, whether the pipeline to be detected bursts or not is determined, and according to the negative pressure wave signal and the sound wave signal, the leakage position of the pipeline to be detectedis calculated. According to the oil and gas pipeline burst detecting and positioning method, in combination with advantages of multiple detection methods, the false alarm probability is reduced, alarminformation can be conveniently found in time, meanwhile, the oil and gas pipeline burst positioning method is provided, the leakage position of the pipeline to be detected can be positioned, and theneeded device is compact in mounting, convenient to operate and capable of achieving independent positioning.

Owner:PETROCHINA CO LTD

Controlling valve

InactiveUS20090045370A1Overcome disadvantagesServomotor componentsAnimal watering devicesPositive pressureControl valves

A controlling valve includes an outer sheet, an end cap and a control valve group. The control valve group is disposed between a flowing bore in the outer sheet and a water bore in the end cap. The controlling water valve is connected with the outlet of a water tube. When the control valve group is pushed upwards, the water bore in the end cap and the flowing bore in the outer sheet are closed in a predetermined sequence, then the water in the tube will not flow out. When the control valve group is pushed downwards, the flowing bore in the outer sheet and the water bore in the end cap are opened, then the water will flow out. When the water is stopped, the occurring positive or negative pressure wave is lowered, and then the vibration and the raspy noise will be avoided.

Owner:HIGHPLUS INT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com