Method for locating leakage position of ore pulp conveying pipe

A leakage location and transmission pipeline technology, applied in the field of transportation control, can solve the problems of enterprise economic loss, environmental pollution, ore slurry leakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The method for the leakage position of the slurry conveying pipeline of the present invention, its steps are:

[0028] (1) When the slurry is transported normally, when the slurry pipeline is in normal operation, the outlet pressure, inlet pressure and flow rate of the upstream and downstream pump stations of the slurry pipeline are in a stable state;

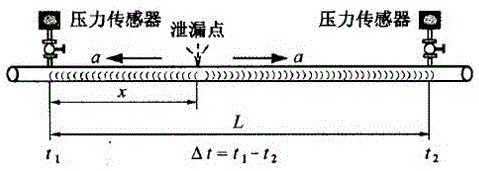

[0029] (2) After a leak occurs at a distance χ from the upstream pumping station of the pipeline, t 1 Time is the time when the negative pressure wave is transmitted to the upstream pumping station of the pipeline, t 2 Time is the time when the negative pressure wave is transmitted to the downstream pumping station of the pipeline. By capturing the time difference between the negative pressure wave reaching the pressure transmitter of the upstream and downstream pumping station of the pipeline, combined with the propagation speed of the negative pressure wave to determine the location of the pipeline leakage, its positio...

Embodiment 2

[0046] A slurry pipeline in China implemented an emergency drill for slurry pipeline leakage in 2014. The inner diameter D of the slurry pipeline is 224.5mm, and the slurry density ρ is 2121kg / m 3, The elastic modulus E of the pipeline material is 2.07*10^11pa, the pipeline wall thickness e is 10mm, the distance L between the upstream and downstream pumping stations is 47 kilometers, and the leakage point is set at a distance of 35.2 kilometers from the upstream pumping station of the pipeline, theoretically calculated by the above method Leakage point, the bulk elastic modulus of the transported pulp is 27*10^7pa measured through experiments, and the negative pressure wave velocity is measured to be about 992m / s through theoretical calculations, and then the negative pressure wave is transmitted to the upstream pump station through the SCADA computer program The time difference Δt with the downstream pumping station is 21.8 seconds. Using the slurry pipeline leakage location f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com