Fiber Bragg rating measurement method for deformation of duckbill-type cross arm primary sheets

A grating measurement, duckbill technology, applied in measurement devices, optical devices, instruments, etc., can solve problems such as inability to realize real-time online monitoring, complex cross-arm force, and inability to reflect the health status of the cross-arm.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] 1. Cross-arm size: choose Q235 steel as the main material of the cross-arm, and the length of the main material of the lower plane is l 1 =1500mm, the length of the main material on the upper plane Cross-arm height h=250mm, cross-arm width b=125mm, cross-sectional area A=375mm 2 , the vertical distance from the hanging point to the hanging point e=500mm

[0042] 2. The material parameters of the cross arm are: Young’s modulus of Q235 steel is E=206GPa

[0043] 3. The technical parameters of the fiber Bragg grating are: central wavelength λ 1 =1547.000nm,λ 2 =1550.000nm,λ 3 =1553.000nm,λ 4 =1556.000nm, effective elastic-optic coefficient p e =0.22

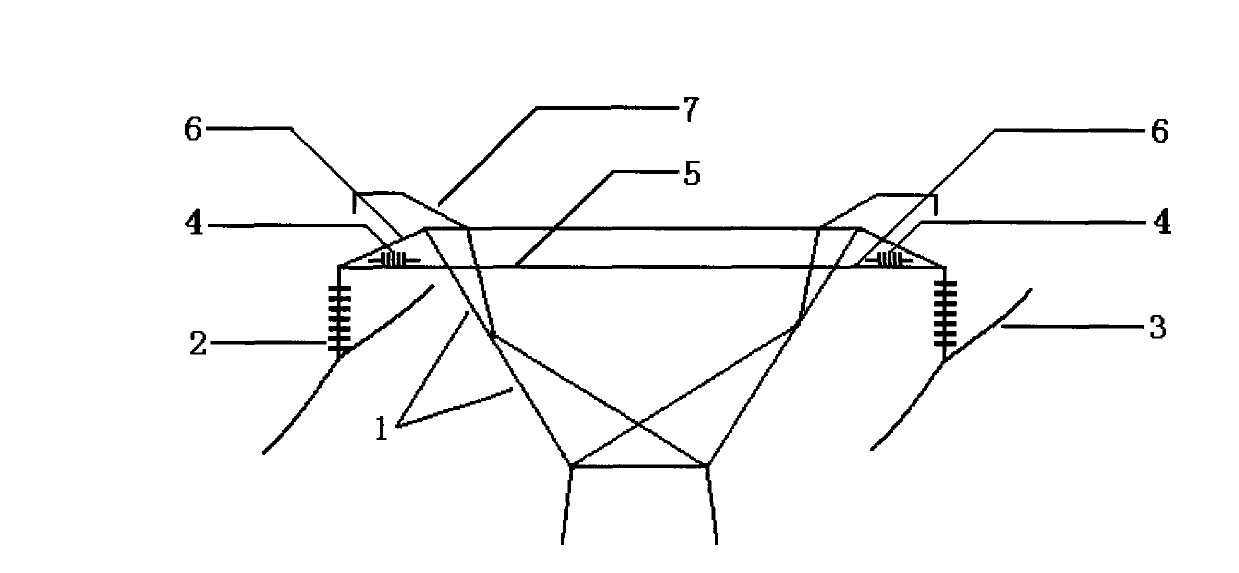

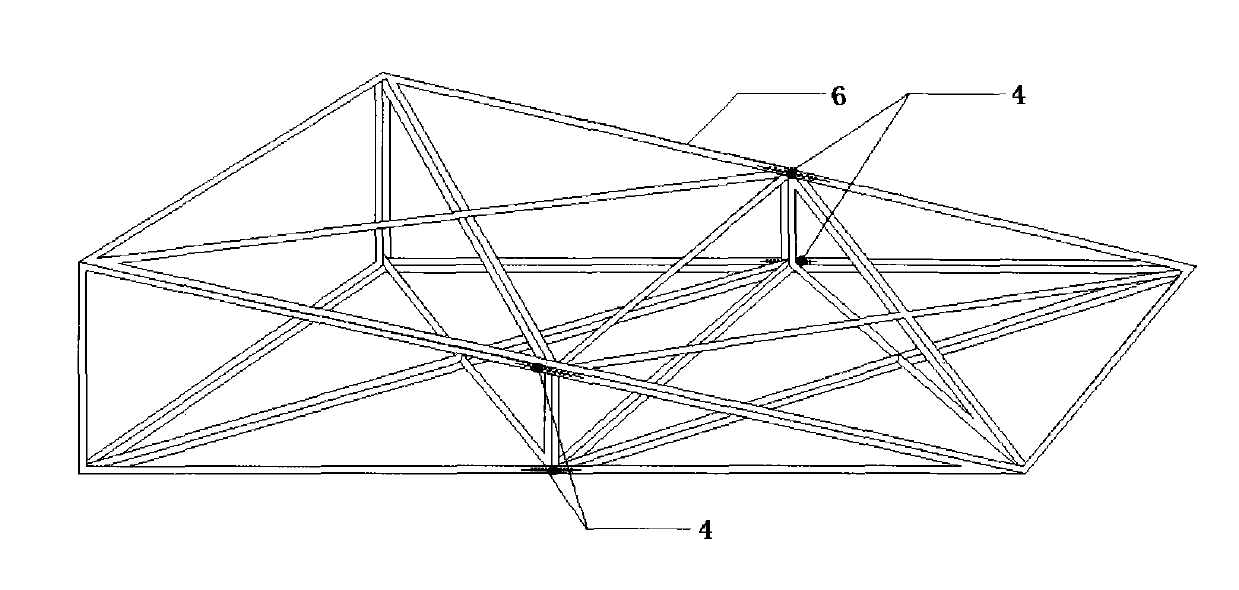

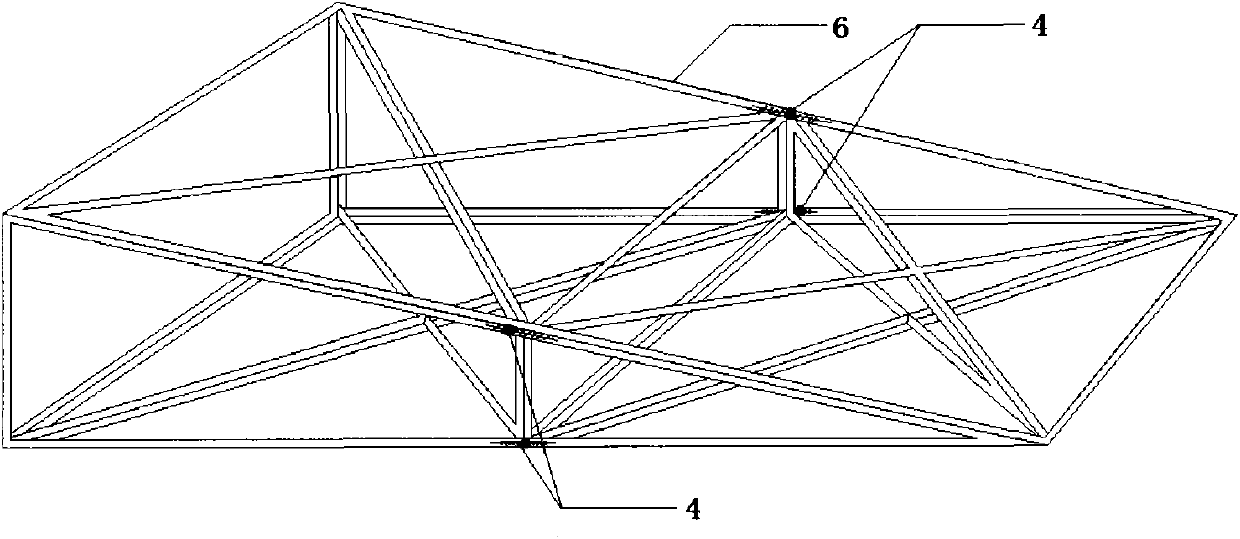

[0044] 4. Attached figure 1 Configure experiment

[0045] 5. Obtain the central wavelength of the fiber Bragg grating with a fiber grating analyzer

[0046] 6. Substituting the known quantity into formula (11), the relationship between the force on the main material of the cross-arm and the shift of the center wave...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com