Multi-parameter fiber bragg grating sensing pipe health monitoring system

A health monitoring system, optical fiber grating technology, applied in pipeline systems, measuring devices, instruments, etc., can solve problems such as errors, inability to prevent in advance, leakage, etc., and achieve improved accuracy, good acoustic transmission, and high measurement accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

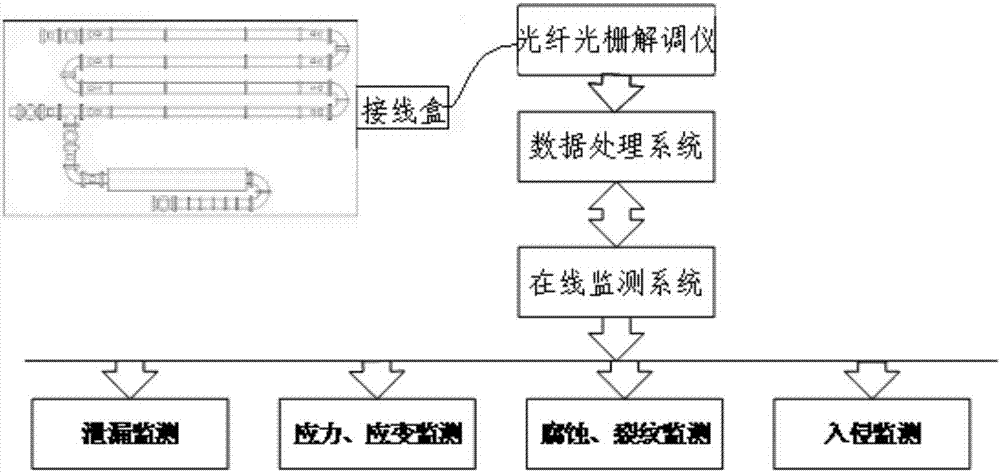

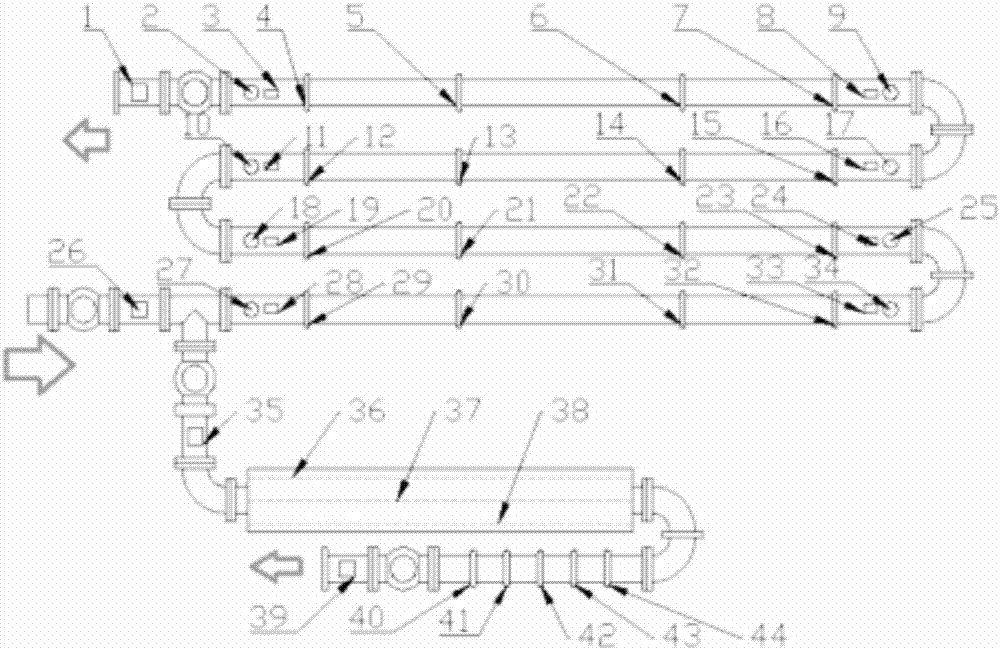

[0022] Such as figure 1 As shown, a multi-parameter fiber grating sensing pipeline health monitoring system is used to monitor multiple parameters of the pipeline and evaluate the health status of the pipeline through the collected parameters, including fiber grating sensors distributed on the pipeline and connected with The fiber grating sensor is connected in turn to the junction box, grating fiber demodulator, data processing system and on-line monitoring system, such as figure 2 As shown, fiber grating flow sensors are installed inside the key nodes of the main line and branch lines of the pipeline, and fiber grating pressure sensors are installed inside the pipeline near the valves and elbows. It is judged by the changes of the monitored flow and pressure and the distribution of the flow. There is leakage; for unburied pipelines, install fiber op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com