Patents

Literature

47 results about "Pressure wave propagation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

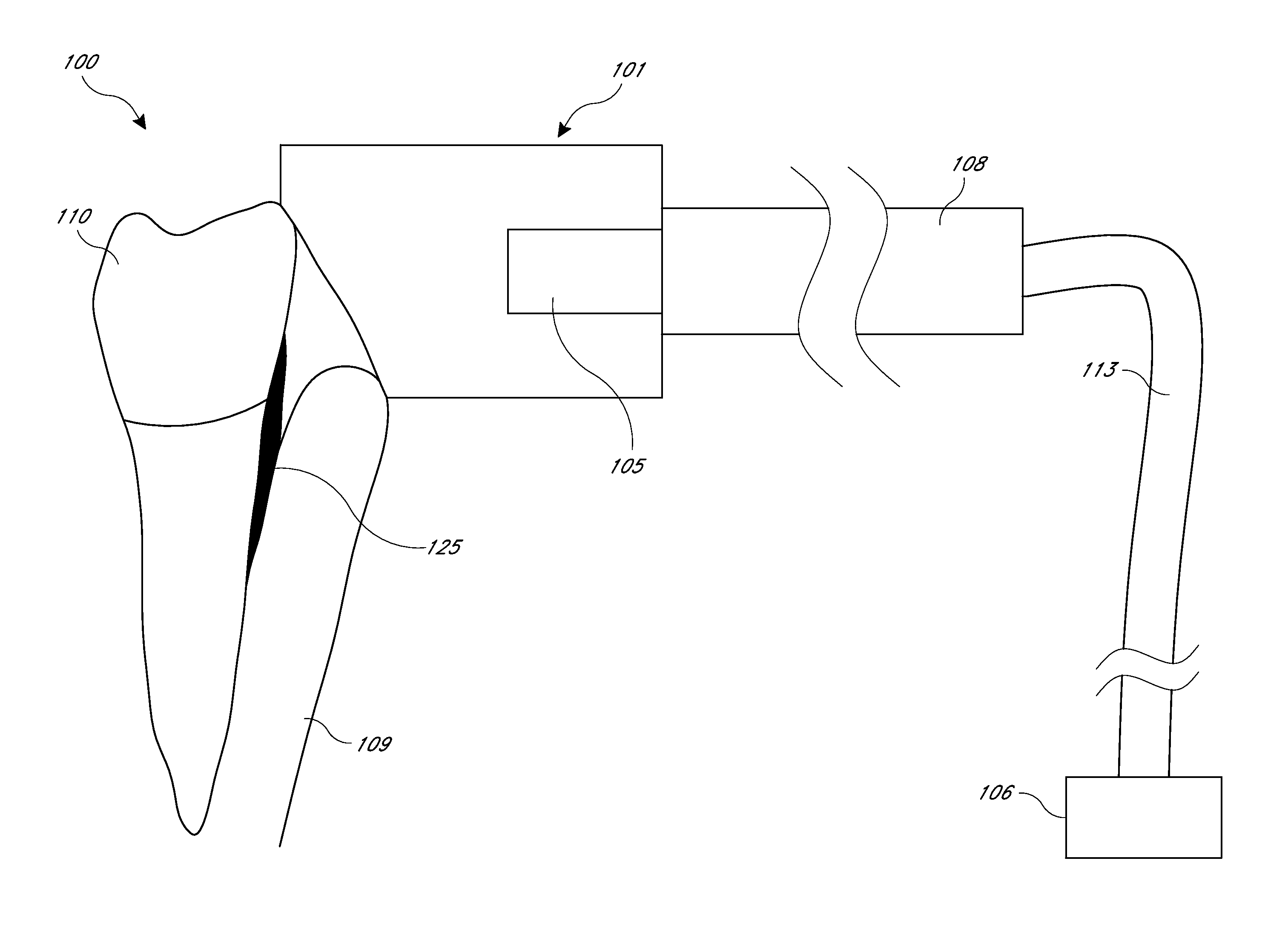

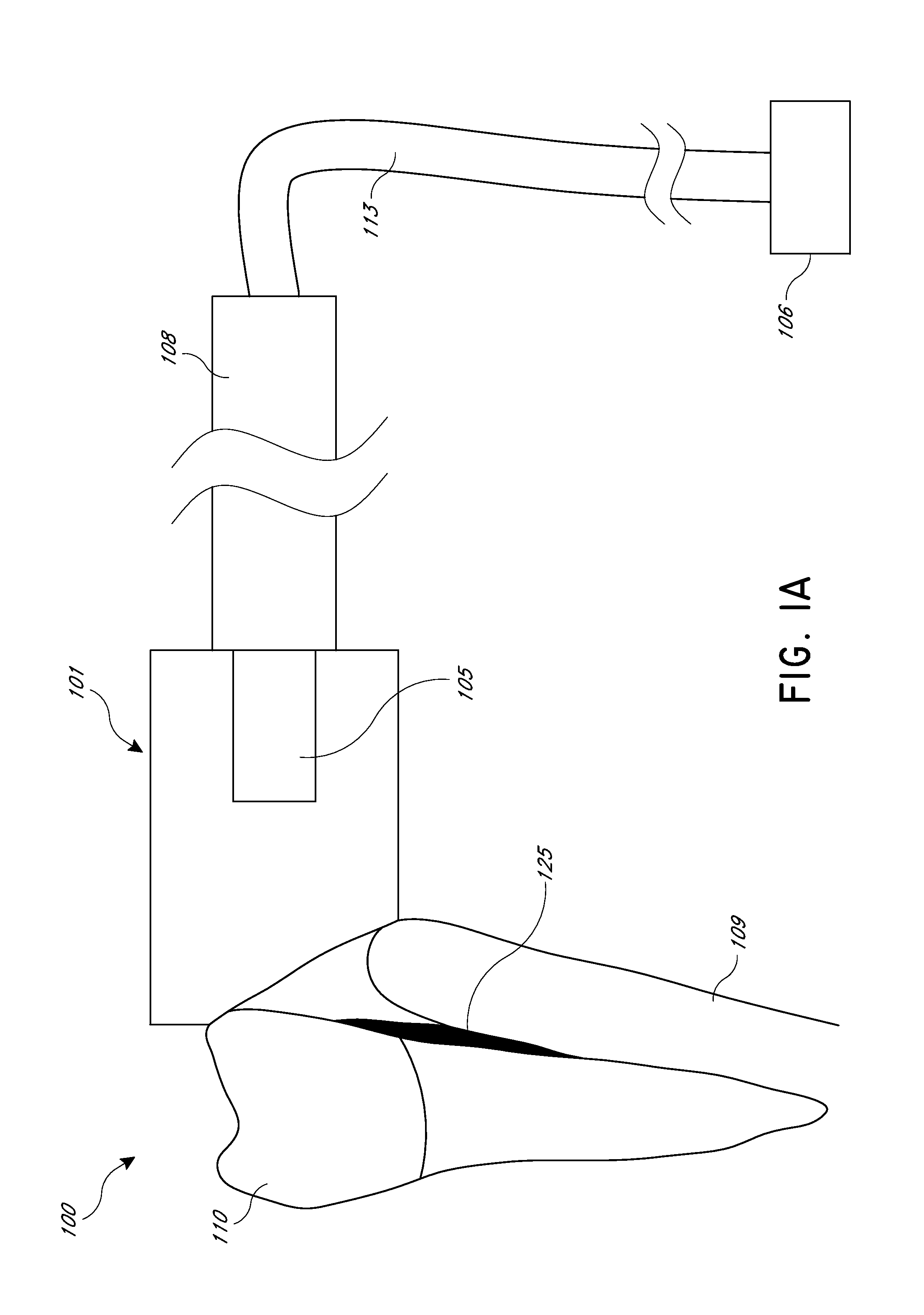

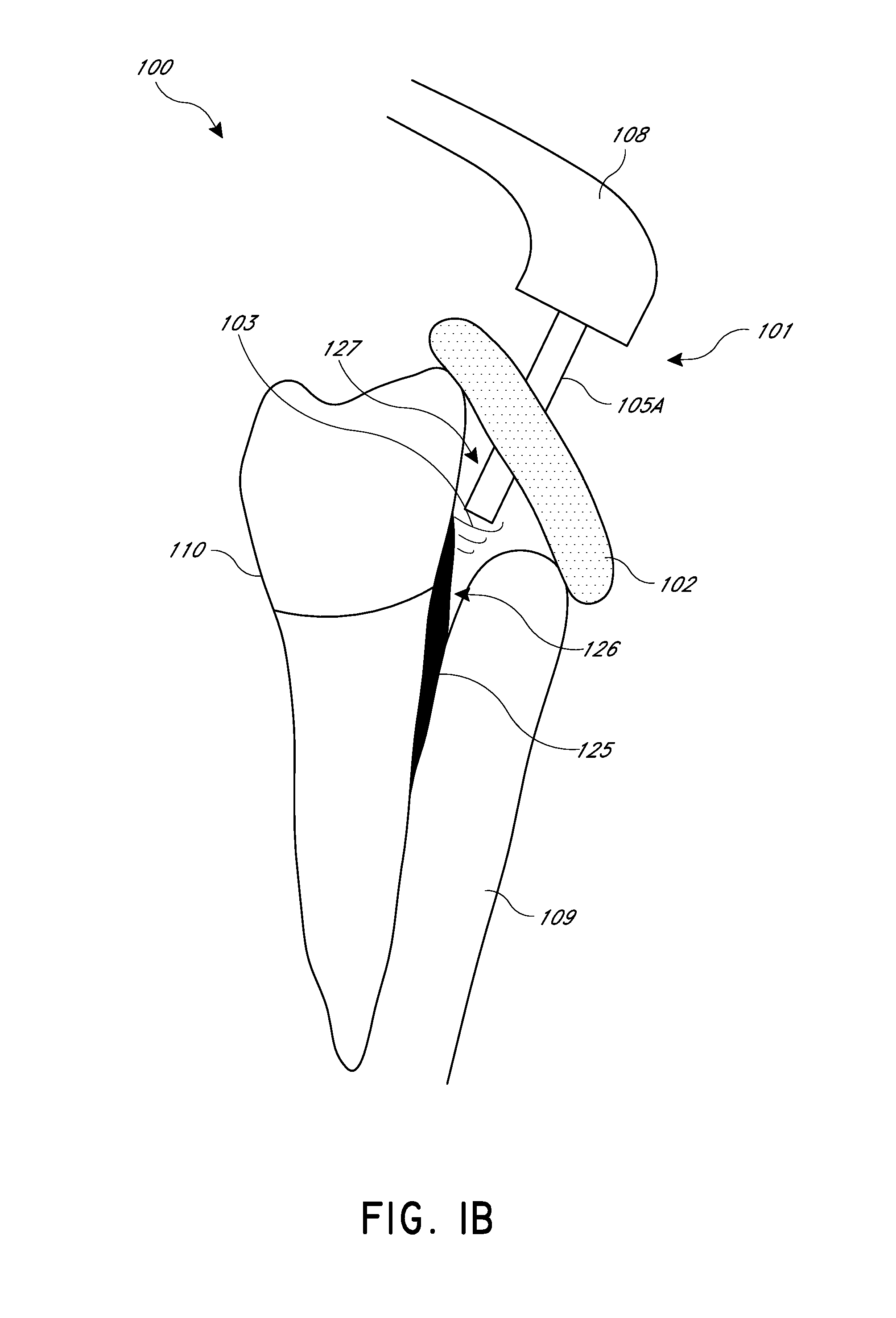

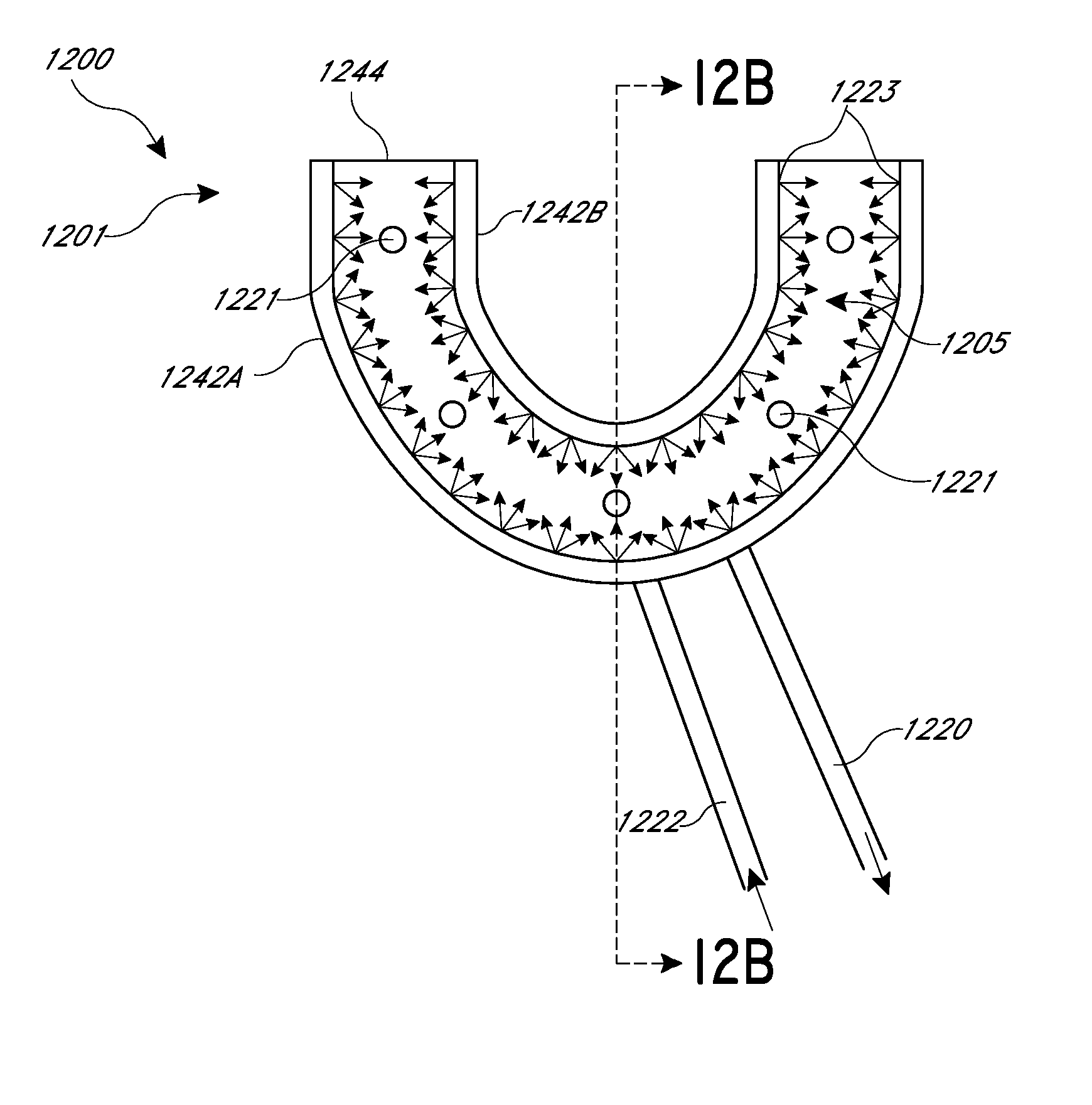

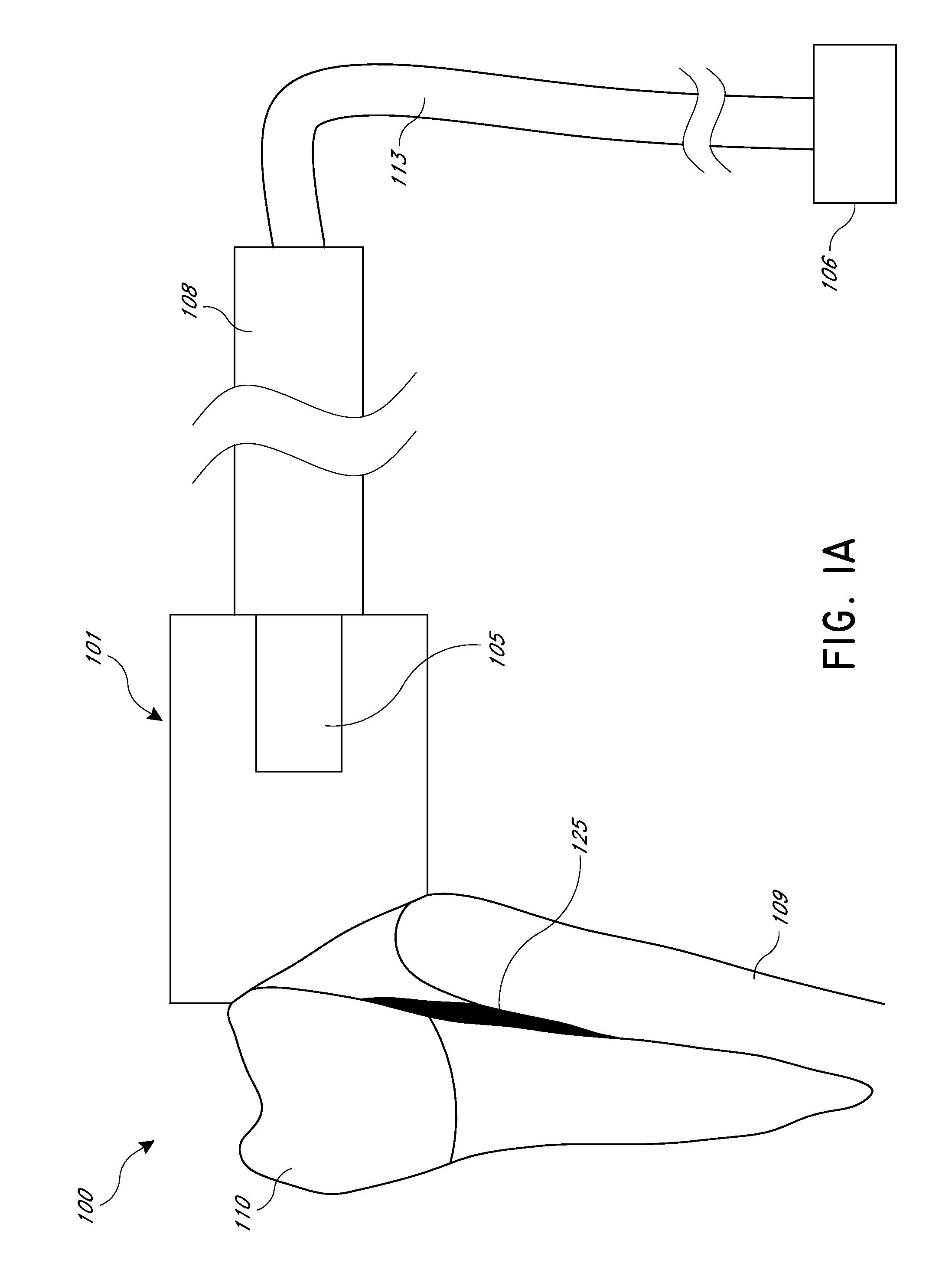

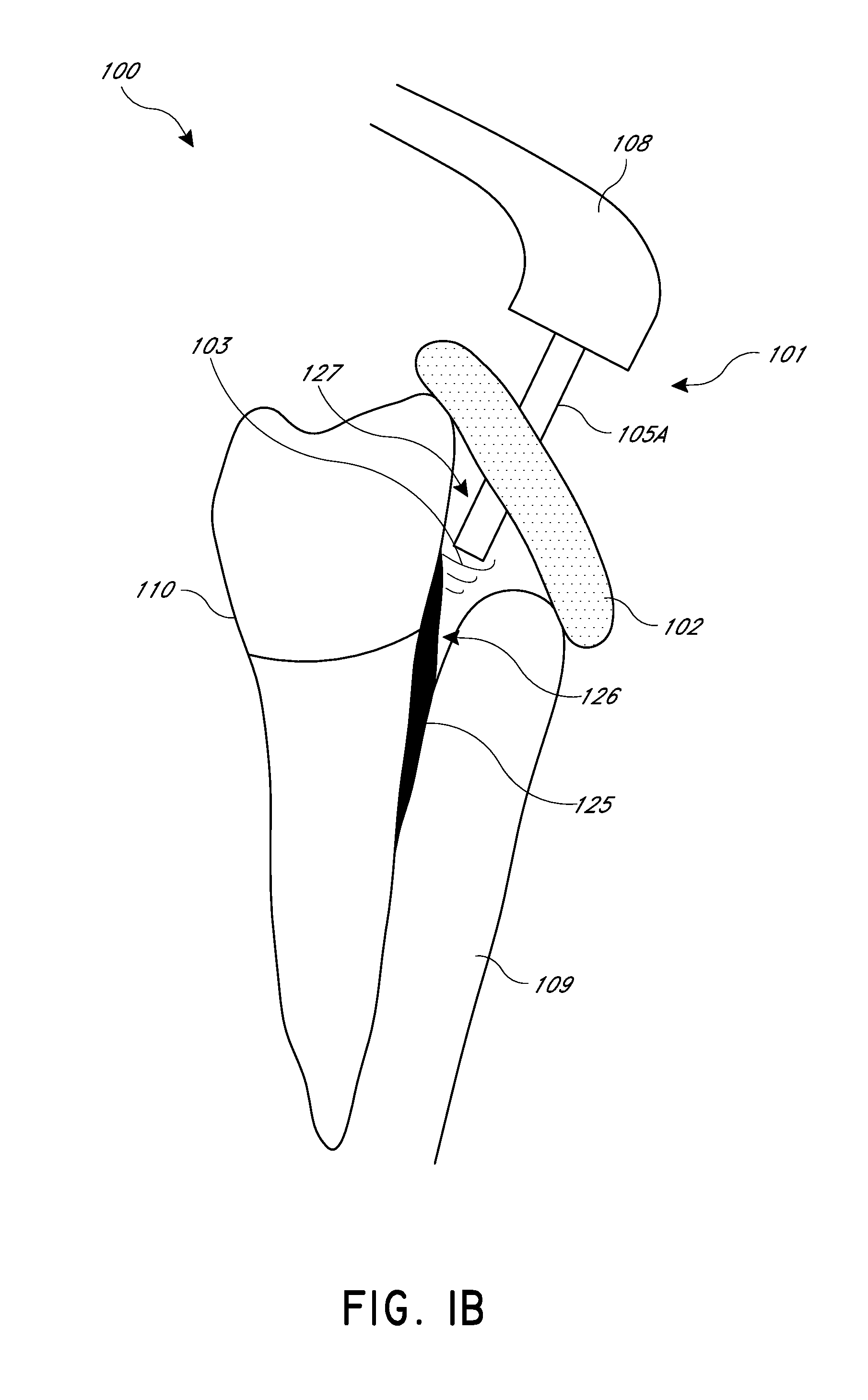

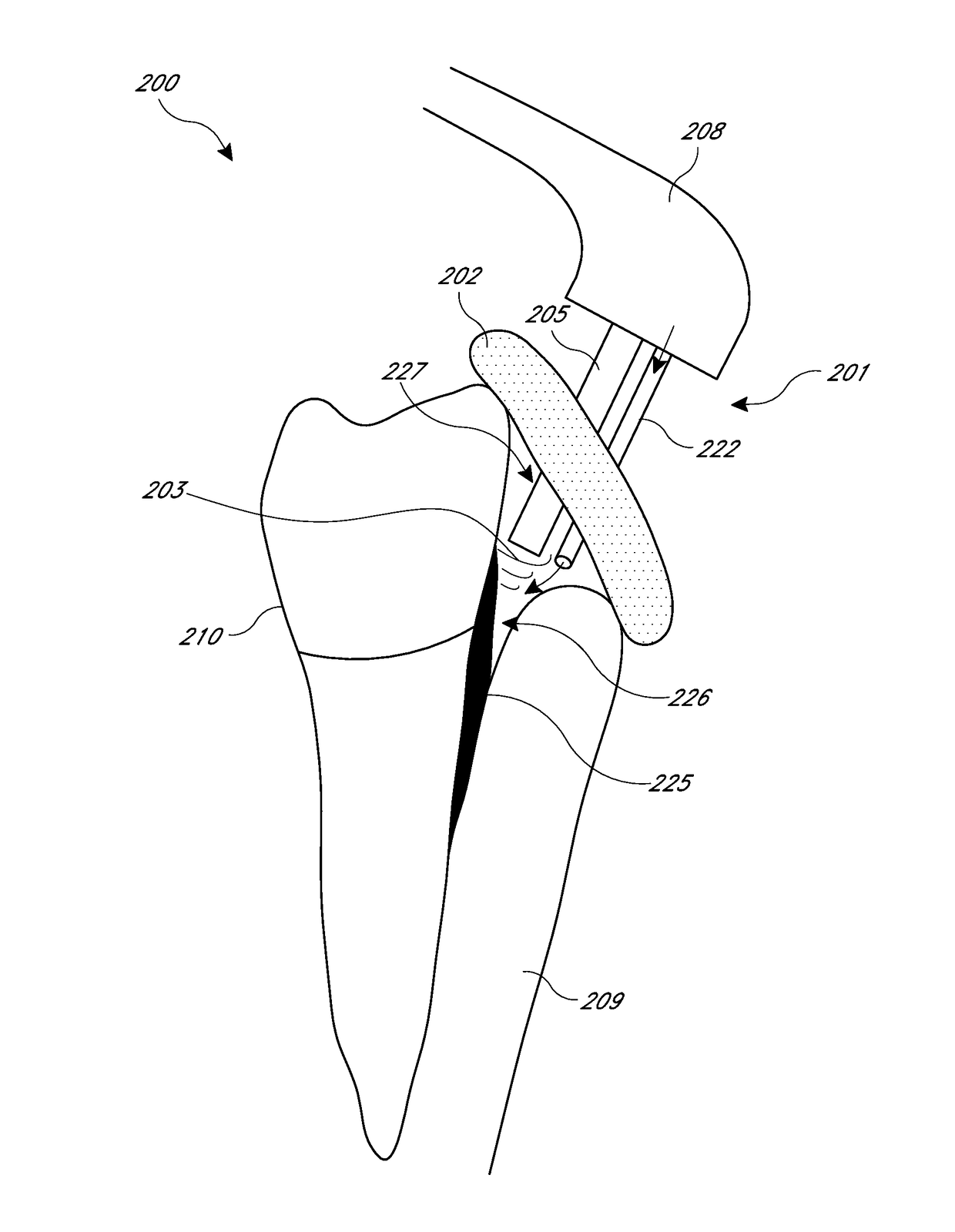

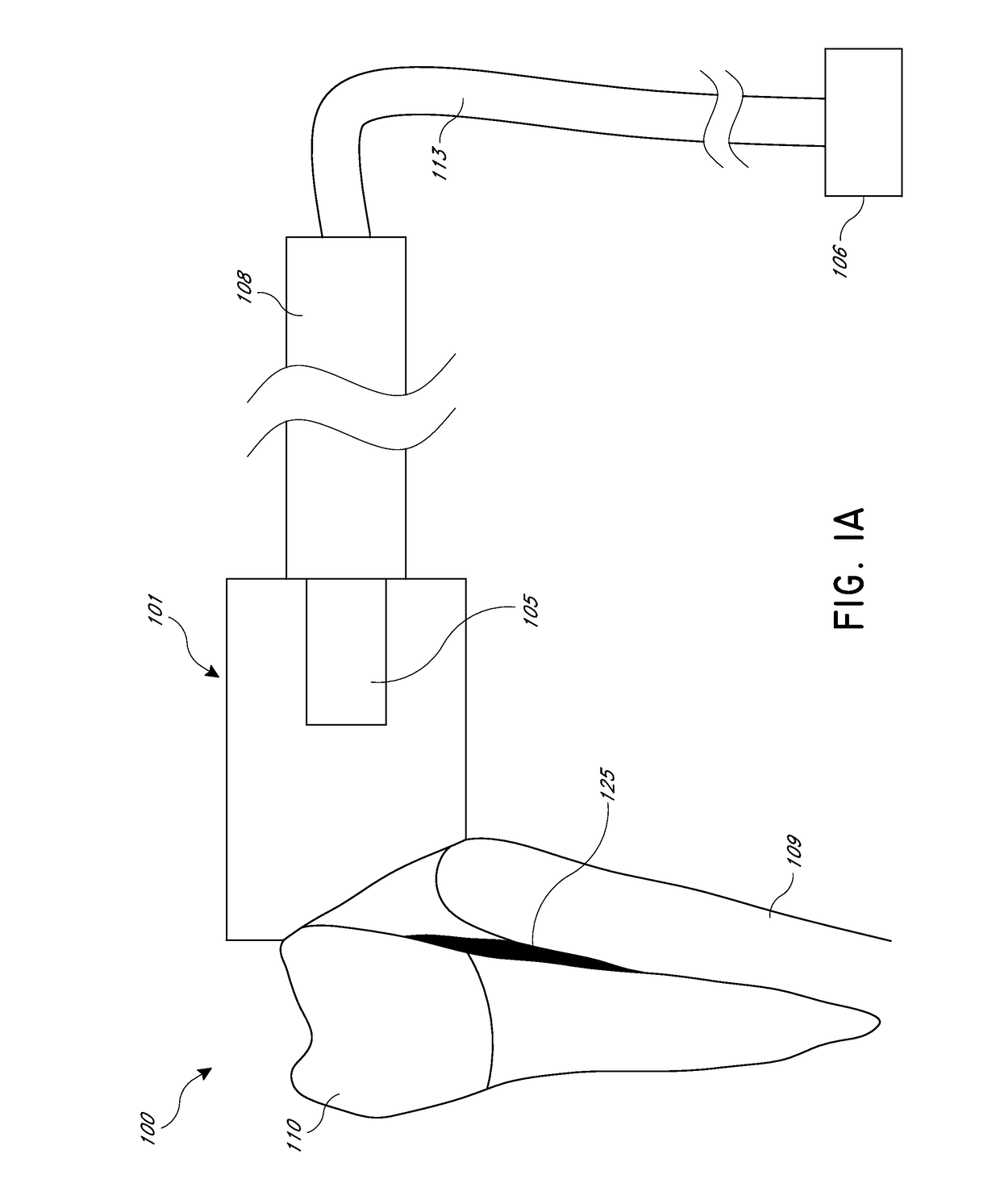

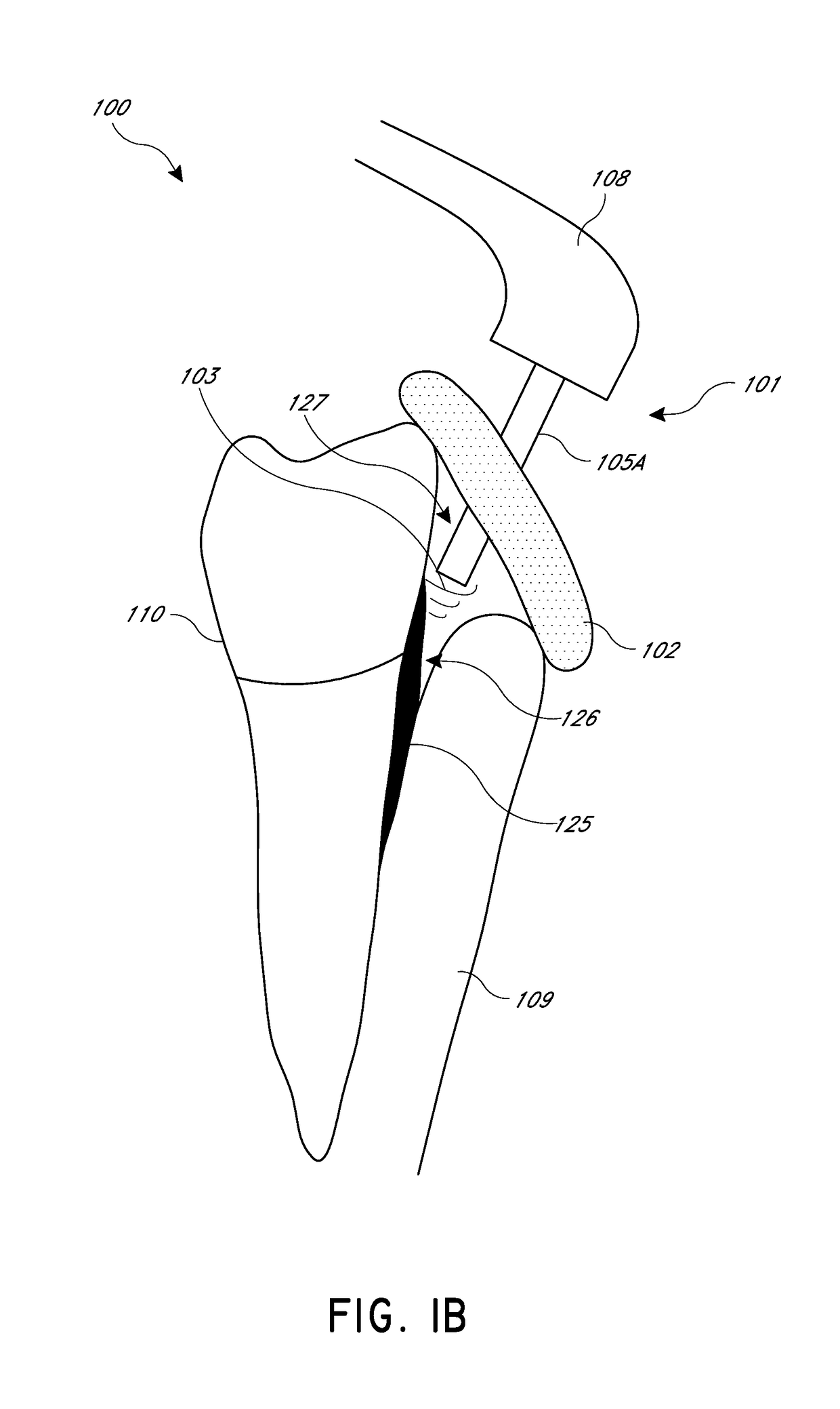

Apparatus and methods for cleaning teeth and gingival pockets

Various apparatus and methods for cleaning teeth and gingival pockets are disclosed herein. A fluid platform can include a pressure wave generator configured to propagate pressure waves through a treatment fluid. The pressure waves may be sufficient to remove undesirable dental deposits from a treatment tooth, neighboring gums, and / or spaces between the tooth and gums.

Owner:SONENDO

Apparatus and methods for cleaning teeth and gingival pockets

Various apparatus and methods for cleaning teeth and gingival pockets are disclosed herein. A fluid platform can include a pressure wave generator configured to propagate pressure waves through a treatment fluid. The pressure waves may be sufficient to remove undesirable dental deposits from a treatment tooth, neighboring gums, and / or spaces between the tooth and gums.

Owner:SONENDO

Apparatus and methods for cleaning teeth and gingival pockets

Various apparatus and methods for cleaning teeth and gingival pockets are disclosed herein. A fluid platform can include a pressure wave generator configured to propagate pressure waves through a treatment fluid. The pressure waves may be sufficient to remove undesirable dental deposits from a treatment tooth, neighboring gums, and / or spaces between the tooth and gums.

Owner:SONENDO

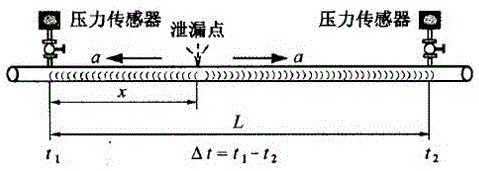

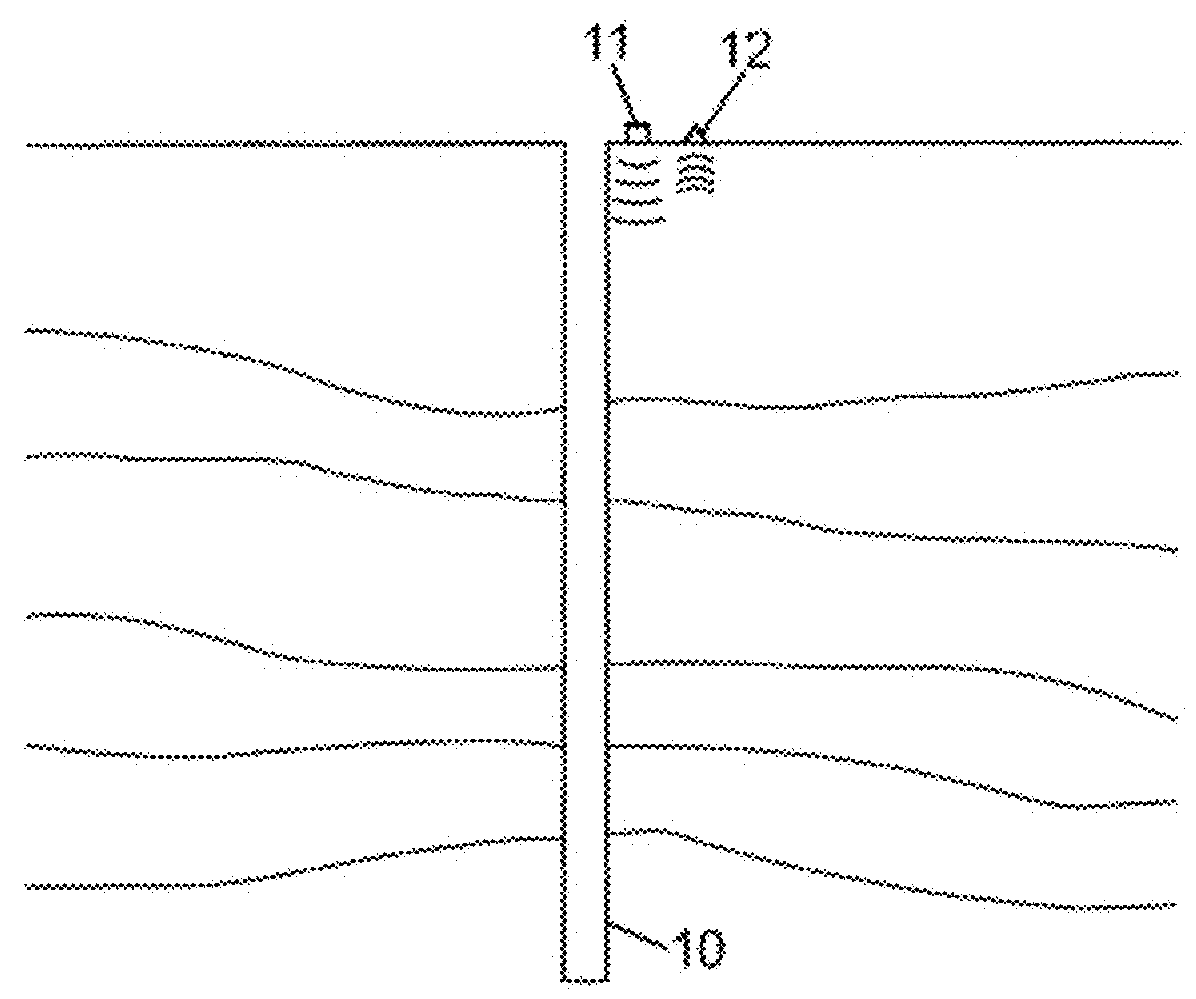

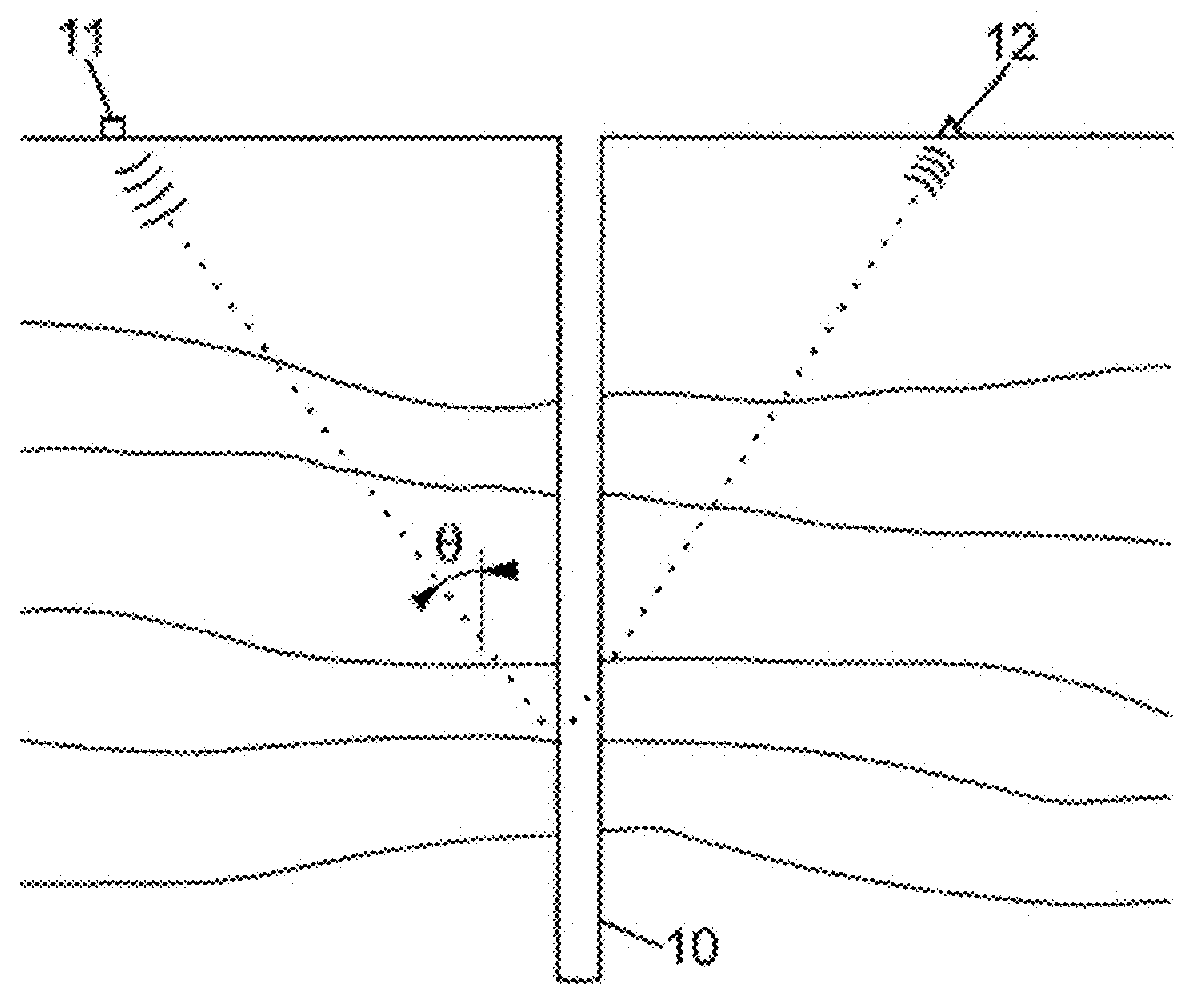

Method for locating leakage position of ore pulp conveying pipe

InactiveCN105135216ARealize real-time online monitoringReduce workloadPipeline systemsInternal pressurePressure difference

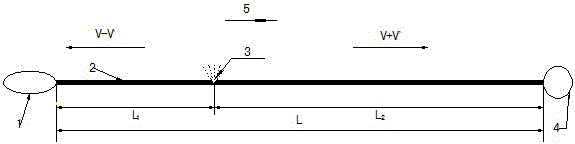

The invention provides a method for locating the leakage position of an ore pulp conveying pipe, relates to a conveying control method, in particular to the method for determining the leakage position when the conveying pipe is blocked in the long-distance iron concentrate ore pulp conveying process. According to the method, by the adoption of a negative-pressure wave method, when the iron concentrate pulp pipe generates leakage, concentrate pulp at a leakage point flows away rapidly due to the difference between the internal pressure and the external pressure of the pipe, and pressure drops down; liquid on both sides of the leakage point is supplemented to the leakage point due to the pressure difference; the above processes are sequentially passed to an upstream pump station and a downstream pump station through the concentrate pulp pipe, that is, negative-pressure waves propagating at a certain speed are generated at the leakage point; and the position of the leakage point can be worked out according to the time difference generated when negative-pressure weaves generated at the leakage point are propagated to the upstream pump station and the downstream pump station and the propagation speed of the negative pressure waves in the pipe. The method has the beneficial effects of being less in required devices, low in operation cost, simple in operation and the like and is superior to an existing method for determining the leakage position of the pipe.

Owner:YUNNAN DAHONGSHAN PIPELINE

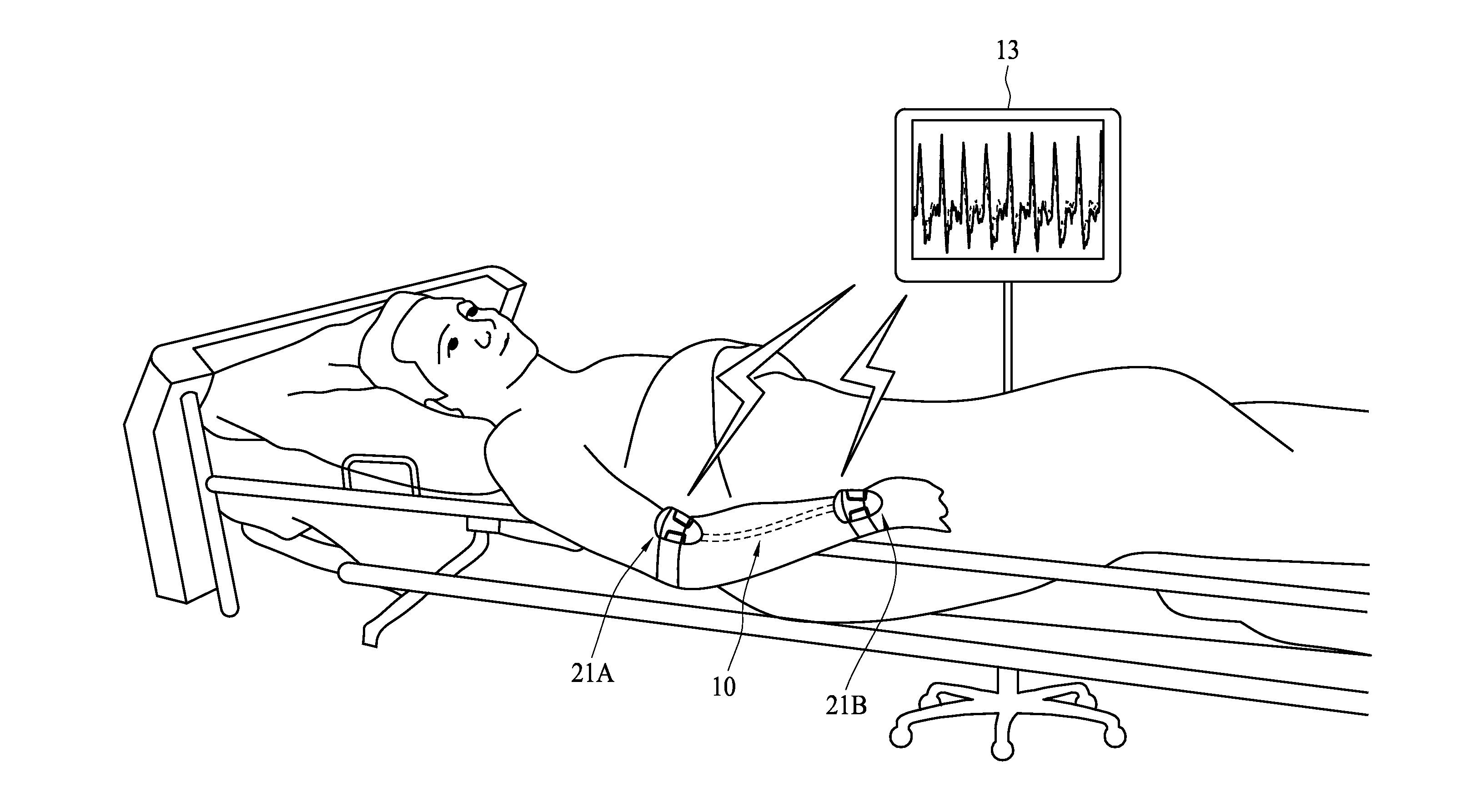

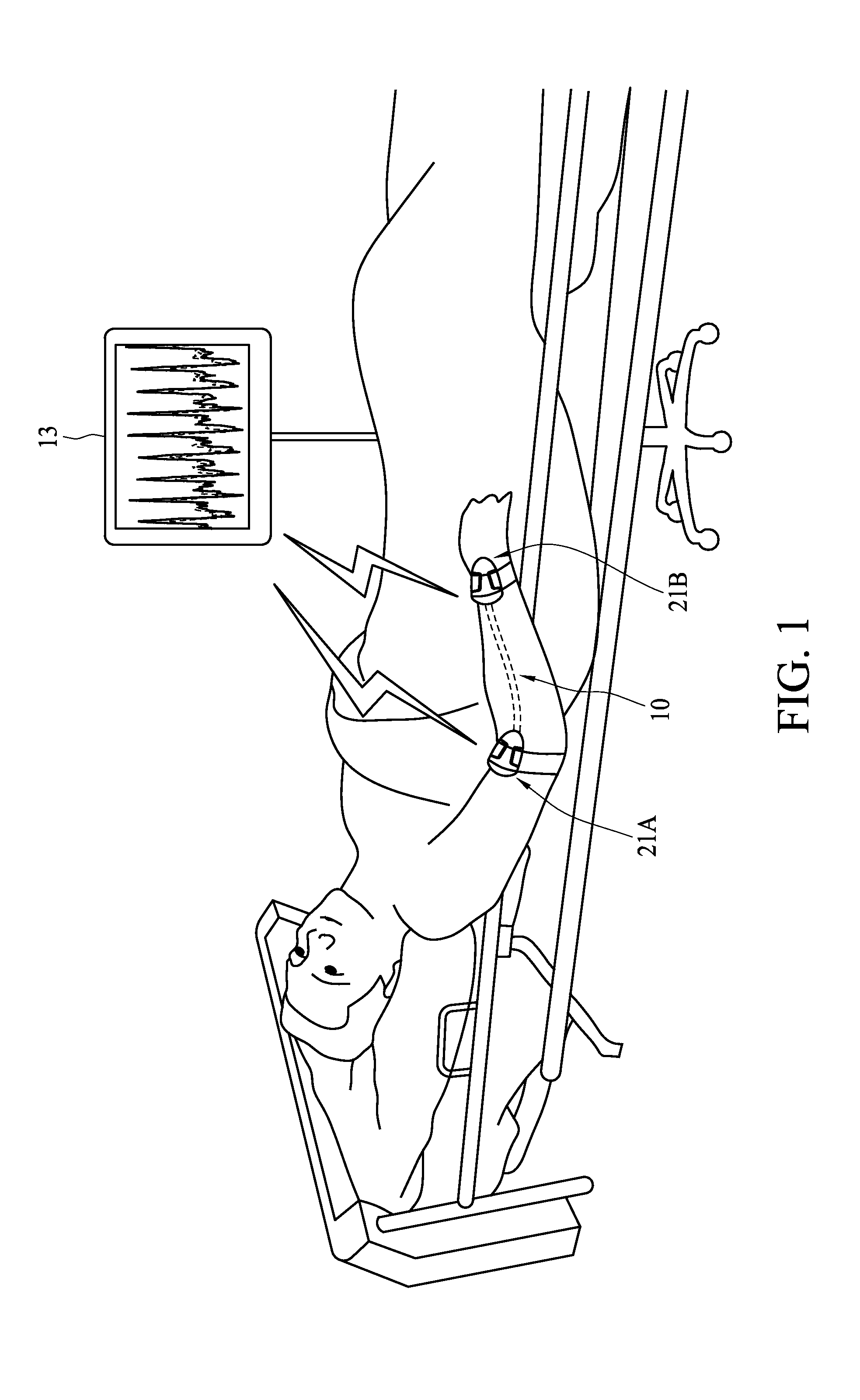

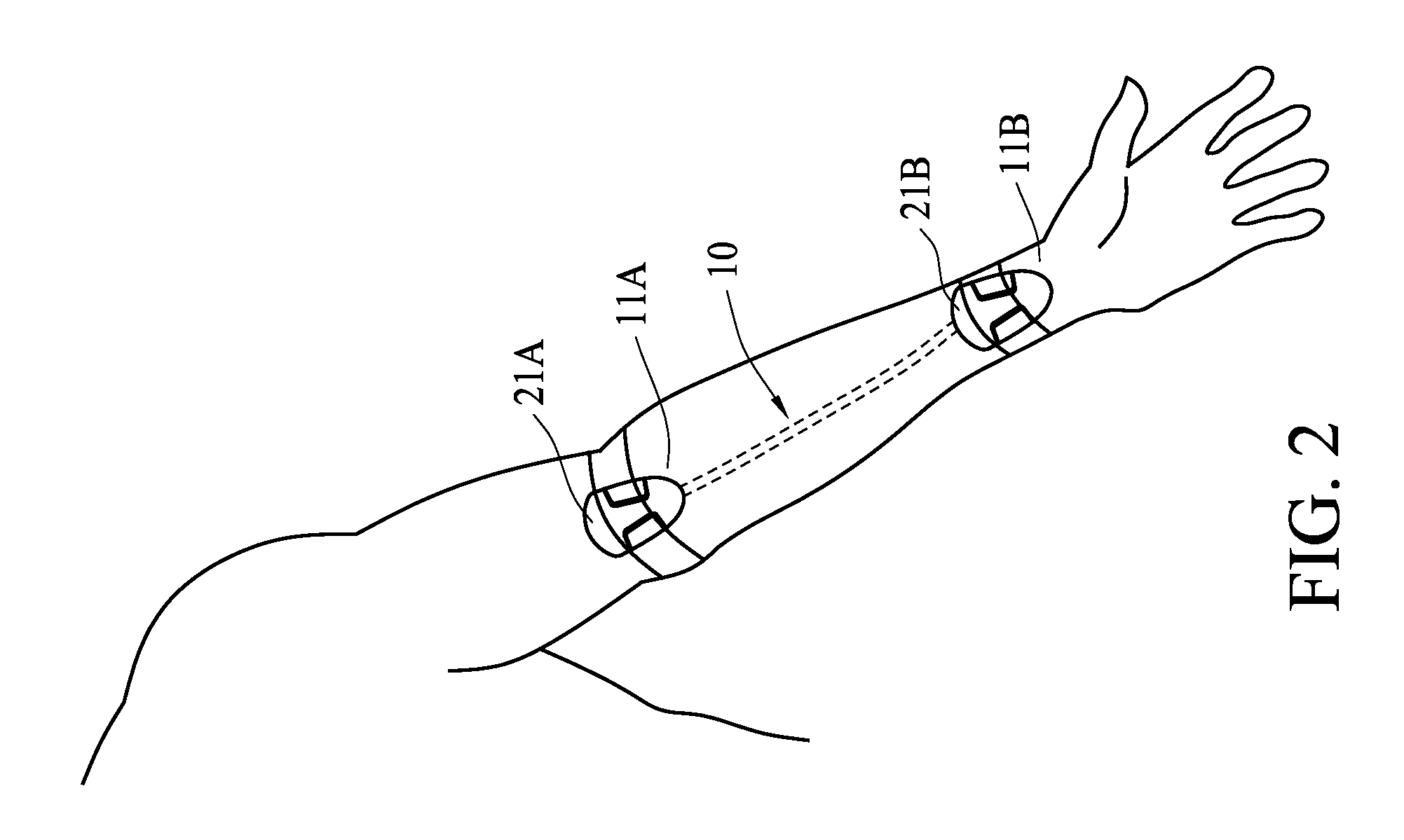

Non-invasive continuous blood pressure monitoring system and method

InactiveUS20140081159A1Less discomfortDiagnostics using lightEvaluation of blood vesselsUltra-widebandMedicine

A non-invasive continuous blood pressure monitoring system includes a first sensor configured to send a first ultra-wideband electromagnetic pulses to an upper site of a blood vessel and receive a first reflected ultra-wideband electromagnetic pulses with phase variations caused by a pressure wave propagating in the blood vessel, a second sensor configured to send a second ultra-wideband electromagnetic pulses to a lower site of the blood vessel and receive a second reflected ultra-wideband electromagnetic pulses with phase variations caused by the pressure wave propagating in the blood vessel, and a signal-processing and blood pressure displaying device configured to calculate an estimated blood pressure by taking into consideration a propagation time of the pressure wave from the upper site to the lower site in the blood vessel.

Owner:HOLUX TECH

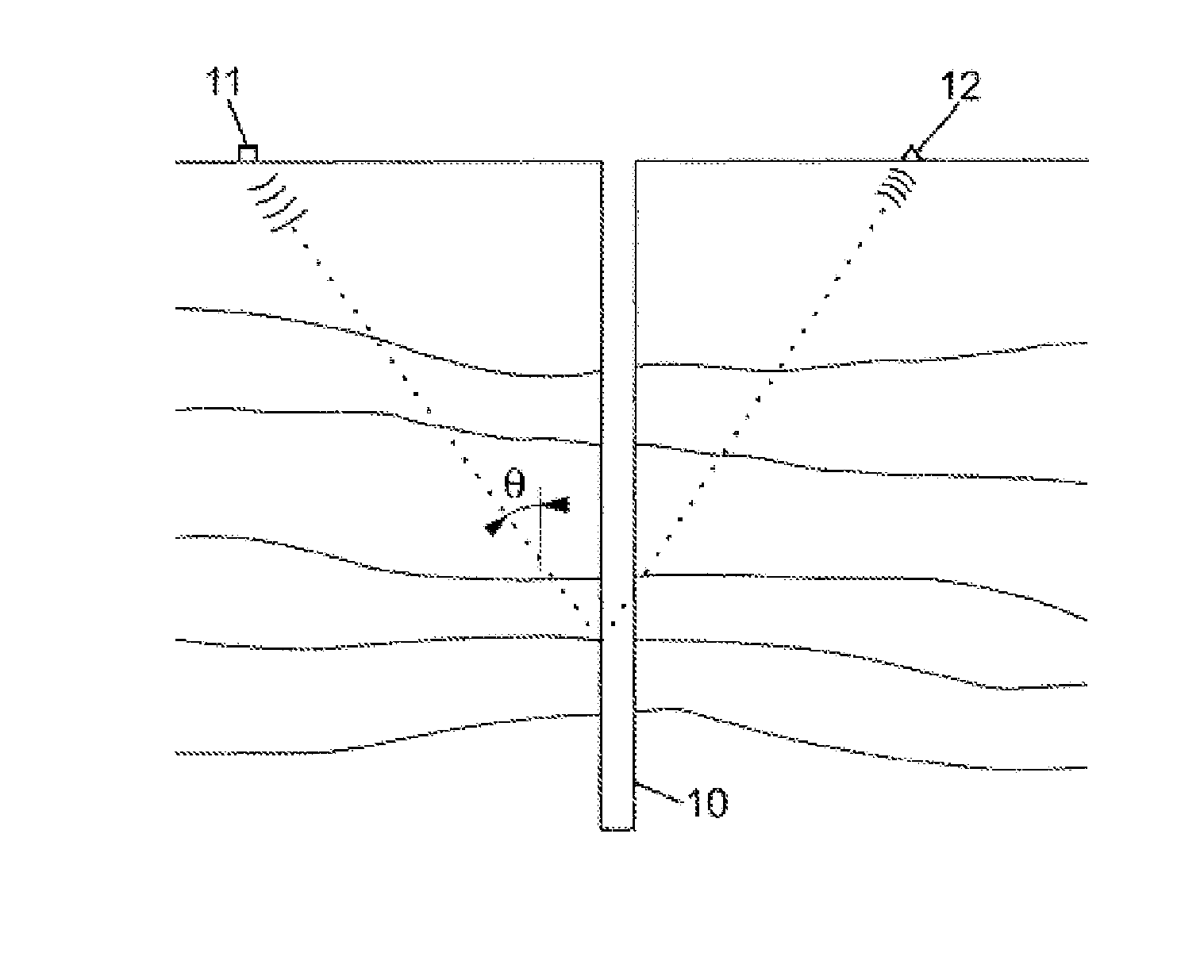

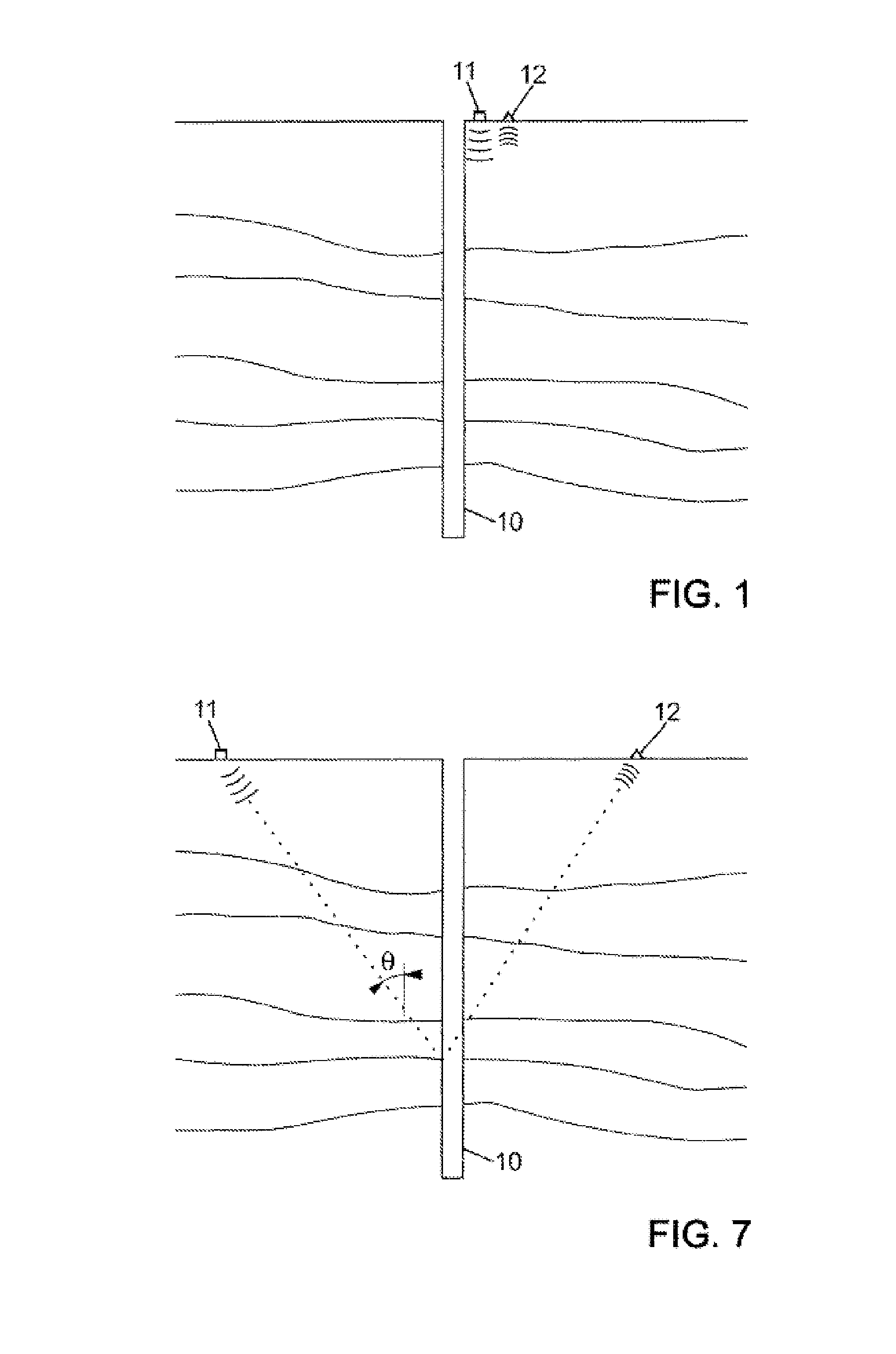

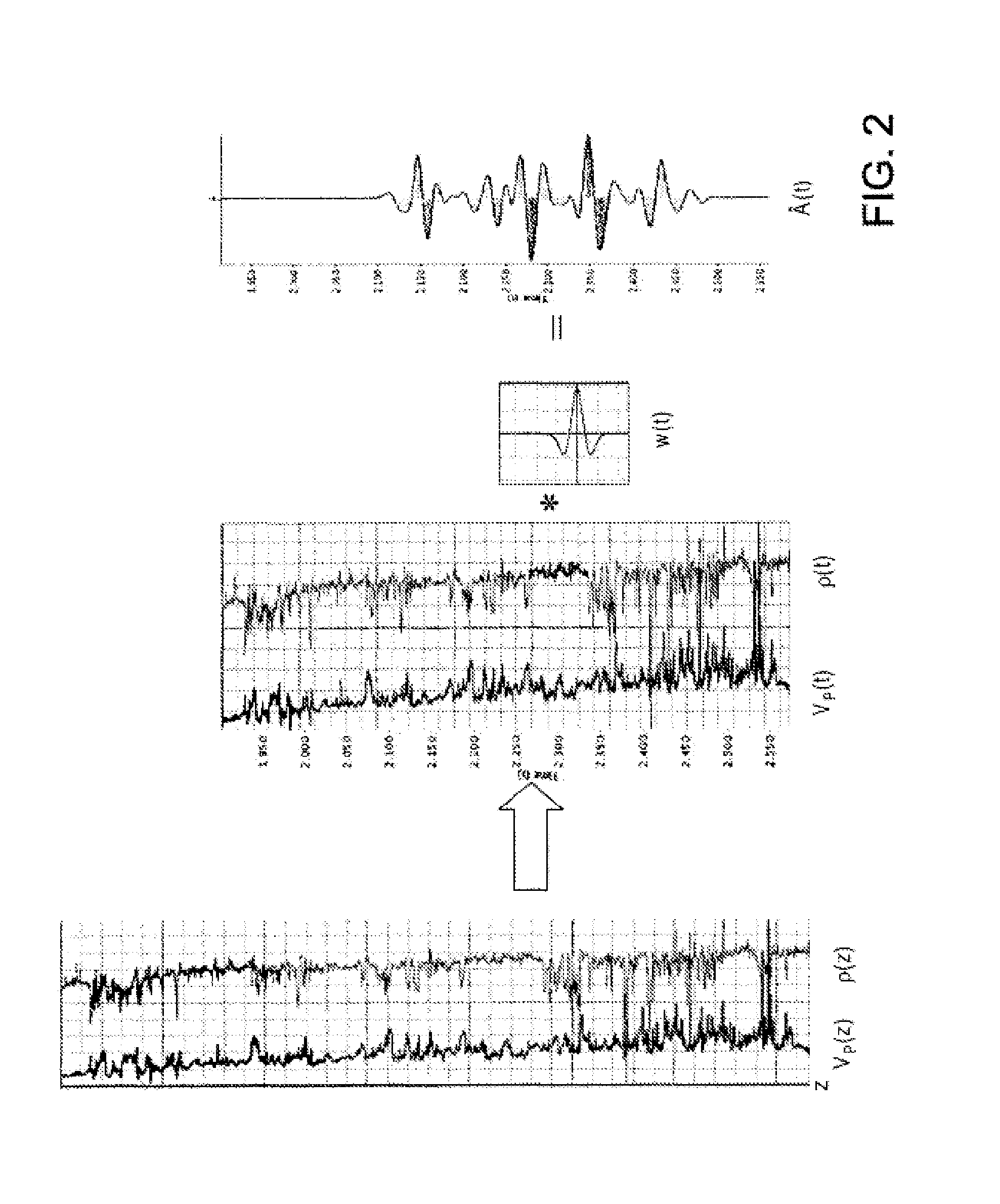

Method for estimating elastic parameters by inverting 4d seismic measurements

ActiveUS20130176822A1Speed up the processing operationsEasy to processSeismic signal processingSpatial changePressure wave propagation

According to the invention, elastic parameters, including density, pressure wave propagation speed, and / or shear in pervious layers located in a dense underground area along an array of horizontal positions, are estimated by inverting 4D seismic data. Firstly, an estimate of variations in the elastic parameters in one or more starting positions of the array, which can be located on bored wells within the area in question, is obtained. Then, a propagation algorithm is used in order to gradually carry out the 4D data inversion on the basis of the starting positions. The inversion takes into account the previously estimated parameter variations. A spatial variation in the depth and / or the thickness of the pervious lavers in question can also be taken into account. Propagation is based on positions that are consecutively selected as providing optimal values for a cost function assessed in order to invert the 4D data.

Owner:TOTAL PUTEAUX FR

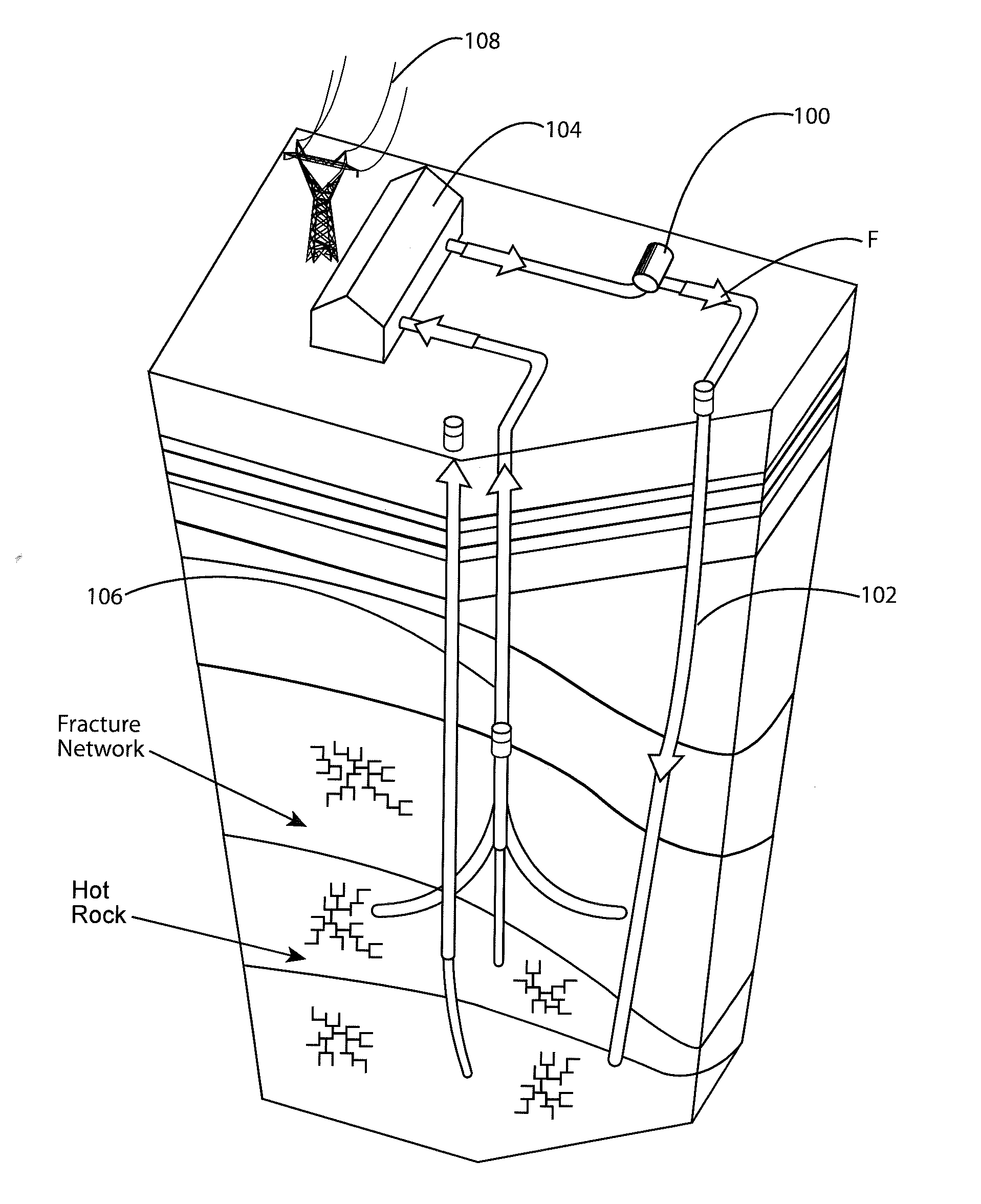

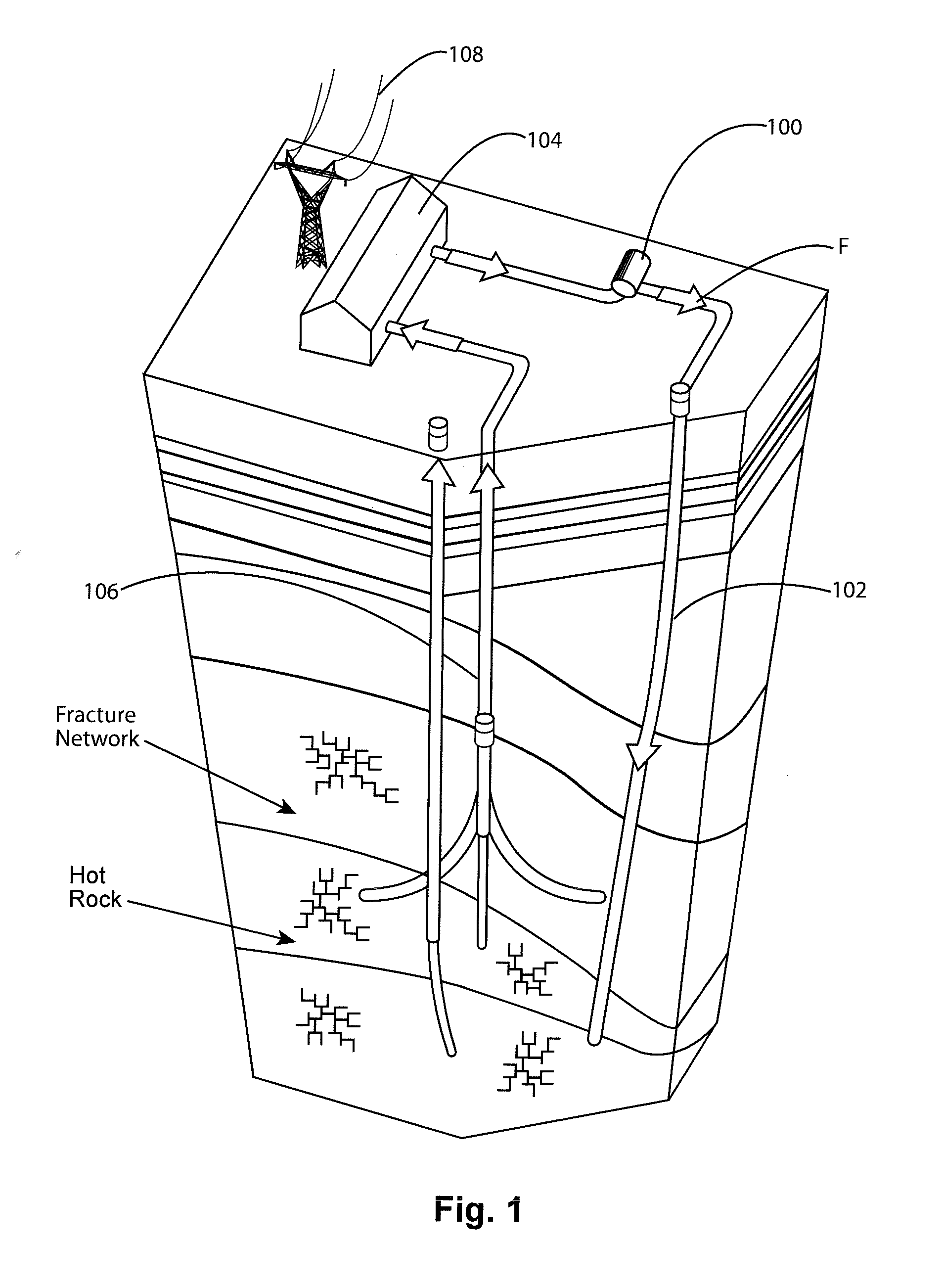

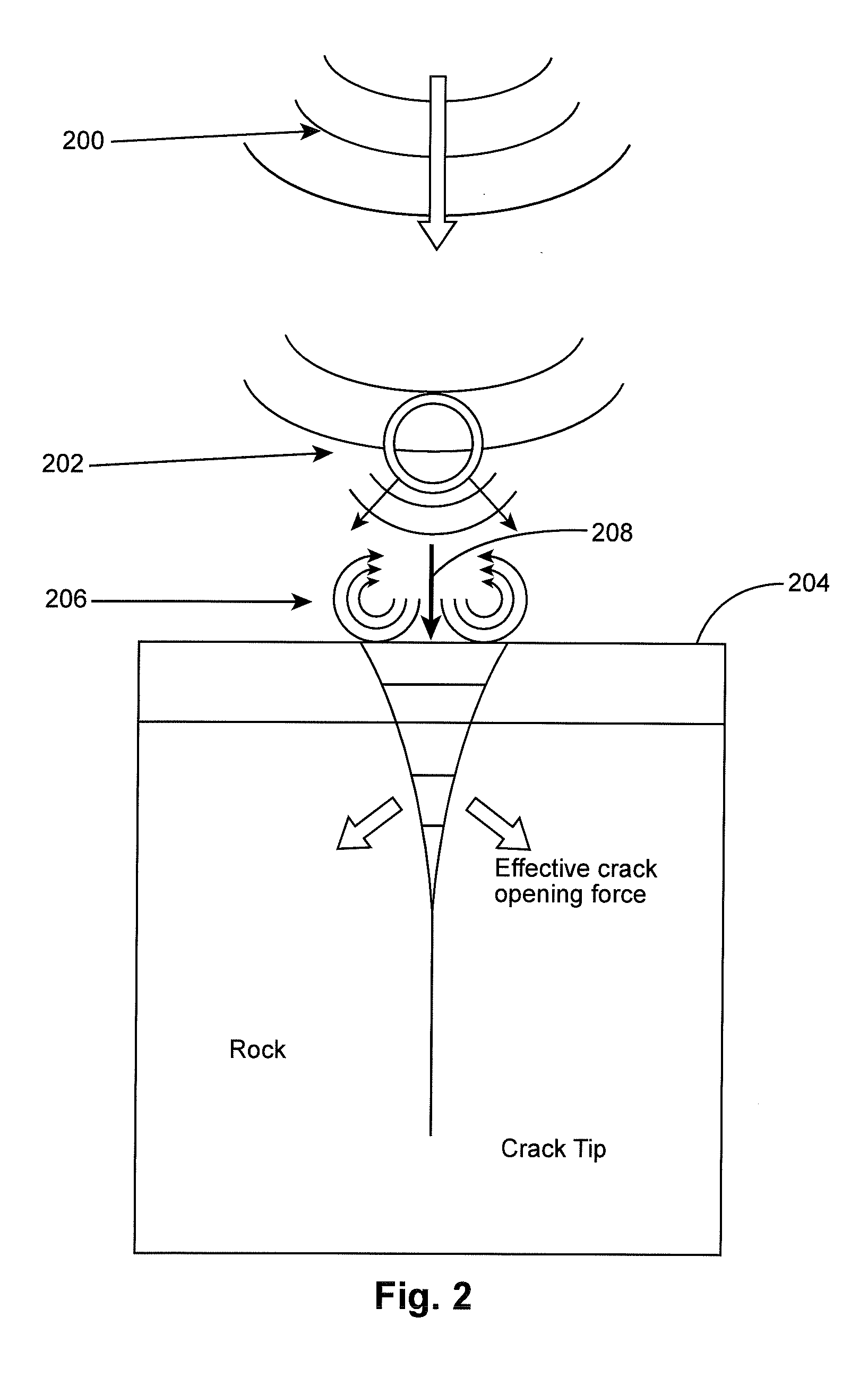

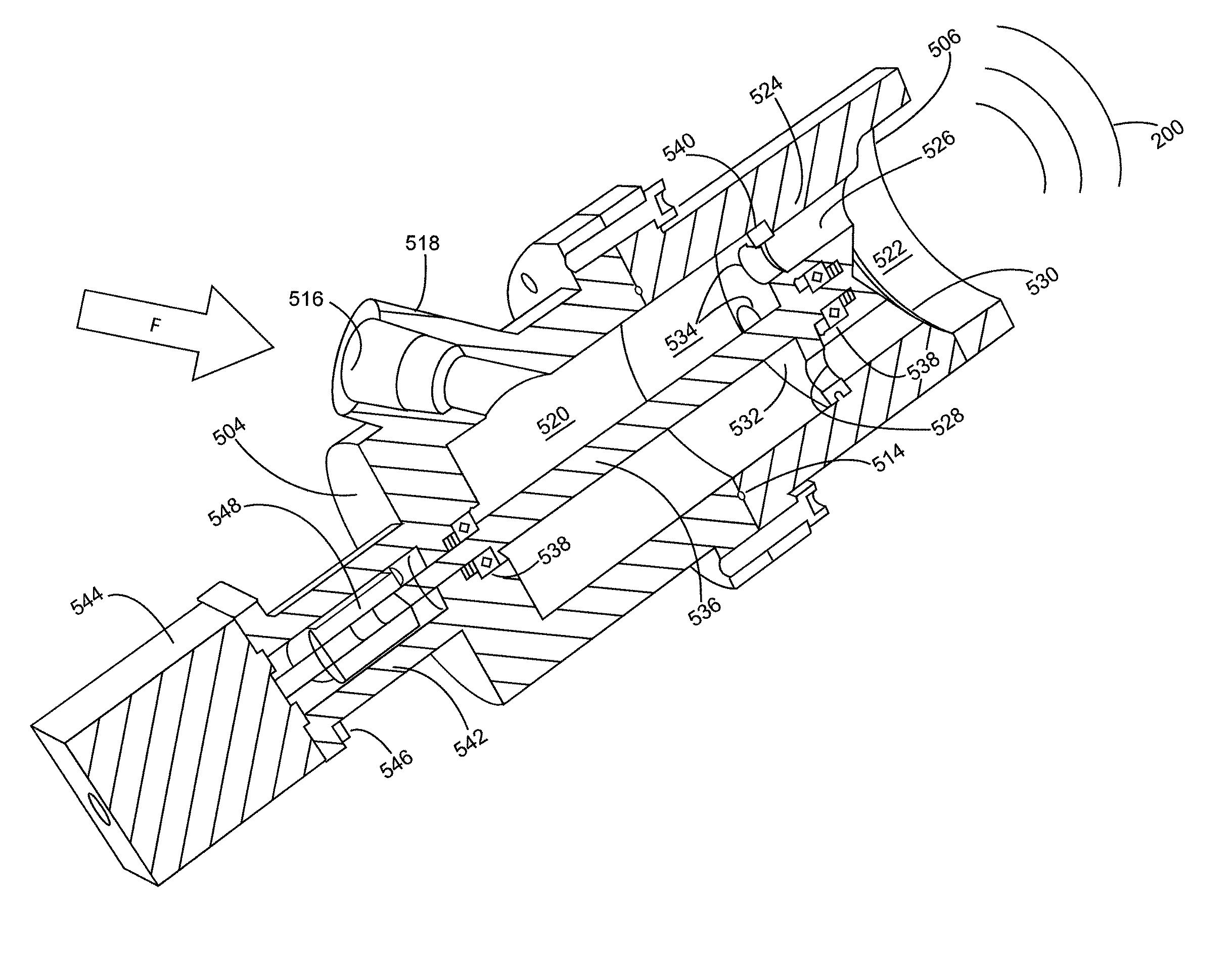

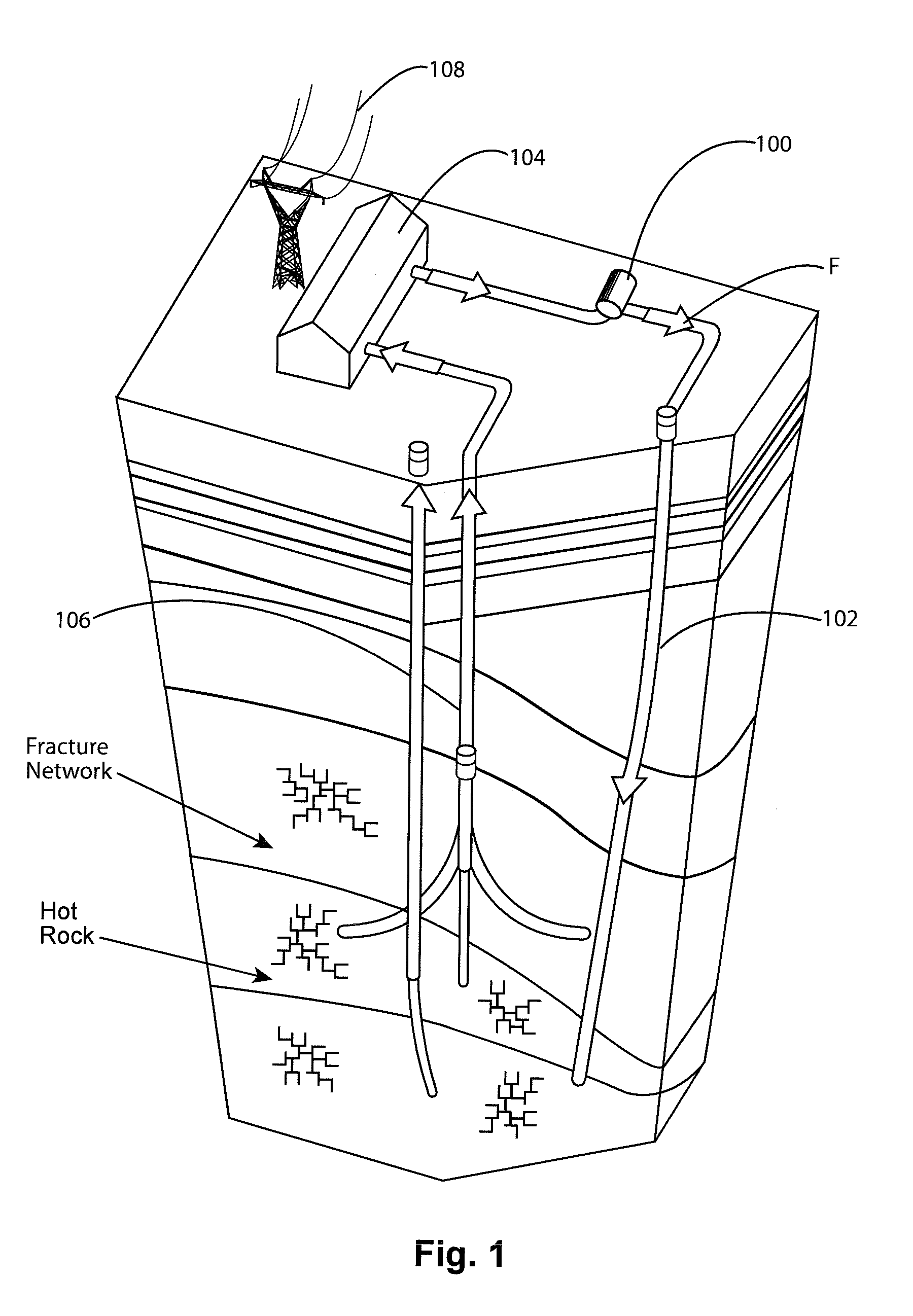

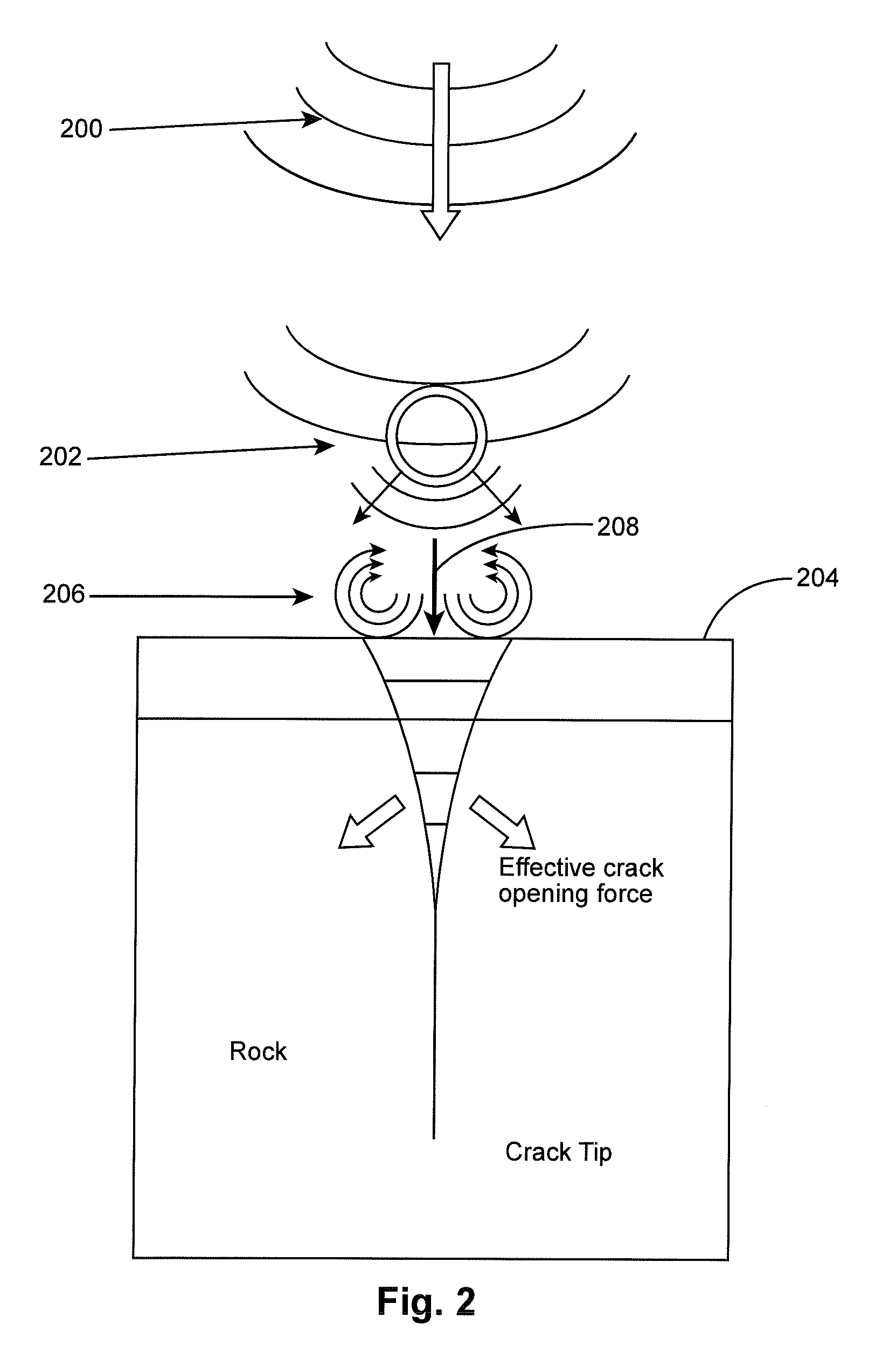

Cavitation-based hydro-fracturing technique for geothermal reservoir stimulation

ActiveUS20150275638A1Improve breathabilityImprove heat transfer performanceCollector components/accessoriesGeothermal energy generationShock waveCavitation

A rotary shutter valve 500 is used for geothermal reservoir stimulation. The valve 500 includes a pressure chamber 520 for holding a working fluid (F) under pressure. A rotatable shutter 532 is turned with a powering device 544 to periodically align one or more windows 534 with one or more apertures 526 in a bulkhead 524. When aligned, the pressurized working fluid (F) flows through the bulkhead 524 and enters a pulse cavity 522, where it is discharged from the pulse cavity 522 as pressure waves 200. The pressure wave propagation 200 and eventual collapse of the bubbles 202 can be transmitted to a target rock surface 204 either in the form of a shock wave 206, or by micro jets 208, depending on the bubble-surface distance. Once cavitation at the rock face begins, fractures are initiated in the rock to create a network of micro-fissures for enhanced heat transfer.

Owner:UT BATTELLE LLC

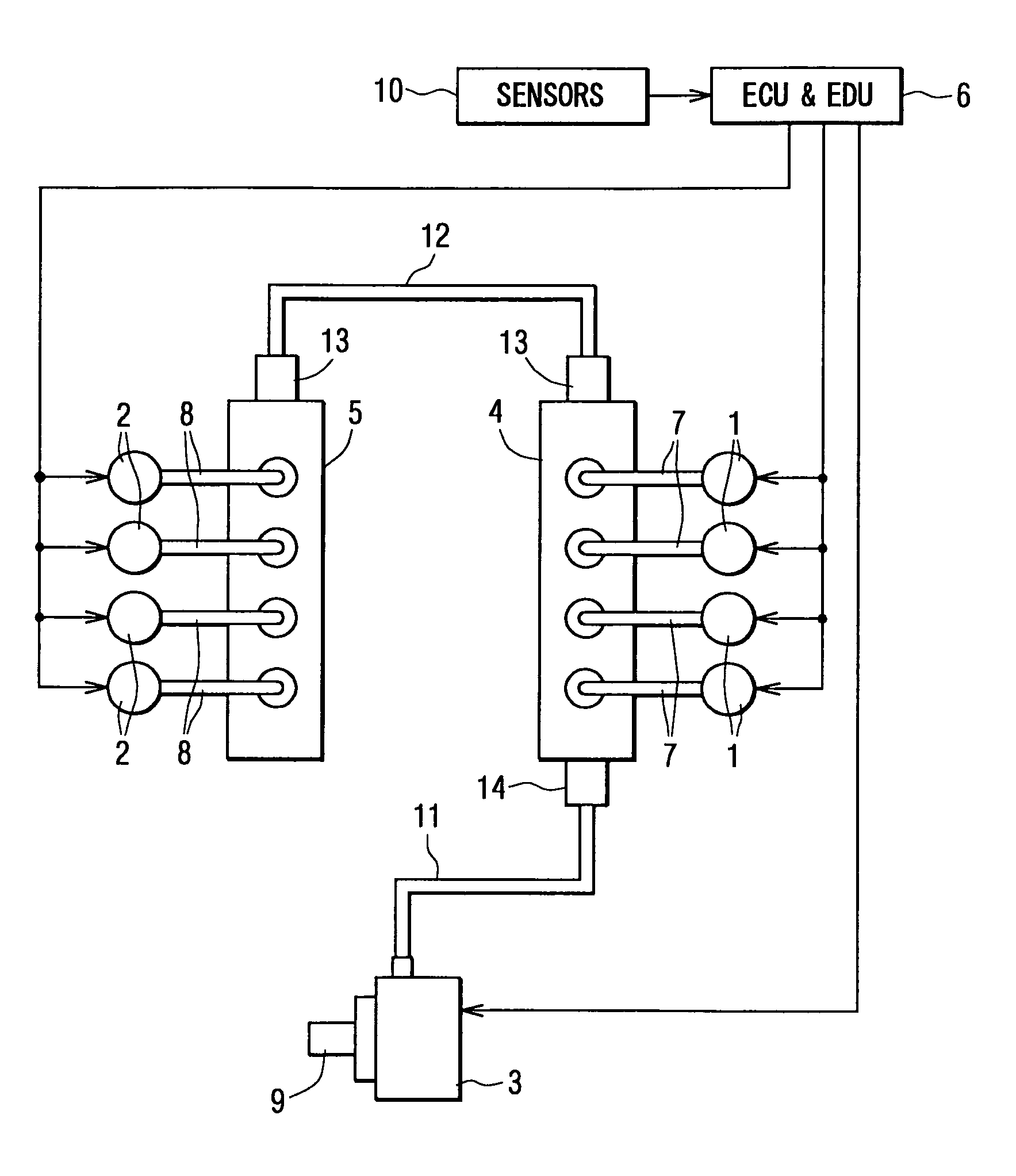

Fuel injection device having two separate common rails

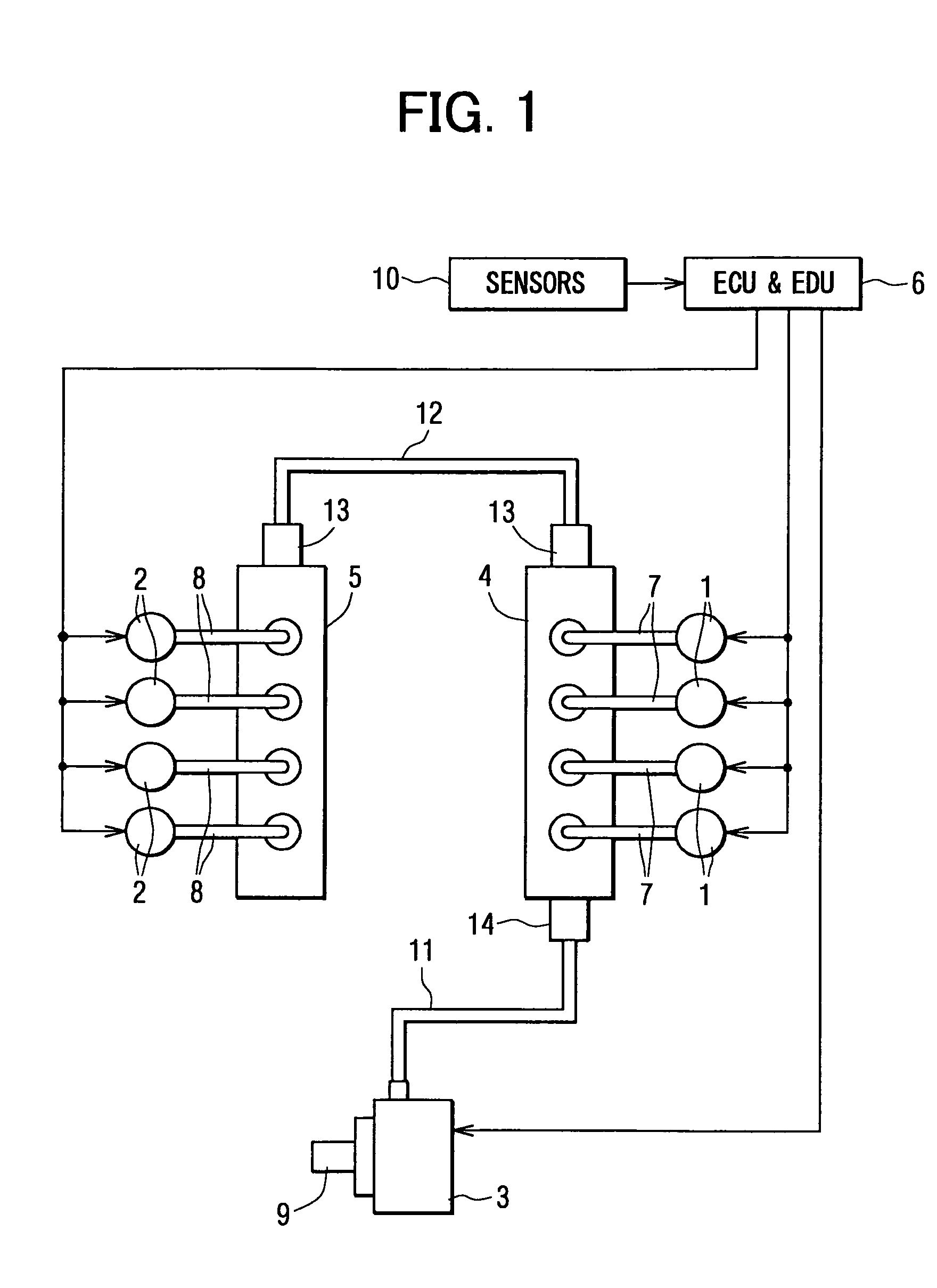

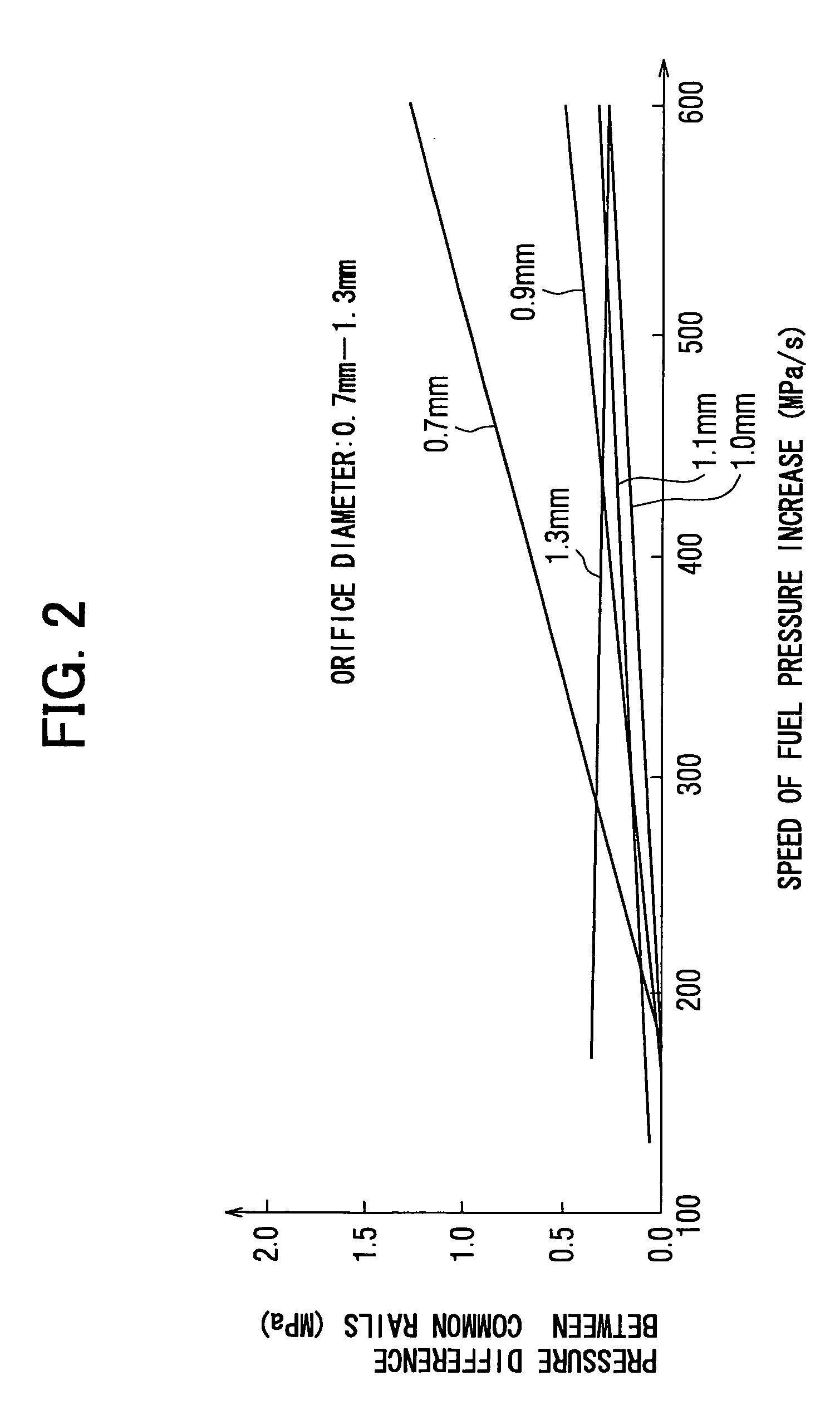

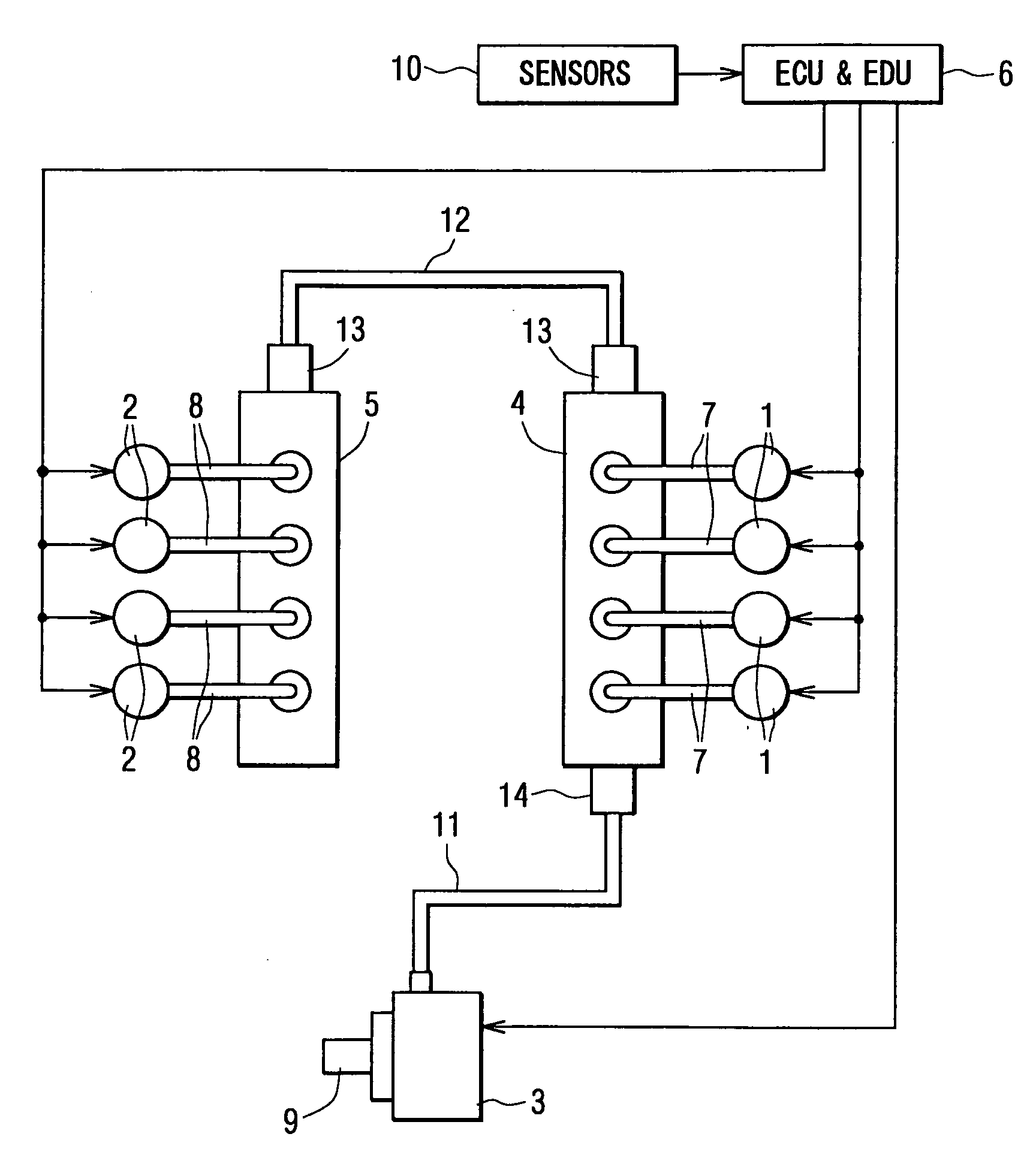

InactiveUS7131427B2Easy to installIncrease flow resistanceLow pressure fuel injectionMachines/enginesControl mannerCommon rail

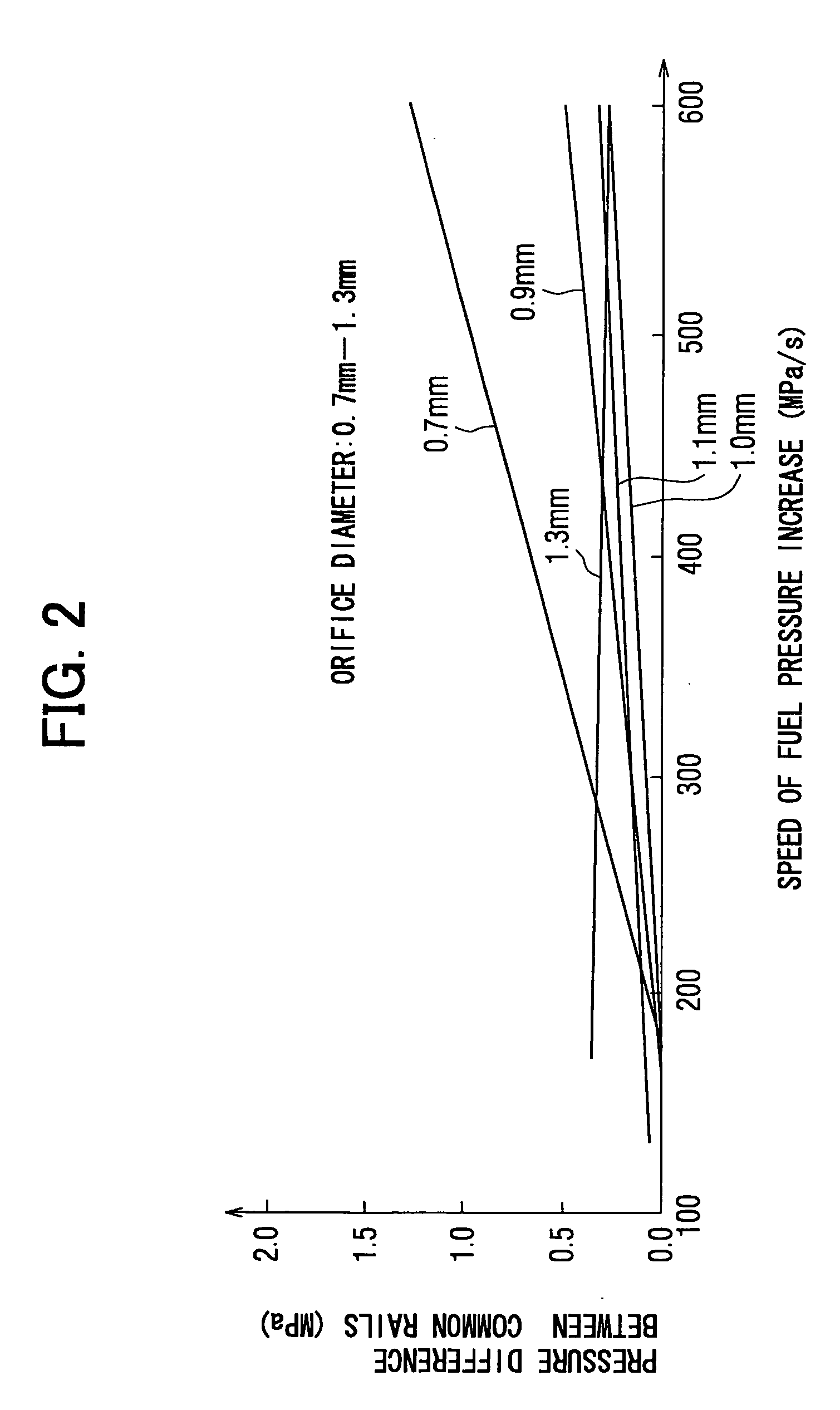

A fuel injection device for supplying high-pressure fuel to an internal combustion engine includes a fuel supply pump, a first common rail and a second common rail. High-pressure fuel is directly supplied to the first common rail and then to the second common rail from the first common rail through a connecting passage having an orifice. The high-pressure fuel accumulated in the common rails is supplied to injectors and is injected into cylinders in a controlled manner. To suppress pressure wave propagation from the first common rail to the second common rail while providing an appropriate flow passage size, a passage diameter of the orifice is set to 0.9 mm–1.3 mm. In this manner, a pressure difference between the first common rail and the second common rail is minimized.

Owner:DENSO CORP

Fuel injection device having two separate common rails

InactiveUS20050115545A1Easy to installIncrease flow resistanceLow pressure fuel injectionMachines/enginesCommon railControl manner

A fuel injection device for supplying high-pressure fuel to an internal combustion engine includes a fuel supply pump, a first common rail and a second common rail. High-pressure fuel is directly supplied to the first common rail and then to the second common rail from the first common rail through a connecting passage having an orifice. The high-pressure fuel accumulated in the common rails is supplied to injectors and is injected into cylinders in a controlled manner. To suppress pressure wave propagation from the first common rail to the second common rail while providing an appropriate flow passage size, a passage diameter of the orifice is set to 0.9 mm-1.3 mm. In this manner, a pressure difference between the first common rail and the second common rail is minimized.

Owner:DENSO CORP

Visual combustion chamber capable of flexibly adjusting flow-pressure wave-combustion interaction

ActiveCN106168540AEffective regulationFlexible adjustmentEngine testingCombustion chamberInlet channel

The invention discloses a visual combustion chamber capable of flexibly adjusting flow-pressure wave-combustion interaction. The visual combustion chamber comprises a glass gasket and a cylinder cover which are arranged on the top part of a cylinder sleeve from bottom to top. A cylinder cover glass view window is inlaid on the cylinder cover. A piston in the cylinder sleeve comprises a metal piston ring matched with the cylinder sleeve. A piston glass view window is inlaid on the top end of the metal piston ring. The lower end surface of cylinder cover, the inner side of the glass gasket, the inner side of the cylinder sleeve, the metal piston ring and the upper end surface of the piston glass view window form a closed combustion chamber body. A vertical air inlet channel is formed in the cylinder cover. A horizontal air inlet / outlet channel is formed in the top part of the cylinder sleeve. The horizontal air inlet / outlet channel is tangential to the revolution surface of the inner cavity of the cylinder sleeve. Two pressure wave inlets consistent in inlet direction, tangential to the revolution surface of the inner cavity of the cylinder sleeve and arranged on the same horizontal plane. According to the invention, the flow field state and the pressure wave propagation and superposition mode can be flexibly adjusted, and optical testing can be carried out on the complete combustion process in the cylinder.

Owner:TIANJIN UNIV

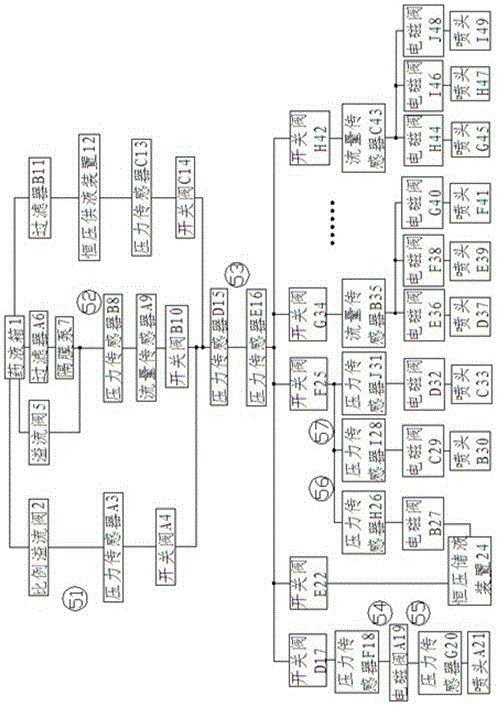

Long-distance pipeline coal conveying leakage detecting control system

The invention discloses a long-distance pipeline coal conveying leakage detecting control system. A pressure wave propagation method has great advantages on the detection of major sudden leakage accidents and is mainly used in the pipeline conveying engineering of liquid such as crude oil at home and abroad. On the improvement basis, the pressure wave propagation method is used in the long-distance pipeline coal conveying leakage detecting control system. A plurality of experiment studies show that when the pressure wave propagation method is used for the long-distance coal conveying pipeline engineering, the following key technical indexes can be obtained: when the leakage flow rate of the warning is greater than 1.5 percent of the total flow rate, the positioning error of the leakage point can be controlled to be 0.97km in the length range of the detecting pipe section, when the leakage flow rate of the warning is greater than 1.2 percent of the total flow rate, the positioning error of the leakage point can be controlled to be 0.68km in the length range of the detecting pipe section, and the warning reaction time is 150s. The leakage detecting system has the major advantages that the leakage positioning error is small, the warning reaction time is short, and longer reaction time is realized in the pipeline transportation industry.

Owner:WUHAN DESIGN & RES INST OF CHINA COALTECH & ENG GROUP

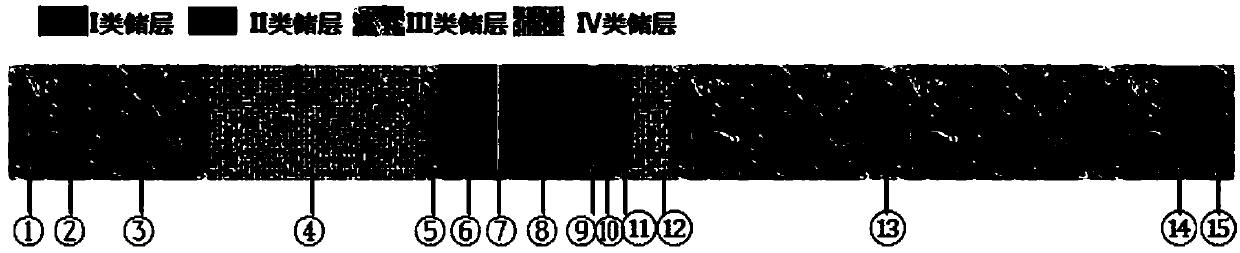

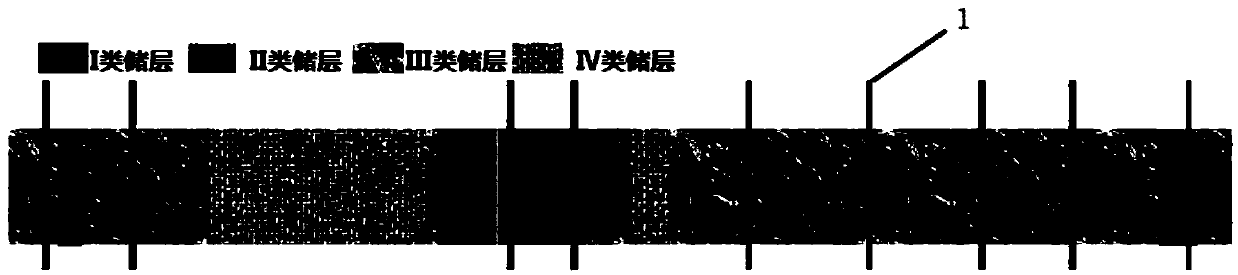

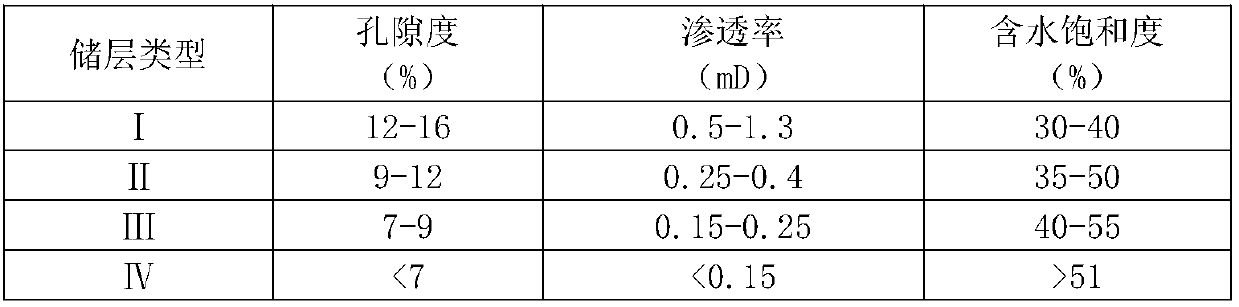

Method for segmental fracturing seaming optimization of horizontal well with high heterogeneity and tight reservoirs

ActiveCN108829999AFully remodeledReduced frac stimulationDesign optimisation/simulationSpecial data processing applicationsInteraction layerSegmental fracture

The invention relates to a method for segmental fracturing seaming optimization of a horizontal well with high heterogeneity and tight reservoirs. The method includes the steps of dividing the reservoirs into different levels; using software for simulating pressure wave situations of an interaction layer model which is provided with barrier zones and used for arranging hydraulic fractures after three years of production, obtaining the permeability and corresponding limit width of the barrier zones, and fitting a relationship between the permeability and the corresponding limit width to determine whether not the effective reservoirs on both sides of each barrier zone need to be divided into two independent seepage units; on the basis of judgement on whether or not the economic limit production capacity can be achieved after fracturing for three years, determining the economic limit seepage unit width of the reservoirs different in level; simulating pressure wave propagation situations after three years of production under the condition that different hydraulic fracture spacings are set in the same continuous sand body, and determining the fracture spacings; according to logging interpretation results and reservoir level division standards, dividing a horizontal segment into multiple reservoir units; in combination with the division limit with of the seepage units and reasonablespacing requirements for the fractures of the continuous sand body, setting several hydraulic fracturing seaming schemes for the horizontal segment and preferentially selecting the economical and effective seaming schemes.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

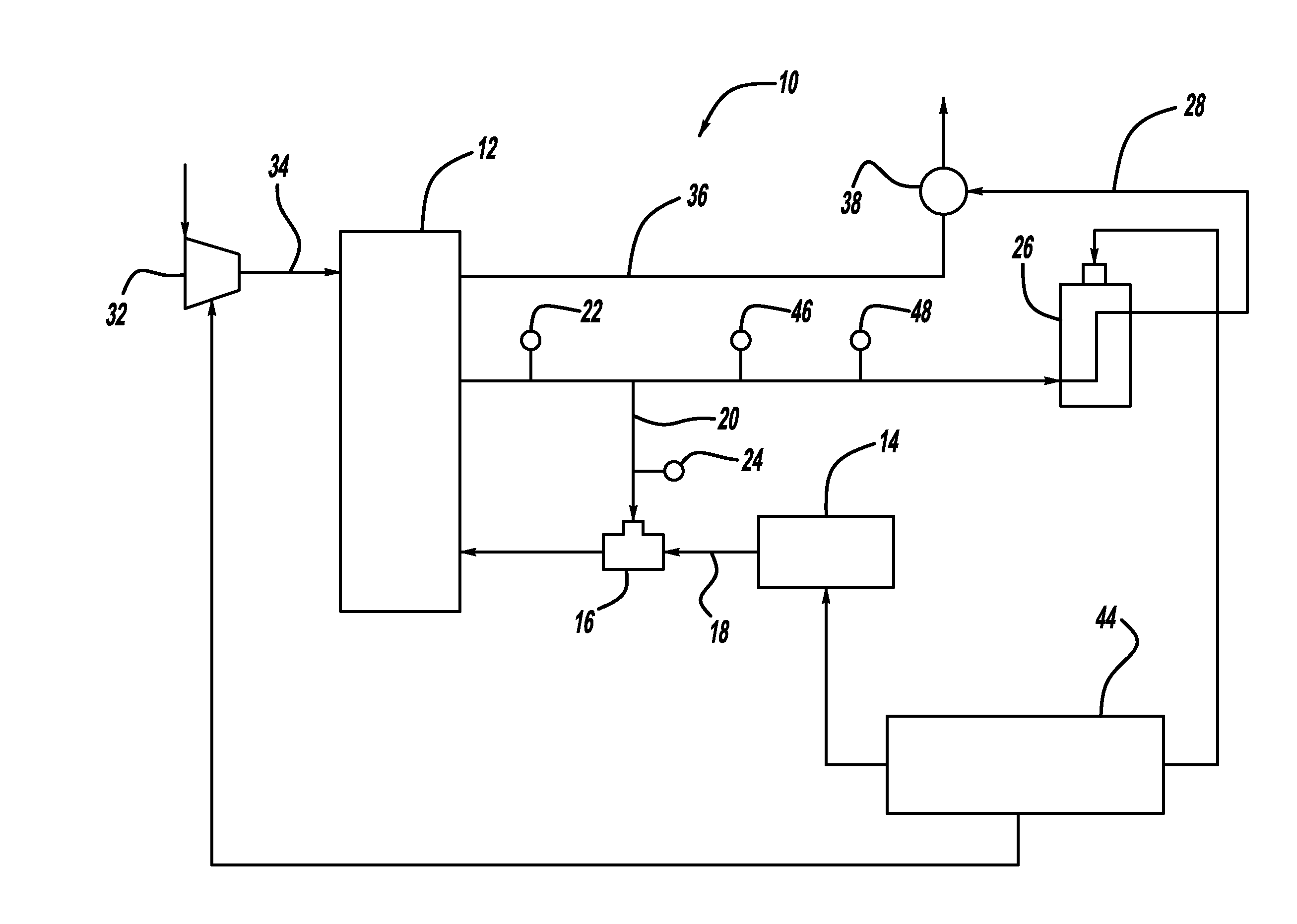

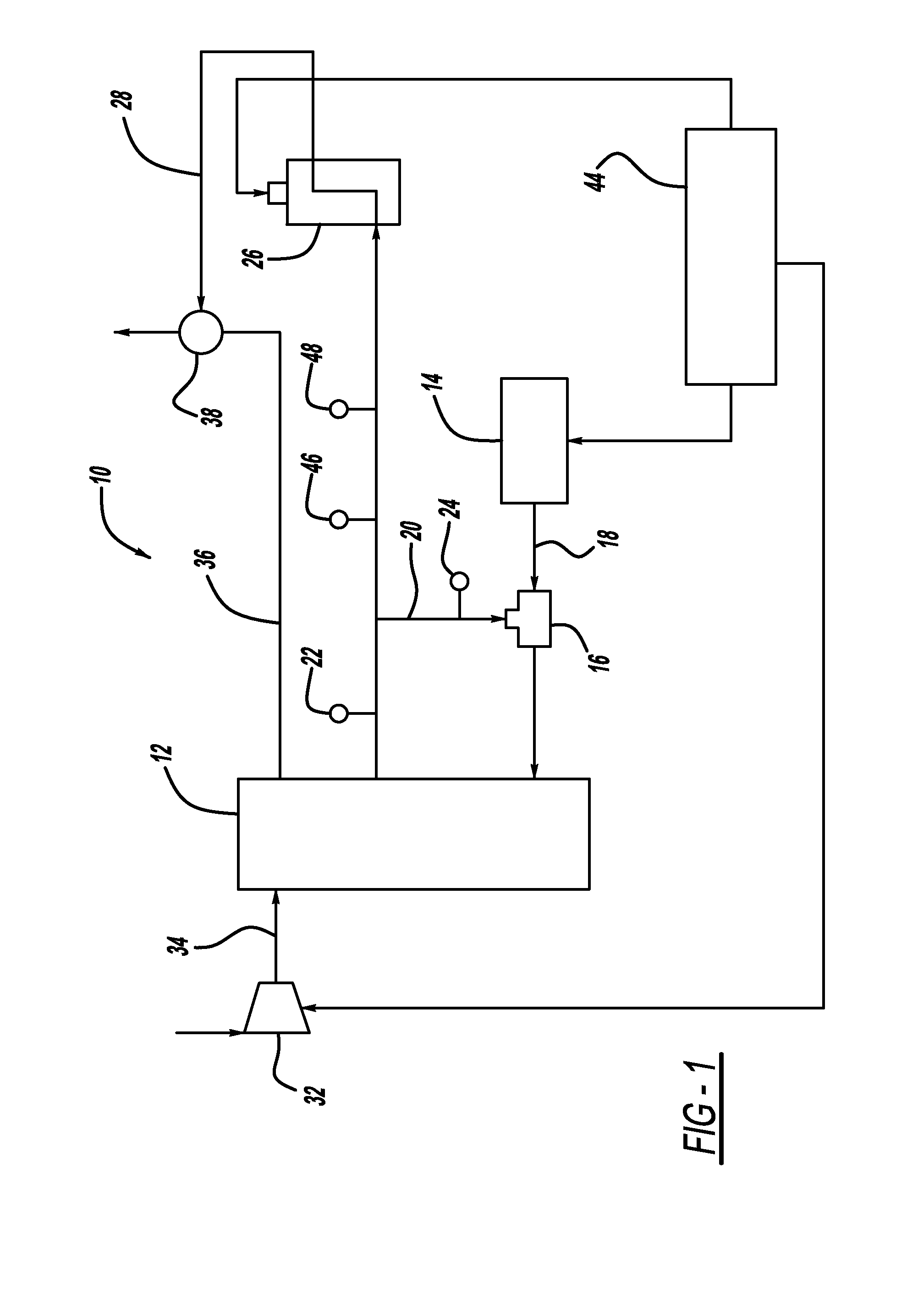

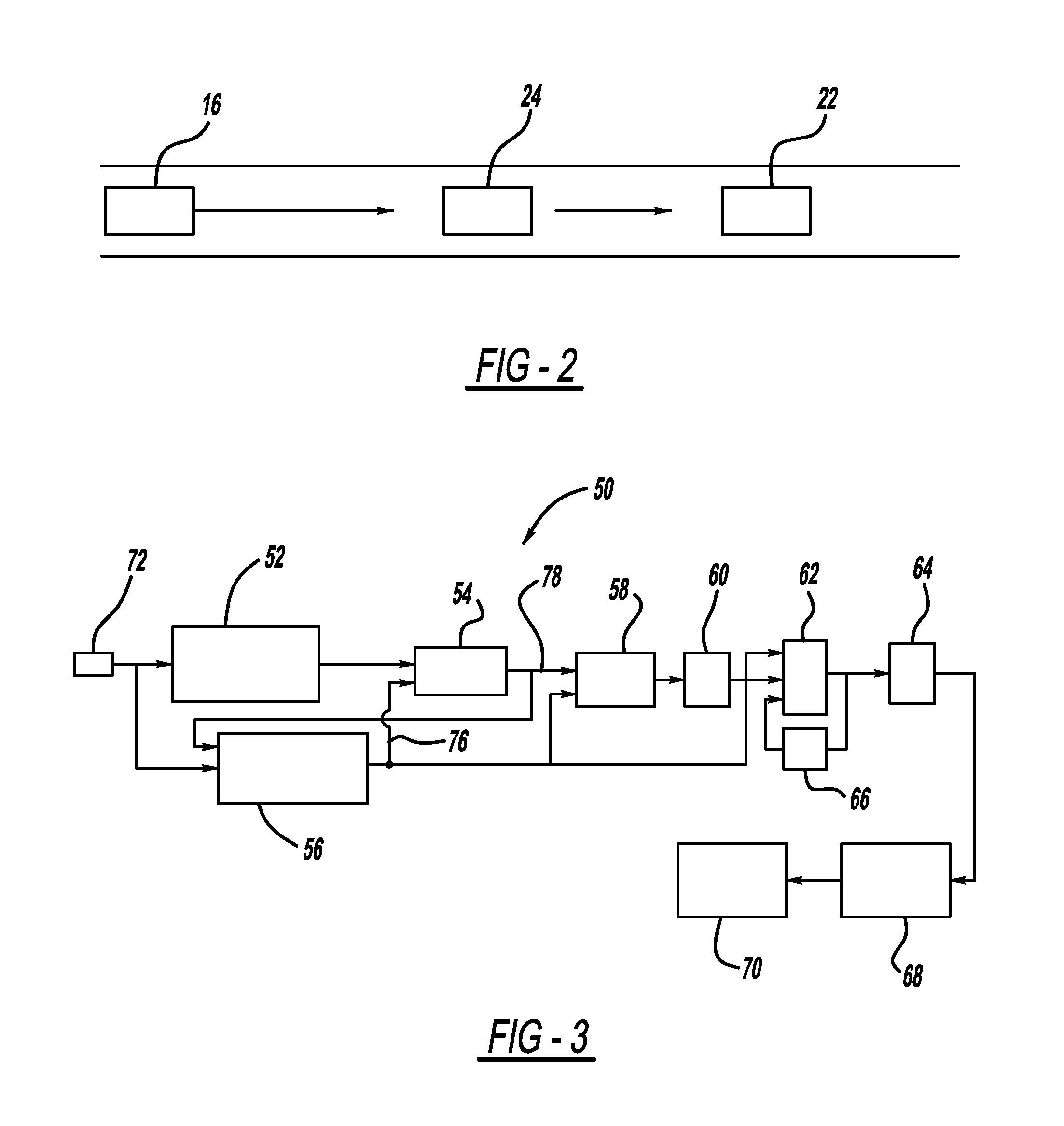

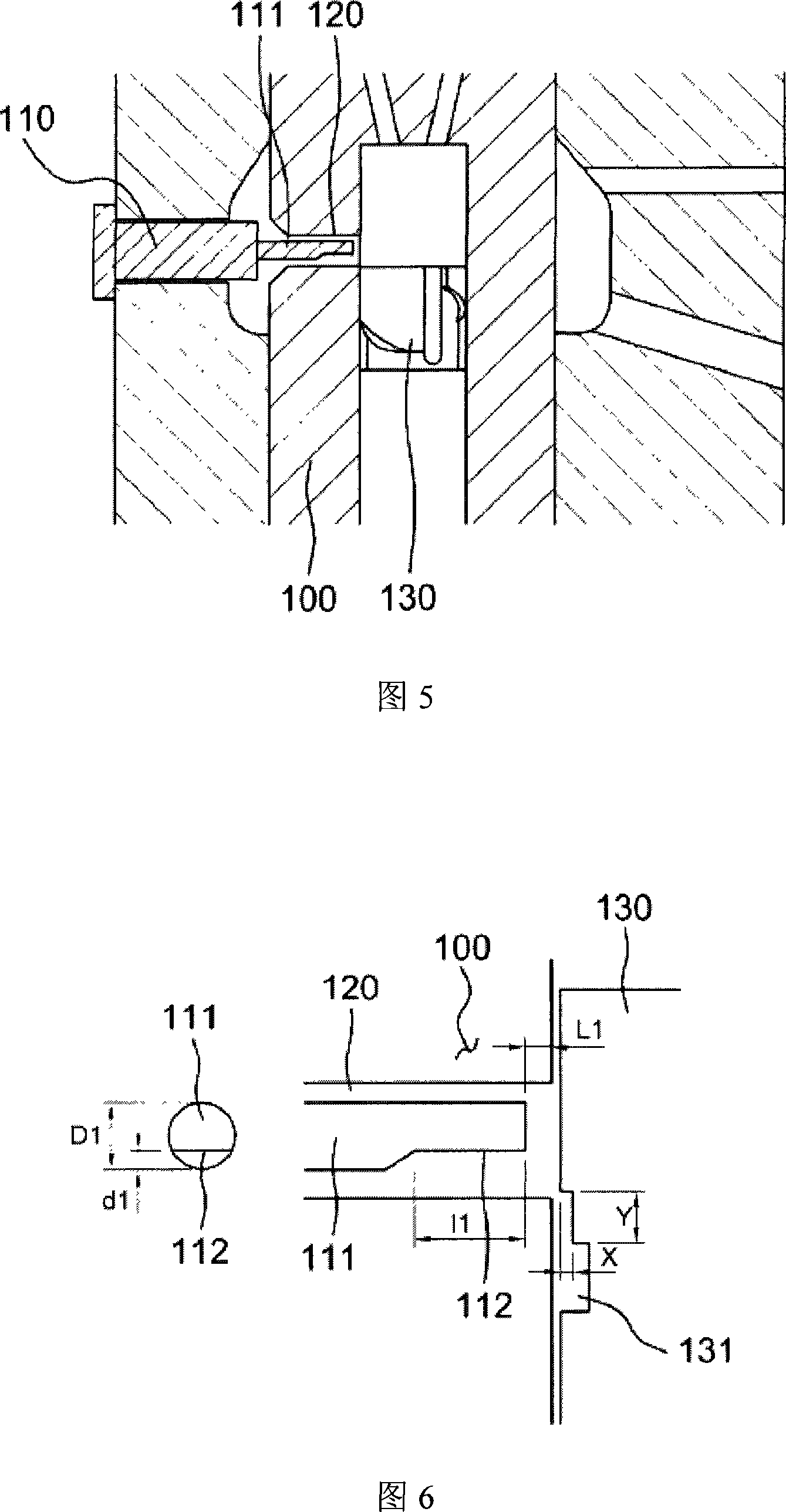

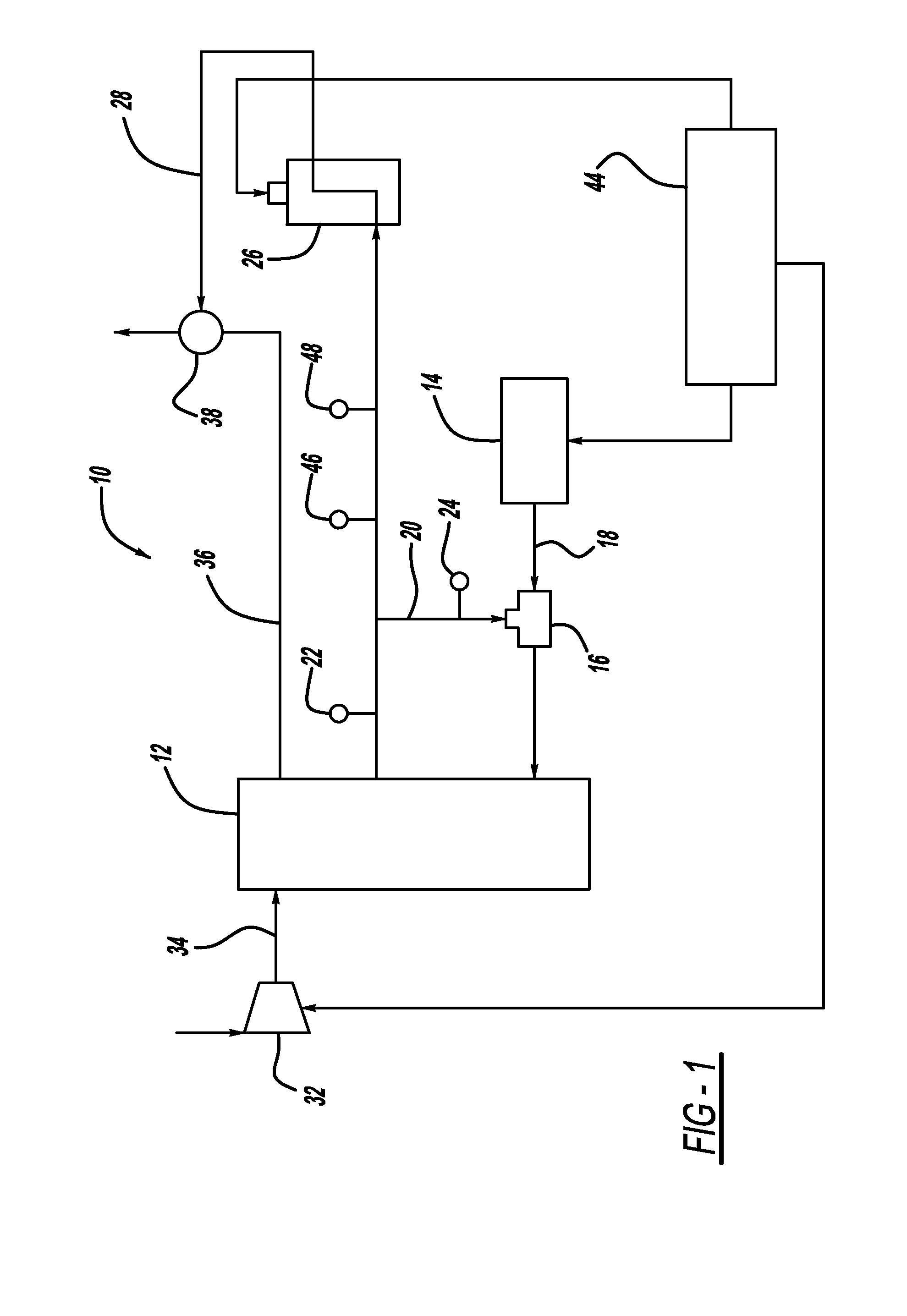

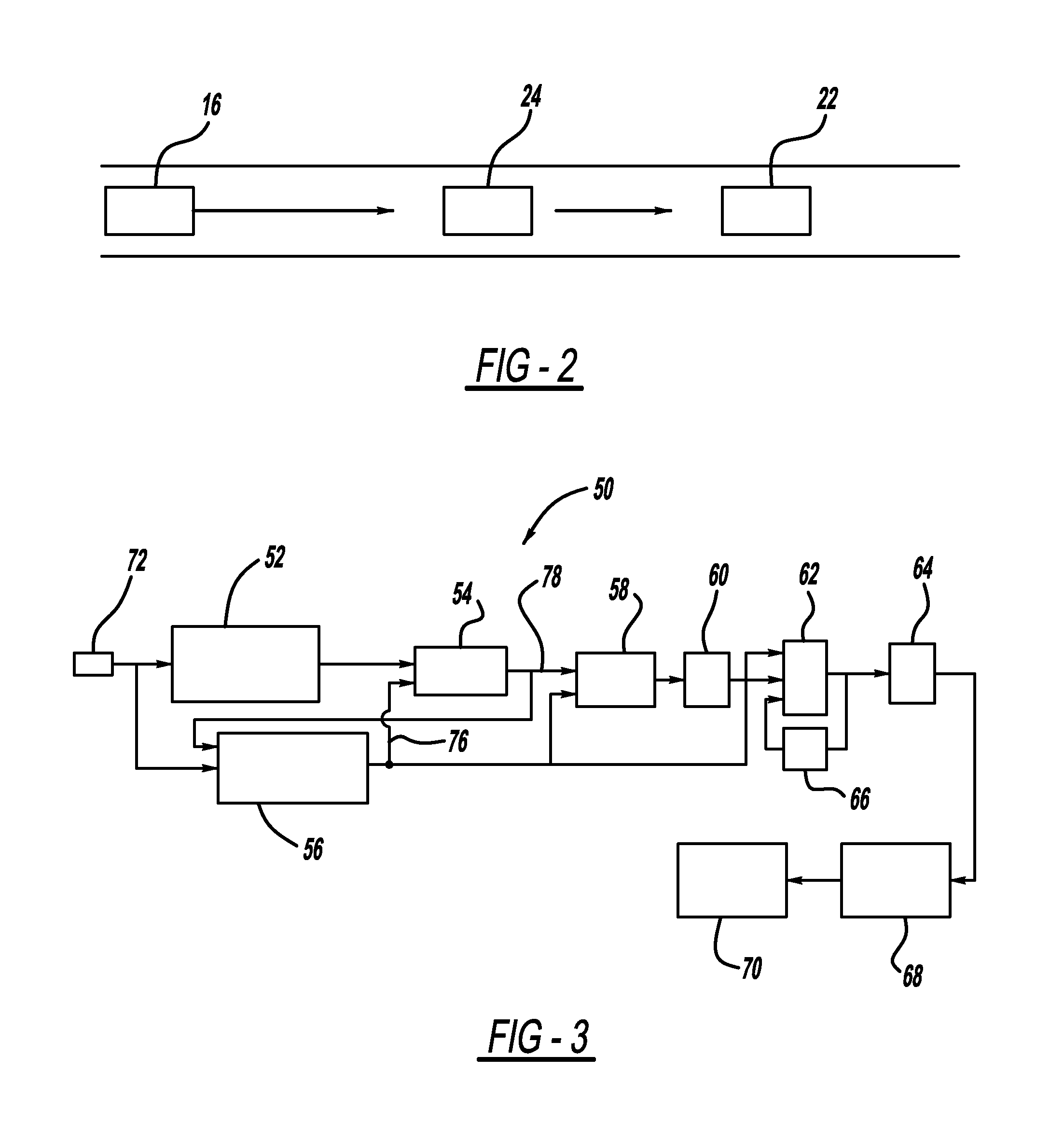

Anode gas composition utilizing h2 injection pressure wave propagation rates

A system for determining the concentration of hydrogen in an anode sub-system of a fuel cell system. The fuel cell system includes at least one fuel cell, an anode inlet, an anode outlet, an anode recirculation line, a source of hydrogen gas and an injector for injecting the hydrogen gas. First and second acoustic sensors are provided in the anode recirculation line and are spaced a known distance from each other. A controller that is responsive to the output signals from the first and second acoustic sensors determines the concentration of hydrogen gas in the anode recirculation line based on the time between when the controller receives the sensor signal from the first sensor and receives the sensor signal from the second sensor.

Owner:GM GLOBAL TECH OPERATIONS LLC

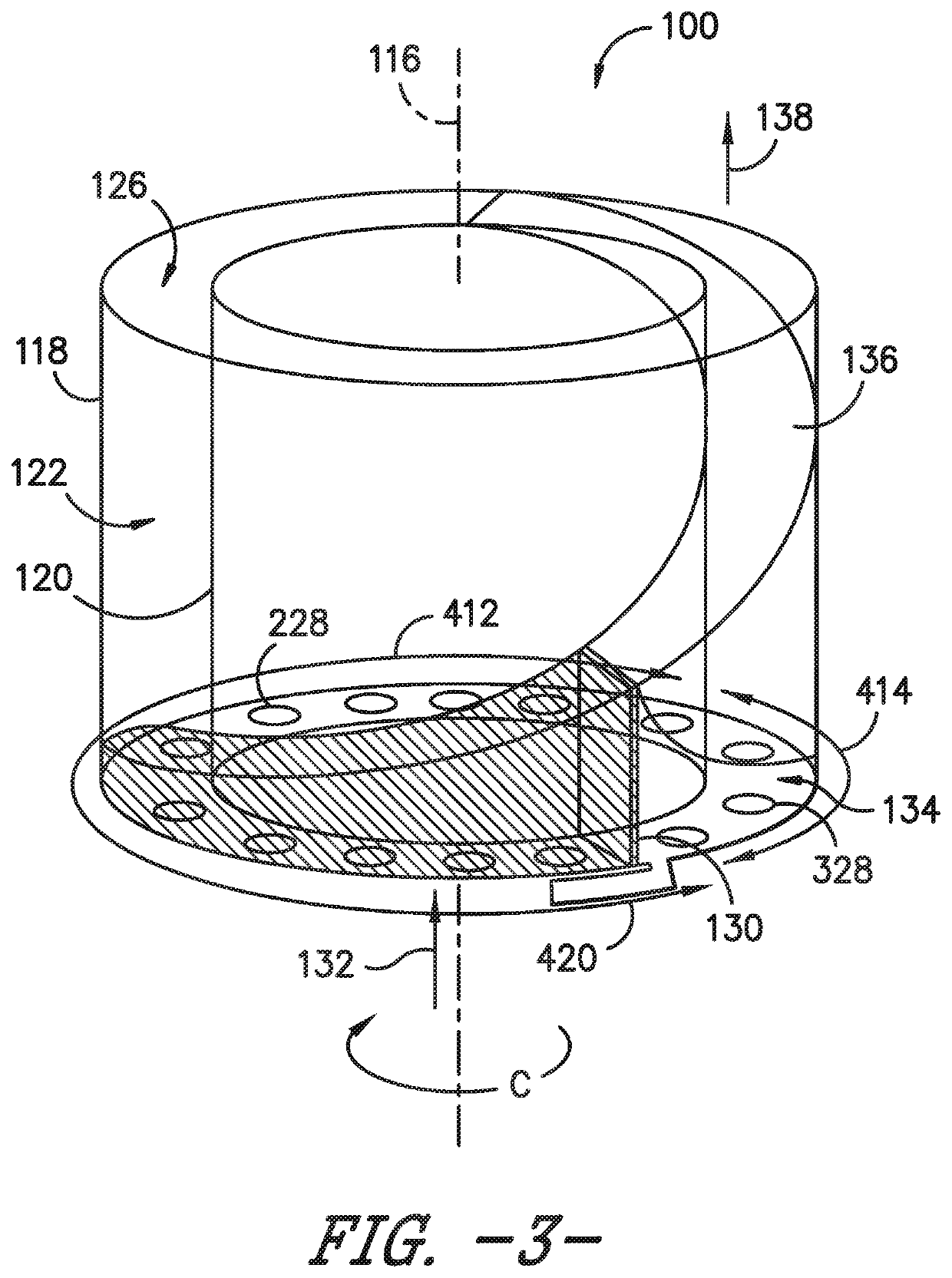

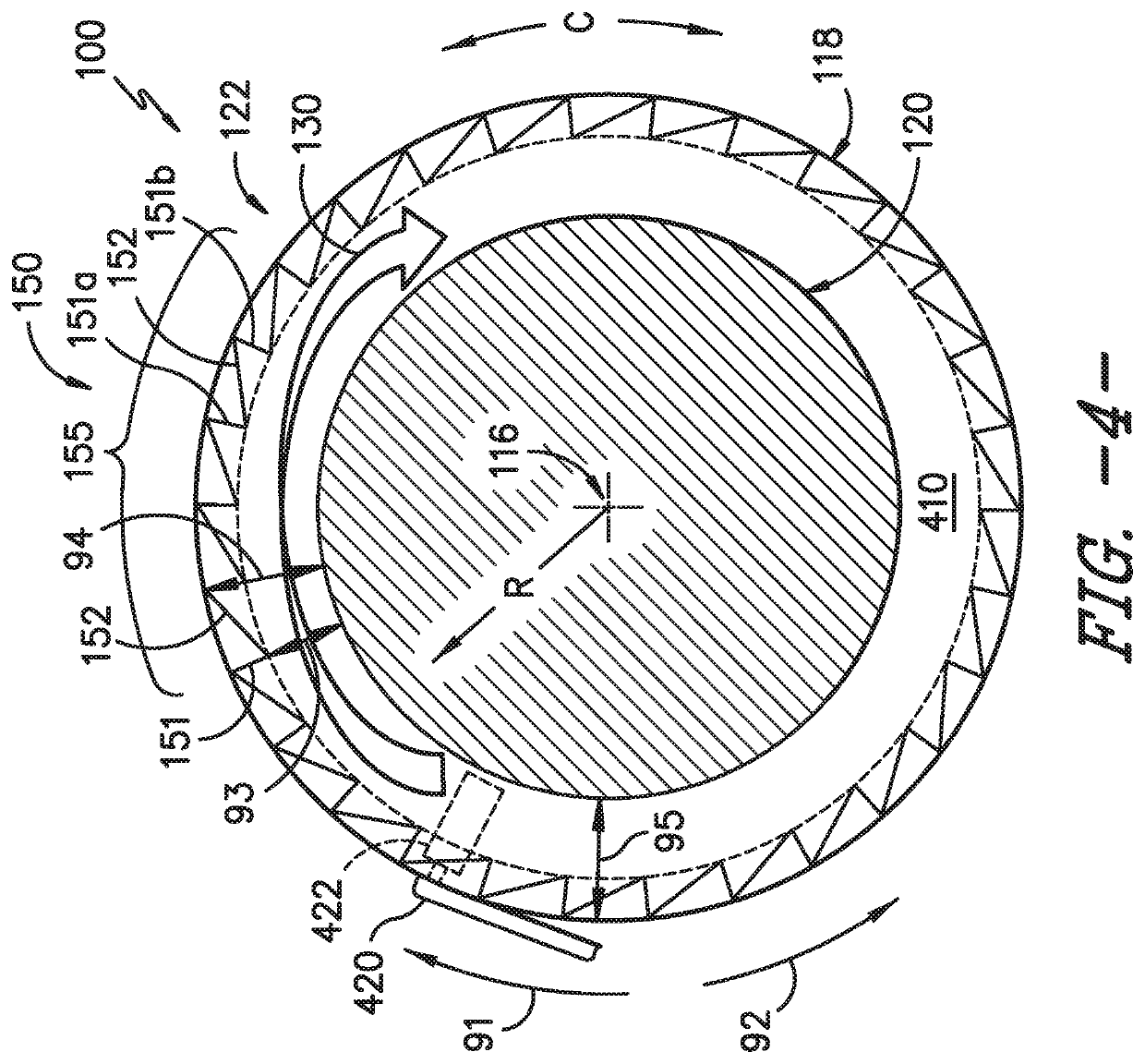

System for Rotating Detonation Combustion

Systems for rotating detonation combustion are provided herein. The system includes an inner wall and an outer wall each extended around a centerline axis, wherein a detonation chamber is defined between the inner wall and the outer wall, and an iterative structure positioned at one or both of the inner wall or the outer wall. The iterative structure includes a first threshold structure corresponding to a first pressure wave attenuation and a second threshold structure corresponding to a second pressure wave attenuation. The iterative structure provides for pressure wave strengthening along a first circumferential direction in the detonation chamber or pressure wave weakening along a second circumferential direction opposite of the first circumferential direction. The first circumferential direction corresponds to a desired direction of pressure wave propagation in the detonation chamber.

Owner:GENERAL ELECTRIC CO

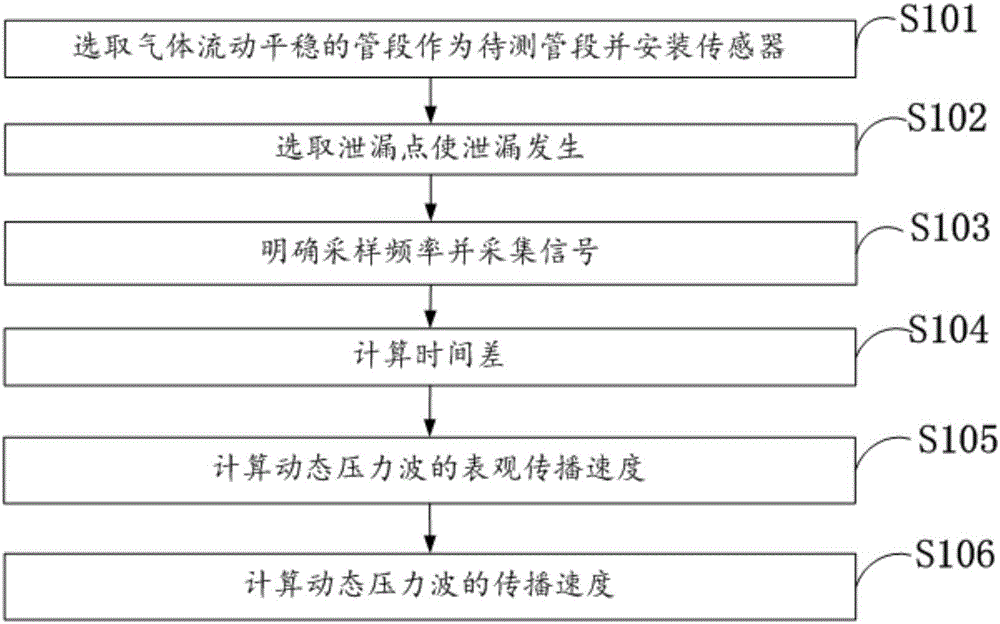

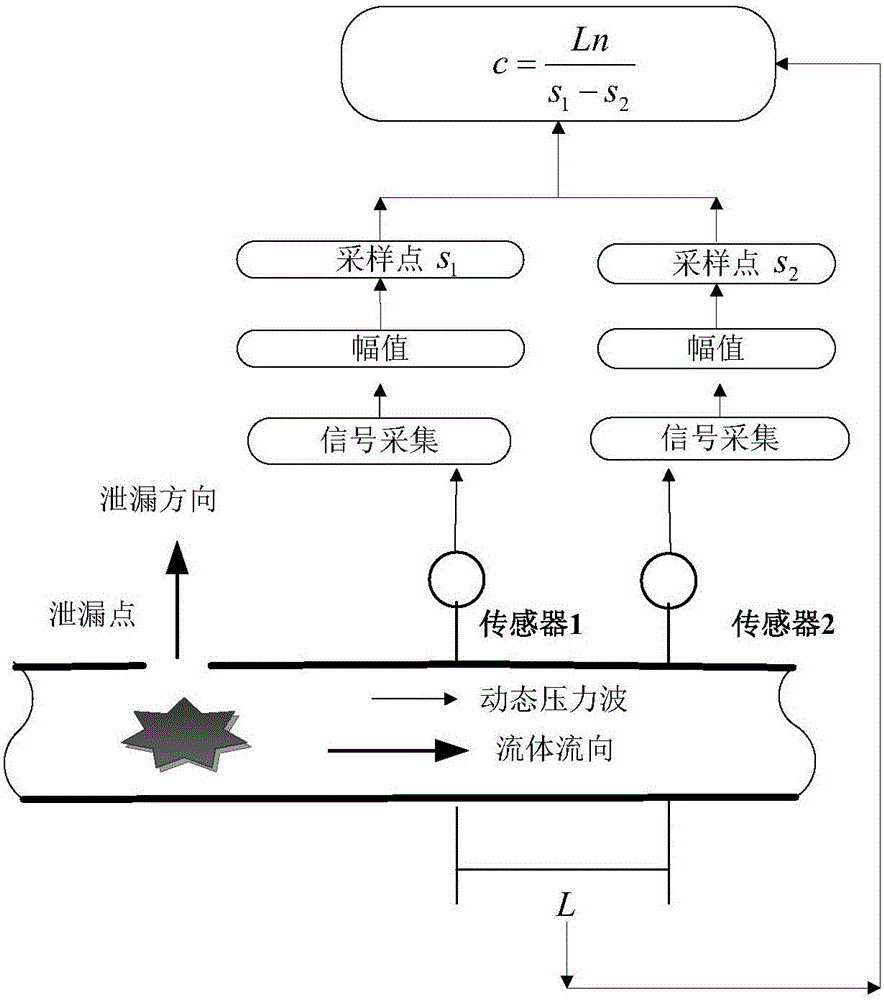

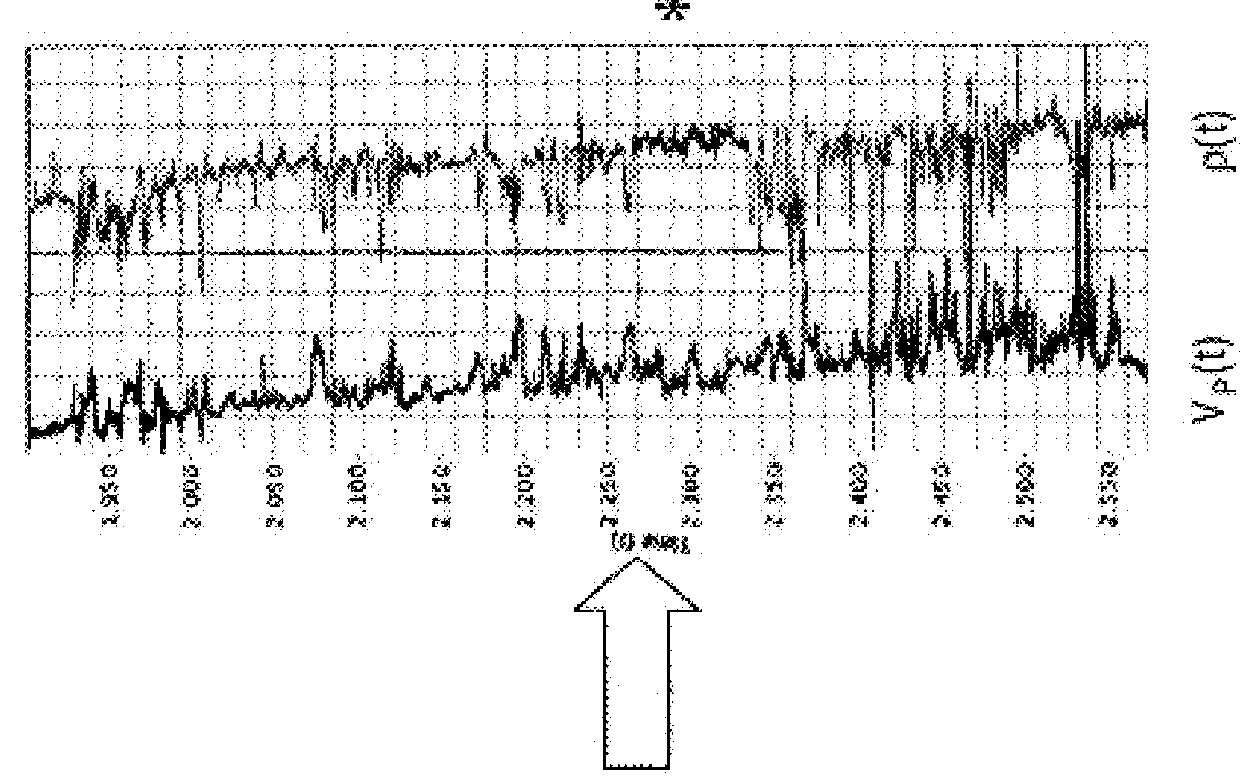

Calculating method of propagation speed of leakage dynamic pressure waves in in-pipe gas

The invention discloses a calculating method of the propagation speed of leakage dynamic pressure waves in in-pipe gas. A pipe section where gas flows stably is selected as a pipe section to be measured, and dynamic pressure sensors are installed at the two ends of the pipe section to be measured. A point on the upstream portion or the downstream portion of the pipe section to be measured is selected as a leakage point, and the leakage point is made to leak. Amplitude values of two leakage signals are obtained through signal processing, then sampling points corresponding to the amplitude values are selected, the difference value which is obtained by subtracting the two sampling points is divided by the sampling frequency, and a time difference is obtained. The distance between the sensors is divided by the time difference so that the apparent propagation speed of the dynamic pressure waves can be obtained, and finally, the propagation speed of the dynamic pressure waves is obtained by taking the gas flow speed into consideration. According to the calculating method of the propagation speed of the leakage dynamic pressure waves in in-pipe gas, the theoretical calculating formula of the propagation speed of the leakage dynamic pressure waves can be verified and corrected, the calculation precision of the propagation speed of the dynamic pressure waves is improved, and accordingly a foundation is provided for improving the leakage positioning precision.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

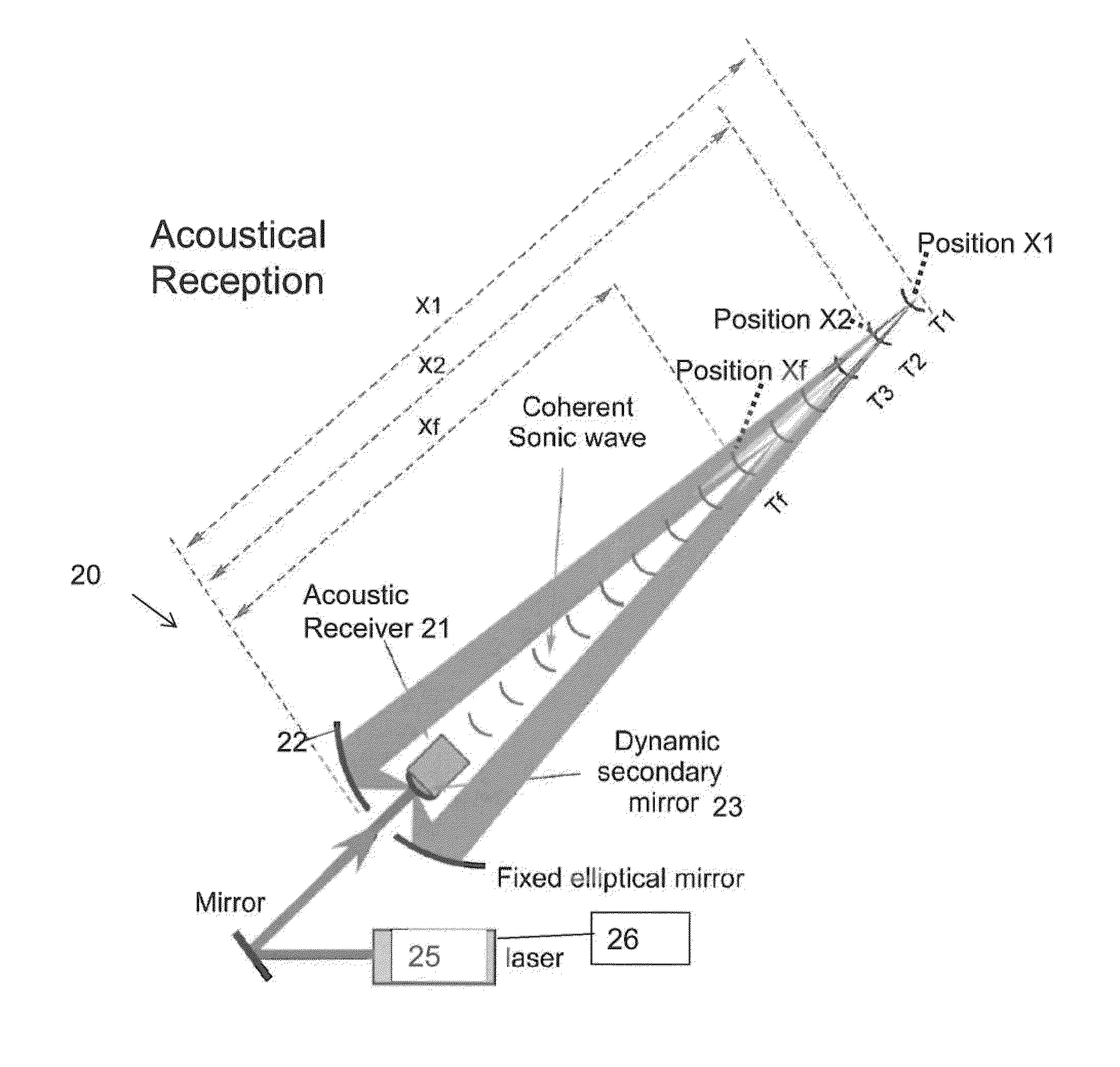

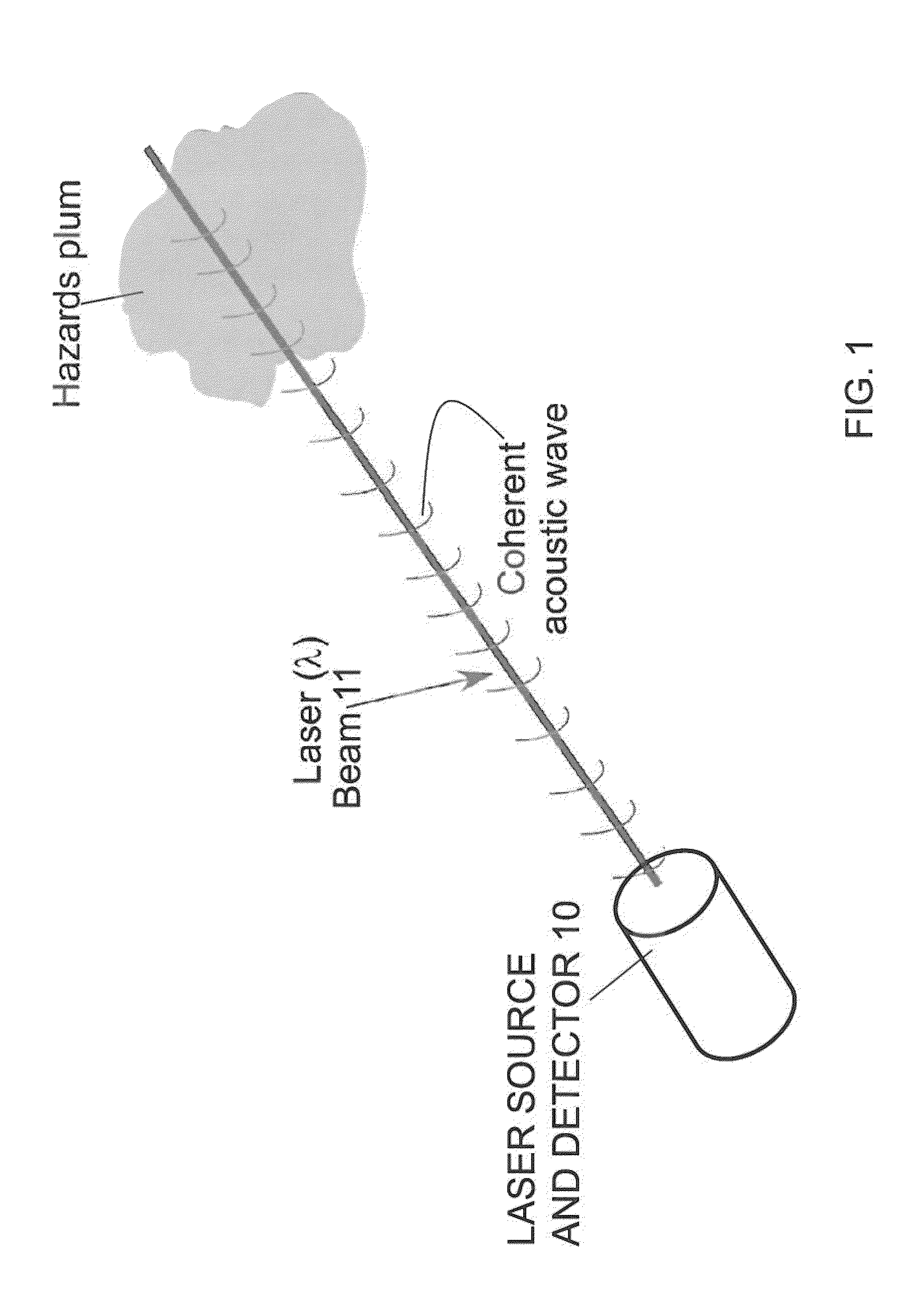

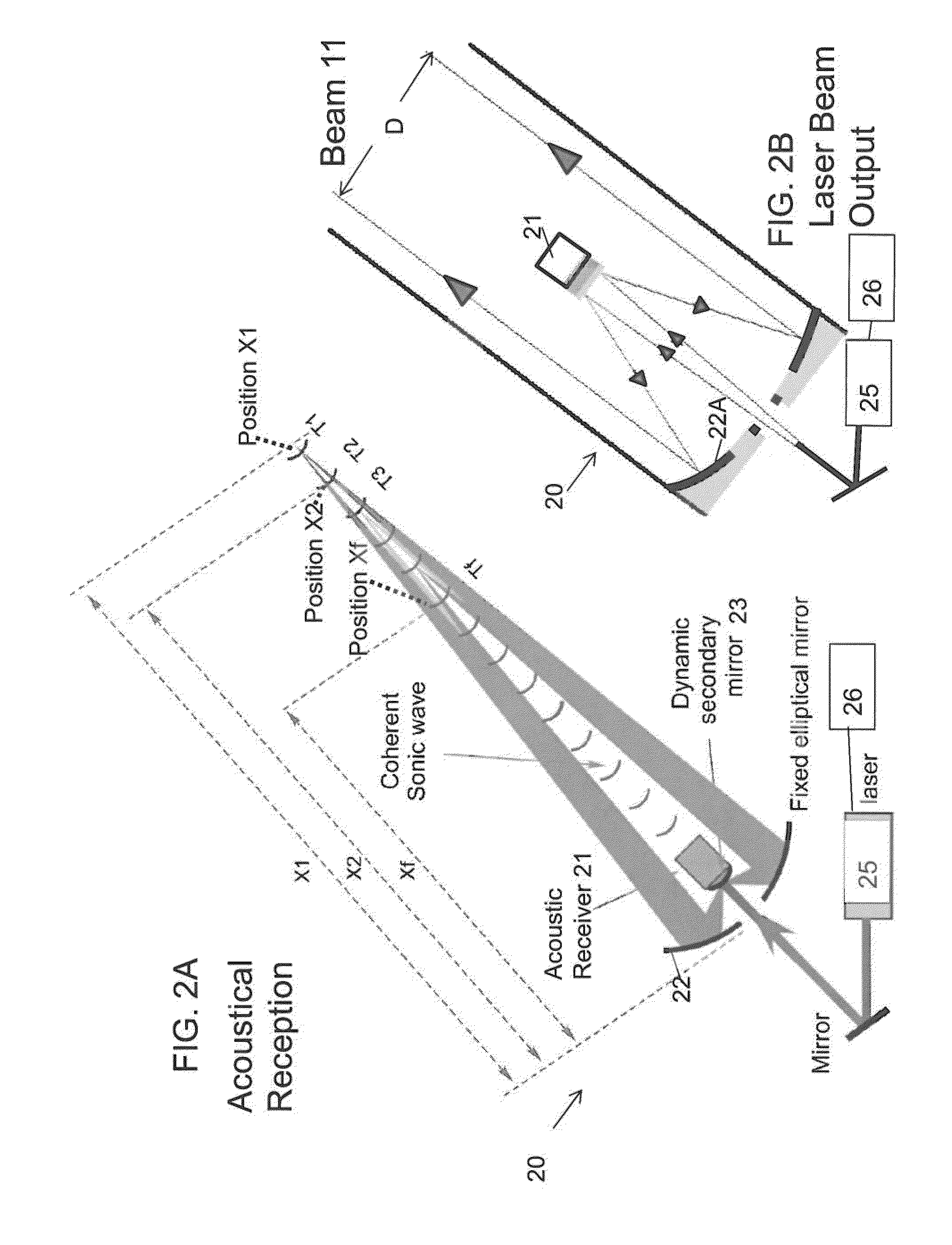

Remote sensing using coherent sonic wave photoacoustic detection and methods

InactiveUS9057778B2Material analysis by optical meansElectromagnetic wave reradiationPhysical spaceLight beam

A method and system for detecting composition of a physical space comprising: a laser beam source; an acoustic sensor; a beam focusing mechanism for focusing the laser beam at predetermined points in the physical space to generate a thermal inhomogeneity which results in the propagation of a pressure wave that propagates outward from the predetermined excitation point at a propagation velocity approximating the speed of sound for the particular composition of the media; at least one processor for controlling the timing for the laser beam focusing to generate thermal inhomogeneities; whereby the laser focal point is moved sequentially along the light-of-sight at various excitation points by the beam focusing mechanism approximately at the phase front velocity to define a series of predetermined excitation points and pressure wave propagations such that the series of pressure wave propagations combine to produce a coherent pressure wave detectable by the acoustic sensor.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

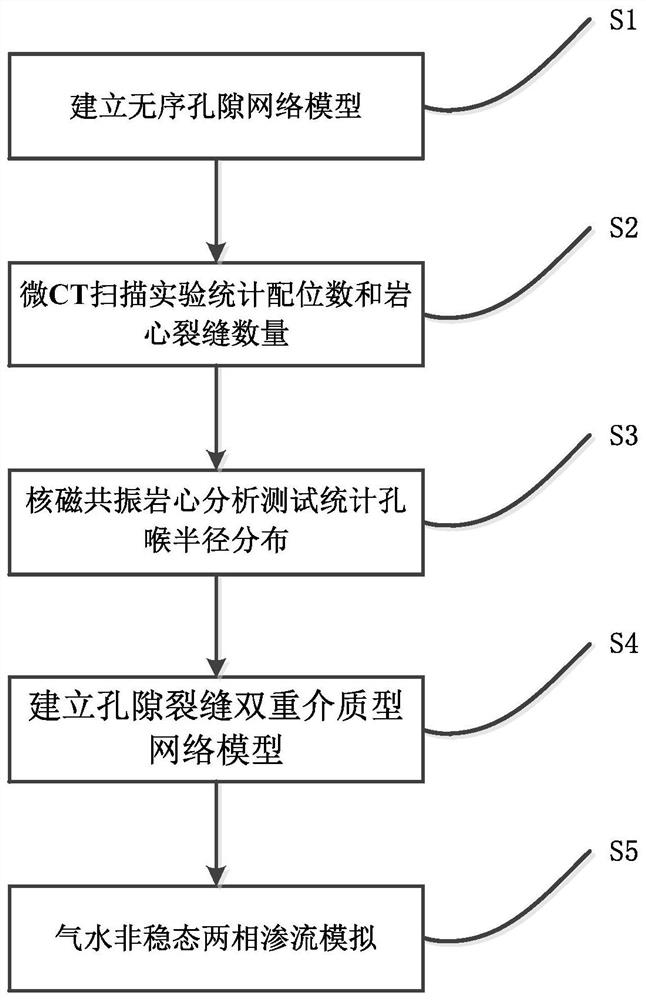

Unsteady gas-water two-phase seepage simulation method for dual-medium gas reservoir based on pore cracks

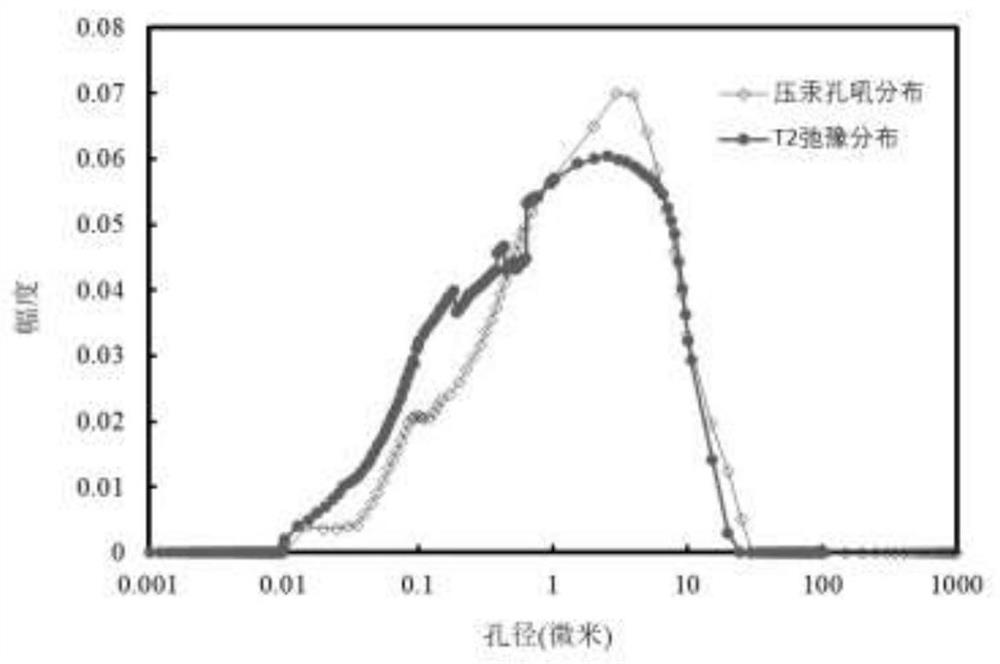

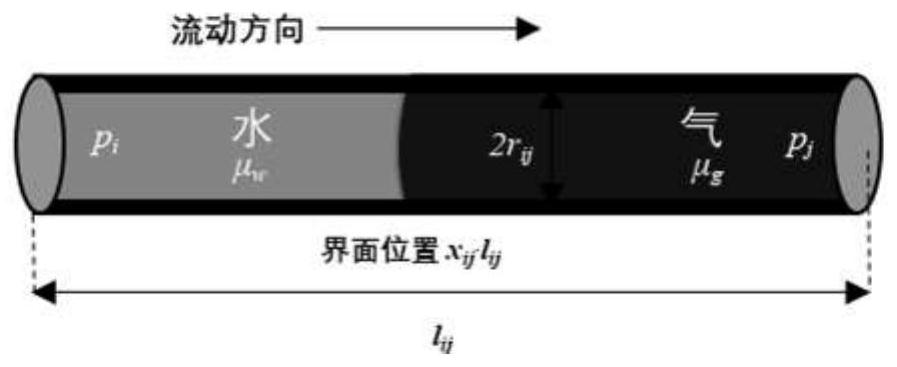

ActiveCN112098293AMeet production needsIn line with reservoir characteristicsMaterial analysis using wave/particle radiationSurface/boundary effectRock coreClassical mechanics

The invention relates to an unsteady gas-water two-phase seepage simulation method for a dual-medium gas reservoir based on pore cracks. The method comprises the following steps: acquiring a T2 spectrum of a rock core, and converting to obtain a pore throat radius distribution frequency and a pore throat distribution function; obtaining the core pore throat length and coordination number for establishing a disordered pore network model through micro CT scanning, and adding the number of cracks; establishing a pore crack type double-medium model; introducing an unsteady seepage theory , and combining a dynamic network simulation algorithm and the unsteady seepage theory to simulate the gas-water two-phase seepage and pressure propagation process of the fluid dual-medium gas reservoir. According to the method, unsteady gas-water two-phase flow simulation is carried out on the basis of a pore and crack dual-medium model, and the pore-level gas-water two-phase flow process can be describedmore accurately through dynamic network simulation considering the compressibility of fluid in the traditional gas-water two-phase seepage process; pressure distribution of the gas-water two-phase inthe pore and crack dual-medium in pressure wave propagation can be analyzed, and flow rules of fluid in pores and cracks can be researched.

Owner:SOUTHWEST PETROLEUM UNIV

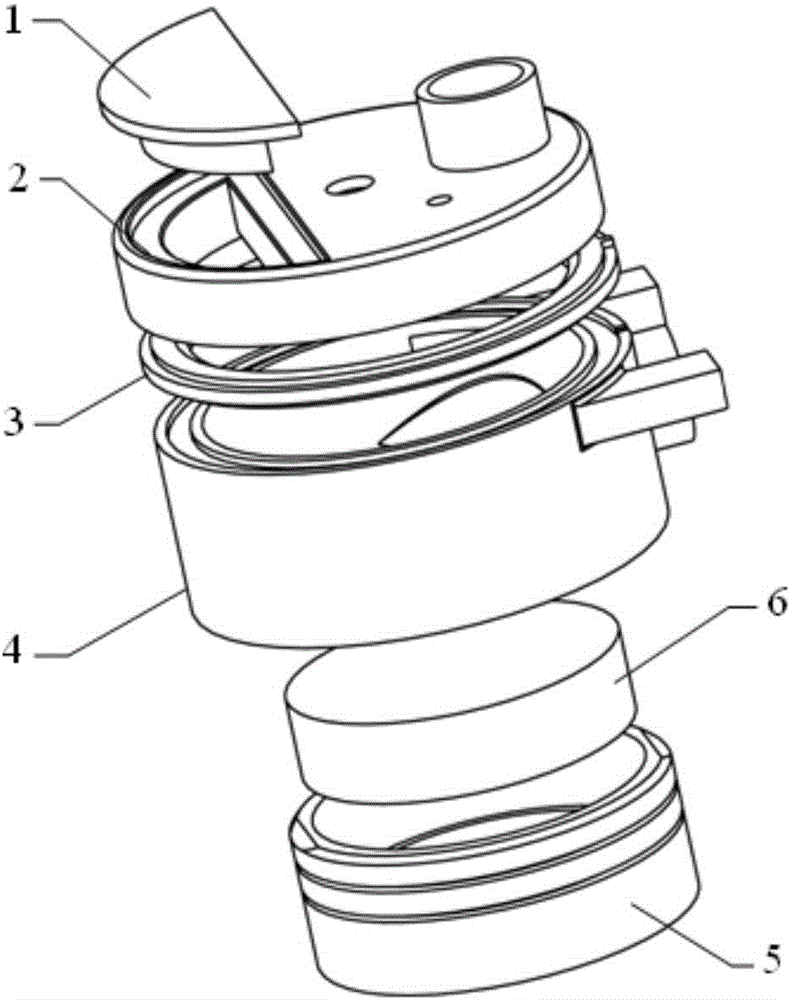

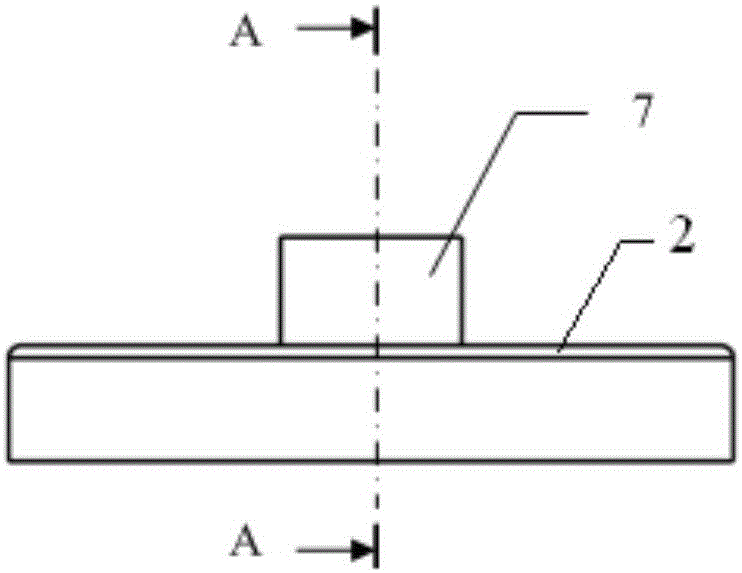

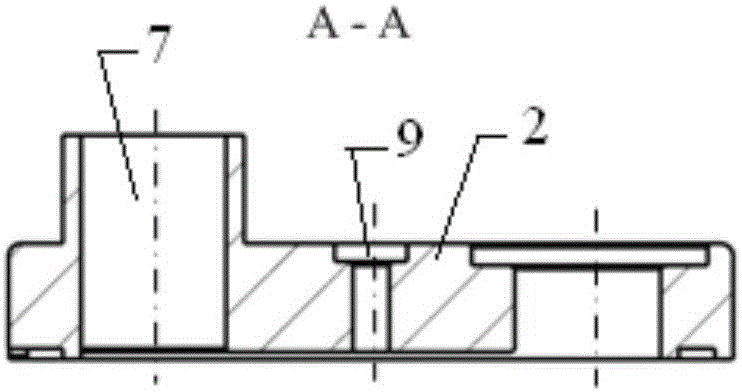

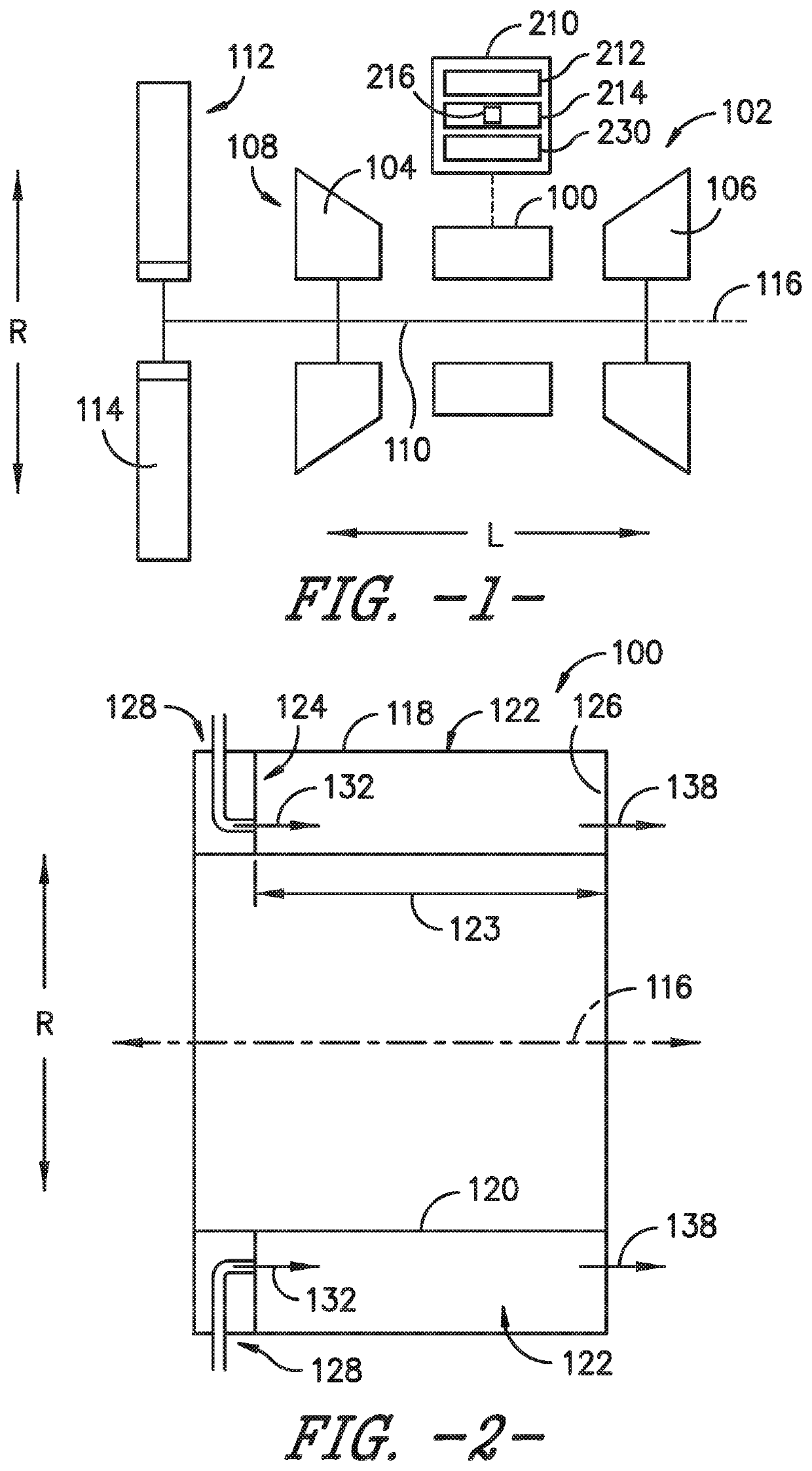

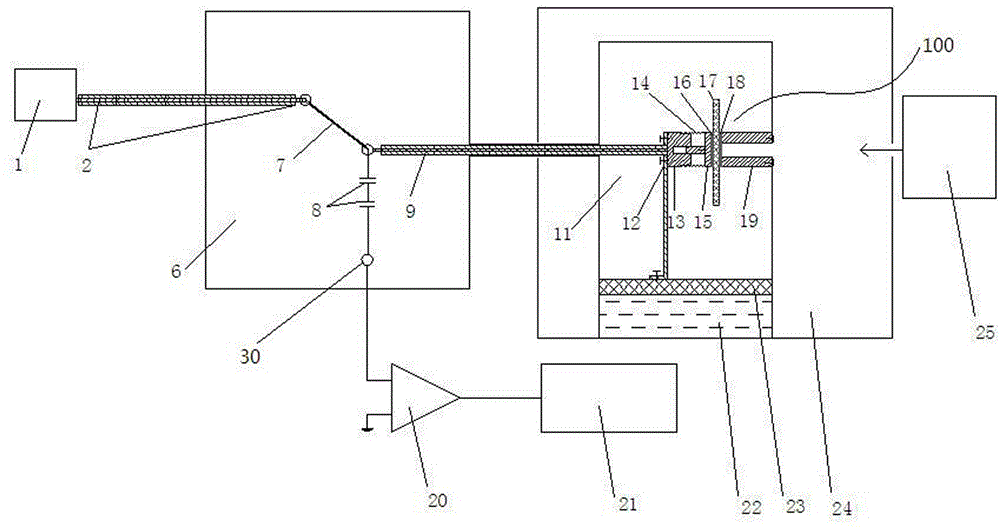

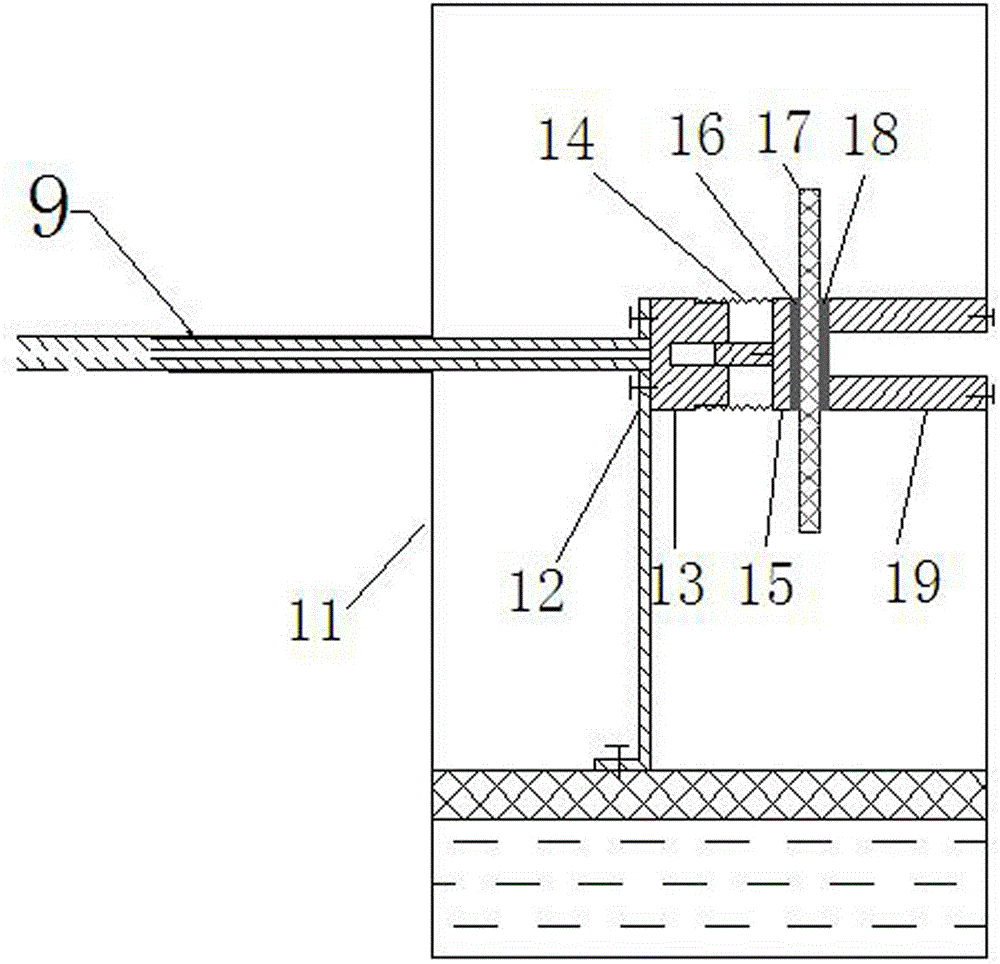

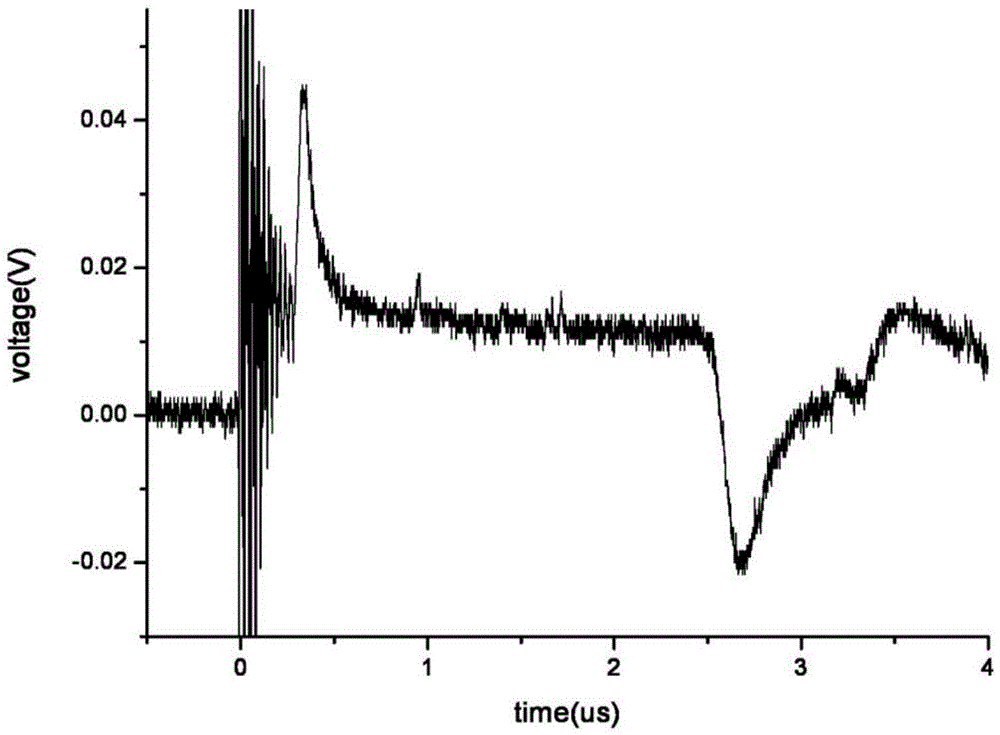

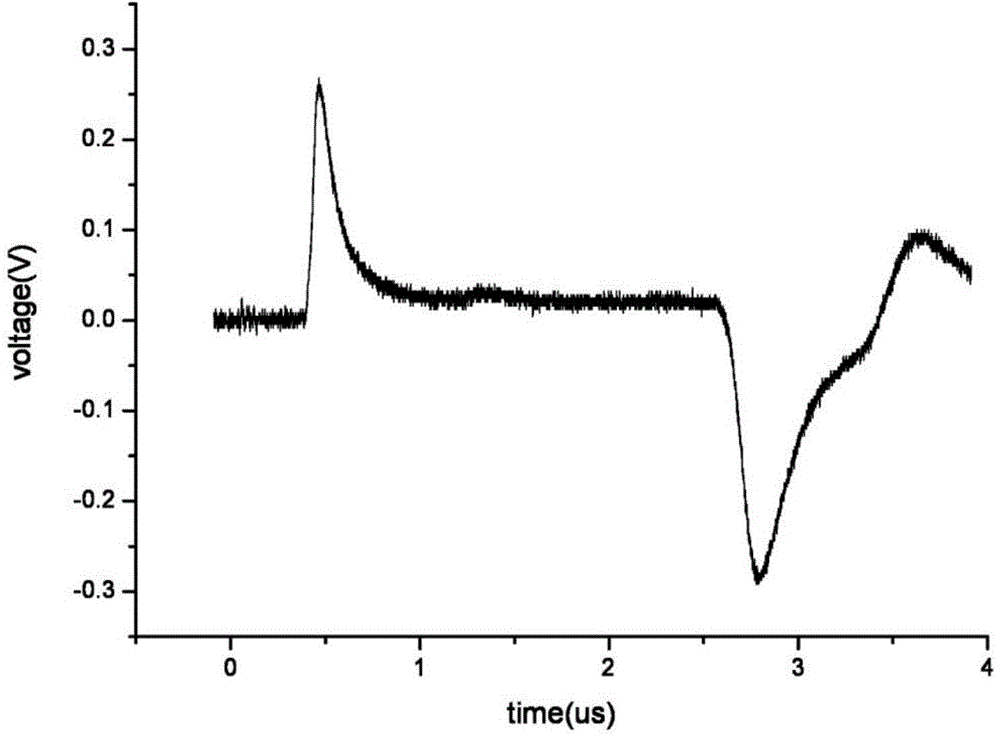

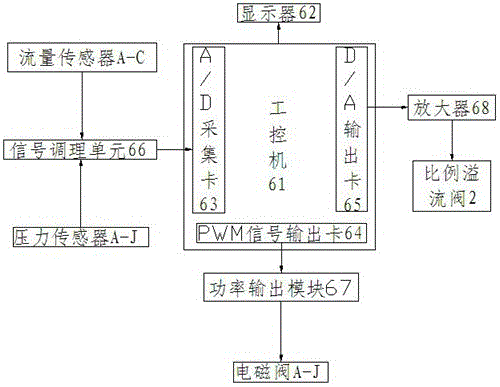

Plate specimen space charge distribution pressure-wave-propagation-method measuring device

ActiveCN104833859AAvoid electromagnetic interferenceRealize space charge distribution measurementElectrical measurementsMeasurement deviceHigh-voltage direct current

The invention discloses a plate specimen space charge distribution pressure-wave-propagation-method measuring device. The device comprises a high-voltage direct-current power supply (1), a high-voltage lead wire (2), a signal shielding box (6), a current-limiting resistor (7), a blocking capacitor (8), a coaxial cable (9), a specimen shielding box (11), an electrode measuring unit (100), an amplifier (20), a digital oscilloscope (21), a metal supporting column (22), a high-temperature drying box (24) and a laser (25). The device is capable of accurately measuring the space charge distribution of an electric insulating material, external interference is effectively eliminated, space charge measurement under different temperatures is realized by a corresponding heating device, and the space charge distribution measurement of a plate specimen insulating material under a direct current and a high voltage is realized; in addition, an electrode system is placed in a specimen shielding box, and voltage increasing loops such as the high-voltage lead wire and measuring loops such as the blocking capacitor are arranged in the signal shielding box, so that electromagnetic interference of the external environment is prevented.

Owner:NANJING NARI GROUP CORP

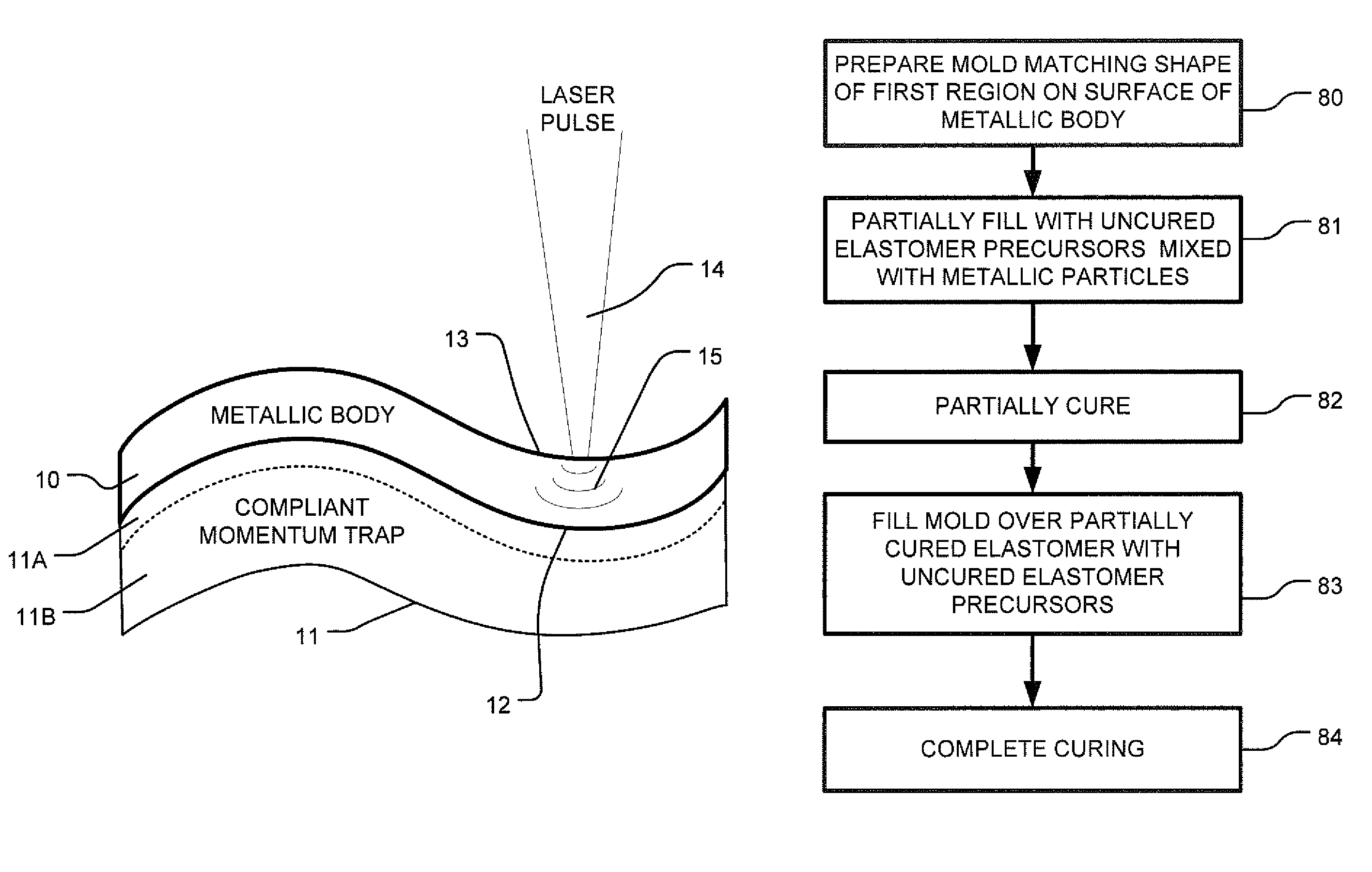

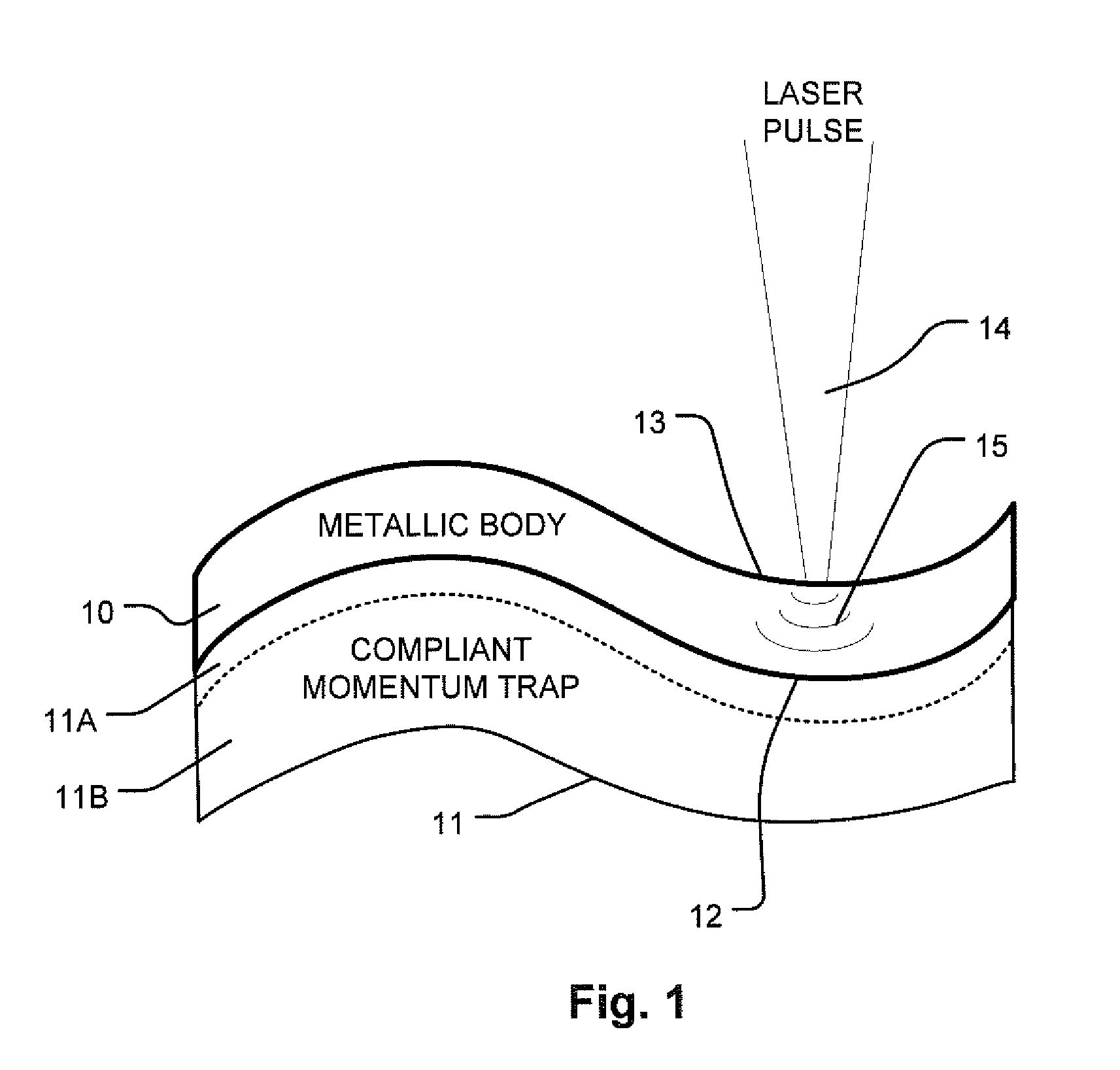

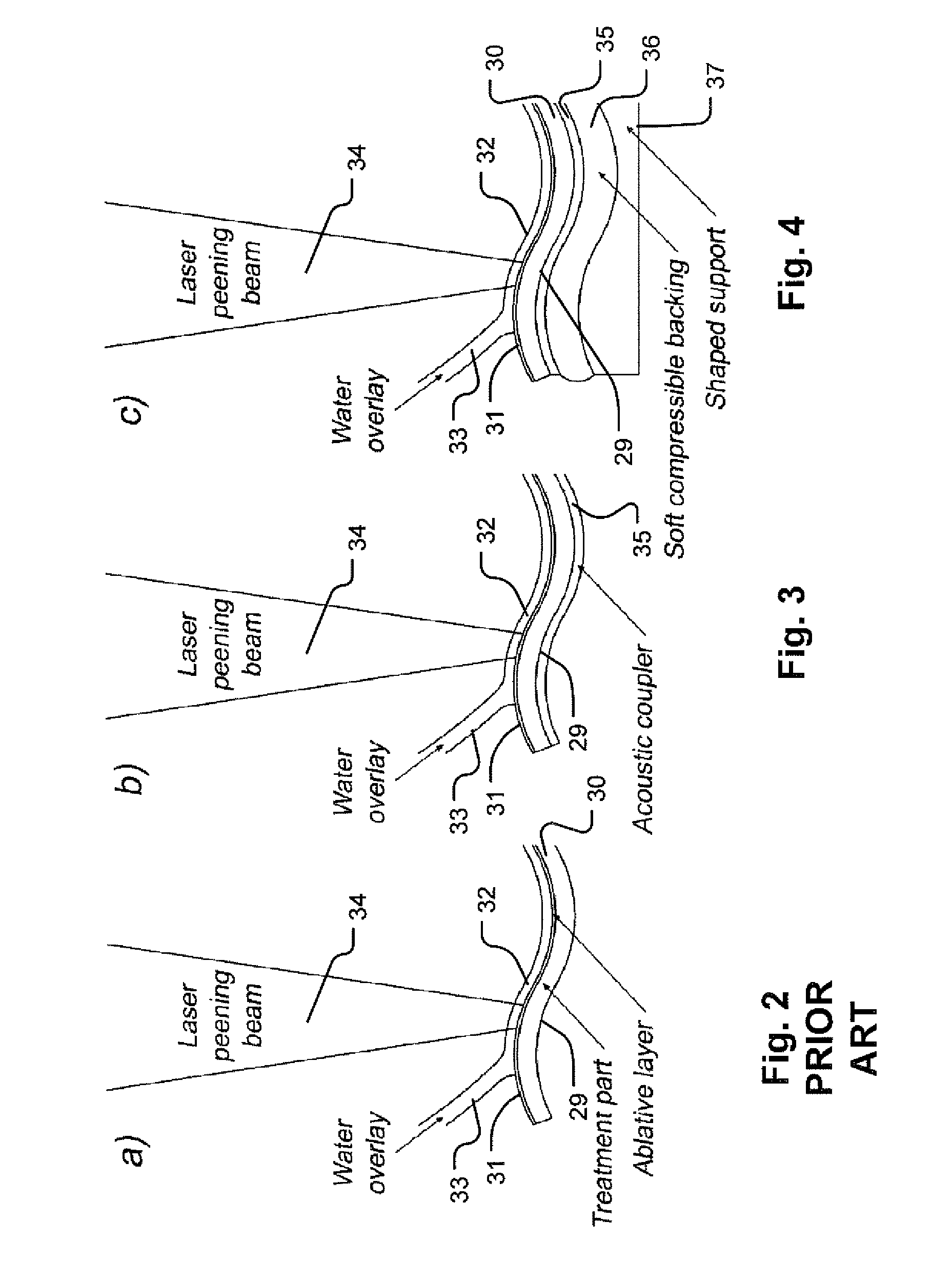

Laser shock processing with momentum trap

ActiveUS7960671B2Avoid reflectionsDifferent modulusPump componentsEngine componentsMomentumAcoustic wave

A method for laser shock processing a device, including a metallic body having a surface, comprises conformally applying a compliant solid material to the first region on the surface of the metallic body and applying a layer of ablative material to the second region on the surface of the metallic body. A damping liquid is flowed over the layer of ablative material. An array of pulses of laser energy is directed through the damping fluid to impact the layer of ablative material on the surface and peen the surface in the second region. The pulses induce pressure waves within the metallic body which propagate to the surface in the first region. The compliant solid material acts as a momentum trap, so that the acoustic waves are at least partially coupled into the compliant solid material and attenuated outside of the metallic body.

Owner:METAL IMPROVEMENT CO INC

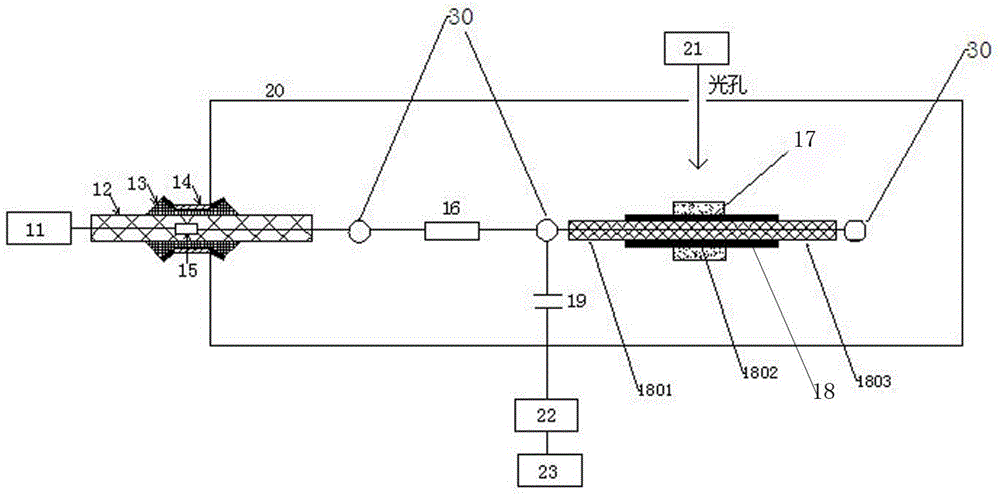

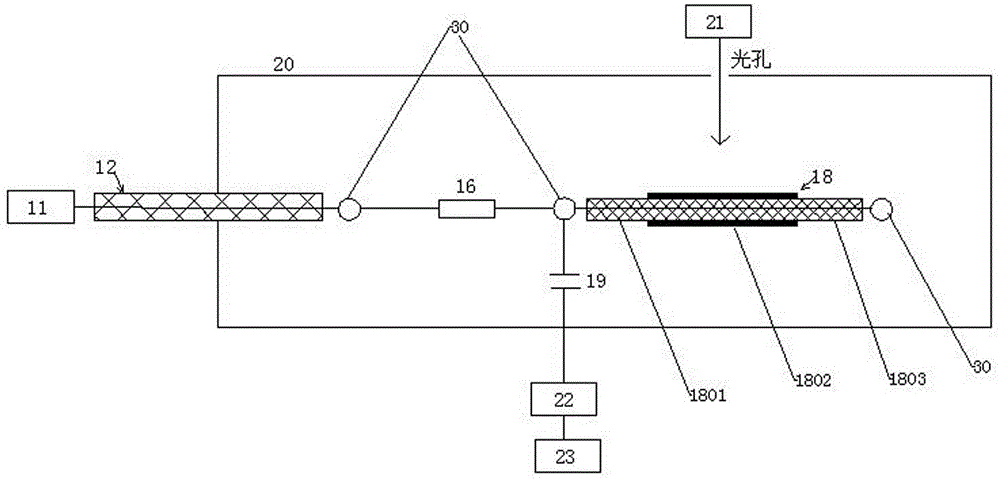

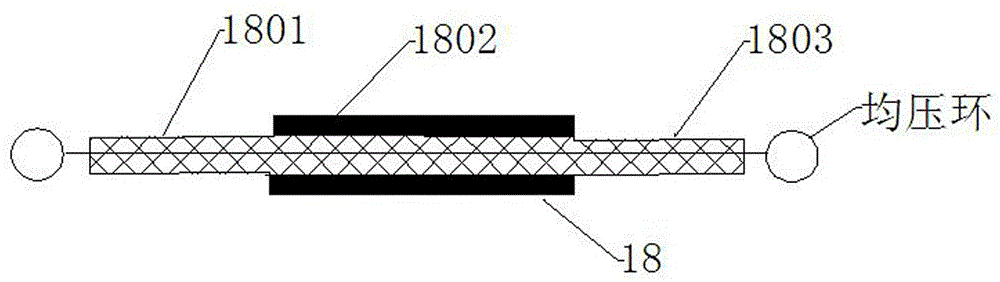

Signal enhanced pressure wave propagation model cable space charge test system

ActiveCN104833867AEnhanced signalNo temperature limitationElectrical measurementsHigh pressureWaveguide

The invention discloses a signal enhanced pressure wave propagation model cable space charge test system. The wall of a metal shielding box (20) is provided with a light hole. A pulse laser (21) is arranged at the light hole. The outer semi-conductive shielding layer surface of a model cable (18) is coated with signal reinforcing agents (17). The light emitted by the pulse laser (21) can shine on the signal reinforcing agents (17) through the light hole. The invention provides a specific structure of the pressure wave propagation (PWP) model cable space charge test system. According to the invention, a waveguide tube is mounted at the entrance of a high-voltage lead, an interference removing resistor is serially connected in the high-voltage lead, and the metal shielding box is employed in the system, so that the influence on the space charge test system by external interference signals can be greatly reduced, and a signal-to-noise ratio of the system can be remarkably improved.

Owner:NANJING NARI GROUP CORP

Pressure wave propagation model cable space charge test system

The invention discloses a pressure wave propagation model cable space charge test system. A protection resistor (16), a model cable (18) and a capacitor (19) are disposed inside a metal shielding case (20). A DC generator (11), a high-voltage lead (12) and the protection resistor (16) are sequentially connected. The high-voltage lead (12) penetrates the wall of the metal shielding case (20). The protection resistor (16) is connected to a conductor of the model cable (18). The model cable (18) comprises a first connecting end close to the protection resistor (16) and a second connecting end far from the protection resistor (16), wherein the first connecting end of the model cable (18) is connected to the capacitor (19), and the second connecting end is grounded. The wall of the metal shielding box (20) is provided with a light hole, and the light emitted by a pulse laser (21) can shine on the model cable (18) through the light hole. According to the invention, the system can carry out pressure wave propagation (PWP) model cable space charge tests, strong signals can be obtained, the reliability of the signals can be tested, and the tests can be carried out without temperature limitation.

Owner:NANJING NARI GROUP CORP +1

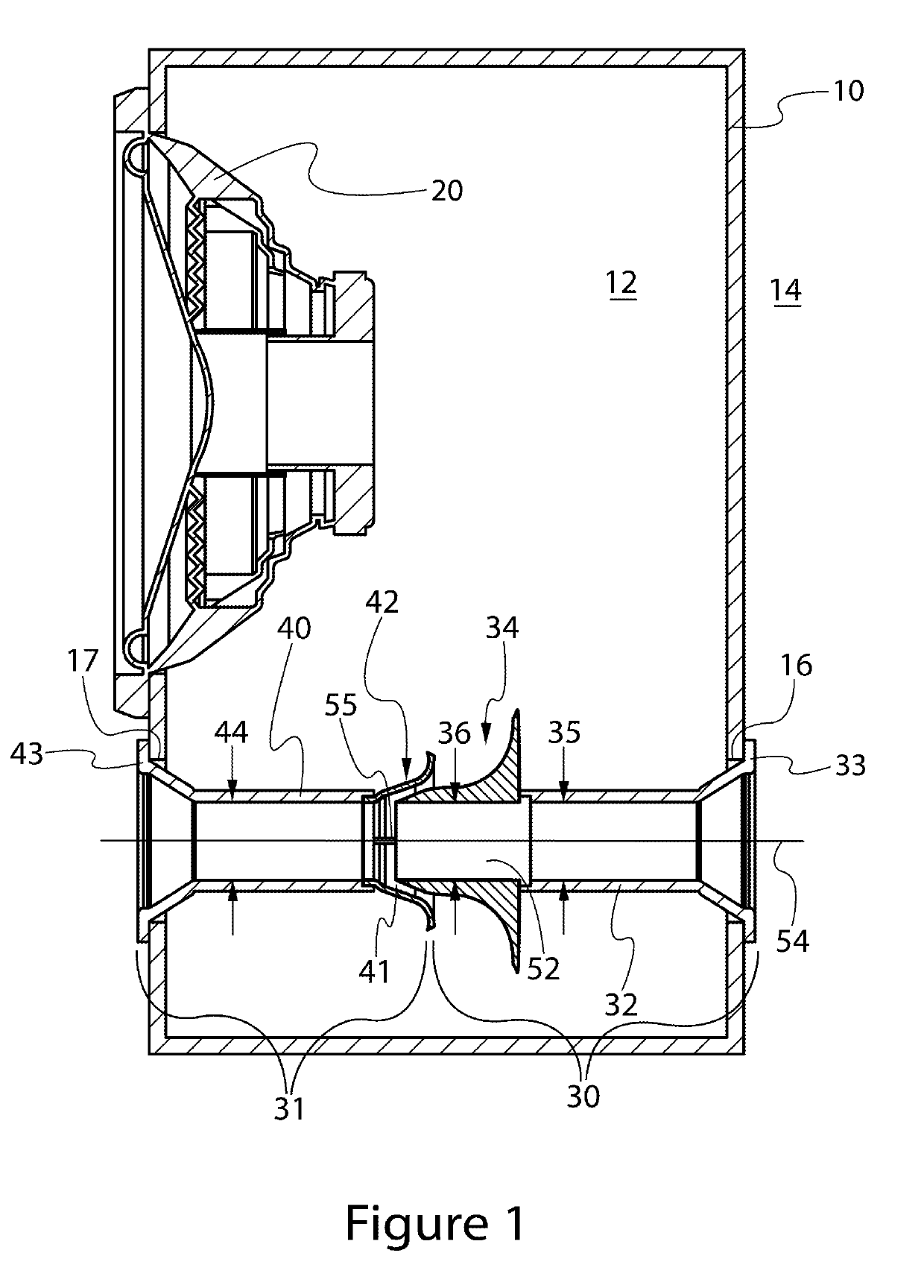

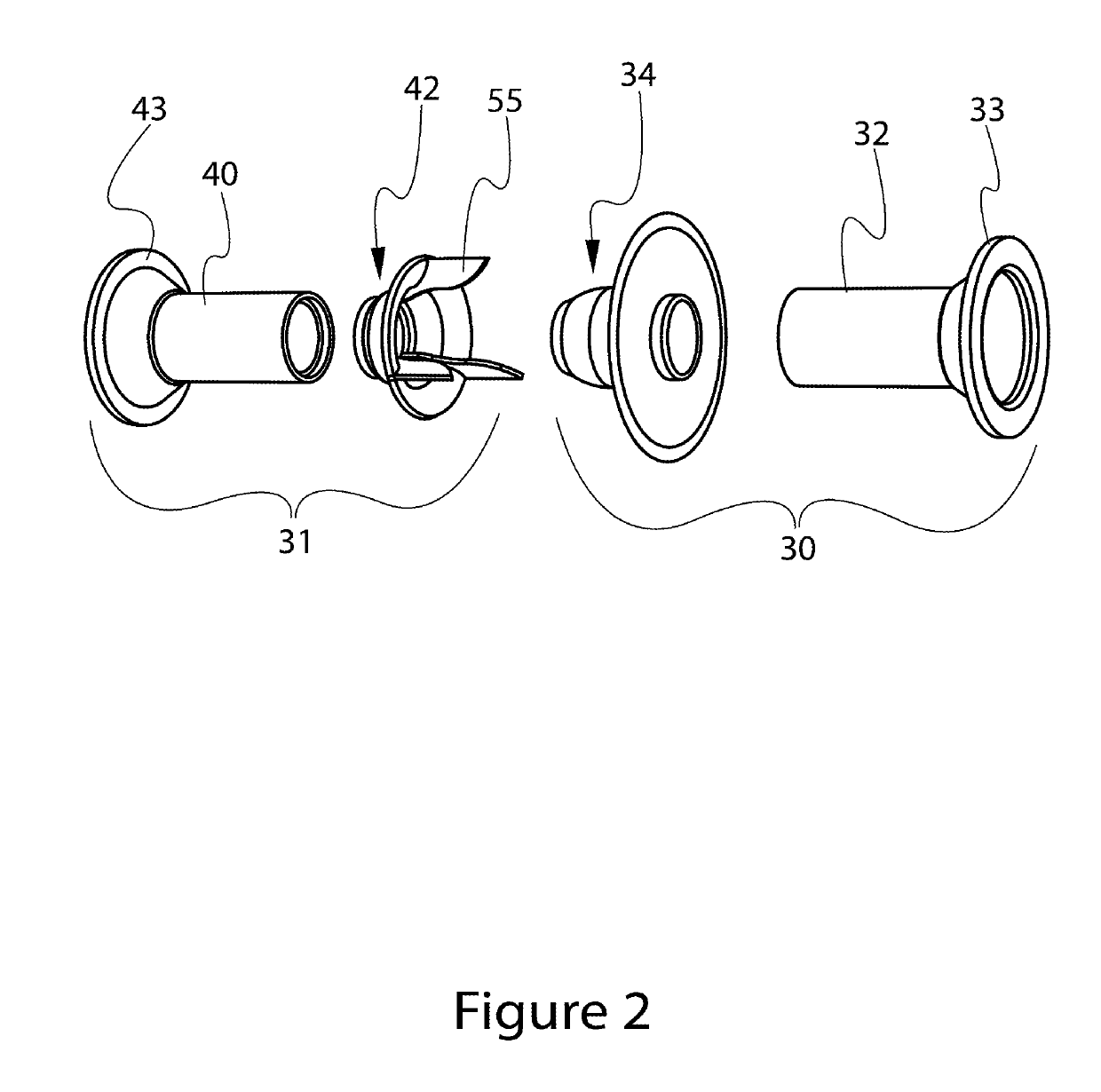

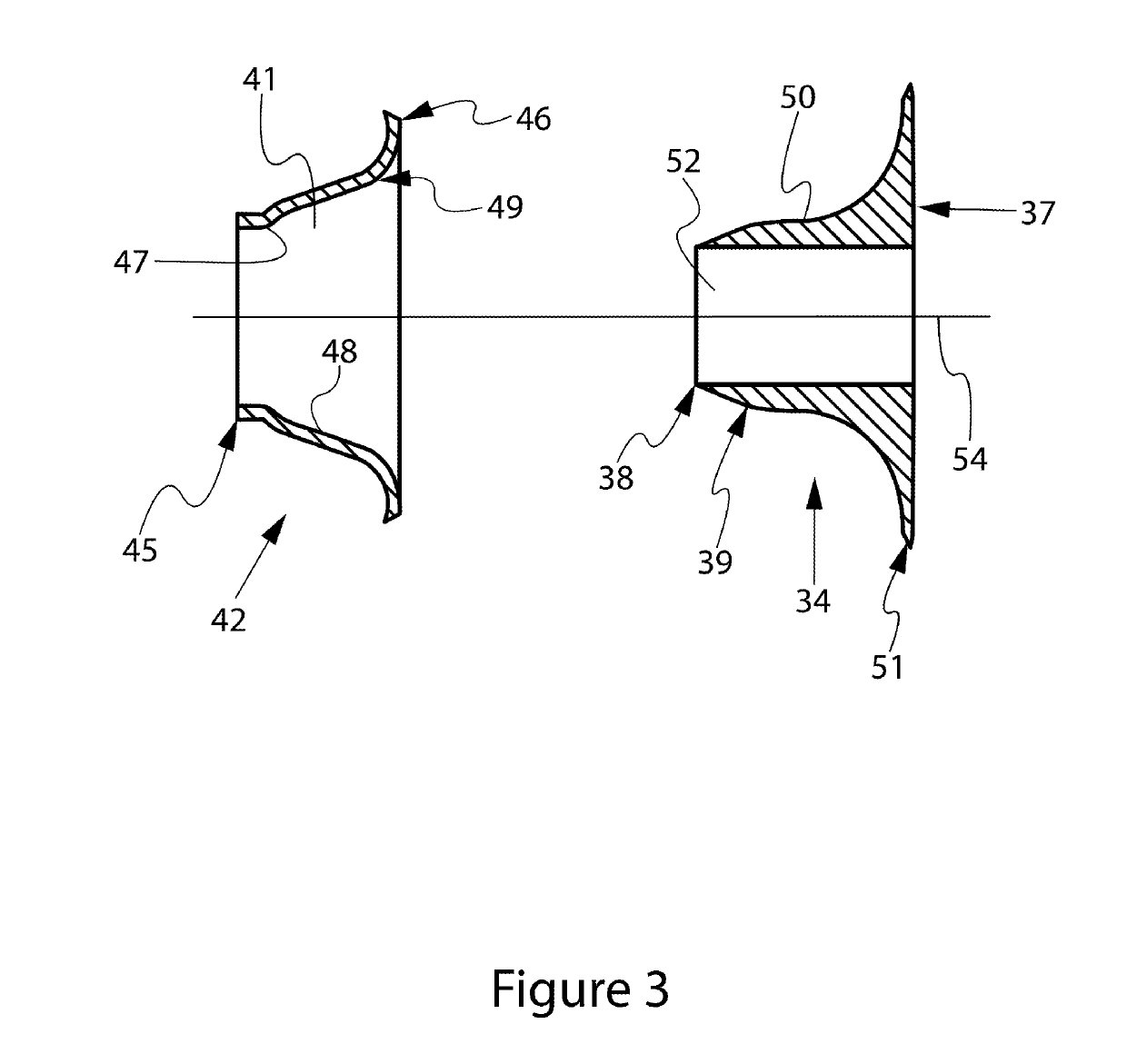

Audio Source Waveguide

Embodiments of apparatus for affecting air flow and / or pressure wave propagation in relation to an audio source enclosure are disclosed. The apparatus may include two waveguide sections mounted within an audio source enclosure. The waveguide sections may include complementary nested first and second funnels disposed relative to each other in a manner to channel air flow in and / or from the enclosure.

Owner:QUEST ENGINES LLC

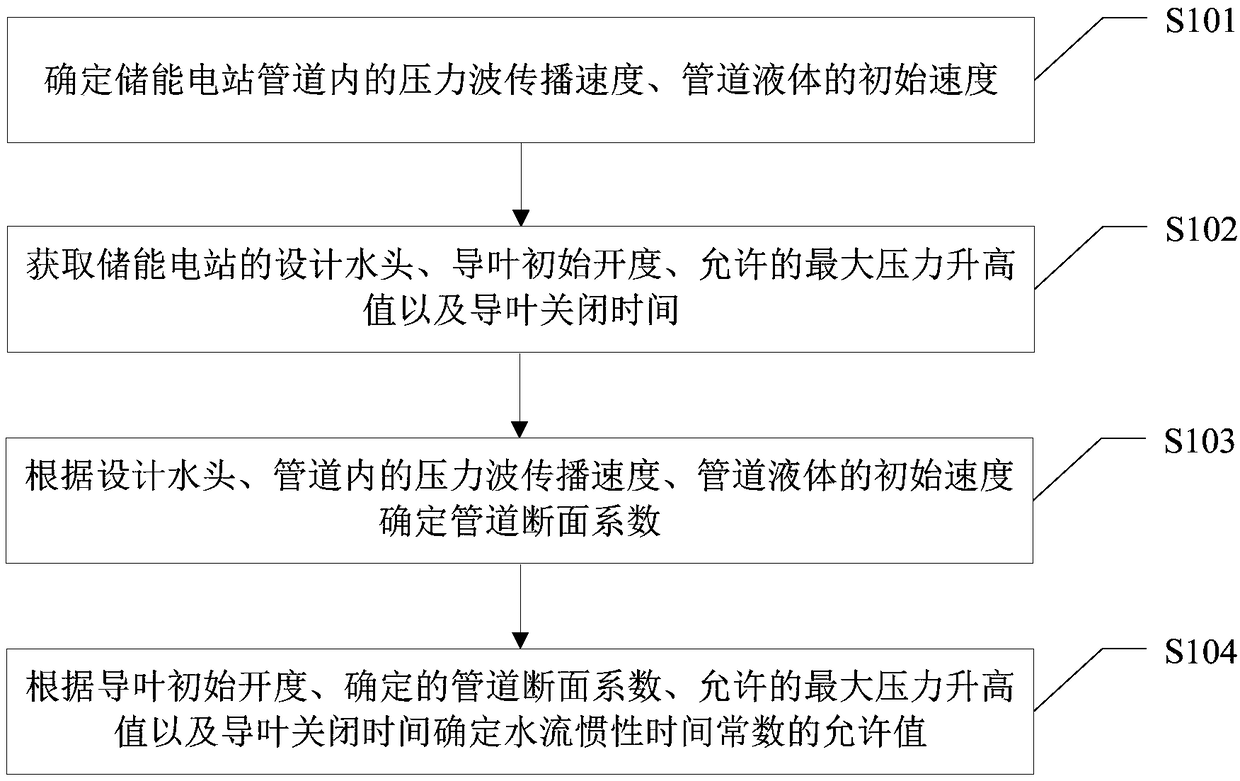

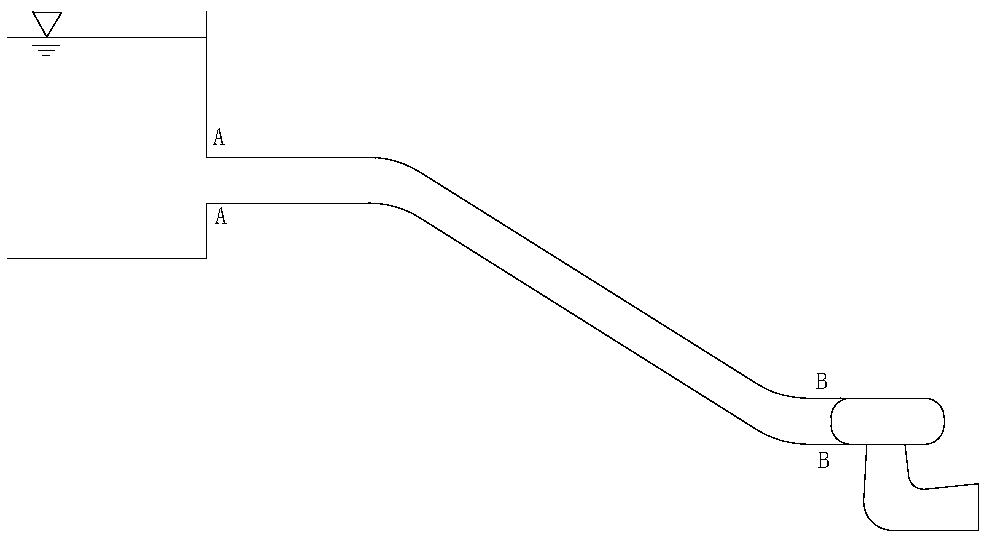

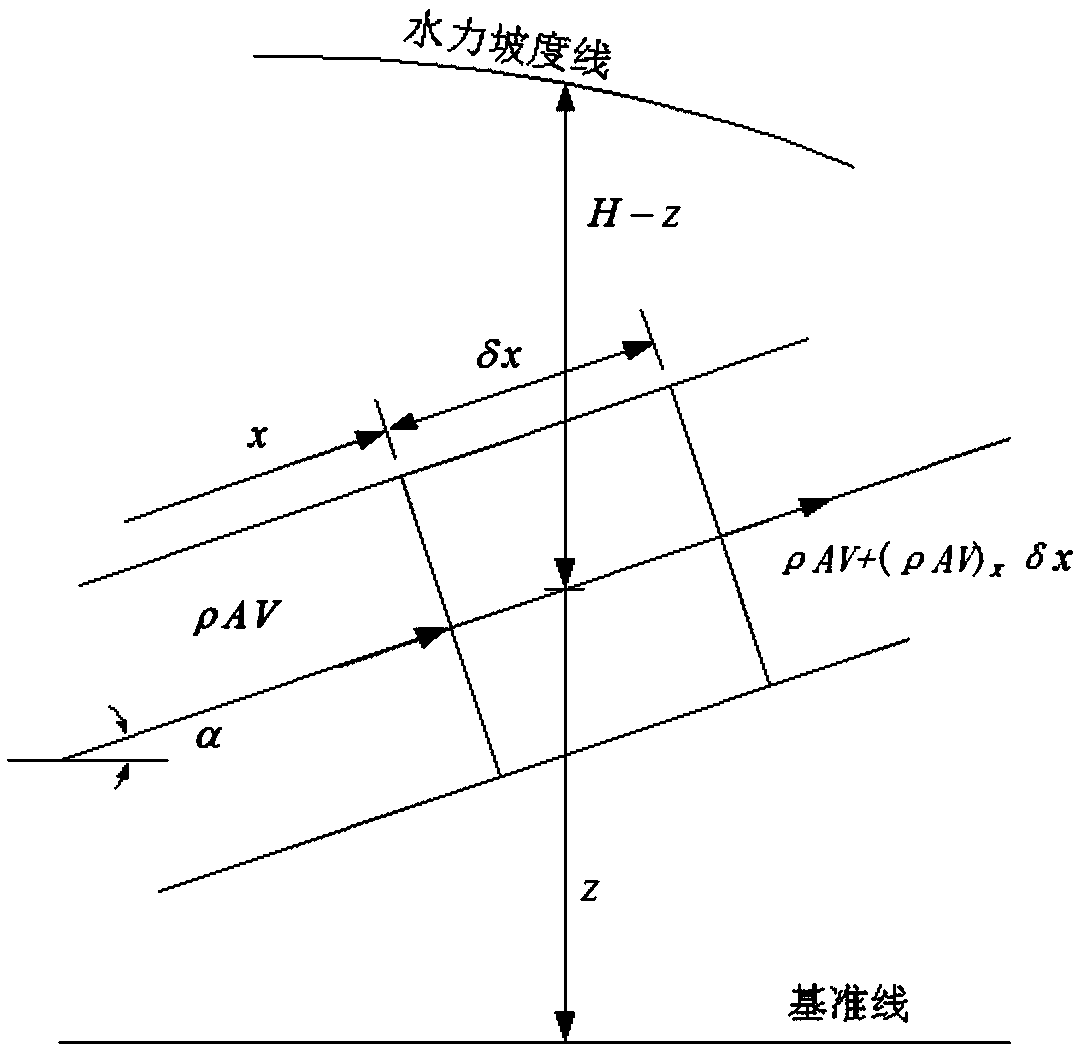

A method and apparatus for determining allowable value of inertia time constant of water flow in a pumped storage surge chamber

ActiveCN109359265AHydro energy generationComplex mathematical operationsPressure riseRC time constant

The invention provides a method for determining an allowable value of an inertia time constant of water flow in a pumped storage surge chamber, which includes determining the propagation velocity of pressure wave in a pumped storage pipeline and the initial velocity of liquid in the pipeline; acquiring the design head of pumped storage, the initial opening of a guide vane, the maximum allowable pressure rise rate and the closing time of guide vane; determining a pipe cross-section coefficient according to the design head, the pressure wave propagation velocity in the pipe and the initial velocity of the pipe liquid; determining the permissible value of the inertia time constant according to the initial opening of the guide vane, the coefficient of pipe section, the maximum allowable pressure rise rate and the closing time of the guide vane. As that allowable value of the flow inertia time constant of the pumped storage power station cannot be dared by enterprises, the invention is suitable for the boundary condition of the pumped storage power station, and has important significance for the design of the pumped storage power station.

Owner:STATE GRID CORP OF CHINA +2

Cavitation-based hydro-fracturing technique for geothermal reservoir stimulation

ActiveUS9574431B2Improve breathabilityImprove heat transfer performanceCollector components/accessoriesOther heat production devicesShock waveCavitation

Owner:UT BATTELLE LLC

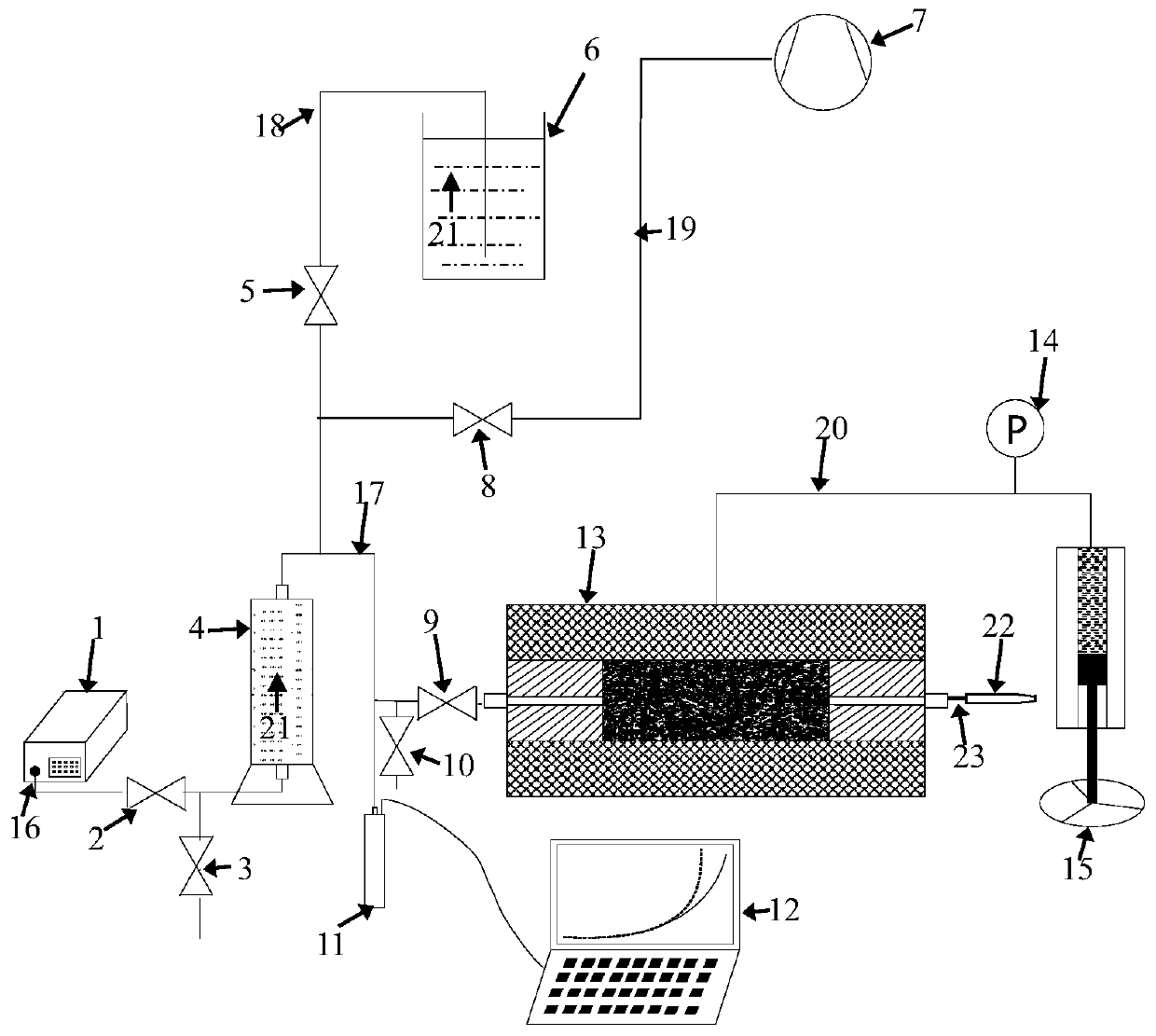

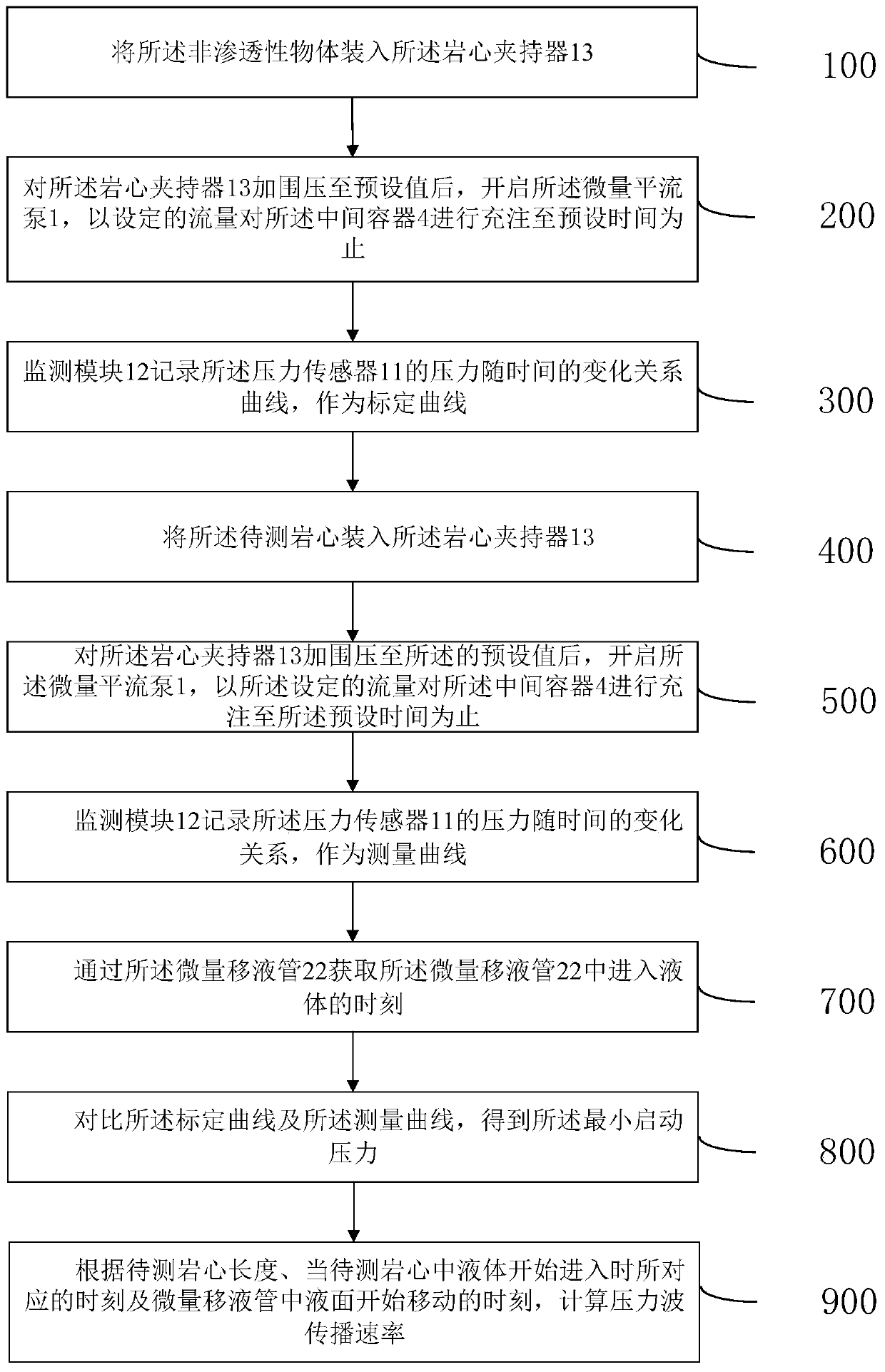

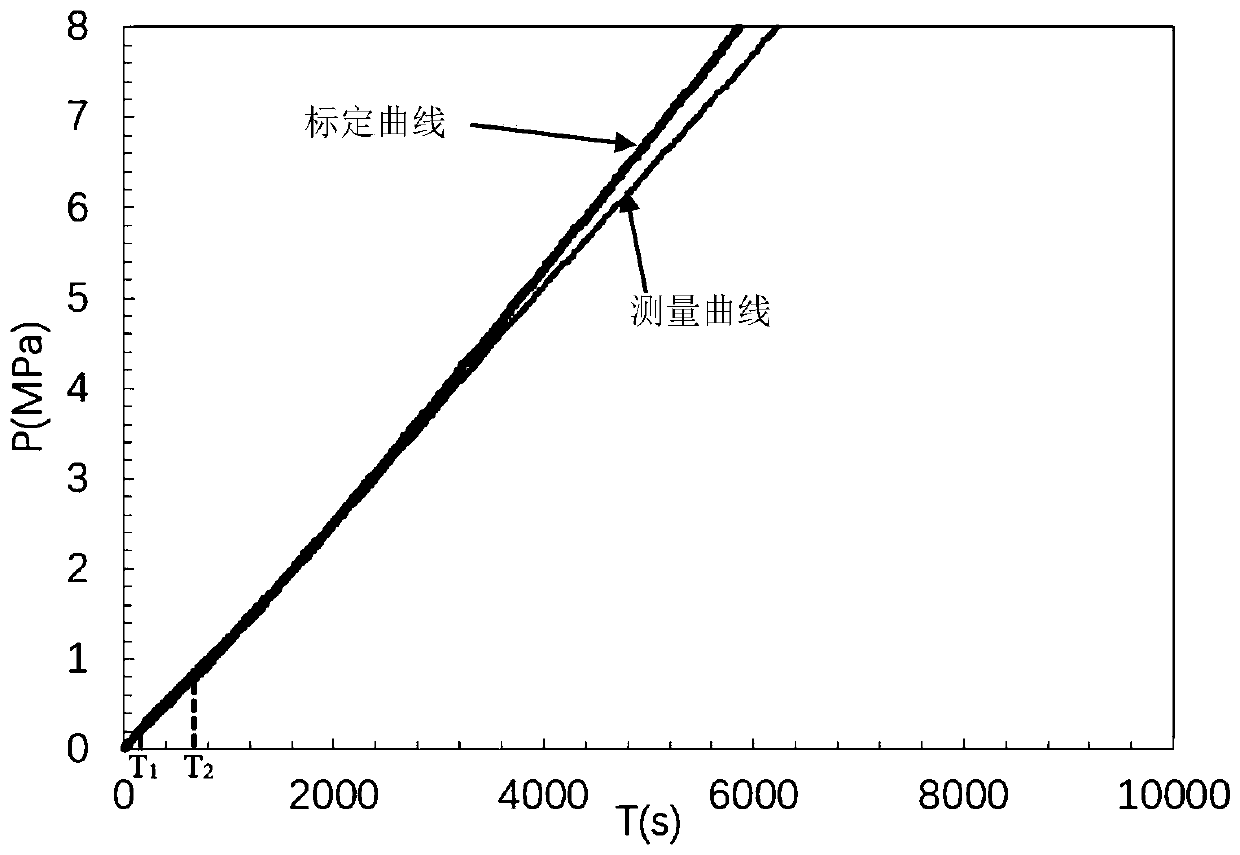

Device and method for measuring minimum starting pressure and pressure wave propagation rate

ActiveCN110044789AAccurate pressure measurementAccurate measurement rateVelocity propogationPermeability/surface area analysisElectricityStart time

The invention provides a device and a method for measuring a minimum starting pressure and a pressure wave propagation rate. The device comprises: a micro constant-flux pump, an intermediate container, a pressure sensor, a monitoring module, a core holder, a micro transfer pipette and a ring pressure pump, wherein the core holder is used for clamping a non-permeable object for calibration and a core to be tested; the micro transfer pipette is connected with the other end of the core holder through a connecting pipe for observing a liquid discharge starting time of the core to be tested so a tomeasure the pressure wave propagation rate; the ring pressure pump is connected with the core holder through a pressurization pipeline; and the monitoring module is electrically connected with the pressure sensor for respectively monitoring a pressure time-varying relationship of the pressure sensor when the non-permeable object and the core to be tested are clamped in the core holder in real time, so as to measure the minimum starting pressure. By adoption of the device and the method provided by the invention, the minimum starting pressure and the pressure wave propagation rate of liquid inthe core can be accurately measured.

Owner:NORTHEAST GASOLINEEUM UNIV +1

Method for estimating elastic parameters by inverting 4D seismic measurements

ActiveUS9377549B2Speed up the processing operationsEasy to processSeismic signal processingSpatial changePressure wave propagation

According to the invention, elastic parameters, including density, pressure wave propagation speed, and / or shear in pervious layers located in a dense underground area along an array of horizontal positions, are estimated by inverting 4D seismic data. Firstly, an estimate of variations in the elastic parameters in one or more starting positions of the array, which can be located on bored wells within the area in question, is obtained. Then, a propagation algorithm is used in order to gradually carry out the 4D data inversion on the basis of the starting positions. The inversion takes into account the previously estimated parameter variations. A spatial variation in the depth and / or the thickness of the pervious lavers in question can also be taken into account. Propagation is based on positions that are consecutively selected as providing optimal values for a cost function assessed in order to invert the 4D data.

Owner:TOTAL PUTEAUX FR

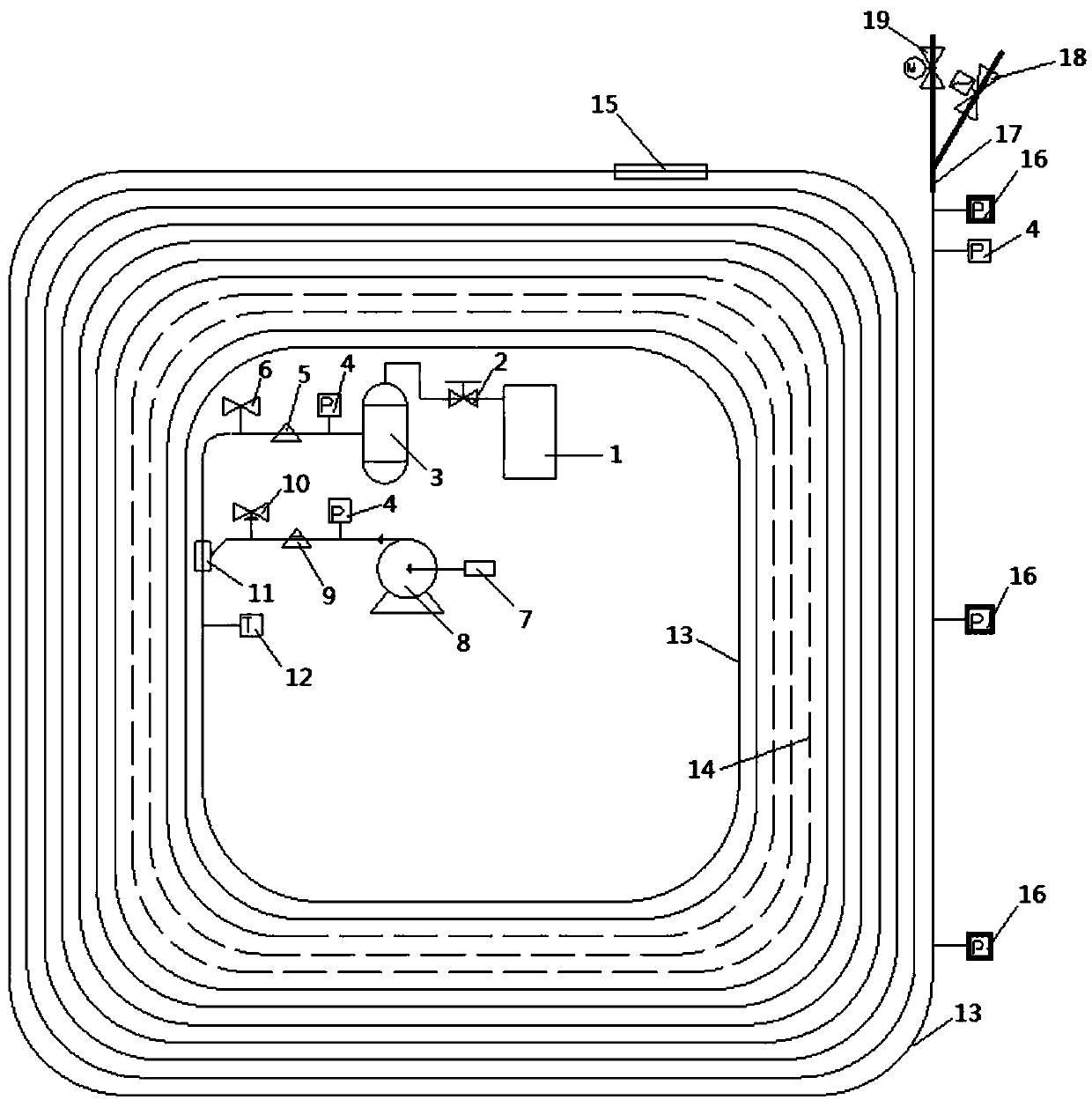

Experiment system for pipeline blockage detection with pressure wave method

InactiveCN109541029AEasy to observeEasy to replaceAnalysing solids using sonic/ultrasonic/infrasonic wavesSurge tankGas cylinder

The invention discloses an experiment system for the pipeline blockage detection with a pressure wave method, and belongs to the technical field of pipeline blockage detecting experiment. The system comprises a main pipeline, a gas flow meter, a gas flow control valve, a surge tank, a gas cylinder set, a large flow pressure reducing valve, and further comprises a mixer, a liquid flow meter, a liquid flow control valve, and a water injection pump. The water injection pump is also connected to a water tank through a pipeline. A Y-shaped branch pipe is connected to the outlet of the outer ring ofthe main pipe, wherein the Y-shaped branch pipe is connected with a solenoid valve on one branch, and a needle valve is connected to the other branch. A simulated blockage pipe section is arranged between the main pipeline, and a transparent pipe section is connected to the outer ring pipe of the main pipeline. The invention can realize the experiment of pressure wave propagation characteristic experiment safely under laboratory conditions and the blockage detection experiment of different types of blockage sections.

Owner:DALIAN UNIV OF TECH

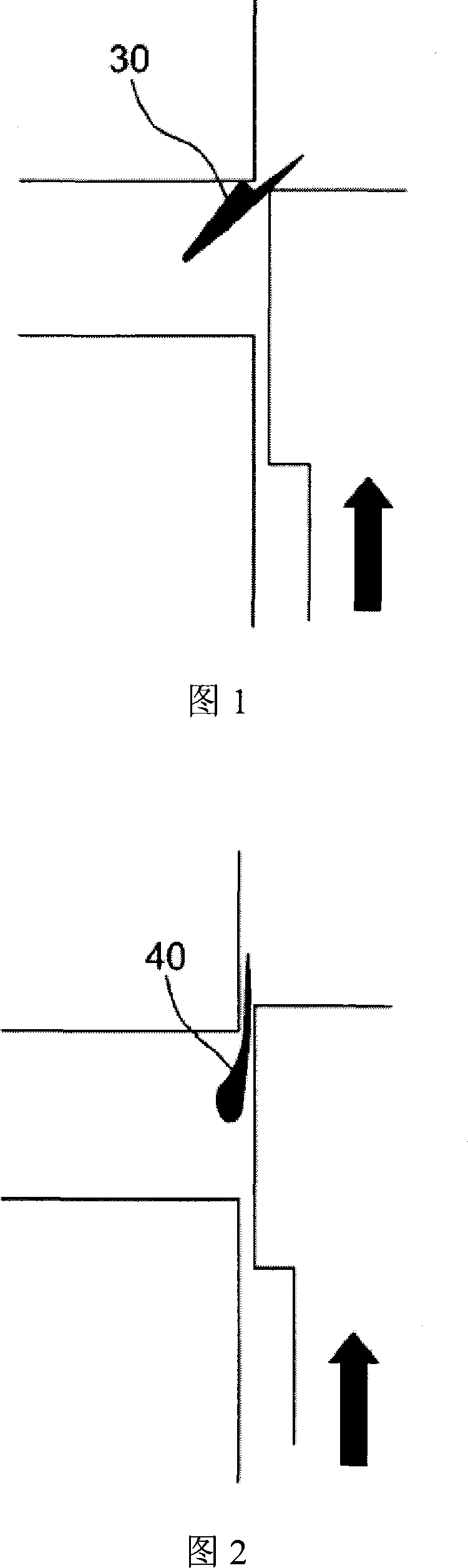

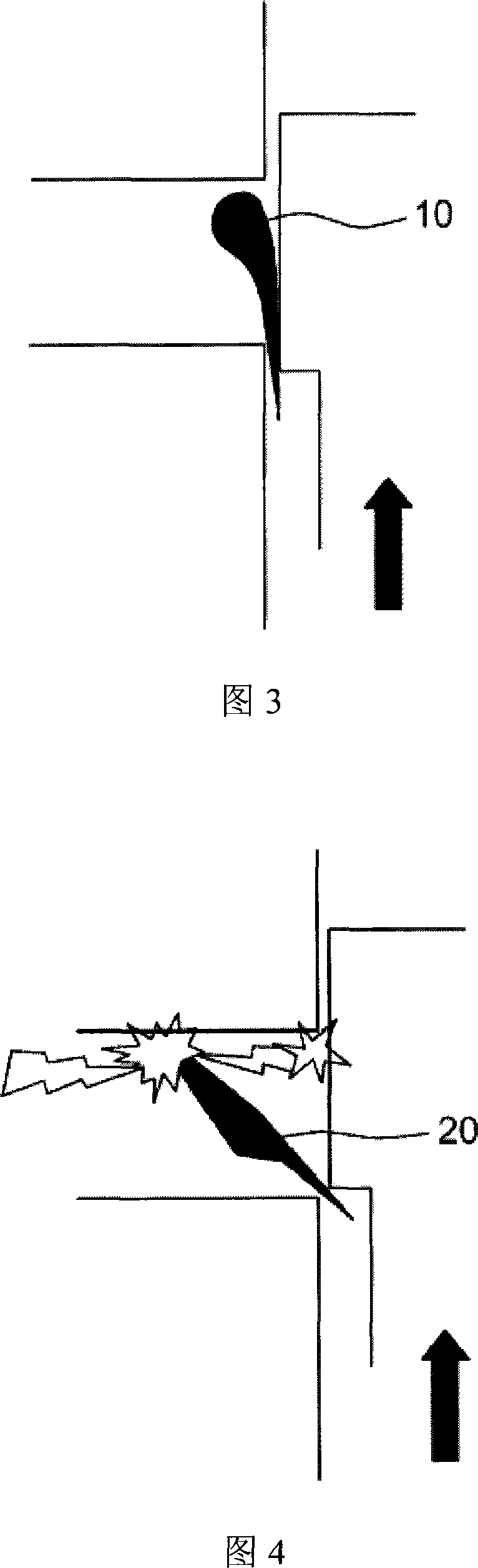

Fuel injection pump having cavitation damage-prevention structure

ActiveCN101087944AAvoid spreadingMachines/enginesFuel injecting pumpsCavitationPressure wave propagation

Disclosed herein is a fuel injection pump having cavitation damage -prevention structure, in which the structure and shape of a deflector (110) and a spill port (120) are improved, thus preventing the spill port and plunger (130) from being damaged due to cavitation. To achieve the above-mentioned purpose, the fuel injection pump of the present invention includes a means for preventing propagation of pressure waves. The propagation preventing means is provided on at least one of the spill port (120) and the deflector (110) such that pressure waves, which are generated when a jet-type cavitation, occurring just after the spill port (120) is opened strikes the spill port (120) or the deflector (110), are prevented from being propagated to cavities that remain around a side surface of the plunger (130).

Owner:HYUNDAI HEAVY IND CO LTD

Anode gas composition utilizing H2 injection pressure wave propagation rates

A system for determining the concentration of hydrogen in an anode sub-system of a fuel cell system. The fuel cell system includes at least one fuel cell, an anode inlet, an anode outlet, an anode recirculation line, a source of hydrogen gas and an injector for injecting the hydrogen gas. First and second acoustic sensors are provided in the anode recirculation line and are spaced a known distance from each other. A controller that is responsive to the output signals from the first and second acoustic sensors determines the concentration of hydrogen gas in the anode recirculation line based on the time between when the controller receives the sensor signal from the first sensor and receives the sensor signal from the second sensor.

Owner:GM GLOBAL TECH OPERATIONS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com