Pipeline leakage detection method and device

A pipeline leakage and detection method technology, which is applied in pipeline systems, mechanical equipment, gas/liquid distribution and storage, etc., can solve the problems affecting the promotion and application of negative pressure wave system positioning accuracy, unclear inflection point of negative pressure wave signal, and reduced acquisition accuracy and other problems, to achieve the effect of strong field operability, high positioning accuracy, and accurate acquisition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

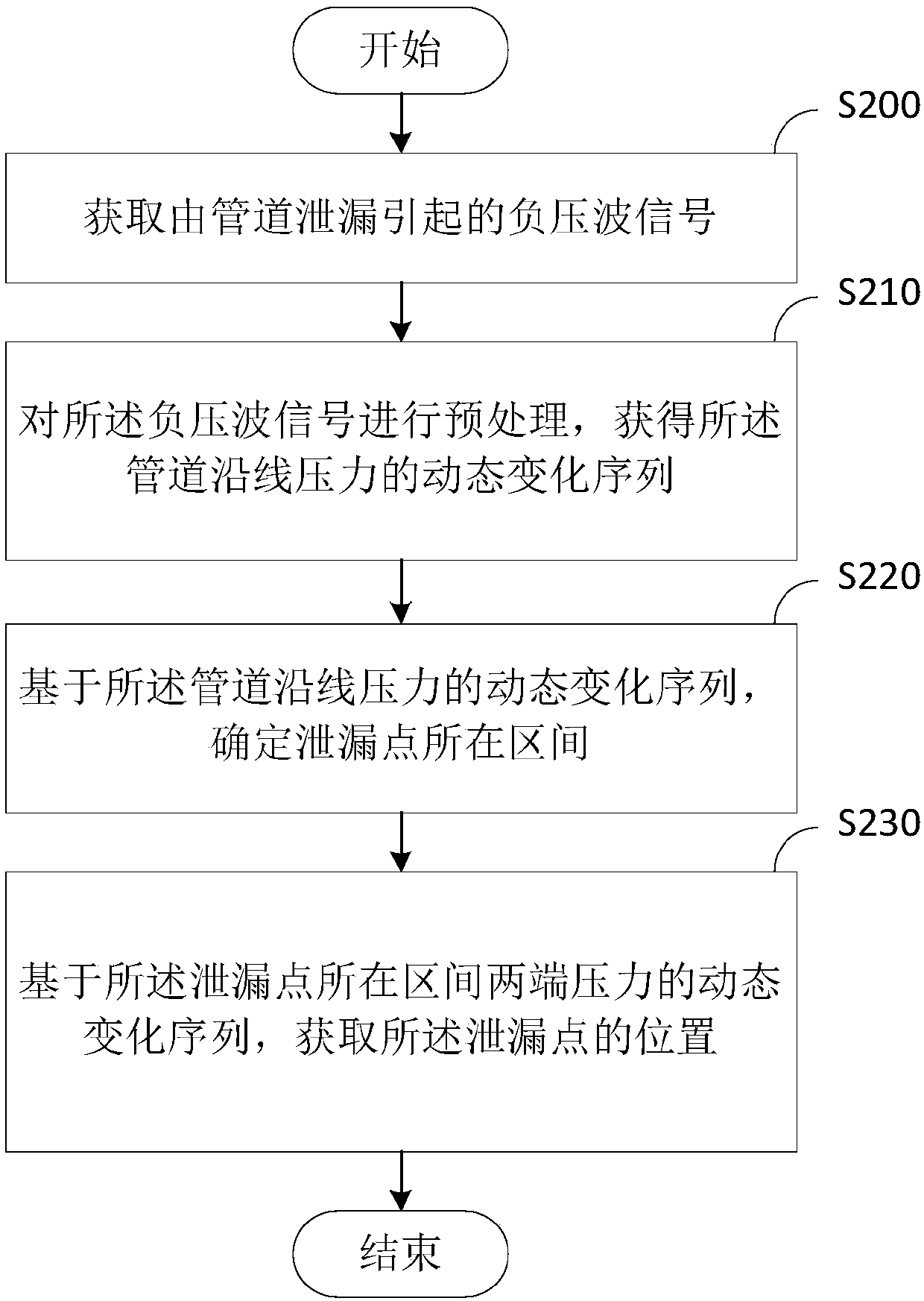

[0035] Please refer to figure 2 , the present embodiment provides a pipeline leak detection method, the method comprising:

[0036] Step S200: acquiring negative pressure wave signals caused by pipeline leakage;

[0037] In this embodiment, a plurality of sensors are arranged at intervals in the section to be tested of the pipeline, and each sensor can be used to obtain a pressure signal in the section to be tested. It can be understood that when a leak occurs in the pipeline to be tested, the pressure at the leakage point of the pipeline will drop suddenly due to the pipeline leakage, that is, a negative pressure wave signal will be generated, and the negative pressure wave signal will be obtained through sensor detection, namely Subsequent analysis of the position of the leakage point can be performed according to the negative pressure wave signal.

[0038] In this embodiment, the sensors may be electronic sensors or optical fiber sensors or other sensors capable of pipel...

no. 2 example

[0087] Please refer to Figure 11 , the present embodiment provides a pipeline leak detection device 600, which includes:

[0088] An acquisition module 610, configured to acquire negative pressure wave signals caused by pipeline leakage;

[0089] A preprocessing module 620, configured to preprocess the negative pressure wave signal to obtain a dynamic change sequence of pressure along the pipeline;

[0090] An interval module 630, configured to determine the interval where the leakage point is located based on the dynamic change sequence of the pressure along the pipeline;

[0091] The position module 640 is configured to obtain the position of the leak point based on the dynamic change sequence of the pressure at both ends of the interval where the leak point is located.

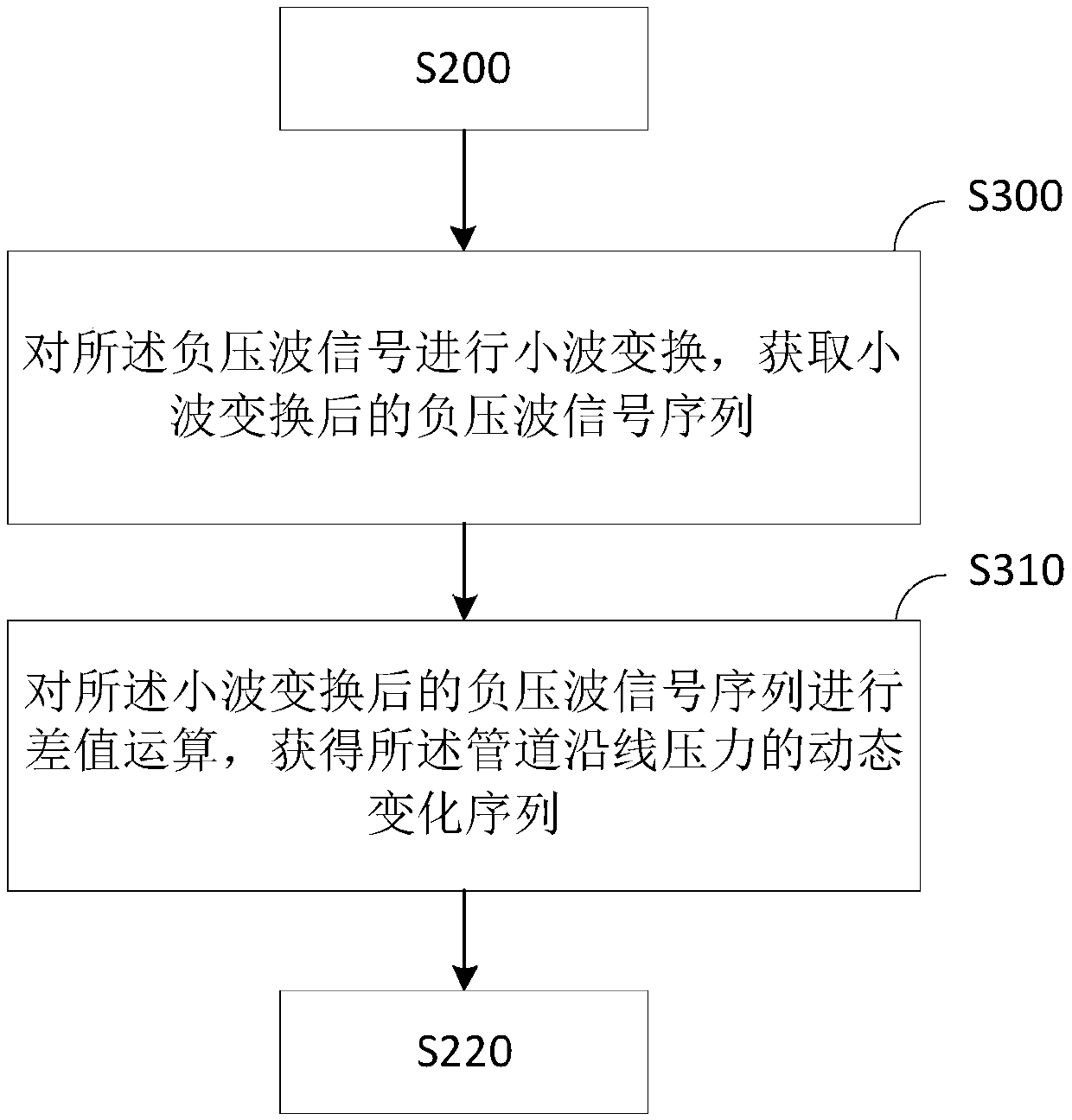

[0092] Please refer to Figure 12 , in this embodiment, further, the preprocessing module 620 may also include the following units:

[0093] A wavelet transformation unit 621, configured to perform wav...

no. 3 example

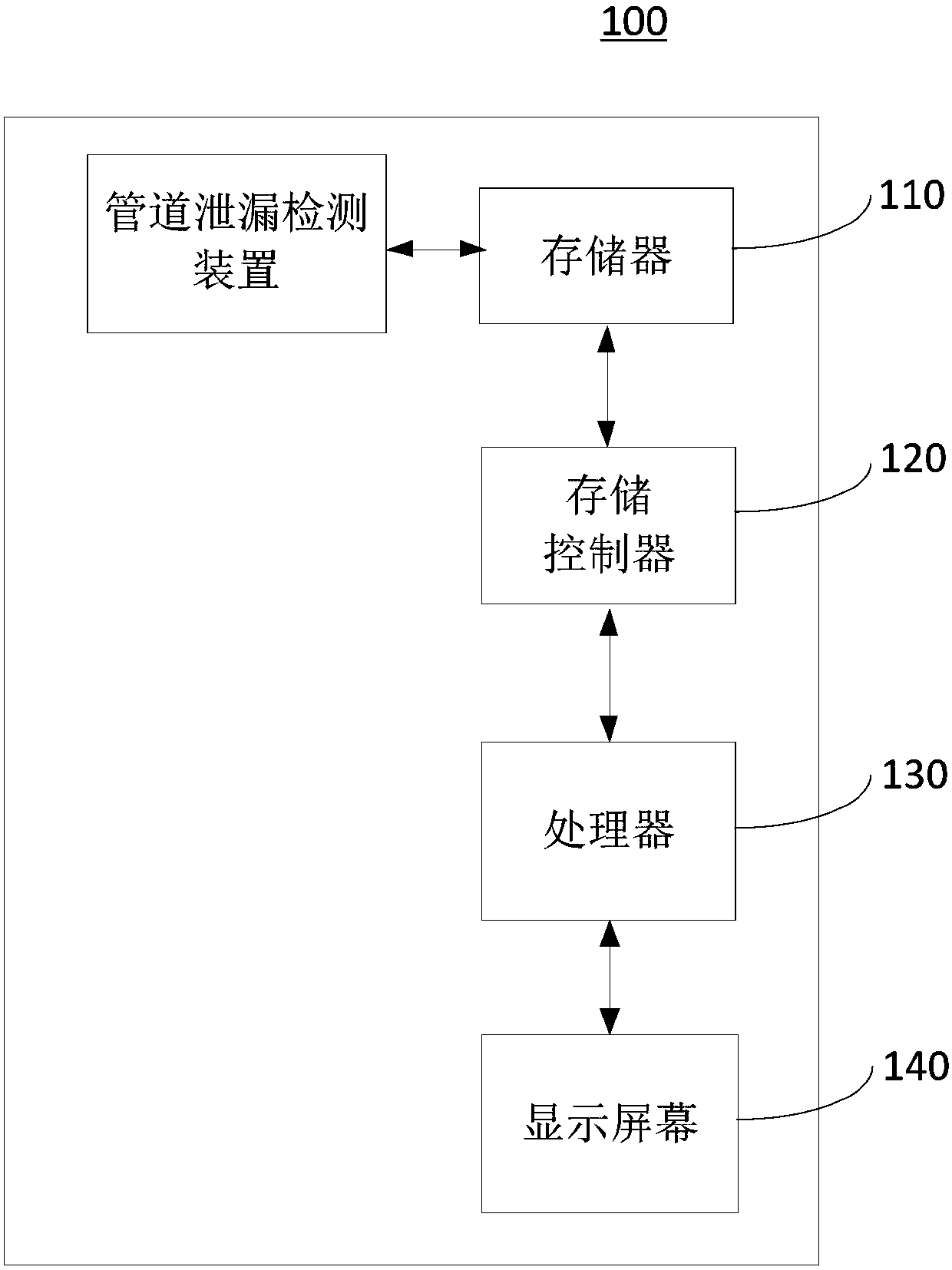

[0104] Please refer to Figure 15 , the present embodiment provides a pipeline leakage detection device 1000, which includes a plurality of sensors 800, and the multiple sensors 800 are arranged on the pipeline 900 to be tested at intervals along the axis of the pipeline to be tested 900.

[0105] In this embodiment, the distance between the plurality of sensors 800 is adjustable, and the sensors 800 are used to detect the negative pressure wave signal generated by the leakage of the pipeline 900 to be tested. Preferably, the distances between the plurality of sensors 800 are the same. It can be understood that the distances between the multiple sensors 800 may not be completely the same.

[0106] In this embodiment, the sensors 800 can be electronic sensors or optical fiber sensors or other sensors capable of pipeline pressure detection, and each of the sensors 800 can transmit the collected negative pressure wave signals to data in a wired or wireless manner. transmission....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com