Long-distance pipeline coal conveying leakage detecting control system

A leak detection and control system technology, applied in pipeline systems, mechanical equipment, gas/liquid distribution and storage, etc., can solve problems such as poor positioning accuracy, poor adaptability to model changes, and large impact on accuracy, achieving simple structure and convenient use. , the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

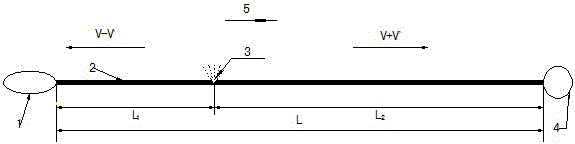

[0022] When pipeline coal transportation is figure 1 When a leak occurs at the leak point shown, the high-sensitivity pressure transmitters installed at both ends of the leak point receive the pressure wave signal formed by the leak. At this time, the detection system firstly judges whether leakage occurs according to the changes of pipeline pressure and flow.

Embodiment 2

[0024] When a leak occurs in the pipeline, the detection system calculates the location of the leak point by measuring the time difference between the instantaneous pressure wave generated when the leak reaches the upper and lower ends and the propagation speed of the pressure wave in the pipeline, under the premise of first making a judgment on whether the leak occurs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com